Are you tired of spending hours trying to remove stubborn rust, old paint, or grease from your surfaces? We get it—it’s frustrating!

Traditional methods like chemical cleaning, sandblasting, or scraping are messy, time-consuming, and often damage the base material. Plus, the results are not always long-lasting.

Luckily, there’s a smarter solution. Laser cleaning machines are changing the way industries clean surfaces, offering a faster, safer, and eco-friendly alternative.

But with so many options available, choosing the right machine can feel overwhelming. Don’t worry—we’ve got you covered!

In this guide, we’ll walk you through simple and practical tips to help you pick the perfect laser cleaning machine for your needs, saving you time, money, and a lot of stress.

Before we dive into the tips, let’s discover how laser cleaning machines work and what makes this technology so effective.

Understand What Laser Cleaning Machines Do

Before choosing a laser cleaner, it’s important to understand how these machines work. Laser cleaning uses focused light energy to remove surface contaminants without physically touching or damaging the underlying material.

A handheld laser cleaning device that incorporates pulsed laser technology offers ergonomic design, precision, and versatility, making it suitable for delicate cleaning tasks across different industries.

Unlike chemical cleaning or abrasive blasting, lasers work by breaking down rust, paint, grease, dirt, or oxides at the molecular level.

The major advantages of laser cleaning include:

- Non-contact cleaning: Prevents scratches, dents, or structural damage.

- Eco-friendly: No chemicals or sand, producing less waste.

- Precision: Ideal for delicate parts or complex geometries.

- Versatile: Works on metals, plastics, stone, concrete, and electronic components, and can remove dirt as well as other contaminants like rust, paint, and oxides.

Understanding the capabilities of a laser cleaner will help you choose a machine that fits your specific application.

Identify Your Cleaning Requirements

Not all laser cleaning machines are designed for the same type of work. The first step in choosing the right system is to identify your cleaning requirements. Selecting the right laser cleaning machine is crucial for your business to ensure optimal performance and return on investment.

Consider the following factors:

1. Material Type

Different materials react differently to laser light. Metals like steel, aluminum, and copper are common, but some machines also handle plastics, ceramics, and delicate electronic parts. Ensure the machine you choose is suitable for the materials you work with.

2. Surface Contaminants

Determine what you want to remove: rust, paint, grease, oxide layers, or coatings. Some machines are better suited for thin layers, while others can handle thick coatings.

3. Surface Area

Consider the size of the parts or surfaces you will clean. Handheld machines are ideal for small or localized areas, and laser cleaning is especially effective for targeting contaminants in a small area, such as tiny spots or delicate parts. Robotic or automated systems are better for large-scale production or continuous operation.

4. Precision Needs

High-precision work, like aerospace turbine blade cleaning or electronics maintenance, requires lasers with adjustable power, pulse duration, and wavelength. Less critical tasks, like removing rust from automotive parts, may require lower-spec systems.

Decide Between Pulsed and Continuous Lasers

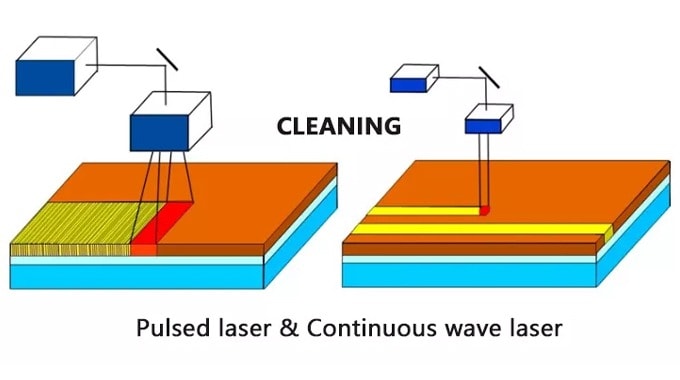

Laser cleaning machines are generally classified into two types: pulsed lasers and continuous lasers.

- Pulsed Lasers: These emit high-energy bursts in very short pulses. Pulsed lasers are ideal for delicate surfaces, small parts, and precise cleaning tasks. They minimize heat damage and prevent over-cleaning.

- Continuous Lasers: Continuous lasers emit a steady beam of light and are suited for larger surfaces or thicker contaminants. High-power systems are especially suited for large-scale industrial cleaning tasks. They can cover broad areas faster but require careful parameter control to avoid substrate damage.

Some cleaning machines use fiber lasers, which offer high efficiency, long lifespan, and are particularly suitable for precision and industrial cleaning applications.

Selecting the right type depends on your application, material, and precision requirements.

Consider the Power Level

The power of a laser cleaner determines how effectively it removes contaminants. Laser power directly impacts cleaning speed and effectiveness. Higher power machines are capable of handling thick coatings, heavy rust, thick rust, or large industrial surfaces, while low-power machines are sufficient for light cleaning tasks.

Tips to select the right power level:

- Start with a machine that matches your most common cleaning tasks.

- Avoid overpowered lasers for delicate surfaces to prevent damage.

- If your cleaning needs may increase in the future, consider investing in a slightly more powerful system for flexibility.

Evaluate Portability and Form Factor

Laser cleaning machines come in handheld, fixed, or robotic formats, each suited to different workflows:

- Handheld Machines: Lightweight and easy to move. Some models are designed to be carried as a backpack or handheld device, making them ideal for use in diverse environments, spot cleaning, small workshops, or maintenance tasks.

- Fixed Systems: Mounted on a workbench or production line. Good for repetitive cleaning of medium-sized parts.

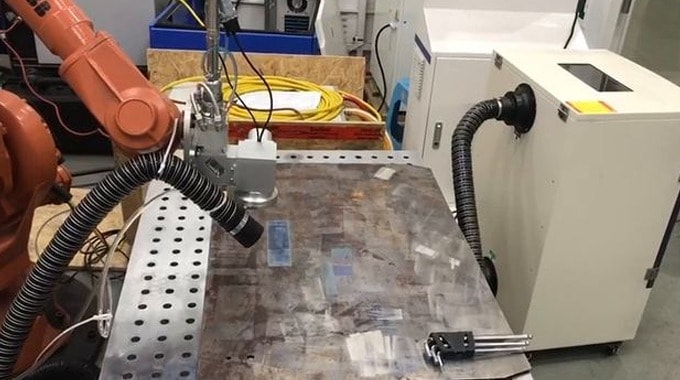

- Robotic/Automated Systems: Integrated with production lines for high-volume or large-surface cleaning. Provide consistent results with minimal human intervention.

Choose a machine that fits your workspace, workflow, and production scale.

Check User-Friendliness

Even advanced laser cleaning machines should be easy to operate. A good machine will have:

- Simple control panels or touchscreen interfaces.

- Pre-programmed settings for different materials or contaminants.

- Clear safety interlocks and alarms.

- Options to store cleaning parameters for repeatable results.

A user-friendly machine reduces errors, training time, and downtime, improving overall efficiency. A short learning curve allows operators to become proficient quickly with minimal training.

Look at Safety Features

Laser cleaning involves high-intensity light, which can be dangerous without proper precautions. Ensure your machine has:

- Laser-rated protective interlocks.

- Safety goggles or shields for operators.

- Automatic shutdown if doors or panels are opened during operation.

- Fume extraction or filtration systems for dust and vapor removal.

Prioritizing safety will protect your staff and comply with occupational health regulations.

Consider Fume Extraction and Ventilation

Laser cleaning produces dust, smoke, and vapors that must be safely removed. Machines with built-in fume extraction systems are highly recommended.

Some coatings, especially paints with lead or plastics, require specialized filtration. Proper ventilation improves operator safety and ensures a clean working environment.

Evaluate Maintenance and Service

A laser cleaning machine is a long-term investment. Consider:

- Ease of maintenance: Can the optics, lenses, and nozzles be easily cleaned or replaced?

- Durability: Look for machines made with high-quality components.

- Supplier support: Ensure your provider offers technical support, warranty, and spare parts.

- Installation: Proper installation should include setup, operator training, and ensuring correct use of the system to maximize efficiency and reliability.

- Training: Availability of operator training for safe and efficient use.

Choosing a reliable machine with good support will reduce downtime and operating costs.

Assess Budget and Total Cost of Ownership

While laser cleaning machines are more expensive upfront than traditional cleaning tools, they save money in the long run. Consider:

- Initial equipment cost.

- Energy consumption.

- Consumables (if any).

- Maintenance and parts replacement.

- Labor and training costs saved.

A slightly higher initial investment can pay off through higher efficiency, lower waste, and reduced chemical or abrasive use.

Test Before You Buy

Before committing to a machine, it’s highly recommended to test it on sample parts:

- Check cleaning speed and efficiency.

- Assess surface impact and quality.

- Determine the optimal power, pulse, and scanning settings.

- Verify fume extraction and safety systems work effectively.

Pilot testing ensures the machine meets your specific requirements and prevents costly mistakes.

Compare Brands and Models

Not all laser cleaning machines are equal. Compare:

- Wavelength, pulse duration, and power.

- Portability and ergonomics.

- Safety features and fume extraction.

- User reviews and case studies from similar industries.

- After-sales support and warranty.

- Whether the machine is equipped with advanced features that enhance performance and automation.

- If the system allows for easy integration with existing automation or production lines.

Choosing a trusted brand ensures long-term reliability and access to technical assistance.

Industry Standards and Reputation

Buying a laser cleaning machine requires good thinking about rules and company names. Good laser cleaning machines must follow clear rules like ISO 9001 for good quality work.

They must also follow ISO 14001 rules for keeping the Earth clean and safe. These rules show the company wants to make good cleaning machines. The machines must work well and be safe for everyone who uses them.

Before buying the machine, check the company’s good name and history first. Look for what other buyers say about their laser cleaning machines.

Read stories from real customers who used these cleaning machines before. Find companies that make good machines for many years. Good companies give help when customers need it and make new, better machines often.

Applications of Laser Cleaning

Laser cleaning works in many ways across different types of work. In metal work, laser cleaning takes rust off fast and strips paint well. It gets metal surfaces ready for more work or putting parts together.

The car industry and plane makers use laser cleaning to clean parts with care. It removes old coatings and gets surfaces ready for glue or new paint.

Mold cleaning is another job where laser cleaning works great. It takes off mold release stuff and dirt from molds without hurting the base material. This helps a lot in work areas that need perfect finishes and less waiting time.

In making electronics, laser cleaning gives the exact cleaning needed for small parts without breaking them. Fixing old items gets help from the gentle cleaning action that keeps the original surfaces and small details safe.

Whether dealing with metals, plastics, mixed materials, or sensitive electronics, laser cleaning gives an advanced way to remove many types of dirt.

This includes rust, paint, oil, and coatings from different materials and surfaces. It works fast, cleans with care, and can work with many things. This makes it a key tool for modern work areas that want good quality and nature-friendly cleaning methods.

Eco-Friendly Considerations

Laser cleaning machines have great benefits for cleaning surfaces in a clean way. These machines do not use bad chemicals or rough materials like old methods do.

Laser cleaning uses laser beams to take off dirt and bad stuff. This cuts down the need for dangerous stuff and makes less waste. Companies get clean results without using harsh things that hurt nature.

Laser cleaning machines are made to clean well and save power at the same time. Many machines have new tech that uses less power but still cleans really good.

The machines work hard but use less energy to do their job. This helps companies spend less money on running costs each month. The machines also do less harm to nature while they clean surfaces.

Companies can stop chemical waste when they choose laser cleaning machines instead of the old ways. These machines reduce dust in the air and avoid the problems that come with old cleaning stuff.

The soft cleaning action of laser beams takes off only the bad dirt from surfaces. The good parts of the materials stay safe and strong during cleaning. This makes even less waste for companies to deal with later.

Tips for Process Optimization

To maximize efficiency and safety:

- Start with lower power and gradually increase.

- Use short test passes to avoid overheating.

- Maintain a consistent distance and angle.

- Rotate irregular parts for even cleaning.

- Keep optics and lenses clean for consistent performance.

- Record successful settings for future repeatability.

Optimizing your process saves time and extends machine life.

Advantages of Choosing the Right Laser Cleaner

- Faster cleaning compared to manual methods for complex parts.

- Minimal damage to the substrate.

- Reduced environmental impact—no chemicals or abrasives.

- Consistent and repeatable results.

- Improved safety for operators.

- Lower long-term operational costs.

Limitations to Keep in Mind

- High initial investment.

- Requires trained operators.

- Slower on very large surfaces unless automated.

- Fume extraction and ventilation are mandatory.

- Thick, multi-layer coatings may need multiple passes or pre-treatment.

Conclusion

Choosing the right laser cleaning machine is key to achieving efficient, safe, and precise cleaning.

By considering factors like material type, contaminants, laser type, power, portability, and safety, you can find a machine that fits your needs perfectly. Proper training, pilot testing, and supplier support ensure smooth operation and long-lasting results.

The right laser cleaner saves time, reduces waste, protects surfaces, and boosts productivity across automotive, aerospace, industrial, and heritage applications. Invest wisely, follow the tips, and experience faster, eco-friendly, and high-quality cleaning every time.

Boost Your Cleaning Efficiency with Baison

At Baison, we offer a wide range of laser cleaning machines that are reliable, precise, and easy to use.

Whether you need to remove rust, paint, or surface contaminants, our machines make the job fast, safe, and eco-friendly.

From handheld systems for small tasks to automated solutions for large-scale production, we have the perfect machine for your needs.

Our experienced team will guide you in choosing the right laser cleaner and setting it up for optimal performance.

Contact us today and upgrade your cleaning process with Baison Laser and enjoy consistent, high-quality results every time.