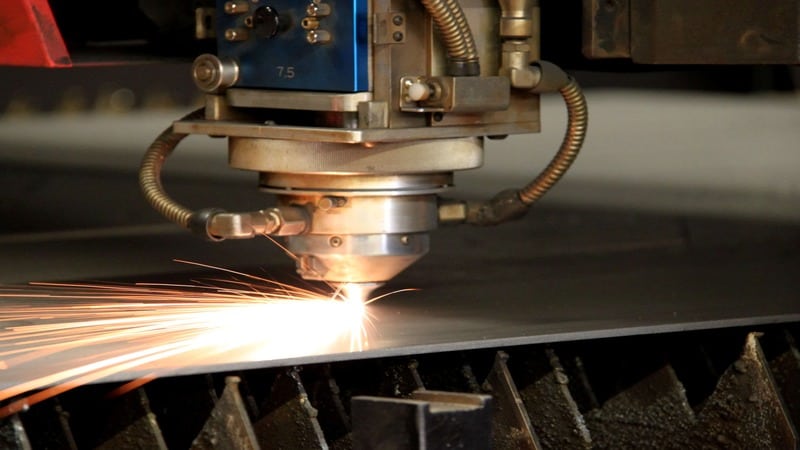

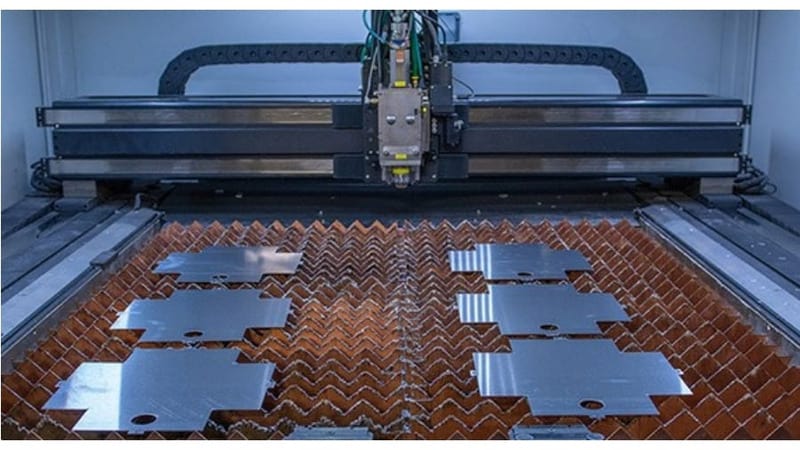

The laser-cutting machine takes control of the reins as the connecting link between power, speed, and thickness. The manufacturing industry’s laser cutting machine is a breath of fresh air. It cuts through thick and hardcore metals with ease and neatly.

We will delve into the entirety of the laser-cutting machine. This blog post will carefully examine the applications, pros, challenges and other vital parts of the laser cutting machine. Hence, you will have better knowledge of the innovative machine in the long run.

What Lasers Are Good for Metal Cutting?

There are various laser cutters used for cutting metals. The following are the top-tier laser types suitable for metal cutting.

CO2 Lasers

Carbon dioxide (CO2) lasers are commonly used to cut metals. The mode of operation is to produce an intense infrared beam that immerses the metals to be cut. They provide top-tier and precise cuts through metals like aluminum, steel, and titanium.

Fiber Lasers

Fiber high-power lasers make precise, excellent, and neat cuts. The mode of operation is the development of potent laser beams using optical fibers filled with the required earth elements. They are best suited for metals of thin or mid-thick components.

If you are interested in the differences between CO2 and fiber laser technology, click the button below.

Nd: YAG Lasers

Neodymium-doped yttrium aluminum garnet (Nd: YAG) is another top-tier laser cutter. The mode of operation is by using a substantial light bean to cut through metals. It is better suited for metals with reflectivity. Examples include silver, copper, gold, brass, and aluminum.

What Metal Materials Can a Laser Cutter Cut?

Stainless Steel Metal

Laser cutters are best suited for stainless steel. They cut metal through precisely without affecting the properties of the steel. Examples of these steel include ferritic or austenitic steel.

Aluminum

Aluminum is part of the lightweight metal class. Laser cutters are used to cut aluminum into intricate styles and patterns. These complex but attractive styles and patterns come with a smooth and neat finish. The higher-power laser beam delivery aids the finishing.

Mild Steel

Laser cutters can also cut carbon steel. It is known that mild steel is popular in the manufacturing industry. Hence, there is a need for laser cutters to take carbon steel and cut them into complex designs and curves.

Brass and Copper

Brass and copper are high conductors. Hence, laser cutters can cut through them accurately and efficiently. It also prevents distortion or errors.

Titanium

Titanium is a metal of high strength and lightweight. The laser cutter is the best option for getting complicated but essential designs and styles. Medical equipment and devices are made from titanium.

What Are the Factors That Have Impacts on Laser Cutting Thickness?

Laser Power

The intensity of the laser power is a vital factor to consider when it involves laser cutting thickness. One of the strong points of Laser cutting power is its ability to effortlessly slice through thick material surfaces. As much as a higher-power laser machine is suitable for thicker sheets, care must be taken to find the right balance to prevent deformation or distortions.

Metal Type and Characteristics

The nature and characteristics of the metal to be cut by the laser cutting machine is worth acknowledging as a factor. Metals have various characteristics, such as reflectivity, melting points, and conductivity. Hence, there are different laser power and thickness for each specified material.

Focal Length and Focus Lens Size

The laser beam’s focal length and focus lens size affect any metal’s precision and cutting depth. It would be best if you had a larger focus lens size and focal length when cutting thicker elements. Interestingly, smaller sizes and focal lengths require a more robust laser beam for precision.

Assist Gas Type and Pressure

Assist gas, type, and pressure play is other essential determinant. Assist gas includes compressed air, nitrogen, and even oxygen. Their primary function is to minimize oxidation by eliminating molten elements from the cut path. Higher gas pressure is best suited got thicker materials.

What Are the Factors That Affect Laser Cutting Speed?

The Intensity of the Laser Power

The speed at which metals are cut is dependent on how much laser power you apply during the cutting process. Enhanced laser power and energy provide for faster cutting. The result is an increased material vaporization rate.

Material Type and Properties

The characteristics and material nature of the metals affect the laser cutting speed. The desired and required cutting speed of a specified material provides for faster or slower cutting speed for precise cutting. Some metal properties that affect the laser cutting speed include conductivity, helping points, and reflectivity.

Cutting the Kerf Width of Materials

Any material surface’s cutting speed depends on the necessary kerf width. The primary definition of kerf width refers to the width of parts of materials cut by a laser cutting machine. Thinner kerf widths increase the laser cutting speed.

Assist Gas Type and Pressure

Assist gas helps clear the metal-cutting paths. When there is an increase in the pressure of the assist gas, an enhanced cutting speed is produced, which makes removal easy and fast.

What Is the Relationship between Thickness and Speed in Laser Cutting?

Impact of Thickness on Cutting Speed

The relationship between a laser cutting machine’s cutting speed and thickness can be likened to two peas in a pod. Thick metals use more energy, time, and cutting resources to cut out the necessary parts. However, slow cutting speed gives the laser cutter additional power and more penetration time.

Balancing Cutting Quality and Efficiency

One hack to getting the perfect blend of efficiency and value is balancing. The metal thickness and cutting speed must be balanced. Slow-cutting speeds are helpful for thicker materials, but slow speed increases production cost and time and reduces service product delivery. Interestingly, fast cutting can cause a lot of distortions or errors.

Required Cutting Parameters for Various Metals and Thicknesses

There is an expanse requirement for the desired cutting parameters for numerous materials and their corresponding thickness. These parameters include power, assist gas setup, speed, and material properties. A cutting guideline is vital during laser cuttings to get the ideal requirements for the various metals and their thicknesses.

How to Choose the Suitable Power Intensity for Your Laser Cutting?

Understand the Material

You have to understand that various materials have different properties and components. The characteristics of any metal or material can positively or negatively affect laser cutting performance.

Hence, the use of suitable cutting power laser beams for some materials is unnegotiable. For instance, aluminum and stainless steel are the best high-fiber laser-cutting power recipients.

Determine the Thickness

The thickness of the metal is another major determinant. Thinner metals require less laser power for precise cuts. Laser cutters come with power requirements that cater to the desired specification of unique metals and their thickness. Hence, you should check those specifications to get the best power volume for the materials.

Consider Cutting Speed

The cutting speed and laser power are interconnected as high laser intensity requires faster cutting speeds and vice versa. Therefore, it is crucial to ensure there is a balance between both to avoid rough edges, errors, and deformation.

Consult Manufacturer Guidelines

Laser-cutting machine manufacturers often deliver guidelines and recommendations for power settings. These settings are based on the material being cut. Adhere to the manufacturer’s suggestions and adjust based on your precise prerequisites and results.

Conduct Test Cuts

Testing cuts before working on a new metal or thickness is wisdom. You get to monitor and determine the best power setting before working entirely on the new material. Observe factors such as the edge finish, kerf width, and the ability of machine tools to cut through the material surface.

Laser Cutting Thickness & Speed Chart

| Metal Type | Maximum Cutting Thickness (mm) | Recommended Cutting Speed (mm/s) |

| Mild Steel | 20 | 600-900 |

| Stainless Steel | 10 | 300-600 |

| Aluminum | 8 | 1000-1500 |

| Copper | 3 | 600-900 |

| Brass | 4 | 600-900 |

| Titanium | 4 | 400-600 |

| Nickel | 3 | 400-600 |

| Zinc | 3 | 400-600 |

How to Optimize Laser Cutting Thickness and Speed?

Adequate Material Selection and Preparation

Choosing materials that are appropriate for laser cutting is important. You must identify and have proper knowledge about their properties. Confirm that the materials are free from elements or contaminants capable of disrupting the fiber laser cutting machine and process.

Fine-tuning the Settings for Cutting Speed and Laser Power

Research the different power and speed setting to find a good combination for the efficiency and desired cut quality. Finding a balance between cutting speed and laser power allows you to achieve the desired cut quality while maintaining an acceptable production rate.

Effective Utilization of Assist Gases

To help remove vaporized or molten material from the cut path, you can make use of some assist gases, including oxygen, compressed air, or nitrogen. The aim is to enhance cutting efficiency. Optimize your selected assist gas and its pressure to suit the cut material.

Routine Maintenance of Laser Cutting Equipment

Regular maintenance and calibration of your laser cutting machine are essential to keep it efficient. You should frequently clean optics and watch out for wear and tear. You must ensure the laser beams are well-aligned for neat and precise cuts. Proper maintenance of the laser cutting head and machine helps to increase product quality and delivery.

Challenges and Limitations in Laser Cutting Thickness and Speed

Limitations and Restrictions of Materials

Laser cutting is often used to cut numerous materials. However, some materials make laser cutting difficult. However, materials like glass, copper, and aluminum can have an adverse effect on laser cutting due to some of their unique properties.

Equipment Capabilities and Constraints

The thickness and speed of laser cutting are affected by the power and beam quality of the laser. The capacities of some materials limit higher-powered lasers from cutting through them, even though they can easily slice through them. Laser settings and configurations can also affect the cutting thickness or speed design.

Heat Accumulation and Thermal Effects

Laser cutting produces high about of heat. It is because of the directing high-energy laser beam on the materials. Thermal effects are the side effects of heat accumulation caused by cutting thicker metals. Examples of thermal effects are degradation, warping, and melting, which can affect product quality.

Speed and Precision Trade-Off

Higher cutting speeds can cause minimized precision. It is common when cutting complex, complicated, or unique designs and patterns. The laser beam’s speed determines the cut’s smoothness and preciseness. Hence, balance is essential.

FAQs

How Does Laser Power Affect the Cutting Thickness and Speed in Laser Cutting?

Laser power is a significant factor in laser cutting, affecting both the cutting thickness and speed. Higher laser power can be used to slice through thicker materials. It is because it allows for more energy to melt the metal.

However, there is a limit to which thick and thin materials that can be cut with high power. Generally, Higher-power lasers directly impact the maximum cutting thickness and speed. This is because these higher-power lasers deliver increased energy to the materials, enabling quicker cutting.

How Does the Laser Lens’s Focal Length Affect Cutting Thickness?

The focal length of the focus lens on the laser lens impacts the spot size and the laser beam’s focus depth. The focal length lens or spot size depends on the cutting point’s energy density, which allows for cutting materials.

How Does the Cutting Speed Affect the Cut Edges in Laser Cutting?

The relationship between cutting speed and edge quality in laser cutting can be a trade-off. Increased cutting speeds can improve production rates but have a negative impact on edge quality. Conversely, reduced cutting speeds provide better control and finer quality cuts, leading to improved edge quality but slower production rates.

What Is the Influence of Assist Gases on the Cutting Thickness and Speed in Laser Cutting?

Assist gases are often used in laser cutting to optimize the cutting process. The selection of assist gas used on a specific material can impact both the cutting thickness and speed.

For instance, oxygen is beneficial as it increases oxidation, eliminates molten elements, and increases cutting speeds. However, it can affect the thickness of a material and cause rough edges plus distortion due to much oxidation.

Conclusion

Laser-cutting metal is a sweet blend of speed, thickness, and power best suited for manufacturing. It has taken laser cutting from a ten to a hundred by enhancing creativity, craftsmanship, and innovation. The blend of power, high speed, and maximum thickness will undoubtedly advance the cause of the use of innovative technologies in all industries.

Discover the Perfect Solution for Your Business with Baison

Explore Baison, the innovative solution that helps businesses uncover the perfect fit for their needs. With Baison, getting the best laser-cutting equipment has been tailored specifically to suit your desired requirements.

Baison is known to go beyond the one-size-fits-all approach—request our sample proof to test our personalized experience. Don’t hesitate to click the button below to contact us today!