What is Laser Cleaning?

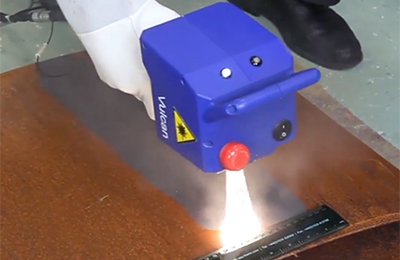

Laser cleaning is a manufacturing process that uses laser technology to remove contaminants or unwanted materials from the solid surface of an object. It is a non-contact method that involves directing a laser beam from the laser head onto the surface, which causes the contaminants to evaporate or sublimate, leaving behind a clean surface.

The focused laser beam used in this process is highly focused and intense, allowing it to efficiently remove dirt, rust, paint, grease, or other unwanted substances without damaging the underlying material. The laser energy interacts with the contaminants, causing them to absorb the laser light and heat up rapidly, leading to their removal.

This breakthrough technique using laser cleaners provides an alternative to traditional cleaning methods that often involve chemicals or abrasive materials. Laser technology offers a more efficient and precise way for laser treatment and laser ablation, revolutionizing the cleaning process. For more information about laser clean surface contaminants, you can click here.

Not only does laser cleaning ensure a spotless finish, but it also promotes safety by eliminating the need for harmful chemicals. With dry laser cleaning techniques, there’s no residue or waste left behind. It’s a game-changer in terms of efficiency and eco-friendliness.

Laser Cleaning Applications

Laser cleaning technology has a wide range of applications across various industries, including automotive, aerospace, electronics, cultural heritage restoration, and more.

- In the automotive industry, laser cleaning systems are used to remove paint from car bodies or clean engine components using dry laser cleaning technology.

- In the aerospace industry, laser cleaning systems are used to aid in the removal of oxidation layers from aircraft parts. These systems also help surface preparation for adhesive bonding through laser ablation.

- In cultural heritage restoration, the removal of particles from precious artifacts can be safely achieved using laser ablation techniques. This allows for thorough cleaning without causing damage or altering the original appearance of the artifacts. The laser ablation process is performed on the substrate of the artifacts, ensuring a precise and effective cleaning method. Here is the tests of laser cleaning on archeological metal artifacts.

How Does Laser Cleaning Work?

Laser cleaning is a process that utilizes high-energy laser beams to remove unwanted material from surfaces. Here’s a breakdown of how it works.

- High-energy lasers: The laser beam is directed toward the target surface, focusing its energy on the area to be cleaned. The process begins with the use of high-energy laser beams. These lasers emit concentrated light energy, which is crucial for effective cleaning.

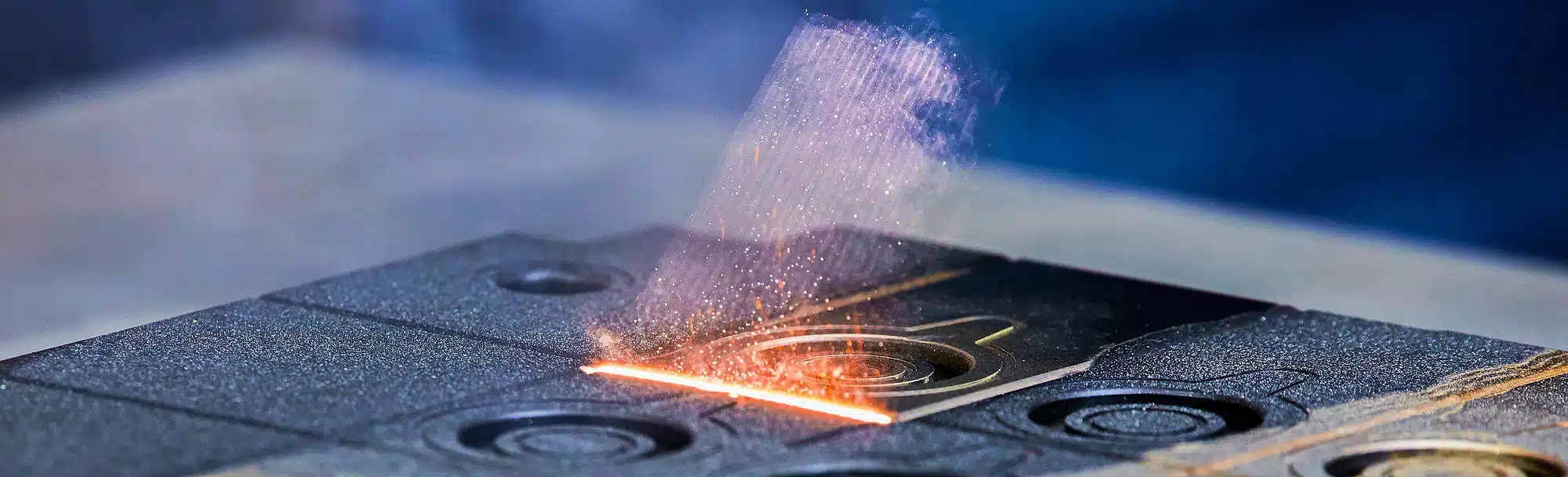

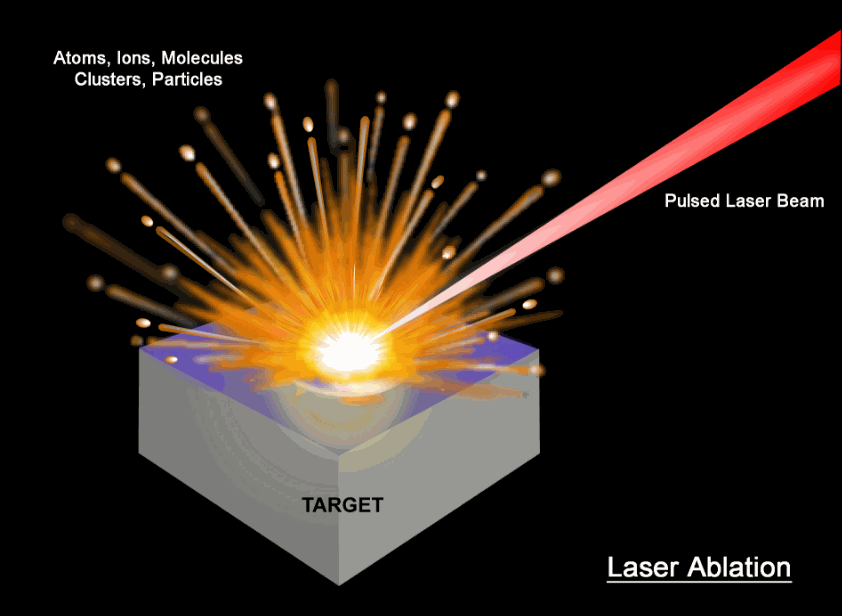

- Vaporization or ablation: Every material possesses a specific ablation threshold depending on its molecular bonds, and the threshold differs from other materials. As the laser hits the surface, its energy heats up and vaporizes or ablates the contaminants present. As the laser beam interacts with the surface, it vaporizes or ablates the unwanted material. This means that the intense heat generated by the laser causes the contaminants to either evaporate or disintegrate.

- Conversion of light energy into thermal energy: The conversion of light energy into thermal energy plays a significant role in laser cleaning. This conversion results in rapid heating and expansion of the contaminants on the surface.

- Rapid removal through shockwaves: This ablation process creates shockwaves. The sudden expansion and heating of the contaminants create shockwaves that rapidly remove them from the surface. These shockwaves act as a forceful push, effectively detaching and expelling the unwanted material.

- After laser processing,To prevent recontamination, a vacuum system or compressed air is used to collect and dispose of the debris generated during the cleaning process.

By following the laser processes, the laser cleaning system achieves thorough and precise removal of various types of contaminants, such as rust, paint, grease, or debris.

Before initiating the laser cleaning process, proper preparation is crucial. Surfaces must be thoroughly inspected and prepared to ensure optimal results. This may involve removing loose particles or applying protective coatings to sensitive areas.

Types of Laser Cleaning Systems

Laser cleaning systems come in various types, each designed for specific cleaning applications. Let’s take a closer look at the different options available.

Pulsed Lasers

Pulsed lasers are ideal for precise cleaning tasks that require high-energy bursts. These lasers deliver short pulses of pulsed laser beam, effectively removing contaminants from surfaces. Whether it’s removing rust from metal or erasing graffiti from walls, pulsed lasers offer exceptional accuracy.

Continuous Wave Lasers

For larger-scale cleaning projects, continuous wave lasers are the go-to choice. These laser systems provide a steady stream of low-power laser beams, making them suitable for tackling extensive surface areas. From industrial machinery to building exteriors, continuous wave lasers ensure efficient and thorough cleaning.

Fiber Lasers

Fiber lasers offer versatility and flexibility in laser cleaning systems. With their compact size and ability to deliver high power lasers, fiber lasers can be easily integrated into various setups. They excel at contaminant removal from delicate surfaces without causing damage. Whether it’s historical artifacts or intricate electronic components, fiber laser cleaners get the job done effectively.

Advantages and Disadvantages of Laser Cleaning

In order to understand laser cleaning technology more fully, we need to know its advantages and disadvantages.

Advantages of Laser Cleaning

Laser cleaning offers several advantages that make it a popular choice for various applications.

Firstly, it is a non-contact cleaning method, meaning there is no physical contact between the laser and the surface area being cleaned. This eliminates the risk of damage to delicate or sensitive substrates.

Another advantage is the precise control that laser cleaning provides. The beam diameter, intensity and focus of the incident laser beam can be adjusted to target specific areas, allowing for the selective removal of contaminants without affecting surrounding materials.

One significant benefit of laser cleaning is its environmentally friendly nature. Unlike traditional cleaning methods that often involve harsh chemicals, laser cleaning requires little to no chemical usage. This reduces the release of harmful substances into the environment and minimizes waste generation.

Laser cleaning can be particularly effective in removing stubborn contaminants such as rust or paint. It offers high levels of cleanliness and can achieve results that are difficult to attain with other techniques.

Disadvantages of Laser Cleaning

However, there are also some disadvantages associated with laser cleaning.

High initial cost: The initial cost of equipment can be relatively high compared to conventional cleaning methods. This may deter some businesses or individuals from adopting this technology.

Surface characteristics: Furthermore, laser cleaning may have limited effectiveness on certain materials like transparent or reflective surfaces. These materials tend to reflect or transmit a significant portion of the laser energy instead of absorbing it for efficient cleaning.

FAQs

Does laser cleaning produce any hazardous waste?

No! One of the major advantages of laser cleaning is that it produces minimal waste compared to traditional methods such as sandblasting or chemical solvents. The process involves vaporizing contaminants without generating harmful byproducts or residue. You can learn more about the differences in these two articles: Laser Cleaning vs. Sandblasting, Chemical Cleaning vs. Fiber Laser Cleaning.

Can laser cleaning remove rust from metal surfaces?

Absolutely! Laser cleaning is highly effective in laser rust removal from the metal surface without damaging the underlying material. The intense energy from the laser beam breaks down the rust particles into fine dust which can then be easily removed.

How long does it take to complete a laser cleaning process?

The duration of a laser cleaning process depends on various factors such as the size and complexity of the surface, the type and thickness of contaminants, and the power of the laser system. However, laser cleaning is generally faster than traditional methods, offering significant time savings.

Are there any maintenance requirements for laser cleaning systems?

Laser cleaning systems require minimal maintenance. Regular checks and cleanings of optical components are recommended to ensure optimal performance. It’s important to follow manufacturer guidelines for proper usage and storage of equipment.

Conclusion

Now that you have a solid understanding of the principle of laser cleaning, you’re ready to harness the power of this cutting-edge technology. It offers many advantages over traditional cleaning methods, whether you need to clean delicate artifacts, restore historical monuments, or prepare surfaces for painting or bonding, laser cleaning can deliver exceptional results.

Unleashing the Power of Laser Cleaning

So why wait? Currently, lasers are used in different material processing applications in the manufacturing sector. Take advantage of laser cleaner today and experience its numerous advantages.

With laser cleaning solutions, you can achieve precise and effective surface treatment while minimizing damage to the substrate. Baison Laser offers different models of fiber laser cleaning machines and other fiber laser machines like laser marking machines. Embrace Baison, embrace this innovative technique and unlock a world of possibilities for your cleaning needs.