What Does Fly Cutting Mean?

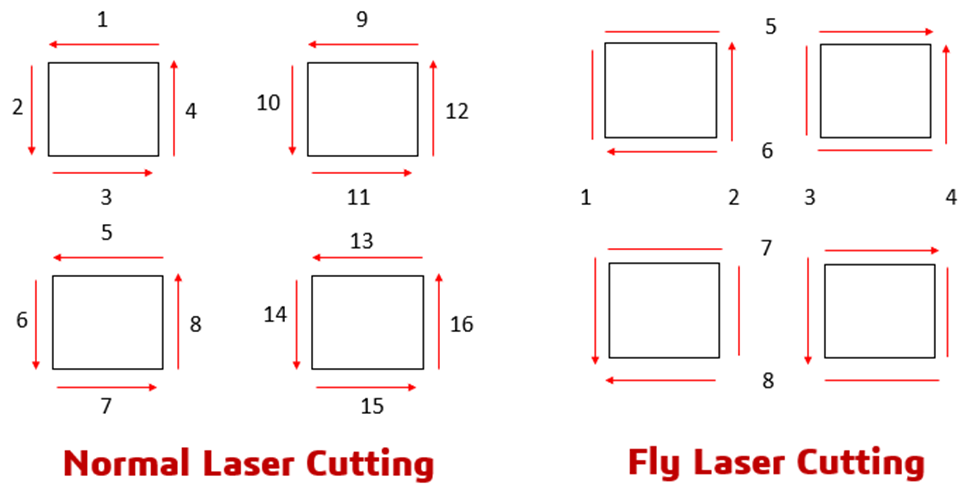

Fly cutting is an approach to laser cutting that exponentially increases the cutting speed while reducing the cutting time, machine wear, material wastage, and power consumption. This technique works best when a high volume of identical holes, shapes, and cuts are required.

It’s based on the path optimization technique, which instructs the laser head to move in grids of horizontal and vertical lines while simultaneously turning on and off at the respective edges, cutting multiple holes at a time. This also reduces laser activation time.

In changing directions, the laser head uses a tangential radius instead of sharp turns to reduce the cutting time and wear.

Originally cutting was done by laser heads moving along a single cut path and not moving to another task until the required shape was achieved. But with fly cutting, you can improve the efficiency of the task manifolds and yield higher profits in your business.

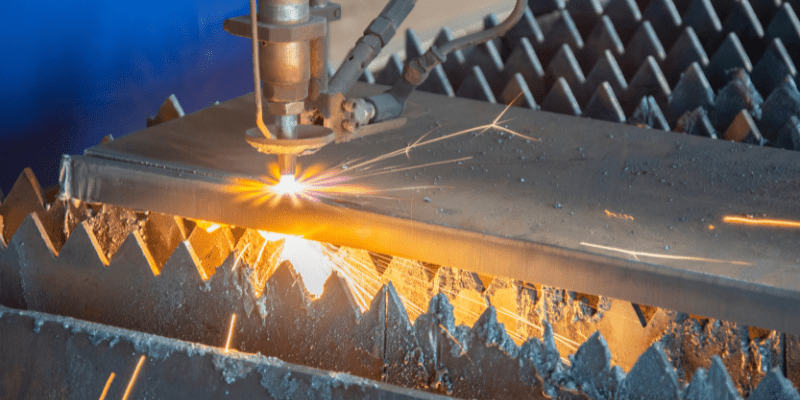

As you can see from the image below, the normal approach to cutting isn’t the most efficient way to achieve a task. This approach is estimated to reduce the cutting time by at least 50%.

Different Modes of Laser Cutting

Fiber laser machines are in a different league regarding high-performance cutting of material parts. By using complex algorithms, CAM programs can enhance the cutting process.

It’s all done by the software, so you don’t have to worry about manually configuring the setup. Here are some popular methods of laser cutting.

Common Cutting

Also known as common line cutting (CLC), it’s a type of approach where laser machines detect common and adjacent edges between multiple shapes. The laser head then starts the process and saves time by achieving multiple cuts.

Fly cutting mode

Fly cutting, also called grid cutting, is perhaps the fastest cutting approach where the laser head divides all the identical shapes into sets of horizontal and vertical lines. The laser turns ON at the cutting edge and turns OFF at empty spaces without moving upwards or changing directions. In short, the whole process is reduced to horizontal cuts and vertical cuts.

All this is done in a fraction of a second, so the cutting time is significantly reduced. This can only be achieved with high-power fiber laser technology and CNC machines. However, this method has some limitations, which are discussed later.

Common Pierce Point

As the name suggests, in this method, the laser beam pierces a single point in the material and starts the cutting process. After cutting the complete shape, the laser head arrives at the same pierced point and starts cutting the next shape from this point. That way, multiple cutting shapes have a single starting point. This allows deeper penetration without wasting energy on piercing every single time. With this, you can optimize the lead-in of the laser beam and reduce overall time.

Normal Cutting

Normal cutting is similar to traditional cutting, which means cutting one shape at a time. This method still holds value when machining complex shapes and thicker material is required.

Advantages of Fly Laser Cutting

Shorter Lead Time

Fly cut exponentially increases the cutting performance. Fly cutting doesn’t increase the cutting speed per se, as it depends on material type, thickness, assist gas, and other factors. But since the software analyses and finds the shortest possible cut paths, the actual speed of the process is increased.

Improved Efficiency

Fly-cutting reduces the lead time and increases overall efficiency. Also, less power is consumed by restricting movements to vertical, horizontal, and diagonal directions.

The rapid switching on and off the machine also introduces some empty movement in the cutting process, but it doesn’t interfere with the cutting performance.

Furthermore, this mode allows the laser head to change directions using arches and segments, which improves the productivity of the process.

Less Slug

Another major benefit of fly cutting is that less slug is generated, leading to lower material wastage. Less slug also means a reduction in kerf at cutting edges. It’s all due to the optimized movement of the laser head.

Longer Machine Life

Since the precisely positioned movement of the laser head is way simpler, there is less wearing of mechanical parts. This lead to lower maintenance and operational cost for the machine. Laser machines are already a big investment on your part; that’s why savings on maintenance will lead to greater benefits for your business.

Greater Profits

Fly-cutting requires very complex logic, and it’s possible that the machine you purchase might not come with a program that can handle such a feature.

These programs are expensive, and many companies tend to avoid purchasing them. That’s a big mistake. Let’s say your annual business revenue is $1 million, and fly-cutting yields only 4% savings which is still a $40k annual profit for your business.

Limitations of Fly Laser Cutting

Fly cutting is an exceptional feature in modern fiber laser cutting machines, but like all good things, this method also has some limitations. Knowing them will help you make better business decisions.

Material Thickness and Type

The whole approach of fly cutting revolves around the concept that one must achieve maximum cuts in one direction. But this reduces the piercing time needed by laser to achieve a clean cut.

Reflective materials like stainless steel and aluminum resist laser absorption, making fly cutting difficult. Similarly, a material with a thickness of more than 1.5 mm is unsuitable for fly cutting.

If settings are not configured properly, fly cutting will result in poor cutting edges. To counter this, always use fly cutting on thinner materials, usually 1 mm or less. Moreover, reduce the cutting speed so the laser has more time to penetrate.

Complex Shapes

The flying cut works best for simpler shapes with sharp edges. This usually includes rectangular holes that are present in the grid. It’s difficult to divide complex shapes into sets of horizontal and vertical cut lines, so it’s not feasible.

Fly laser cutting of complex shapes also cause heat to accumulate at certain edges and affects the material integrity. For complex shapes, it’s best to use other cutting modes for better results.

Risk of Collision

Sometimes improper cutting speed, poor path optimization, and low-pressure flow of assist gas can cause the slug to collide with the laser head. This has serious repercussions. Fly cutting has a serious risk of such collisions. To prevent damage, CAM programs must be capable of performing intelligent path optimization.

Softwares Used for Fly Laser Cutting

Fly cutting requires complex logic and algorithm, which can be done with high-performance numeric control software. Here are some popular programs available in the market.

Cypcut

Cypcut is all one CAD/CAM software for CNC machines. It can be used to optimize drawings and configure cutting settings. It has a built-in feature for correcting the “dual drive position” error, which increases the precision of the process.

Jet CAM

Jet CAM is another option for high-quality laser cutting. It can produce extremely complex G-codes without any error. JetCAM is user-friendly and enables the operator to efficiently generate nesting programs.

Cut Assist v2.0

Cut Assist is an application launched by ANCA Motion. It’s a highly interactive and easy-to-use interface for the machine operator. It can optimize the fly-cutting procedure by configuring laser width, cutting speed, and switching frequency.

Conclusion

Fiber lasers have distinctive characteristics that yield great results when combined with high-level computation programming. An example of this is “Fly Cutting.”

You can use this option to reduce the lead time and save resources. Be mindful of the limitations discussed above, as they can cause inconvenience. However, fly cutting can be very profitable for any industry with the right implementation.

Baison Laser Provides Best Laser Cutting Solutions in the Industry

Fiber laser machines deliver higher performances and intricate designs in shorter lead times. If you want your business to enjoy similar benefits, we can help you. At Baison Laser, we make premium-quality laser machines for numerous manufacturing industries. These machines are made under the supervision of leading experts in high-tech plants.

Our prices are market competitive, and we provide exceptional after-sales to our esteemed customers. Furthermore, Baison Laser machines are durable and give error-free performances.

Our 24/7 customer service is always there to help if you need assistance. You can also customize the product according to your requirements. So, what are you waiting for? Contact us for a free quote now.