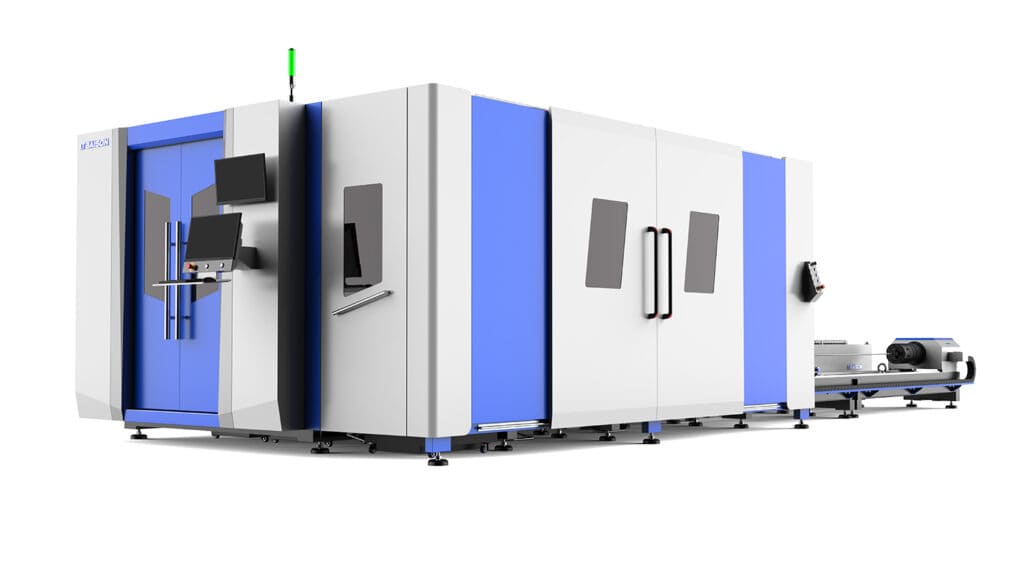

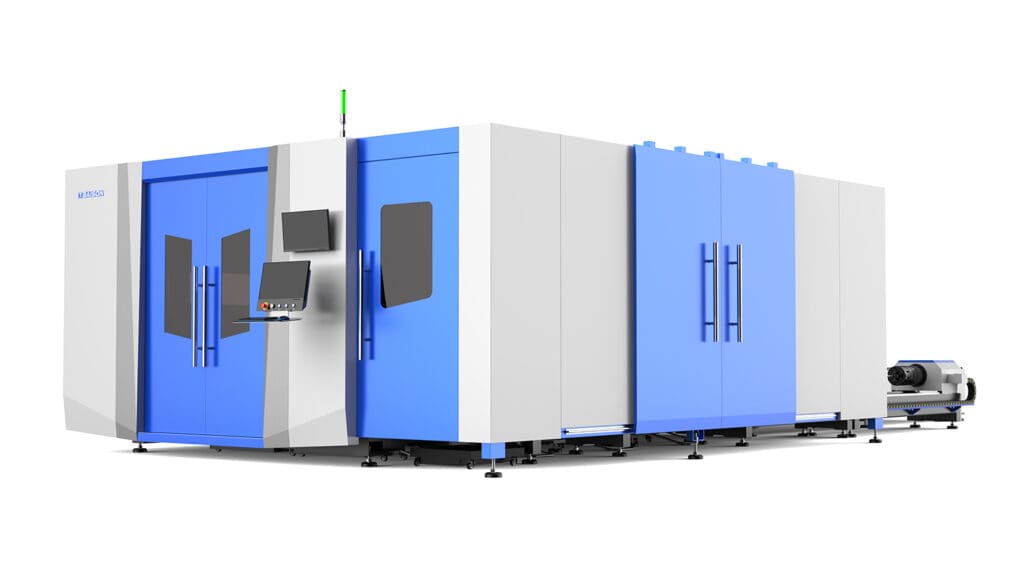

Dual Platforms Sheet Metal & Tube Laser Cutting Machine

The new dual platforms sheet metal and tube laser cutting machine are more than a powerful upgrade. It takes advantage of the strengths prevalent in both platforms: short processing times for large ranges or possible tubes, as well as cutting through thicker materials with an increased power level! You’ll see why this version will be unbeatable when you check it out yourself today.”

Multi-function laser cutting machine

B Series Dual Platform

BSH3

9.84’×4.92′(3000mm×1500mm)

Tube Range φ 0.79″ -9.45″ (20-240mm )

1500W-6000W

BSH4

13.12’×6.56′(4000mm×2000mm)

Tube Range φ 0.79″ -9.45″ (20-240mm )

1500W-6000W

Features That Increase Your Productivity

The multi-purpose fiber laser cutting machine is an excellent investment for any business. It saves you money, space and increases production efficiency!

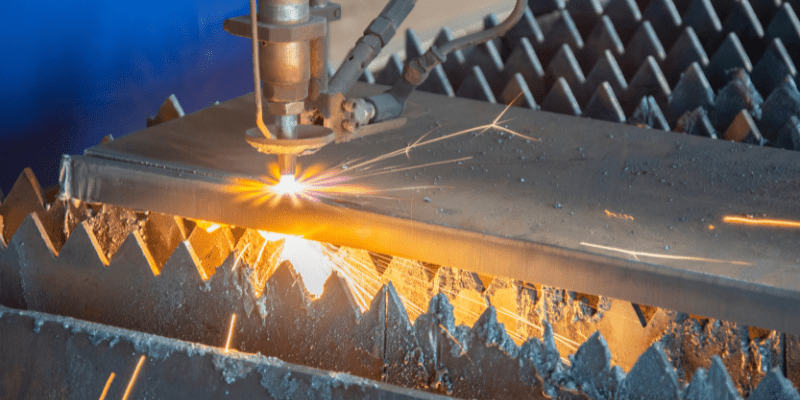

Patented Climbing Exchange Platform

More accurate as it allows the laser cutting head to cut without changing the z-axis.

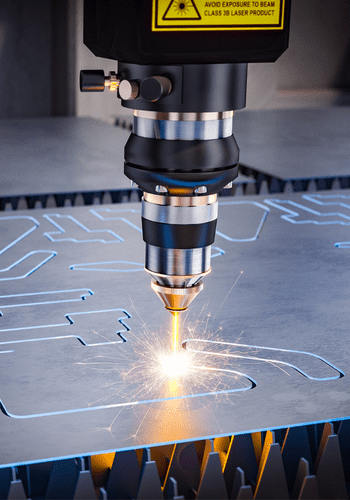

Quality Cutting Results

Guaranteed cutting accuracy without sacrificing cutting speed.

Energy-saving Tech

Energy consumption can be reduced by 15-20% compared to similar products.

Fully Enclosed Machine Design

A fully enclosed design with an advanced ventilation system makes it cleaner.

Easy to Operate

You can operate this performance machine after 15 minutes of learning.

Stabe Production

You can always count on the machine to deliver when you need it.

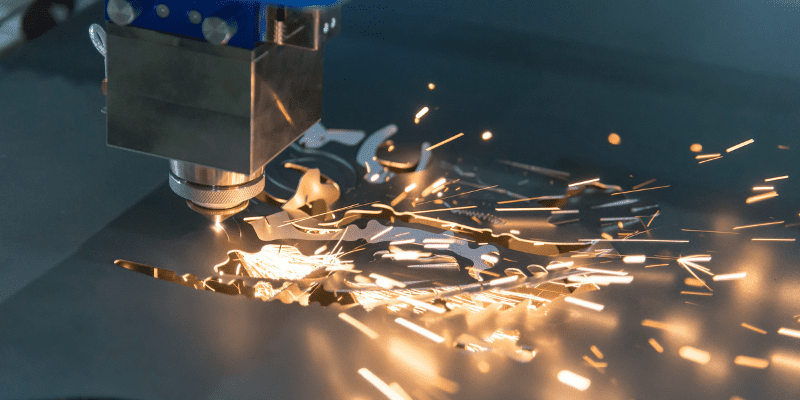

Laser Cutting Machine Wide Applications

Fiber laser cutting is the most advanced and widely used technology, from metal processing to vehicle manufacturing. It’s the best choice for those who need precision cuts!

Storage Racks

Furniture

Gym Equipment

HBDE Laser Cutting Machine Capabilities

Get a sense of how much more efficient your operations can be by examining the specs of our Dual Platforms Sheet Metal & Tube Laser Cutting Machine at Baison.

| Model | BSH3 |

|---|---|

| Laser Power | 1500W-6000W |

| Processing Size | 3000mm×1500mm |

| Pipe Processing Range | QG60T7(6500mm): φ20-240mm square tube 20-240mm QG60T5(6500mm): φ20-350mm □20-245mm |

| Max Moving Speed | 100m/min |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Max. Acc. Speed | 1.0G |

Configuration for Great Machine

A good configuration is key to making a good machine. That’s why we only partner with the best companies in the world to produce our fiber laser cutting machines.

IPG Laser Source

The industry's most stable and highest-performing lasers.

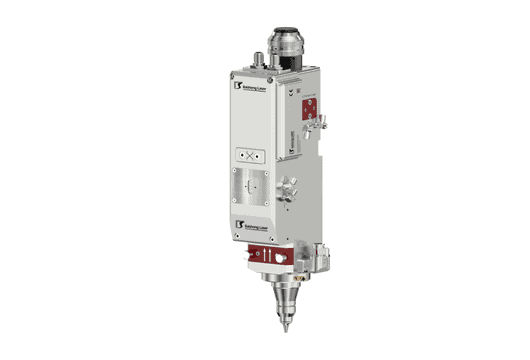

Ospri Cutting Head

High-precision cutting lasers help you maintain production levels.

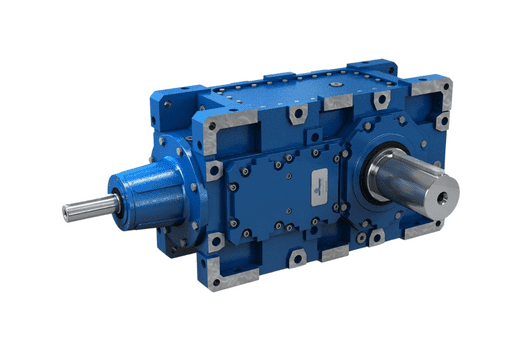

Motovario Motoreducer

Dependable electric motors will help you get the job done.

Schneider Servo Motor

Create more efficient digital operations with mechatronics.

Smart Operating System

Baison’s HBDE dual platforms sheet metal and tube laser cutter use CypCut operating software. Which is not only does it have powerful features, but it also has a very user-friendly interaction design.

CypCut is a cutting-edge design for fiber laser printers. It simplifies complex CNC machine operation and integrates CAD, Nest & CAM modules in one! From drawing to nesting or even workpiece cutting, all can be completed by clicking on some buttons – it’s that easy with Cypcut sheeting software.

- Statistics of machine production to help you manage the workload.

- Automatically optimize its errors, delete duplicates, smooth curves, and join line segments.

- Quickly and easily set up lead lines, micro joints, and kerf width compensations for parts in small or large quantities.

Fiber Laser Cutting Knowledge & Resources

With all these new technologies, there is a need to stay on top of the latest trends. Our resourceful team provides you with articles written by engineers who designed our fiber laser cutting machine so your company can keep up and thrive in this ever-changing industry!

What is Fiber Laser Cutting?

Laser Cutting VS. Plasma Cutting: Which Procedure is Better for You?

What is the Laser Cutting Thickness Limit for Different Materials?

Frequently Asked Question

Below is some common questions regarding our dual platforms sheet metal & tube laser cutting system. Please feel free to contact us if you have any other questions.

Where do you manufacture and ship your machines from?

Our manufacturing center is located in Foshan, China, and most machines will be shipped from our Foshan factory. We also have many dealers worldwide who sometimes have ready-made machines for you to choose from.

How long does it take to receive the machine after placing an order?

After receiving your order, we need 10-15 working days to produce the machine you need. If you need a customized solution, the time may take more. This does not include shipping time, which usually takes 15-35 days, depending on your location.

Does your company provide training on the operation of machines?

We offer free lifetime training to our customers even though our machines are very easy to operate. After you purchase the machine, our engineers will come to your workshop or online to train your operators, and we have many operating tips in our Knowledge Base for you to learn.

What is the warranty for your fiber laser cutter?

Quality is our culture, and all machines enjoy a three-year quality guarantee. We have 24/7 engineering available if something comes up unexpectedly. In addition, we offer our customers a lifetime maintenance service. And all consumables and accessories are available at the best prices.

Contact with Baison Today

Use our machines to simplify your work. Let us know about your inquiry, and we will get back to you as soon as possible.