We often use laser labeling, laser marking, and laser engraving to discuss product information labeling. These terms look the same but each one is different. Laser marking and engraving refer to writing legible information on the product and packaging. This information can be on the product itself or the packaging.

In this article, we will discuss laser marking vs. laser engraving and see how both are similar and different. We will explore their benefits and how to choose between the two. So before further ado, let’s discuss what laser marking and engraving are.

Laser Marking Process

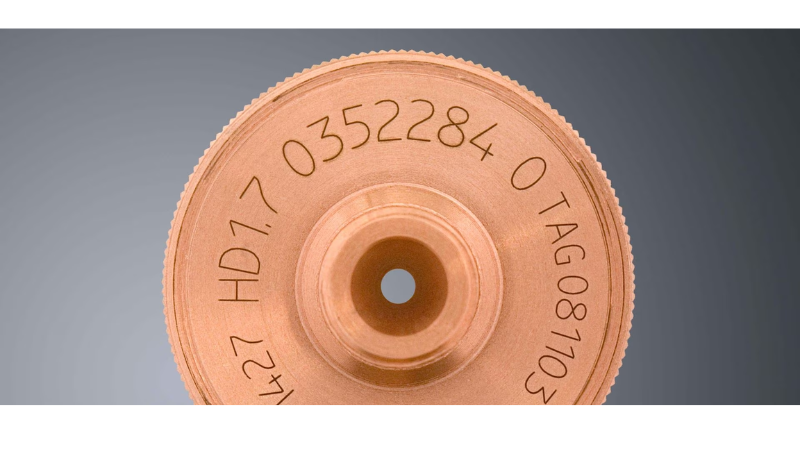

Laser marking is marking information like bar codes, serial numbers, model numbers, important data, and other instructions on the surface. It can include laser coloration, discoloration, images, charring, or dark laser marking. It’s the most efficient way of marking, which is accurate and fast.

All other laser markings processes, like inkjet printers, electrolyte chemicals, or dot peen, cannot compete with laser marking regarding accuracy, durability, and speed. Laser marking can improve the quality of product control.

How Laser Marking Works?

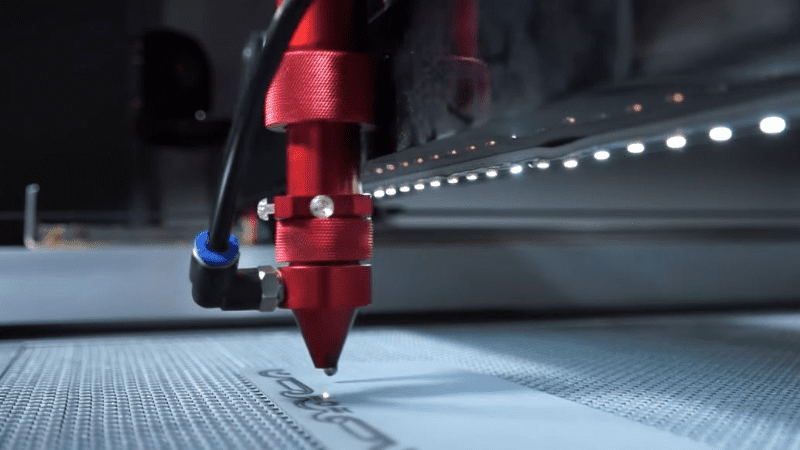

Laser marking uses a high-powered laser beam to create labels or marks on the product surface. Laser marking discolors the surface to create a design; it works through a beam and does not touch the surface. That is called non-contact marking on the surface. Laer marking directs the laser beam through a mirror over the product surface. Laser marking software directs the movement of the beam. Thus it leaves permanent marks on the surface.

Types of Laser Marking

There are several types of laser marking methods, including:

Engraving: The laser engraver removes material to create marks on the surface of the material.

Laser Etching: The laser etching process chemically changes the material’s surface to create a mark.

Annealing: The laser heats the surface of the material to create an oxide layer. It changes the color of the surface without removing the material.

Foaming: The laser heats the surface of certain plastics to create a raised, foam-like surface.

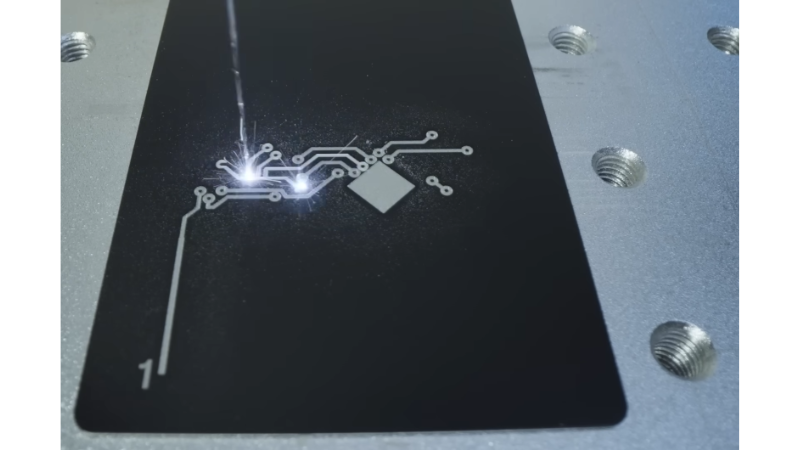

Ablation: When the laser removes a material layer to create a contrast between the marked and unmarked areas.

Carbon migration: The laser changes the chemical composition of the material to create a dark, high-contrast mark.

Coloration: The laser beam heats the surface and creates a permanent, colored mark.

Laser marking applications

Laser marking can be used in several industries for product identification, tracking, and branding or marketing. Here are a few industries where laser marking can be used;

Medical Devices: Laser marking is often used in a medical device to mark critical safety parts or surgical instruments, implants, and other devices with identification information. This helps with tracking and compliance with regulations.

Aerospace and Defense: Laser marking is used in the aerospace and defense industries to mark parts and components with identification information and add barcodes and other tracking data. It also includes marking safety critical parts.

Electronics: Laser marking is used in the electronics industry to mark components with identification information and to create micro-features for electronic devices.

Automotive: Laser marking is used in the automotive industry to mark parts with identification information and create decorative markings on high-end vehicles.

Jewelry: Laser marking is used in the jewelry industry to engrave designs and text onto precious metals and gemstones.

Advantages of Laser Marking

Here are a few advantages of laser marking:

1. Non-Contact Marking

Laser marking is the only way to mark where you are not touching the material’s surface. It can label or mark very fragile, thin, or difficult materials.

2. Permanent Markings

Almost all other marking techniques fade and discolor with time. Laser marking is for a lifetime. They remain unaffected by water and light and can withstand extreme weather conditions.

3. Speed

Laser machines work fast. They can produce ten times more markings on the products than other methods.

4. Precision and accuracy

Laser machines are directed by computer software. They can produce precise markings on the surface. They can produce high-precision small signs, graphics, text, numbers, or other marks on the surface.

5. Versatility

Unlike another method where each suited some specific type of material, laser marking machines can mark almost all types of materials, including metal, alloys, glass, ceramic, plastic, and paper.

Limitations of Laser Marking

Here are a few limitations that you can encounter with laser marking.

1. Depth Limitations

Laser marking does not produce a deep mark on the surface. As it is a non-contact method, the marking does not create deep lines on the surface.

2. Color Limitation

Some material does not produce the desired colors, and high-quality color resolutions may not be possible.

Laser machines require special safety features. If the operator is not a skilled professional, the laser beam can cause damage to the surrounding and the environment.

The size of laser marking is limited. They may work well for smaller objects, but larger areas require multiple passes.

Laser Engraving Process

Laser marking is a non-contact process. Laser engraving refers to the process where a laser beam physically removes the part of the product surface and engrave signs, number, and data by physically removing the material from the base surface. The process removes the cavity and engraves images or numbers that can be felt with the hand.

What is laser engraving

A laser engraving machine sends a laser beam through a lens or mirrors onto the base material. The beam evaporates or burns the surface material, creating a permanent and precise design. A computer control system controls the beam and sends it to exact to create different patterns or designs.

The depth of design is also controlled by computer software. The process of deep laser engraving removes the material’s surface layer, and one can feel the design with the hand.

Laser engraving can create intricate designs on different materials. It can be used to engrave jewelry designs or create personalized gifts. Manufacturers use it on an industrial scale to mark logos or serial numbers on the surface.

How does laser engraving work?

Laser machines produce high-powered laser beams. The laser beam heats the material surface, which causes the surface to vaporize. The laser machine works fast and removes the material with each pulse. It’s a perfect way to engrave product information, serial number, images, logos, and other marketing content on the product.

Advantages of laser engraving

Here are a few advantages of laser engraving:

1. Permanent Design

As the laser beam melts and creates a design on the material’s surface, the laser engraving stays as long as the product’s life.

2. Flexible

Laser machines are designed to follow the pattern from the software. You can change the text, design, or graphics very easily. The same machine creates multiple patterns, text, serial numbers, or graphics on different materials.

Besides all these advantages, laser engraving is also precise, permanent, customizable, and accurate.

Limitations of laser engraving

Despite all benefits of laser engraving, here are some possible limitations of laser engraving:

1. Material Selection

Laser engraving may only be suitable for some types of materials. It is better suited for metal, glass, wood, and plastic. Certain reflective or highly conductive materials may not be suitable for engraving.

2. Surface Quality

The base material’s surface finish may affect the engraving’s quality. An uneven or rough surface may change the finished look.

3. Depth Limitations

Laser machines can engrave to a certain depth. They must engrave only a little into the material.

4. Size

Laser engraving machines have size limitations. Larger objects may take longer and multiple passes to engrave.

Difference Laser Marking and Laser Engraving

Let’s sum up the difference between laser marking and laser engraving:

Laser marking uses a laser beam to change color or create a chemical reaction on the material’s surface. This does not penetrate the material, leaving a clear and legible mark on the surface.

Laser engraving involves removing the layer of surface material to engrave the design. The laser beam penetrates deeper into the material. It creates a groove on the material’s surface that can be filled with ink or contrasting colors. You can feel the design on the surface. The mark created by engraving is deeper and more clear.

Beam Quality

Laser marking typically requires a high-quality beam with a small spot size and low divergence angle to produce precise, high-contrast marks on the material’s surface. On the other hand, laser engraving may require a beam with a larger spot size and higher power density to remove material from the surface and create deeper marks or engravings.

Depth

The beam penetrates only a few microns on the surface in laser marking. It remains on the surface and does not go deeper.

In laser engraving, the beam penetrates deeper into the material. Depending on the laser machine settings, it can travel a few hundred microns deeper into the surface to melt the material.

Suitable Material

Laser marking can be used for metal, glass, ceramic, textile, paper, plastic, and leather.

Laser engraving can be used for metal, stones, glass, wood, marble, and leather.

Speed

Laser marking is fast as it only involves changing the color of the surface.

Laser engraving takes longer because it removes the material surface and creates a deeper design.

Another difference is that touching the marking surface cannot feel the design. However, laser-engraved design can be felt with hands.

Conclusion

Laser technology has revolutionized marking, labeling, and engraving. Both laser marking and laser engraving are effective methods of creating permanent labeling on the surface material of products. They can be used to engrave or mark serial numbers, bar codes, product instructions, warnings, signs, lines, graphics, or logos on the products.

Choosing between marking and engraving depends on whether you want to make the design a part of the material or just a mark. Both have their significance. Both are permanent and accurate methods of labeling.

Enhance your Production Quality with Baison’s Laser Marking Machines

Baison offers laser marking matches that both small and heavy industries use. Our machines are reliable, user-friendly, fast, and require little maintenance. We trained staff our machines not only increase the production but also play a great role in increasing the production quality and trackability.

Contact us to revolutionize your product marketing and engraving with our laser machines, whether it’s the manufacturing of machinery parts or simple packaging. Our laser machines can work on multiple surfaces with equal finesse ad ease.

Basion offers a free application evaluation to help customers choose the best machine for their businesses. Contact us to learn more about our different laser marking machines.