So if you are also wondering what type of laser is best for cutting metal, then you are not alone… The short answer is that you can use a CO2 laser cutter or a fiber laser cutter for processing most types of metals (ferrous & non-ferrous).

In addition, crystal laser cutters can be used to cut thick metals, but they are usually more expensive. The preferred choice is the gas (CO2) or the fiber laser cutters.

Now, let’s take an in-depth look at different types of laser cutting technology available in the market. In addition, we will also look at which types of laser cutters are ideal for cutting metals.

And in the end, we will look at some practical tips on how you can set the ideal parameters for laser cutting metals. So let’s get into it:

3 Types of the Laser Cutting

Currently, there are three types of laser-cutting machines available in the market:

- CO2 laser cutters

- Fiber laser cutters

- Crystal laser cutters

1. CO2 Laser Cutters

The first ever laser cutter was based on CO2 laser cutting technology. The name “CO2” was due to the mechanism used for cutting materials.

In a CO2 laser cutter, electricity passes through a gas-filled tube and produces light beams. There’s a reflective mirror on one end of the beam, while the other contains a partial mirror.

As a result, the light passes through the partial mirror and can be used to cut metal or other materials.

The gas-filled tube usually contains a mixture of carbon dioxide (CO2), hydron, nitrogen, & other gases.

Depending on user requirements, different CO2 laser machines are available in the market ranging from a few watts to multiple Kilowatts.

Generally, a CO2 laser cutter with a higher power consumption can cut through thick materials. On the contrary, a CO2 cutter with low power consumption is only suitable for cutting through thin materials.

A CO2 laser cutter is ideal for cutting non-metallic materials such as:

- Plastic

- Wood

- Leather

- Wallpaper

- Fabric

In addition, it can also process thin sheets of non-reflective metals. On the contrary, reflective metals are usually not suitable for cutting with a CO2 laser machine.

The reason behind this is straightforward – The laser beam from a CO2 machine bounces back from the metal’s reflective surface.

2. Fiber Laser Cutters

The next type is the fiber laser cutting machine, also known as the solid-state laser cutter. In these machines, the light particles are passed through the optical fiber cables. That’s the reason why they are called fiber laser cutters.

One of the key advantages of fiber lasers is that it doesn’t require as much maintenance as CO2 lasers. It isn’t wrong to classify them as maintenance-free.

Another benefit of fiber laser is that it can last up to 25,000 working hours. And last but not least, these machines can produce intense laser beams that can cut through metals much faster.

Depending on which model of fiber laser machine you buy, it can be a continuous, pulsed, or MOPA. Out of all these types of fiber laser systems, the one that offers the most flexibility is MOPA. In MOPA, users can adjust the pulse durations.

For most metal cutting, the preferred choice is fiber laser machines as they are fast, accurate, & can last for a long time. In addition, fiber lasers are also popular for cutting through reflective metals such as copper, bronze, stainless steel, etc.

If we talk about the downside of fiber laser machines, it is more suited for metal cutting. Similarly, a more high-powered is required to cut through materials thicker than 20 mm. And last but not least, these machines are also not recommended for cutting non-ferrous metals.

In a sense, fiber laser cutters are more cost-effective than CO2 lasers. On the contrary, a CO2 laser cutter is more cost-effective if you want to cut non-metals.

3. Crystal Laser Cutters

The next type on our list is crystal laser cutters, also known as “nd: YAG” or “YVO.”

The Nd: YAG type uses a crystal called “neodymium-doped yttrium aluminum garnet.” And the nd: YVO uses the crystal known as “neodymium-doped yttrium ortho-vanadate, YVO4”.

One of the major advantages of these laser machines is their high precision and cutting power. However, they tend to be more expensive than any other laser-cutting process.

On average, the shelf life of crystal laser cutters is between 8000 – 15000 hours. That’s why when it comes to cutting various metals & even difficult materials, the default choice is usually fiber or CO2.

Which type of laser cutting machine is best for cutting metals?

The exact answer to this question depends on which metal you want to cut and the thickness of the metal sheets.

For starters, a CO2 laser machine is only suitable for cutting stainless steel sheets. However, the same machine can also cut most materials such as wood, plastic, acrylic, etc.

The preferred choice is a fiber laser system for cutting metals. For cutting sheet metal under 5mm, these machines can deliver the best speed & finer cut. A higher-power fiber laser cutter can get the job done even for thicker metals.

But its wavelength is the best fiber laser quality, making it ideal for metals. As mentioned earlier, the light beam of the CO2 machine can bounce off metal surfaces. But the wavelength of fiber lasers is metal-friendly & is absorbed into metals readily.

Another advantage of the fiber laser beam is its small spot size, allowing high-precision cutting at a fast speed.

On average, a fiber laser cutter can achieve up to 3 times faster speeds than a CO2 machine. And the best part is that a fiber laser cutter only consumes 1/3rd power compared to CO2 laser machines.

So it is safe to say that fiber laser cutters are the best choice for cutting metals!

Tips On Setting the Parameters for Laser Cutting Metals

The exact parameters for laser cutting metals usually depend on metal type, metal thickness, & even the power of the machine. That’s why it can be difficult to pinpoint the exact parameters, as they might not work for you.

However, we will discuss each parameter along with some actionable tips that will help you to cut metals:

Laser Power

The first parameter is the laser power which defines what materials you can cut with it. In addition, the thickness of the materials is also directly proportional to the laser power.

Generally, a higher laser power means cutting through thick metal sheets. On the contrary, a lower-powered machine can only cut through thin metal sheets.

With a 1kW (1000 watts), you can cut stainless steel sheets up to 5mm in thickness. But with a 3kW (3000 watts) fiber laser cutter, you can cut metal sheets up to 12mm thick!

Auxiliary Gas

The next factor to consider is the output pressure & the purity of the auxiliary gas. The main function of auxiliary gas in a laser cutting machine is to blow away any molten or leftover material during the cutting process.

So if you don’t have enough gas pressure, it will not blow away the leftover waste material and will affect the finish quality of the cuts.

This means you should always check the auxiliary gas pressure to ensure it is sufficient. And last but not least, the gas mixture used in the machine must be 99.5% pure.

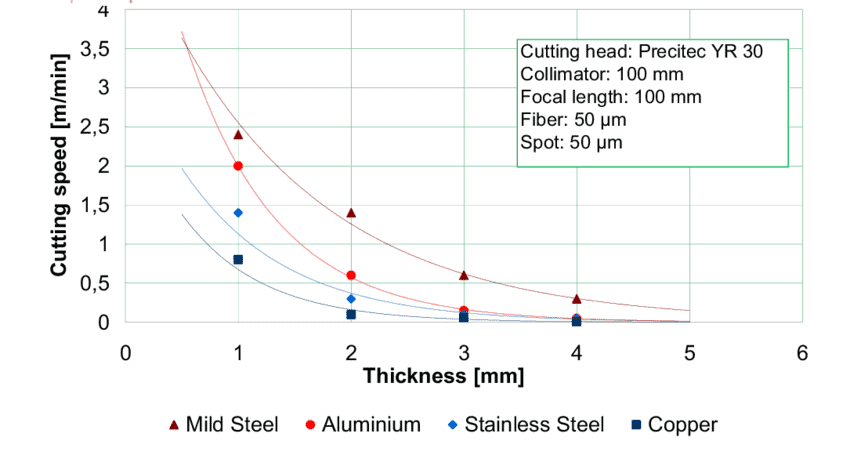

Cutting Speed

Cutting speed is also an important parameter that can affect the cutting quality of metals. A machine with a slow cutting speed can lead to burning marks and too much-melted material. Similarly, a cutting speed that’s too fast will fail to cut through metals properly.

This means that you will have to find the ideal cutting speed based on the material thickness and the power of the machine you are using. For this purpose, it is usually best to run a few tests on the material to find the ideal cutting speed before starting the actual cutting process.

For a 1000w laser cutting machine, the cutting speed is as follows for different materials:

Mild Steel:

- 1mm thickness – Cutting speed of 15.0 to 22.0 m per minute.

- 2mm thickness – Cutting speed of 5.0 to 6.6 m per minute.

- 3mm thickness – Cutting speed of 2.5 to 3.85 m per minute.

- 4mm thickness – Cutting speed of 2.0 to 3.3 m per minute.

- 5mm thickness Cutting speed of 1.4 to 2.0 m per minute.

Stainless Steel:

- 1mm thickness – Cutting speed of 16.5 to 22.0 m per minute.

- 2mm thickness – Cutting speed of 4.5 to 6.5 m per minute.

- 3mm thickness – Cutting speed of 2.0 to 3.1 m per minute.

- 4mm thickness – Cutting speed of 1.0 to 1.065 m per minute.

- 5mm thickness Cutting speed of 0.4 to 0.7 m per minute.

Aluminum:

- 1mm thickness – Cutting speed of 1.00 to 13.2 m per minute.

- 2mm thickness – Cutting speed of 2.0 to 4.5 m per minute.

- 3mm thickness – Cutting speed of 0.6 to 1.32 m per minute.

For more high-powered laser cutters (2kW, 3Kw, etc.), you can set even higher cutting speeds & cut through material in less time.

Continuous or Pulse Wave Mode

Another parameter to select is whether you want to use the continuous or the pulse wave mode.

In continuous wave mode, the light beam is emitted continuously. While in pulse wave mode, a greater amount of light particles can be emitted in one go over multiple intervals.

The continuous wave mode is ideal if you only want to cut metal in sharp corners and straight lines. And for cutting small holes, the pulse wave mode is considered best.

Conclusion

If you only want to cut metals, then the best choice is a fiber laser cutter. But if you want to cut non-metals mostly, you can use a CO2 laser that can also handle some metals.

Another important thing to remember is the power of the laser cutter you want to buy. It would be best if you always went with high-powered machines to cut through thick metal sheets. And if you are only going to work with thin metal sheets or engraving, you can also do fine with a low-powered machine.

If you are still unsure about which laser cutter is the right fit, contact us today! And if you have already decided on a particular type of laser cutter, you can request a quote!