Stainless steel may be as tough as nails, but you can cut it like butter with the right moves. Wracking your brain on how to cut stainless steel for your next DIY project? Fear not, dear reader, for we have got you covered!

In this article, we’ll show you 5 different ways to cut stainless steel that will make your jaw drop and your sparks fly. From traditional sawing to futuristic lasers, we’ve scoured the metalworking world to bring you the most effective and mind-blowing techniques. So get ready to slice, dice, and chop your way to stainless steel glory!

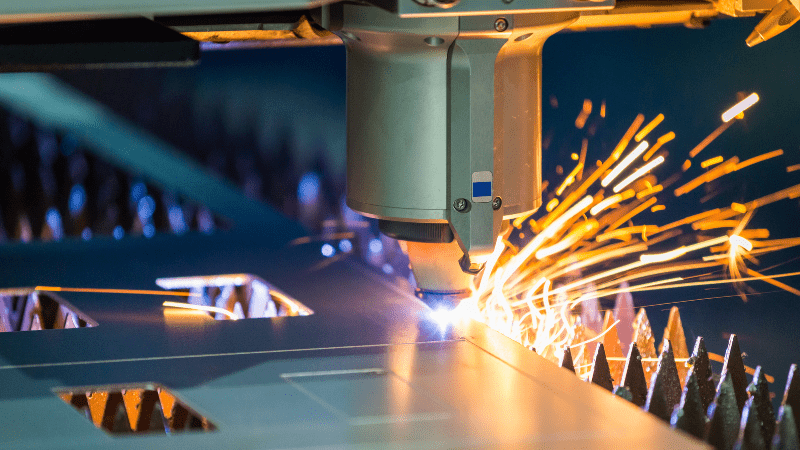

Method 1 — Laser Cutters

Due to laser cutter’s precision in cutting a variety of materials including stainless steel, they have become increasingly popular over the years. Their ability to make intricate designs and complex cuts has made them an essential tool for both professionals and DIY enthusiasts.

Laser cutters use a high-powered laser beam to melt and vaporize the stainless steel. The laser beam is directed on the surface of the metal and creates a narrow, concentrated beam of heat. This melts and evaporates the metal.

The tool is controlled by a computer program that guides the laser along the given path. As a result, you cut a clean, precise cut that needs little to no finishing!

Mastering the Art: How to Use Laser Cutters

Here’s how to use a laser cutter to cut stainless like a breeze.

- Thoroughly clean the material so that there are no debris or contaminants to affect the quality of the cut.

- Set up the laser cutter. You will have to adjust the laser beam power, the focal length of the lens, and the cutting speed. These settings will differ based on the thickness of the material and the type of cutter you are using.

- Place the material on the bed of the laser cutter. Clamp the sheet securely in place to keep it from moving.

- Start the cutting process. The cutter will follow the path that has been programmed into the computer.

- Check the cut to ensure it fulfills your requirements. You can use a deburring tool if there are any burrs or rough edges.

- Voila! Your work is done!

Things to Keep In Mind

There are several things you need to keep in mind while buying a laser cut. Look for a laser cutter with a high power output to ensure it can handle cutting through stainless steel. The cutting speed is another factor since a faster cutting speed will increase your productivity and save you time.

Ensure that the tool has a cutting capacity that meets your needs, depending on the thickness of the stainless steel you will be cutting.

| Sr. | Pros | Cons |

| 1. | High Precision and Accuracy | Expensive |

| 2. | Minimal Finishing Work | Require replacement |

| 3. | Customizable Cuts | Large and heavy |

| 4. | Reduced Material Waste | Require a lot of consumables such as electrodes and nozzles |

| 5. | High Speed | Noisy |

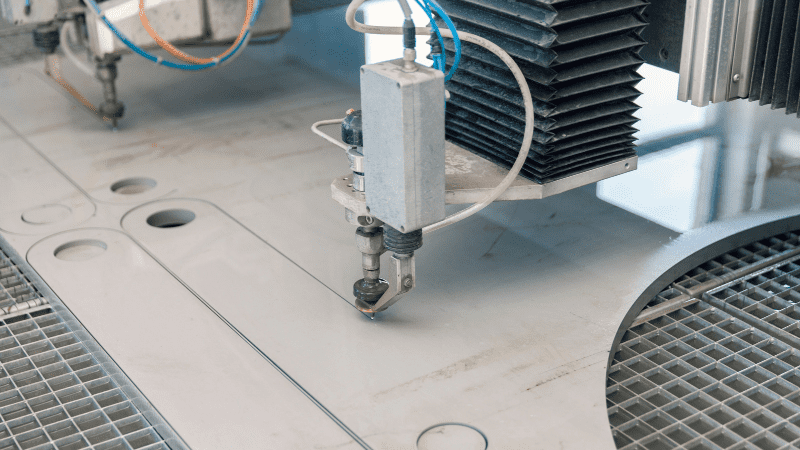

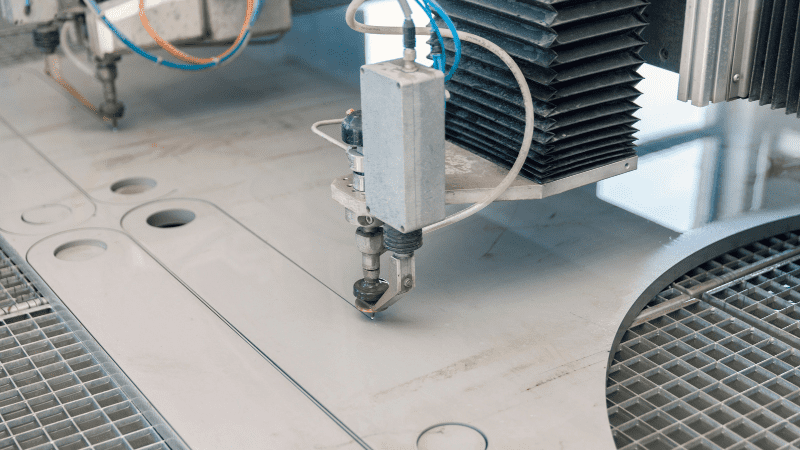

Method 2 — Water Jet Cutters

Another versatile and effective tool for cutting stainless steel is the waterjet cutter. This tool uses a high-pressure stream of water mixed with abrasive particles. The water is pressurized to around 60,00 PSI and is forced through a small nozzle. To know the difference between water jet and laser cutters, you can see the article “Laser Cutting vs. Water Jet: Which One to Choose?“.

This creates a fine stream of water that easily cuts through various materials, including stainless steel.

Mastering the Art: How to Use Water Jet Cutters

Here’s how to use water jet cutters to cut through stainless effortlessly.

- Clean the stainless steel and remove any dust particles.

- Set up the water jet cutter. You will have to adjust the water pressure, the abrasive flow rate, and the nozzle position. Check the technical manual to make the right adjustments.

- After setting everything up, start the cutting process. Move the nozzle in a slow, steady motion over the stainless steel and follow the desired path.

- Remove any excess abrasive particles or debris from the surface once you are done.

Things to Keep in Mind

The size of the nozzle as well as the abrasive you use, depends on the thickness and hardness of the stainless steel that you want to cut. Consult the technical specs and select the correct nozzle and abrasive.

The water jet cutter you choose should have enough power and pressure to cut through the hardness and thickness of the material you will be cutting. Make sure that you are wearing protective equipment while you are working.

| Sr. | Pros | Cons |

| 1. | Reduces risk of warping or distortion | Noisy and Messy |

| 2. | Easy to use | Needs proper ventilation and cleanup procedures |

| 3. | Minimal material waste | Needs a lot of water |

| 4. | No risk of tool wear | High operating costs |

| 5. | High Speed | Limited thickness capability |

Method 3 — Angle Grinder

An angle grinder is a powerful, versatile tool that you can use for cutting and grinding stainless steel. It uses a rotating abrasive disc to remove material from the metallic surface, creating a groove or a cut. They come in various sizes and power ratings, so you can choose the one that is the right fit for your little project!

Mastering the Art: How to Use an Angle Grinder

Here’s how you can use an angle grinder to cut stainless steel.

- Position the cutting disc at the starting point of the cut.

- Turn the grinder on.

- Move the disc along the metal surface slowly and steadily.

- Apply even pressure to create a straight and clean cut.

- Don’t apply a lot of pressure as it will cause the metal or disc to deform.

Things to Keep in Mind

Angle grinders are affordable and widely available. This makes them a popular choice for DIY stainless steel projects. However, they can produce a lot of noise and dust. Moreover, they require proper handling as well.

Ensure the cutting disc on your angle grinder is compatible with stainless steel and correctly installed on the grinder. Before you start working, it is pertinent that you wear proper protective gear — such as safety glasses, gloves, and a face shield.

| Sr. | Pros | Cons |

| 1. | Large cutting depth | High-frequency rotation of the grinder causes sparks |

| 2. | Precise | Generate a lot of heat |

| 3. | Accessible in tight spaces | Dust and Debris |

| 4. | Can be used with a variety of blades and accessories | Limited flexibility |

| 5. | Highly maneuvrable | Require some expertise for proper use |

Method 4 — Circular Saws

Circular saws are usually used to cut wood but also work perfectly well for stainless steel and other metals. This tool has a circular blade with teeth that is rotated at high speeds to cut through metal.

Similar to angle grinders, circular saws also come in different sizes and have varying specs so make sure you choose the one that fits your needs.

Mastering the Art: How to Use Circular Saws

Follow these simple steps to cut through stainless steel using a circular grinder.

- Prepare the material.

- Clamp the stainless steel to a work surface securely to keep it from moving as you cut it.

- Use a rule or straight edge to mark a cutting line on the steel.

- Set the blade depth on the saw so that it is just deep enough to cut through the metal. This will keep the saw from getting stuck during the cutting process.

- Turn the circular on and allow it to reach full speed. Slowly guide the saw along the cutting line and let the blade do the work!

Things to Keep in Mind

The size and type of blade of the circular saw you select will depend on the thickness and size of the material you want to cut. Give the teeth per inch value a look as well while selecting the tool, as it will affect the quality of the cut.

A lower TPI will give you a faster but rougher cut while a higher TPI will give you a smooth cut but in a longer time. Lubricating your tool and adjusting the speed of the saw to suit the thickness of the steel will extend the life of your blade.

| Sr. | Pros | Cons |

| 1. | Fast and Efficient | Frequent blade changes as the blade become dull over time |

| 2. | Versatile — Can cut through a variety of materials | Produces a lot of noise and vibrations |

| 3. | Accurate | Safety hazard if not used properly |

| 4. | Lightweight and portable | Limitations on cutting depth |

| 5. | Cost Effective | Difficulty with intricate cuts |

Method 5 — Plasma Cutter

A plasma cutter is a tool that you use to cut metal using ionized gas or plasma. The plasma melts the metal, allowing the cutter to make a clean and precise cut. These cutters are really good for cutting stainless steel because they can generate high temperatures that can easily melt the metal. Laser and plasma cutting are used in a wide range of industrial settings.

When you are working with stainless steel, it is essential to cut it without distorting or warping the metal, which is an issue with traditional cutters. Plasma cutters are perfect in this case and are useful for applications that require high precision and accuracy.

Mastering the Art: How to Use Plasma Cutters

Here’s how to use a plasma cutter to quickly and efficiently cut stainless steel.

- Make sure that the work area is clean. No flammable materials should be around that can ignite due to the sparks generated while cutting the steel.

- Follow the manufacturer’s instructions to set up the plasma cutter, such as connecting the air compressor, grounding the cutter, etc.

- Adjust the amperage according to the thickness of the stainless steel. You will need high amperage levels for cutting thick sheets and vice versa.

- Use a marker or chalk to mark the cutting line.

- Position the plasma cutter at the start of the cutting line, keeping the nozzle perpendicular to the metal.

- Press the trigger on the tool to start the cutting process. Maintain a consistent distance between the material and the nozzle while cutting.

- Once the cutting process is complete, turn the device off and allow it to cool before you store it.

Things to Keep in Mind

It is important to select the correct nozzle according to the thickness of the steel that you are cutting. A large nozzle will cause excessive heating and warping. On the other hand, a small nozzle will result in slow cutting speeds and reduce precision.

You also need to keep an eye on the power output of the plasma cutter. For stainless steel, you need a cutter with high amperage output so that it can easily melt through the material. Look for a tool with an output of at least 40 amps.

Another thing you should look at is the duty cycle of the cutter. It is how long the cutter can operate continuously before you have to cool it down. Select a plasma cutter with a high-duty cycle.

| Sr. | Pros | Cons |

| 1. | High Speed | High initial cost |

| 2. | Minimal Heat-Affected Zone | Require regular maintenance |

| 3. | Smooth Edges | Large and heavy |

| 4. | No need for pre-drilling | Require a lot of consumables such as electrodes and nozzles |

| 5. | Versatile | Noisy |

Finding the Perfect Fit: Tips and Tricks for Selecting the Optimal Way to Cut Stainless Steel

Now that you are well-versed in different options and ways to cut stainless steel, comes the million-dollar question: how to you select the right one for you? With so many options available, it can seem a daunting task. However, it is very straightforward and simple if you keep the following things in mind.

Consider the Thickness of Stainless Steel

Keep the thickness of the material while choosing the right method for you. Different cutting options are suitable for different thicknesses. For instance, plasma cutting would be the right choice if you are cutting thicker stainless steel. On the other hand, laser cutters work miracles with thinner sheets.

Complexity of Design

Another thing to consider is the complexity of the design. If you need to create intricate designs and cut complex shapes, then laser cutting is the way forward, as it creates precise cuts with minimal distortion.

Quality of Finished Product

Some cutting methods produce a rougher finish, while others give you a smooth finish. For example, an angle grinder will never give you the finish that a plasma or laser cutter can.

After weighing the pros and cons of each option, laser cutting seems to be the optimum option due to various reasons. Laser cutters are highly precise and ideal for intricate designs. With these cutters, you get clean, smooth edges with no burrs or roughness.

The finished product will have a high-quality, professional appearance. Laser cutters are not only great at cutting steel but are versatile and can cut through a variety of materials. You can produce a large volume of cuts quickly and with minimal waste.

Laser cutters are a great choice for a wide range of applications — from industrial manufacturing to DIY hobby projects.

Final Word

Cutting through stainless steel seems like a daunting task. However, with the right tools and guidance at hand, this task becomes a breeze. Whether you go for plasma cutting, water jet cutting, or laser cutting, each method has unique advantages and limitations. Keep each method and its benefits in your mind and compare it with your requirements — this will help you make an informed decision.

Hopefully, the above-mentioned 5 methods to cut stainless steel will inspire you and be of ample help to you.

Unlock the Secret to Perfect Stainless Steel Cuts: Book Your Free Consultation Now!

If you’re still unsure which cutting method is best for your project, why not take advantage of a free consultation or demo? We have a team of experts who can guide you through the process and help you make an informed decision.

Don’t miss out on this opportunity to get personalized advice and recommendations tailored to your specific needs! Contact us now to schedule your consultation or demo and take the first step toward a successful project.