Laser marking is a non-contact way of labeling or marking the product or its parts. It’s the latest technology to add information to the product. Laser marking systems are efficient machines that work better than other marking systems.

They are fast, accurate, and capable of transferring complex designs and labels onto the product. These laser machines can work on different types of material with equal ease.

This article will discuss laser marking and how laser marking machines are more efficient. We will also discuss what applications can benefit from a laser marking machine.

What Are Laser Marking Machines?

Marking or labeling is to add product information on the product, its different parts, and packaging. Laser marking is when laser machines add marking on different materials. These machines are equipped with high technology. Mostly there are CO2 or fiber laser machines. It uses a non-contact method. That means the product is not touched physically, but the machine works through a laser beam.

How Does the Laser Marking Process Work?

They use a laser beam to produce energy. The laser beam is directed to the material surface through a lens or mirrors. The laser beam is controlled by the computer software of the laser machine that directs it on the material surface according to the pre-designed pattern.

Laser marking machines can add complex designs, marking, serial numbers, bar codes, warnings, and other signs and numbers on the product.

Laser marking machines can engrave, etch, or mark the material. The devices can work on several materials, including metal, alloys, glass, ceramic, wood, and stones. Even laser marking is of different types.

A laser marking machine can

- Discolor

- Etch

- Mark

- engrave

Advantages of Laser Marking Machines

A laser marking machine can be used in both small and big industries to label and mark different products. Let’s look at some of the advantages of laser markers.

Non-contact Laser Marker

One of the biggest advantages of laser marking machines is that they use a non-contact marking system. It means no actual part of the machine touches the material surface. There is also no need to handle the product manually.

These machines can transfer design without touching the material surface. That means it is safe for almost all types of material. There is no risk of contamination or damage to the material.

Permanent Identification Marking

Laser engravings or markings are for a lifetime. Almost all other types of marking, like dot peen marking or inkjet, fade or discolor with time. Even mechanical engraving takes a long time, and it’s almost impossible to label so many parts manually. So laser marking machines remain the only way of adding permanent marks.

These permanent marks or engravings can withstand light, water, or chemical exposure. Laser markings remain legible to the product life. The lifetime marking of serial numbers or model numbers makes them useful for a lifetime.

Precision and Accuracy

Laser marking machines provide high accuracy. They can transfer complex designs, graphics, or even minute signs or numbers. As the laser beam is controlled by computer software, it moves and focuses the small points that can follow intricate patterns and designs.

The accuracy of design and transfer on the material surface increases product quality and performance.

Versatility and Adaptability

Laser marking machines can work on a range of materials. It works on almost all materials, including plastic, paper, fabric, ceramic, wood, and metal. It can work on tough materials like tough metal like stainless steel or fragile glass surface with equal precision. That adaptability and versatility make it a useful option for industries.

High Speed

Laser marking machines work at high speed. They are fast than any other method of labeling.

Safe Process

Laser marking is a non-contact method. If the staff and operators are professional and take care of safety procedures, it’s a safe process.

Fully Automated Machines

laser markers can work as fully automated machines. They can be streamlined with other machinery and automatically handle the marking or engraving process. They work with CO2 laser or fiber laser systems.

Limitations of Laser Marking

Here are some possible limitations of laser marking systems:

- Costly Machines: Laser machines are expensive. They incur more upfront prices and may be overkill for DIY projects or small industries.

- Selecting Right Maring Machine: Choosing the right laser system for specific applications is difficult. Baison offers a free evaluation system to help customers choose the right machine for their business.

- Safety Concerns: Fiber lasers or any other laser machine pose potential hazards to staff and the environment. It requires trained staff who know how to follow all safety guidelines. They need to be sure that the focused beam stays on the laser marking area.

Applications of Laser Marking Machines

Let’s see in which fields laser marking machines are useful:

Automotive Industry

The automotive industry uses numerous smaller parts that are joined together to make big vehicles. Clear marking and labeling of these parts are essential. They need serial numbers and model numbers on direct parts of products.

Electronics

Electronic Industry uses both small and big parts of different materials. These parts can be non-metals like devices and —- that need warnings, numbers, and other information.

Aerospace Industry

Industries like aerospace must assemble numerous small to big parts of different materials. There are aircraft components and turbine blades that require unique serial numbers and other information for joining these parts.

Jewelry Making

Laser engraving can be useful to transfer designs on delicate surfaces. They can transfer designs, color contrasts, and other types of ornament on stones and metal jewelry.

Medical Devices and Tools

The medical industry is another sector that can use different devices, tools, implants, and surgical instruments. Clear and permanent marks on these tools are important. They can be made of plastic or high-quality metal.

Packaging

The packaging industry is another industry that can use laser marking machines. These machines can transfer all the information relating to the product on packages, including serial numbers, bar codes, warnings, product information like ingredient lists, or how-to-use information.

Manufacturing

Almost any manufacturing industry must transfer logos, images, or marketing content to their products. These products are easier to transfer to different products. Then there is often furniture or other products that require assembling. These products need to have clear and accurate information on the product surface.

Laser Marking vs. Laser Engraving Machines

Laser marking and engraving are laser-based techniques that leave permanent and precise product marks. Laser marking and laser engraving both work for transferring labels, designs, information, or signs on the base material.

Laser engraving removes some material from its surface to engrave the content, be it text, signs, codes, or graphics. Laser beams focus on the surface of the material and vaporize the material with heat. Laser engraving creates deep marks on the material.

Marks of laser engraving are deep and can be felt with hands. Laser marking, on the other hand, changes the surface color with

What’s the Purpose of Laser Engraving Machines?

The purpose of laser engraving is the same as laser marking. It creates identification marks on parts like code, model, or serial numbers. Laser engraving works explicitly for very tough materials like metal or glass.

These marks can be for advertisement, identification, tracking, or safety warnings. Laser engraving is more suitable for hard materials and jewelry markings. Both laser marking and laser engraving work are almost the same.

Difference Between Laser Engraving and Laser Marking Systems

Laser engraving and laser marking machines work the same way. Both use the laser beam to create marks or engrave the surface. The difference is between their laser beam and how deep it penetrates the material’s surface. Laser engraving also only works on some thin materials and for packaging.

Choosing between a laser engraving machine and laser marking depends on industrial needs. If your business needs to label metal parts and jewelry and is about something other than packaging, then laser engraving is suitable. Laser marking is suitable for thinner materials or packaging as well.

Why It’s Essential to Choose Fiber Laser Marking Machines for Your Business

Laser marking and laser engraving machines are important to almost all industries. Labeling products and their different parts is essential for big and small industries. Laser machines mark the materials with crucial information like serial numbers, logos, warnings, or other information.

These labels help in streamlining and enhancing product quality. You can not only track these products; most importantly, product identification is critical for assembling. All heavy industries like aerospace, automotive, and electronics depend on product identification.

You can learn about how to choose a fiber laser marking machine for your business.

Conclusion

Laser machines are an efficient and time-saving way to mark the material permanently. These machines can create permanent marks that are the need for different industries.

These machines use laser technology to transfer accurate and precise markings on the material. They can work on any material, including hard and fragile materials. Laser marking machines can even help with packaging.

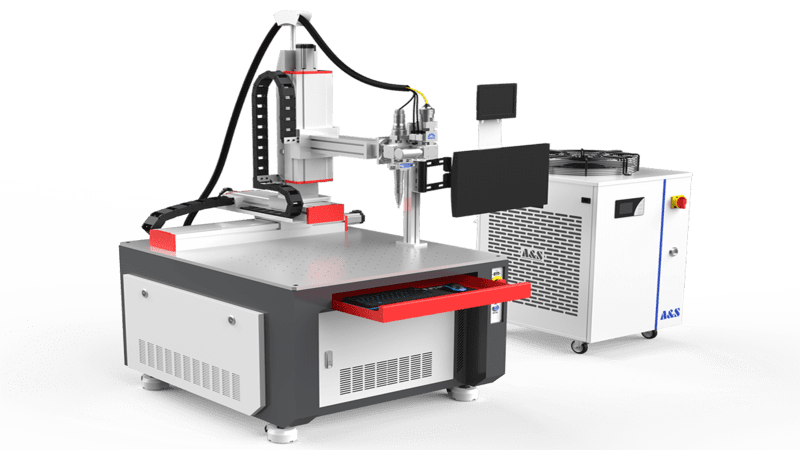

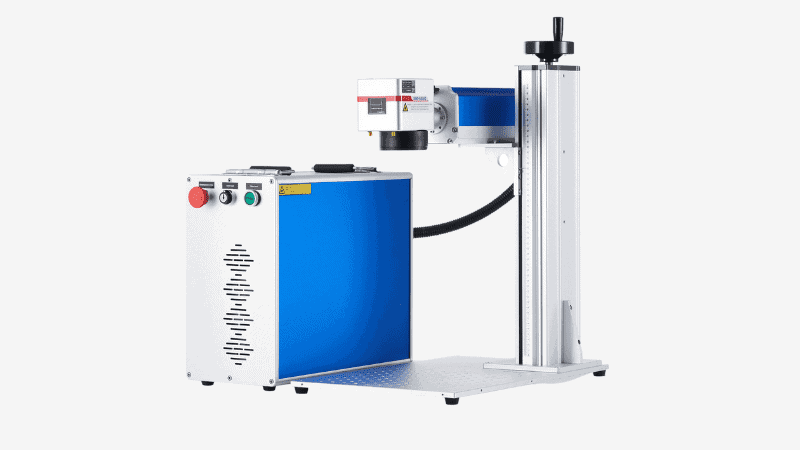

Revolutionize Your Marking Needs with Baison’s Laser Marking Machines.

If you want a reliable and efficient laser marking system for labeling your product, visit us. Baison offers high-tech laser machines for marking and engraving. These machines are equipped with the latest laser marking technology.

Our fiber laser marking machines can be fully automated, and you can streamline them with your other industrial machines to create machine-readable data on different materials.

Baison’s laser machines can not only rescue y our product cost but are designed to increase product quality. Our fiber laser machines require minimum maintenance and

Contact us to learn more about our solid-state lasers. We offer a free application evaluation to help our customers choose the laser machines that suit their needs.