The laser cleaning process is a safer, greener, and more precise alternative to traditional cleaning methods like sandblasting or chemical treatments. However, the steep price tag can reasonably surprise any buyer.

In this article, we’ll break down the key factors behind the cost, explore the return on investment (ROI), and explain the business logic for industrial buyers.

What Is a Laser Cleaning Machine? (Quick Overview for Buyers)

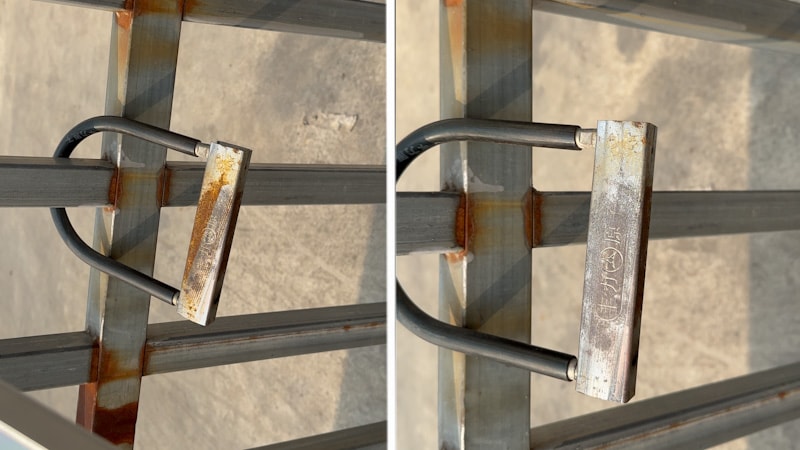

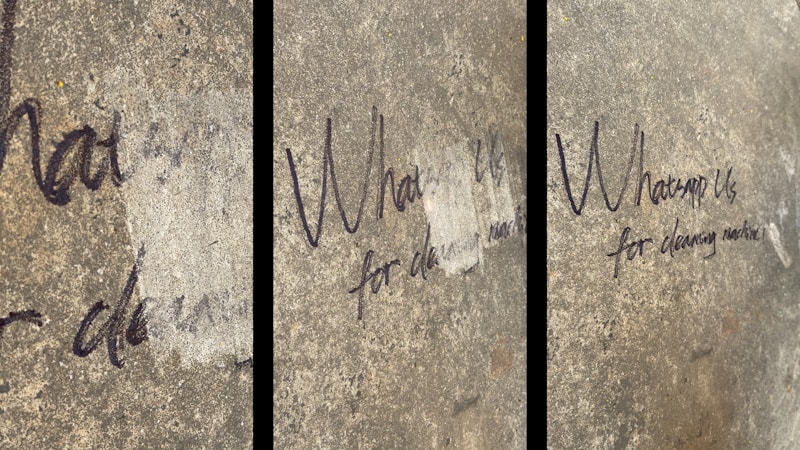

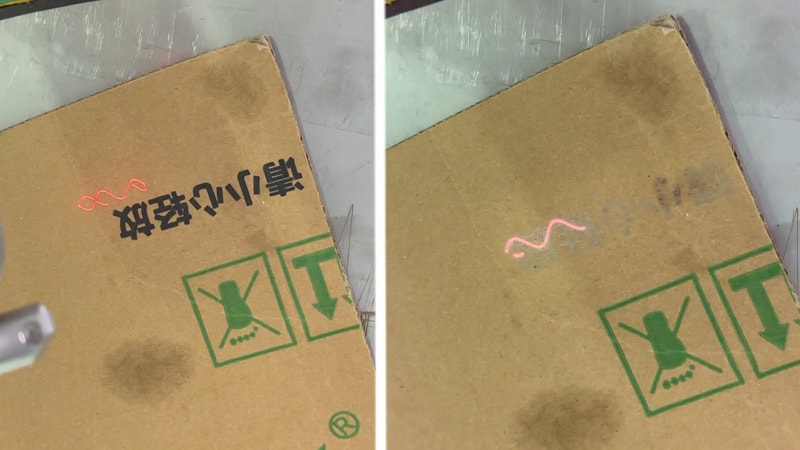

A laser cleaning machine is an advanced industrial tool that uses focused laser beams to remove contaminants such as rust, paint, oil, oxides, and other residues from underlying metal surfaces as well as wood, acrylic, stone, etc. This surface cleaning process, known as laser ablation, vaporizes or detaches unwanted materials without damaging the underlying substrate.

It’s getting more and more popular as the best cleaning method for delicate or complex parts. Especially the laser rust removal has been reviving corroding metal surfaces and giving them a second wind.

How It Works

The machine directs a high-powered laser beam onto the target surface. The intense energy rapidly heats and ablates contaminants, turning them into gas or particulates that can be easily removed. The process is non-contact, precise, and environmentally friendly since it eliminates the need for chemicals or abrasive materials.

Types of Laser Cleaning Machines

Pulsed Laser Cleaning Machines: Emit short, high-energy pulses for precise material removal with minimal heat input. These are best for sensitive or high-value components where substrate damage must be avoided, such as molds, electronic parts, or heritage artifacts.

Continuous Wave (CW) Laser Cleaning Machines: Deliver a constant laser beam suitable for large-scale or heavy-duty cleaning tasks like rust removal or stripping paint from steel plates, pipelines, or ship hulls. They are generally more cost-effective for bulk applications but introduce more heat to the substrate.

Common Use Cases

- Automotive parts restoration (rust, paint, oil removal)

- Heritage and historical artifact restoration

- Aerospace component maintenance (oxide, corrosion, paint removal)

- Mold cleaning, electronics, and more

Why Industries Are Shifting to Laser Cleaning

Industries are rapidly adopting laser cleaning due to its non-contact, precise, and eco-friendly nature. It eliminates the need for hazardous chemicals, reduces waste, and minimizes risk to workers. Although the initial investment is higher, operational costs decrease over time thanks to reduced consumables, less downtime, and longer equipment life. This technology also supports regulatory compliance and sustainability goals.

Learn why Laser Cleaning is superior to Sandblasting.

Why Are Laser Cleaning Machines So Expensive?

1. Advanced Laser Technology and Precision Optics

The core of a laser cleaning machine is its high-performance fiber laser source. Depending on power and quality, these laser modules alone can cost thousands of dollars. Precision optics-such as high-grade lenses, galvanometer scanners, and advanced beam delivery systems-are essential for focusing and controlling the laser beam with micrometer accuracy.

Manufacturers invest heavily in research and development to ensure stable operation at high frequencies and energies. The electronics and optics directly affect beam quality and reliability. This R&D not only covers hardware but also the software and algorithms needed for consistent, repeatable cleaning results. The combination of costly components and significant engineering investment also directly drives up the price of each machine.

2. Industrial-Grade Hardware and Engineering

Laser cleaning machines are engineered for demanding industrial environments like construction and advanced thermal management. Heavy-duty casings protect sensitive internals, while sophisticated water cooling systems are required for stable operation and to prevent overheating in high-end models. They are more suited for continuous usage.

Touchscreen control systems and integrated software provide user-friendly operation and allow for precise process customization. Manufacturing standards rival those of CNC machinery, with tight tolerances and anti-reflection or anti-corrosion finishes to maximize durability and lifespan.

This level of build quality, combined with complex integration of electronics, mechanics, and optics, adds substantial cost to each unit.

3. Safety Concerns and Compliance Certifications

Operating at Class 4 laser levels, these machines require extensive safety features, including emergency stops, shielding, and interlock systems to prevent accidental exposure to harmful laser radiation. Compliance with international standards-such as CE for Europe, FDA for the US, and ISO for global quality and safety, demands rigorous testing and certification.

Additionally, pricing often includes operator training and personal protective equipment (PPE). The regulatory requirements and risks associated with high-powered laser systems may inevitably increase cost. These built-in safety and compliance measures are critical but costly components of the overall machine package.

4. Long R&D and Engineering Cycles

Laser cleaning machine price includes years of research into pulse-width optimization, energy delivery, and material interaction. Manufacturers invest in proprietary software and firmware to maximize cleaning efficiency and adaptability for different materials and surface contaminants.

Many innovations are protected by global patents, which not only require significant upfront investment but also add licensing and legal costs. The result is a product that embodies years of engineering expertise and intellectual property, further elevating its market price.

5. Limited Market and Low Production Volume

Laser cleaning machines remain specialized, niche equipment used primarily in industrial and high-value restoration settings. This limited market means manufacturers cannot leverage the economies of scale enjoyed by mass-produced machinery. Each unit may require customization, such as integration with robotic arms, handheld modules, or trolley-mounted systems, to suit specific industry needs.

Cost Breakdown: What Are You Really Paying For?

| Cost Component | % of Price | Estimated Price (USD) | Description |

| Laser Source & Optics | 35-45% | $10,000–$45,000 | High-power fiber laser modules (IPG, Raycus, etc.), precision lenses, scanners, and beam delivery. |

| Industrial Hardware | 15-20% | $5,000–$20,000 | Heavy-duty casing, cooling systems (air/water), CNC-grade frames, touchscreen controls, and software. |

| Safety & Compliance | 10-15% | $3,000–$15,000 | Class 4 laser safety features, shielding, interlocks, CE/ISO/FDA certifications, and operator training. |

| R&D, Software, Patents | 10-15% | $3,000–$15,000 | Proprietary firmware, pulse optimization, global patent protection, and engineering development. |

| Customization & Integration | 5-10% | $2,000–$10,000 | Robotic arms, automation, special mounts, tailored configurations for specific industries. |

| Maintenance & Support | 5-10% | $2,000–$10,000 | Warranty, after-sales service, routine maintenance, spare parts, and technical support. |

Note: Percentages and price ranges are typical for industrial-grade laser cleaning machines, with total prices ranging from $20,000 to $100,000+, depending on power, features, and configuration.

Hidden Value – What You Gain from a Higher Upfront Cost

Lower Operating Costs

Laser cleaning machines don’t need abrasive media, harmful chemicals, and other consumables, which significantly reduces ongoing expenses. Unlike traditional methods, they require minimal materials, cutting supply costs and waste disposal fees. Additionally, these machines often need only one operator and can be integrated with automation systems that ultimately lower labor costs and improve efficiency.

Their non-contact process causes less wear and tear on equipment. As a result, these systems experience fewer breakdowns and minimal maintenance costs. Overall, the lower operating costs help offset the initial investment and deliver substantial savings over the machine’s lifecycle.

Higher Cleaning Precision and Productivity

Laser cleaning provides unmatched precision by targeting contaminants without harming the underlying material. This eliminates damage and reduces the need for costly rework, ensuring surfaces are perfectly prepared for coatings or further processing. The high accuracy also improves product quality and extends the lifespan of parts by preserving their structural integrity.

Faster cleaning cycles boost throughput and lead to higher productivity and quicker turnaround times. This combination of precision and efficiency makes laser cleaning a valuable asset for industries demanding consistent, high-quality results.

Environmental and Compliance Benefits

Laser cleaning generates no hazardous waste or chemical runoff. They have remarkably low environmental impact and compliance costs. This eco-friendly process helps companies meet increasingly strict environmental regulations and avoid fines or remediation expenses.

By supporting sustainability initiatives and ESG (Environmental, Social, and Governance) goals, laser cleaning enhances corporate responsibility and brand reputation. The reduced need for PPE and safer working conditions further contribute to compliance and employee well-being. Investing in laser cleaning aligns with modern industrial priorities for greener, safer, and more responsible operations.

Laser Cleaning vs. Traditional Cleaning: Cost Over Time

| Feature | Laser Cleaning | Sandblasting | Chemical Cleaning | Dry Ice Blasting |

| Initial Cost | Very High ($40k–$170k) | Low–Medium ($5k–$30k) | Low ($2k–$10k) | Medium ($10k–$40k) |

| Operating Cost | Low (no consumables, $6–$140/hr) | High (abrasives, dust control) | High (chemicals, disposal) | Medium (dry ice, moderate waste) |

| Maintenance | Low (minimal wear, simple) | High (abrasive wear) | Medium–High (corrosive damage) | Medium (ice handling, equipment wear) |

| Precision | Very High (no substrate damage) | Low–Medium (can damage surface) | Medium (risk of etching/corrosion) | Medium–High (gentle, but less precise than laser) |

| Waste Disposal | None (no secondary waste) | High (dust, spent media) | High (hazardous waste) | Medium (CO₂ gas dissipates, some residue) |

| Worker Safety | High (enclosed, minimal PPE) | Low (dust, flying debris, PPE) | Low (chemical exposure, PPE) | Medium (cold burns, PPE) |

| Environmental Impact | Very Low (no chemicals, no waste) | High (dust, media disposal) | High (hazardous chemicals) | Low (CO₂, but energy use) |

| Labor Needs | Low (1 operator, automation-ready) | High (multiple operators often needed) | High (handling, application, cleanup) | Medium (operator + handling ice) |

| Downtime | Minimal (fast, automated) | High (cleanup, media refill) | Medium–High (application, drying) | Medium (setup, ice supply) |

| Lifespan/ROI | Long (spreads cost, high ROI) | Short–Medium (abrasive wear) | Medium (corrosive wear) | Medium (equipment wear) |

Is the Investment Worth It? (ROI for Industrial Applications)

Short-Term vs. Long-Term ROI

Laser cleaning machines require a significant upfront investment, but the payback period is typically between one and three years, depending on usage and application. Many manufacturers see rapid returns due to reduced maintenance, lower operating costs, and improved productivity.

For example, U.S. factories have reported that laser cleaning systems often pay for themselves within 12 to 24 months through direct cost savings and increased throughput. Over the long term, companies benefit from extended equipment life, fewer downtimes, and consistent product quality.

Factors Affecting ROI

Several factors influence the return on investment for laser cleaning machines. Cleaning volume is critical: higher throughput leads to faster payback. Machine utilization rate also matters-systems used continuously in production lines deliver greater value. Industry type plays a role, as sectors like automotive, shipbuilding, and aerospace often demand high precision and strict standards. Customization, automation, and integration with existing processes can further improve ROI.

Who Should Invest in High-End Models?

High-end laser cleaning machines are best suited for high-volume manufacturers who need to process large quantities of parts quickly and efficiently. Facilities with strict surface preparation standards, such as those in aerospace or automotive, gain the most from the precision and repeatability of advanced laser systems. Companies aiming to reduce their chemical and waste compliance burden also benefit, as laser cleaning eliminates hazardous materials and simplifies regulatory requirements.

How to Choose the Right Laser Cleaning System for Your Budget

Let’s quickly asses your needs and select a system that can satisfy your needs.

- Pulse lasers offer high precision and minimal heat for delicate or detailed cleaning; continuous lasers deliver faster results for large, heavily contaminated surfaces.

- Choose power based on your workload: 100W for light duty and fine work, 200W for general rust or paint removal, and 1000W+ for industrial-scale tasks or thick coatings.

- Fixed models are ideal for production lines and automation; portable units suit fieldwork, maintenance, or hard-to-reach areas.

- Single-use systems target specific contaminants or materials; multi-purpose models offer flexibility for varied cleaning jobs and future needs.

- Prioritize manufacturers with strong support, comprehensive warranties, and operator training to ensure reliability and long-term value.

Read our guide on “How to Choose the Best Laser Cleaning Machine” for more insights.

Frequently Asked Questions (FAQ)

Q1: Can a laser cleaning machine replace sandblasting?

A1: Yes, it can. It’s often more effective and less abrasive.

Q2: What’s the price range for laser cleaning machines?

A2: The price range for laser cleaning machines typically spans from $3,000 to over $200,000, depending on power, features, and industrial application.

Q3: How long do these machines last?

A3: 5 to 10 years on average. With proper usage and maintenance, they’ll easily last longer.

Q4: Can it damage delicate materials?

A4: It certainly can. Using high power output (1000W+) on delicate/soft materials can damage/burn/warp the material. Always use the recommended laser power output for specific materials.

Q5: Is training required to operate them?

A5: Training is crucial. Although the operation is quite straightforward, laser is still a very risky tool. Proper handling and protection must be exercised.

Q6: What’s the best model for small-scale manufacturing?

A6: For small-scale manufacturing, a 100–300W portable pulsed fiber laser cleaning machine is the best choice. The Baison WM2 pulsed laser cleaner may be the best for such jobs.

Conclusion:

Now that we’ve broken down the expenses for you, let’s explore how to start earning! Read our guide on how to make money with laser cleaning equipment. You’ll understand why the investment is worth it once you see the possible returns you can get!

Final Thoughts – Don’t Let the Price Fool You

Don’t let the price estimations intimidate you. Reach our experts and ask for a quote. At Baison Laser, we have a perfect cost-effective solution for your specific business!