Laser Marking: Let the Magic Begin

Before saying anything about these important factors, let us lay the ground for understanding the basics of laser beam marking.

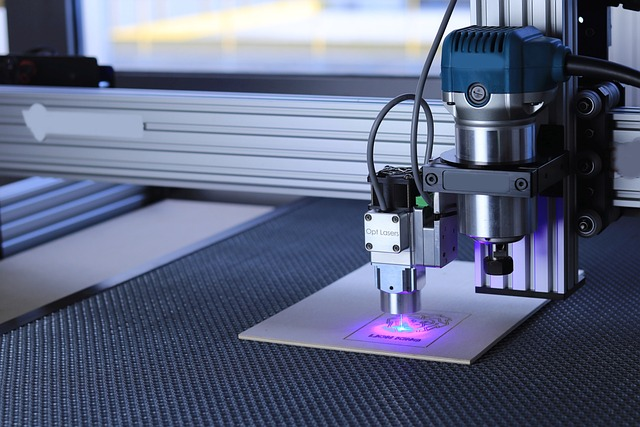

The working principle behind its incredible accuracy is its ability to focus the energy beam on tiny, pinpoint spots, allowing it to create beautiful designs, symbols, text, etc.

It is basically a focused beam of light that can be written or engraved on various materials, from metal and plastic to ceramics and glass, like a permanent pen.

The excellent preciseness of fiber laser marking makes it a game changer across various industries, including automotive and appliance manufacturing.

Unlike other traditional marking methods, it is enduring, resistant to fading, and protective against environmental factors like moisture and heat.

Laser Power: Force Behind Marking Brilliance

Now, let’s divert our attention to one of the main factors and essential ingredients behind marking brilliance: Laser Power.

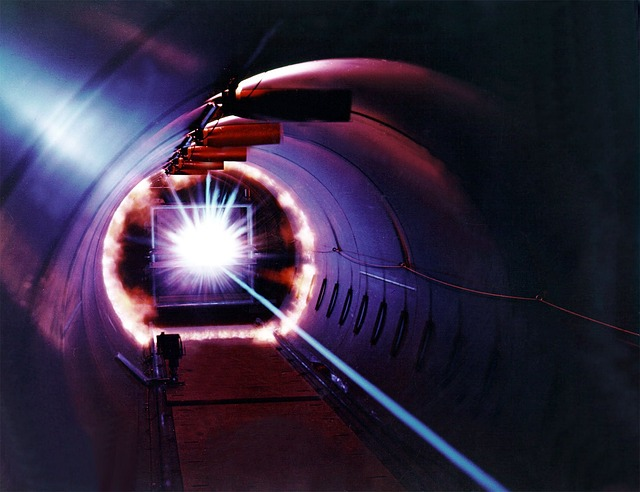

It is the laser engraving source energy that decides and derives the strength or intensity of the laser beam, just like adjusting the heat on the stove.

Higher laser power will create faster and more intense marks in materials, while lower laser power will offer and engrave precise and delicate patterns.

It works like a control knob whose power is adjustable to decide the intensity of the laser beam travels and ensures your mark is right, whether etching a pleasing design on plastic or engraving a deep mark on metal.

Pulse Duration: Reason Behind Perfect Laser Marks

Continuing our journey through the world of laser marking, the second important factor we will encounter is Pulse duration.

It is also called “pulse width,” which decides how long the laser energy interacts with the material surface. It is like the rhythm of the laser beam in which each pulse shapes the mark character.

In simpler words, the length of time a laser beam is applied to a specific point on a material surface during marking is called pulse duration.

Moreover, it impacts the laser welding and laser cutting process and gets measured in seconds or a fraction of seconds using different instruments, such as Autocorrelators or streak cameras.

So, understanding this aspect will allow us to open the gate of endless possibilities to select the best and most suitable pulse beam rhythms that best suit our material and design.

How do Laser Power And Pulse Duration Dance Together?

Now, it’s time to explore and understand how laser power and pulse interact together to offer excellent laser marking across different materials.

You can imagine the laser power of the marking machine as the strength of a spell that determines how powerful it will be during engraving on the material. On the other hand, pulse duration is the speed at which the spell is being cast.

We can use them together in a symphony that suits and applies to a wide range of materials. For example, you can use high power with a short pulse duration to have deep and swift markings on metal and lower power with a longer laser pulse duration to do delicate work on ceramics. (You may be interested in calculating the energy of laser pulses.)

Marking Magic on Different Material

After understanding the harmony between the dynamic duo of power laser and pulse duration, it’s time to buckle up and see how both adapt together to work on different materials.

You might have an idea that metals require powerful laser beam with short durations to have bold and deep marks, while on the other hand, material like ceramics and glass needs gentler touches for delicate marks.

Let’s do an in-depth analysis of how these essential factors play a role in transforming different materials into a work of art.

1. Metals

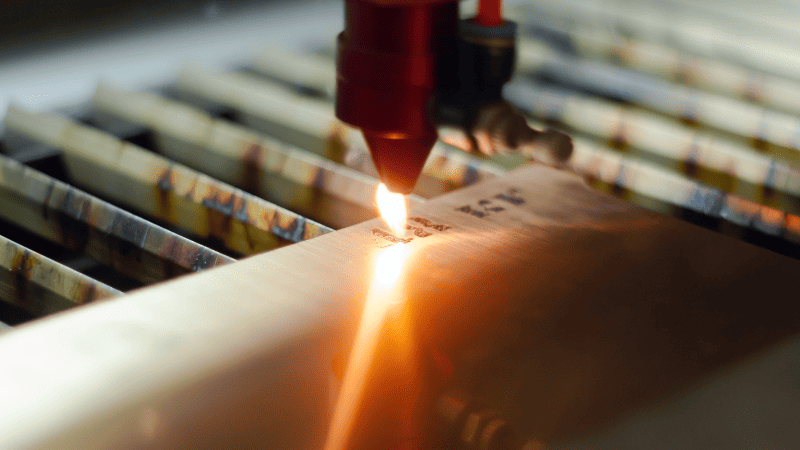

When it comes to metal materials, this duo of power laser pulses must unleash their full potential in the laser marking process.

For deep and bold cuts, high power with a short duration is required, but in the case of delicate metals, like jewelry, a gentler approach is needed.

2. Glass

Glass is brittle in nature and needs careful handling during laser marking processing speed as it requires low to average laser power settings.

It is necessary to control and maintain the application of heat in the case of labeling laboratory glassware and other glass products to keep their structural integrity intact.

High laser power can lead to rapid heat and cooling, causing cracks and even shattering of the glass material.

However, longer duration pulsed laser is a gentler and more heat-controlled approach for glass material marking and cutting.

3. Ceramics

The choice of laser power is critical when marking ceramics as high laser power can cause thermal stress and cracking on the surface of ceramics, so the laser power setting must be adjusted to avoid such issues.

The combination of lower laser power and longer pulse duration is ideal for creating precise marks on ceramics such as decorative pottery, and the precise time length of the beam offers more balance and gradual application of heat, keeping its structural integrity intact.

4. Wood, Plastic & More

When it comes to other materials, such as plastic and wood, longer pulse durations are preferred to achieve the desired outcomes for both. In plastic, it gives more control during melting and bonding, while in wood, it offers more control in engraving and burning, making it suitable for wood artwork, engraved furniture, and wooden gifts.

However, for soft materials like leather, fabrics soft plastic, and others you must read a unique tale of How to mark Soft Products before performing laser marking on these soft arrays of materials.

Precision Meets Real-World Needs

Learning how laser beam power and pulse dance together, it’s time to explore the real world where their magic truly shines.

Precision, durability, and permanence are paramount across various manufacturing industries, which is why the laser marking process is their go-to choice for adding serial numbers, logos, barcodes, etc.

In the medical field, it is used to mark surgical instruments to ensure patient safety, while in tiny components of electronics, it helps to create deep and long-lasting markings.

From labeling critical parts of safety and maintenance in aerospace engraving delicate jewelry to laser cutting and marking automotive parts, the application of laser beams is vast, and the results are impressive.

Moreover, the results ensure laser marks on your products withstand the test of time and use, allowing your business to excel in their respective fields.

Avoid Common Slip-Ups for Spotless Results

Moving towards the end of our journey of exploring the laser beams world, we must be aware of common pitfalls and prepare accordingly.

Using excessive laser power can lead to burning and melting, especially in soft and delicate materials —in addition to this, misjudging a pulse duration is also problematic choosing a longer pulse duration or inconsistent laser wavelength results in blurry and illegible marks.

On the other hand, poor laser power can result in shallow and faint markings that lack visibility. So, to avoid these mistakes here are some common tips to follow,

- It’s important to thoroughly understand the type and composition of the material being marked to adjust the laser power and pulse duration accordingly.

- Conducting test markings on sample materials can help you fine-tune the settings and ensure optimal results.

- In case of deep or multilayered markings, consider using multiple passes at lower power levels. It helps to avoid excess heat buildup and ensures clean, legible marks.

- Make sure the laser beam is precisely focused. Proper calibration is critical for achieving sharp, high-quality marks on material as misaligned lasers can result in distorted or incomplete markings.

- Furthermore, consulting experts in laser marking, such as Baison Laser, can give you valuable insights and guidance to ensure precision and accuracy in your laser marking system.

Conclusion

Wrapping up our discussion around the marking process and its two crucial aspects, laser power and pulse duration, we witnessed how laser wattage and its duration play essential roles in deciding the accuracy and precision of laser beam marking across materials.

Marking is not only a traditional fiber laser technology but an advanced form of art that requires you to carefully apply its pulse width, pulse frequency, and laser energy flow on the material being marked.

Its application in manufacturing industries, from glassware to electronics, indicates how they rely on this process to ensure product quality and functionality.

However, in this intricate dance of power and pulse, you must avoid some missteps, such as continuous lasers and high laser power on delicate materials.

Your Path to Perfection – Choose Baison laser for Laser Marking Excellence

By partnering with Baison Laser, you’ll not only avoid common laser marking mistakes but also upgrade your marking experience to a level of accuracy and perfection that sets your business apart.

We encourage thorough testing of laser settings on sample materials, and you can even take advantage of our free sample proofing to fine-tune your marking approach. To explore how we can help you further, don’t hesitate to Contact Baison Laser today!