This article will cover what these machines do, why they’re important, and how they can improve the fabrication industry. We aim to show you how metal coil processing equipment and machines can help make your manufacturing processes more efficient.

What Is a Metal Coil Processing Machine?

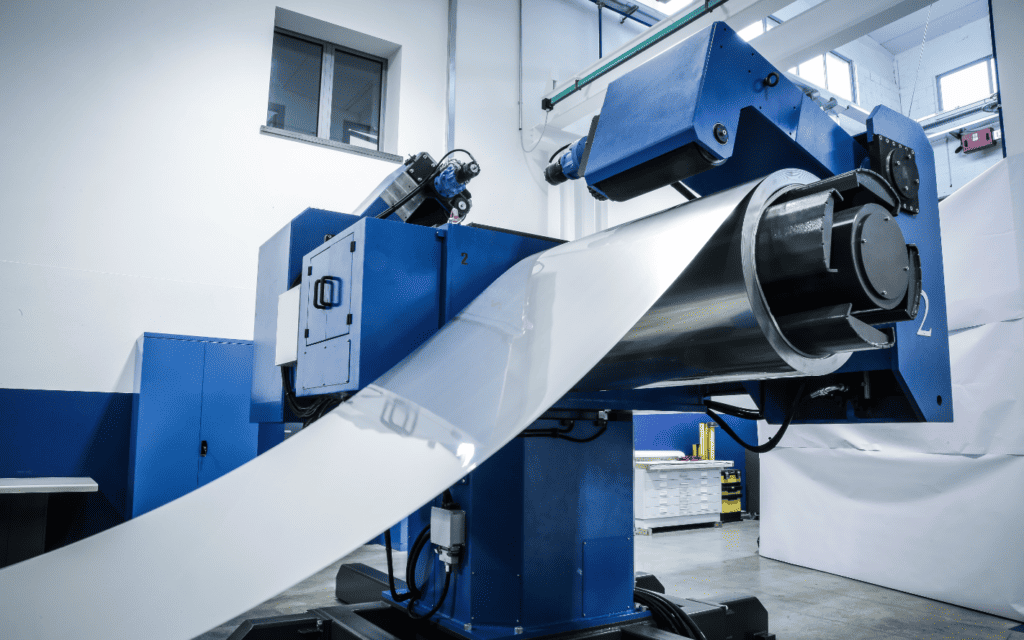

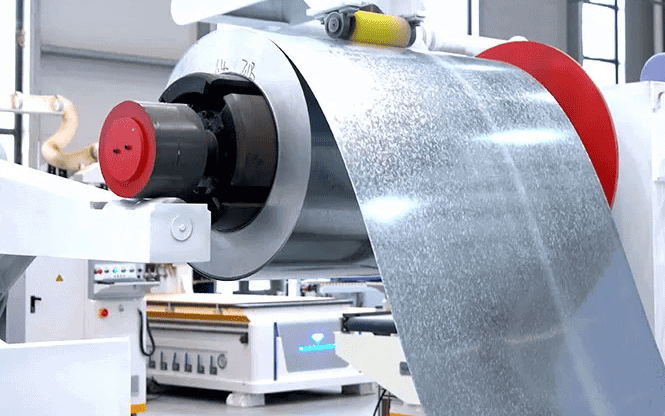

A metal coil processing machine is a specialized piece of equipment used in the fabrication industry to transform large sheet metal processing into raw materials for manufacturing. This machine typically involves uncoiling, straightening, measuring, cross-cutting to length, and stacking material.

Hence, it is safe to say that these machines play a crucial role in the industry. For instance, these machines enable fabricators to process large metal coils swiftly and accurately in such a competitive environment. By automating repetitive tasks, they significantly increase production efficiency, reduce waste, and enhance the quality of the final product – a game changer in the fast-paced world of metal fabrication.

Different Types of Metal Coil Processing Machines

Choosing the right type of metal coil processing machine is crucial for businesses that wish to optimize their manufacturing processes, reduce waste, and save on costs. However, making the right choice can be challenging with several types of machines available. Understanding the specifics of each type can help make an informed decision.

Water Jet Cutting Machines

Water Jet Cutting Machines, on the other hand, use a high-pressure stream of water to cut materials. They are best for industries that need to cut materials sensitive to high temperatures. A good example is in the aerospace industry, where heat can distort the material and compromise the integrity of the finished product.

Plasma Cutting Machines

Plasma-cutting machines utilize a high-velocity stream of ionized gas or plasma to cut through conductive materials. They are well-suited for heavy industries that deal with thick metals, such as shipbuilding or construction, where the speed and capability to cut through dense materials are a priority.

Oxy-Fuel Cutting Machines

Oxy-fuel cutting machines are another excellent choice for industries that work with thick metals. These machines use a combination of fuel gases and oxygen to cut metals. A large-scale infrastructure project, for example, can benefit from this type of machine due to its ability to handle heavy-duty materials.

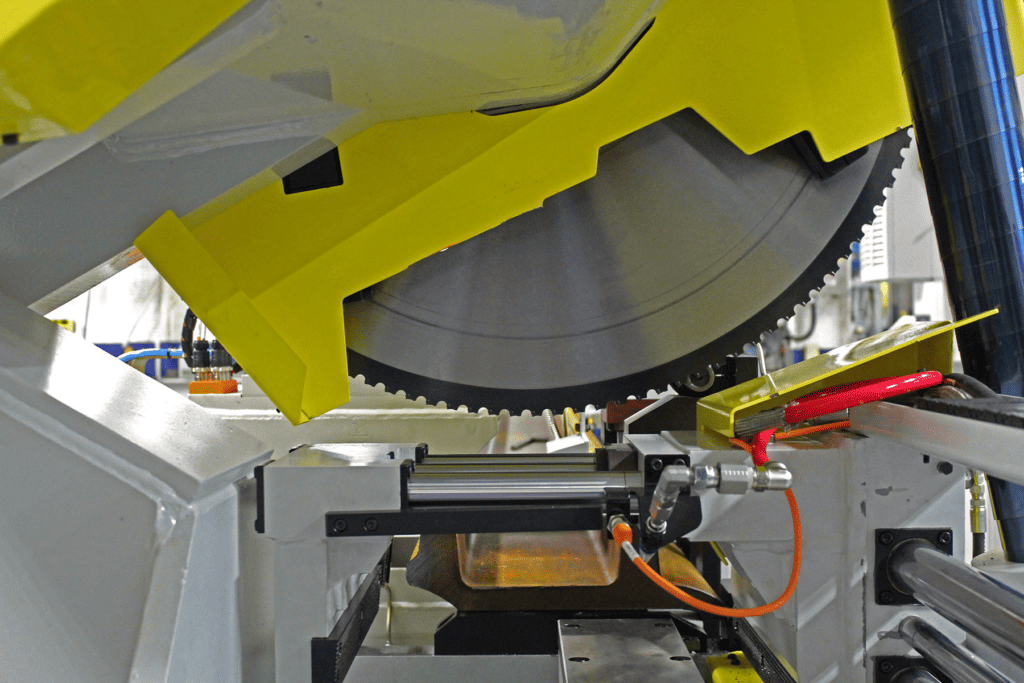

Cold Saw Cutting Machines

Cold saw-cutting machines are ideal for businesses that require precise, burr-free cuts and high-speed production. For instance, a company involved in automotive parts manufacturing can significantly benefit from the precision and speed these machines provide.

Electric Punching Machines

Electric punching machines are excellent for industries that need to make a large number of similar cuts. An example of this could be a manufacturer of metal racks or shelves, where identical holes or patterns need to be punched into the metal.

Mechanical Cutting Machines

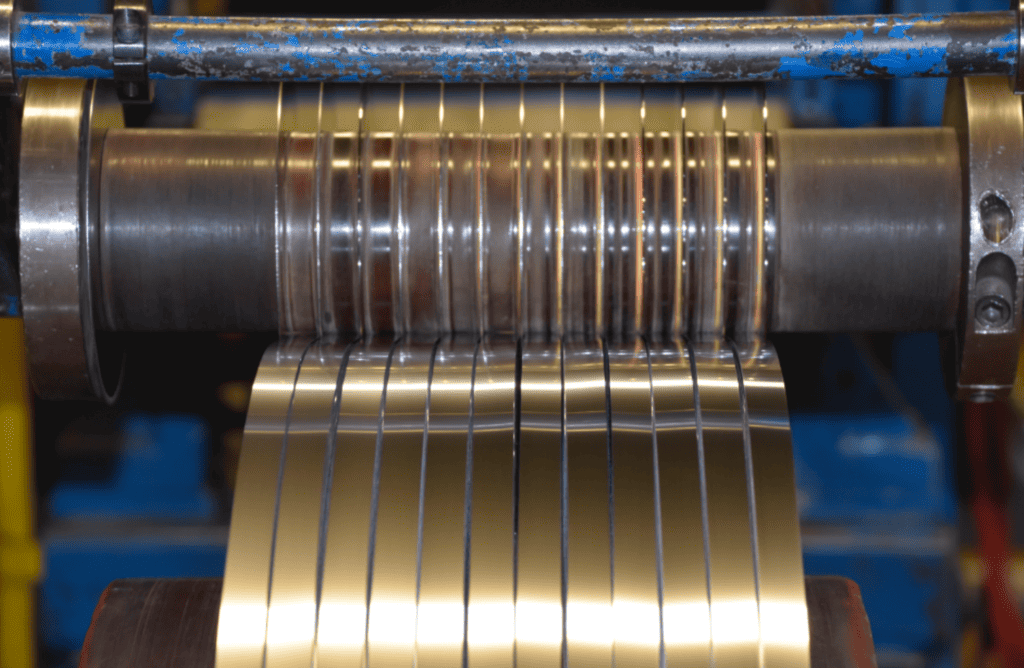

Lastly, mechanical cutting machines, which utilize a variety of mechanical tools to cut materials, are a versatile choice. They are beneficial for companies that work with a wide range of materials and thicknesses, offering a comprehensive solution to meet diverse cutting

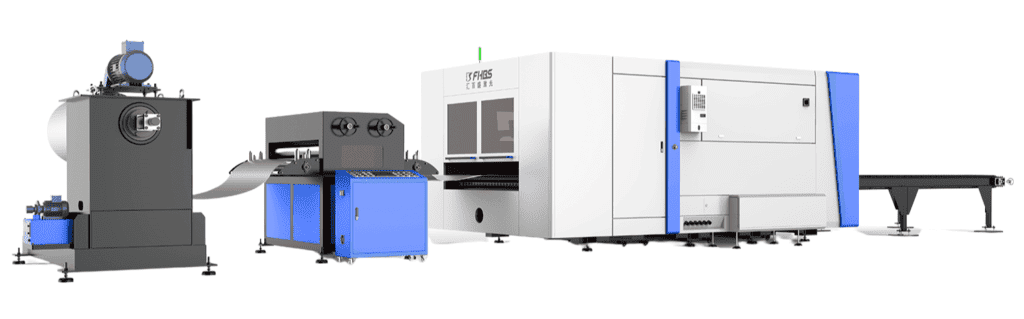

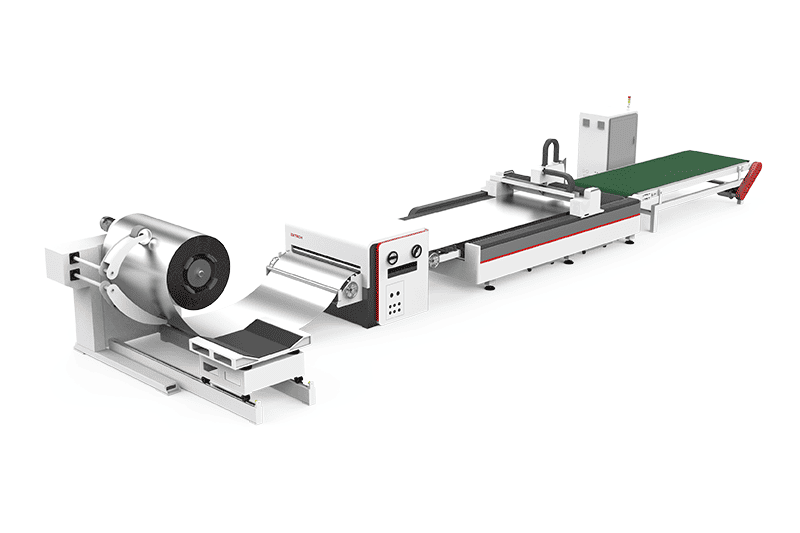

Laser Cutting machines

Laser-cutting machines are used to cut metal coils into specific shapes or sizes, it can operate at high speed and accuracy, making them suitable for a variety of metal processing applications.

Laser-cutting machines use focused light to cut through materials. They’re an ideal choice for businesses that need high precision in their operations, such as those involved in the production of delicate items or complex shapes. For instance, a manufacturer of intricate metal furniture can benefit from laser cutting machines due to their accuracy and the fine finish they provide.

Advantages of Metal Coil Laser Cutting Machines

It’s no secret that businesses need to keep their production processes as efficient as possible to stay competitive. For companies handling metal coil processing, the advent of laser cutting machines has been a game-changer. Let’s delve into some of the machine capabilities of steel coil laser cutting machines and how they can help address typical industry challenges:

Precision

Laser-cutting machines provide exceptional accuracy, even when dealing with complex or intricate designs. This precision ensures uniformity in production and reduces the risk of wasted materials.

Speed

These machines operate at high speed, reducing the time it takes to process metal coils. This feature can help to significantly boost your production rate.

Flexibility

The versatility of these machines allows them to handle a variety of materials and thicknesses, from steel coils to aluminum sheets. Such flexibility enables businesses to cater to different project requirements with the same equipment.

Clean Cuts

The laser cutting process produces clean, burr-free cuts. This reduces the need for further finishing processes and enhances the final product’s aesthetic appeal.

Minimal Contact

Laser cutting is a non-contact process, meaning it minimizes the wear and tear on machinery and the risk of material deformation. Thus it helps extend the machine’s lifespan.

Reduced Waste

Laser-cutting machines offer high precision, leading to fewer mistakes and less material waste. This benefit not only saves costs but also contributes to sustainability efforts.

The Importance of Choosing the Right Metal Coil Processing Machine

When it comes to metal coil processing, selecting the right machine is crucial. It’s also not just about the right coil processing equipment. Your decision can significantly impact your production efficiency, product quality, and overall operational cost. Several factors need consideration to make the right choice.

Material Type: Different machines are better suited for different materials. For instance, laser-cutting machines excel with materials like stainless steel coils and aluminum, while plasma-cutting machines are ideal for thicker, less sensitive materials.

Thickness: The thickness of the material you’re processing is another critical consideration. Thicker materials may require more robust machines, like plasma cutters. On the other hand, laser-cutting machines can deliver excellent precision for thin sheets.

Size: The size of the material can determine the type of machine you need. Larger coils might need machines with larger processing capabilities, affecting the size and power of the equipment you choose.

Production Volume: Your production volume is also important. For high-volume operations, a machine that prioritizes speed, like a laser cutter, can be more beneficial. With the right coil processing equipment you can do wonders for your steel coil business.

Tips for Successful Metal Coil Processing Machine Use

Here are some tips for successful metal coil processing machine use:

- Proper setup and calibration for optimal performance.

- Follow recommended operating parameters for different materials.

- Regular maintenance to prevent breakdowns and ensure accuracy.

- Thorough operator training for machine functions and increased safety.

- Implement quality control measures for consistent output.

- Stay updated on technology advancements for efficiency and actual process function.

- Maintain an organized workspace for a smooth workflow.

- Have spare parts and coil processing equipment on hand to minimize downtime.

- Collaborate with suppliers for troubleshooting and improvement.

- Continuously evaluate and optimize machine settings for productivity.

By following these tips, you can enhance machine performance and productivity in steel coil processing.

Conclusion

In summary, choosing the right metal coil processing machinery is vital for manufacturing businesses. Consider factors like size, thickness, and material type to ensure optimal performance. Proper machine use, maintenance, and training are essential for success. Explore our range of cutting machines to meet your sheet metal processing needs.

Ready to Take Your Metal Coil Processing to the Next Level?

Request an instant quote or schedule a free application evaluation with Baison Laser, your trusted partner in laser cutting solutions. Contact us today to explore how our cutting-edge technology can transform your coil processing solutions. Visit our website at https://baisonlaser.com for more information.