What is Laser Marking?

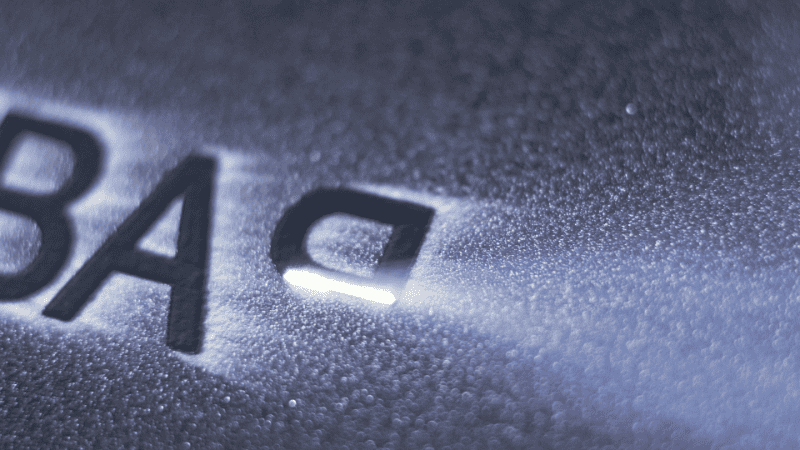

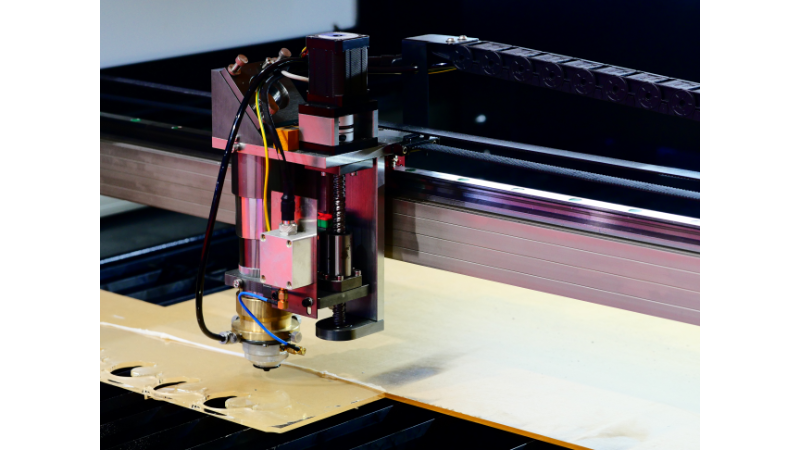

Laser marking is an innovative method that offers a permanent mark for labeling objects. It is a cutting-edge method used to label or engrave objects permanently. It’s like giving them a unique tattoo! This advanced technique utilizes a high-powered laser beam to create precise and everlasting marks on various materials. The best part? It doesn’t cause any damage or deformation to the material surface.

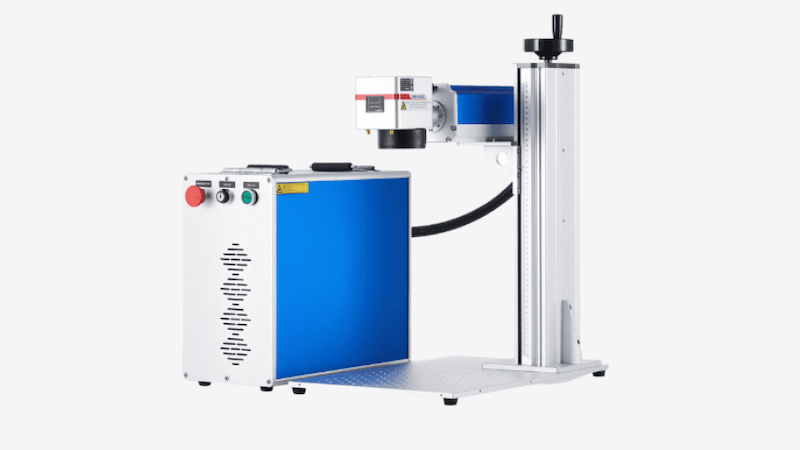

Industries such as automotive, electronics, and medical devices rely heavily on laser marking machines for their labeling needs. These fiber laser machines can also be used for laser engraving and cutting metal surfaces and more. With their incredible accuracy and versatility, lasers have revolutionized the way we mark our products. The engraver uses a computer to precisely mark the workpiece.

How does Laser Marking work?

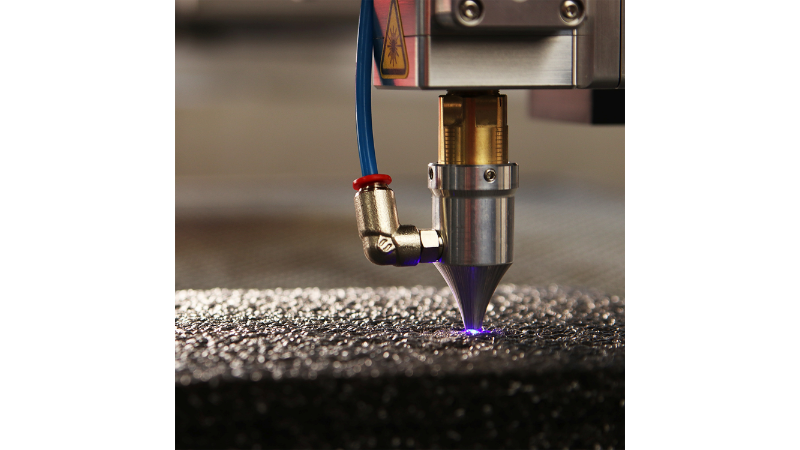

Laser marking is a process that involves a focusing lens that send a laser beam and set the focus distance at a fixed position from an engraving machine onto the surface of an object. This intense heat generated by the laser beam leads to either oxidation or vaporization of the material, resulting in visible marks. Different types of lasers are used depending on the material being marked.

For instance, fiber lasers are commonly used for metals, while CO2 lasers are suitable for plastics. Raster engraving is also a technique used by the engraver to create precise and detailed marks on various materials. The laser head travels left to right across the laser bed and then moves down a hair and repeats until it has engraved the image.

The laser engraving process can be precisely controlled through computer software, allowing for intricate and accurate markings. Here’s a breakdown of how laser marking works.

- Laser focus: The marking machine focuses the laser beam onto the workpiece surface for precise and clear markings during the laser marking process.

- Material interaction: When the focused laser beam interacts with the material, it generates intense heat. This heat causes either oxidation (chemical reaction with oxygen) or vaporization (conversion into gas) of the material.

- Mark creation: As the material is removed with laser pulses, images or engraved areas are created on the material surface. As a result of oxidation or vaporization, permanent marks like text, logos, barcodes, and patterns are created on the surface of the object. These marks can take various forms such as text, logos, barcodes, or patterns.

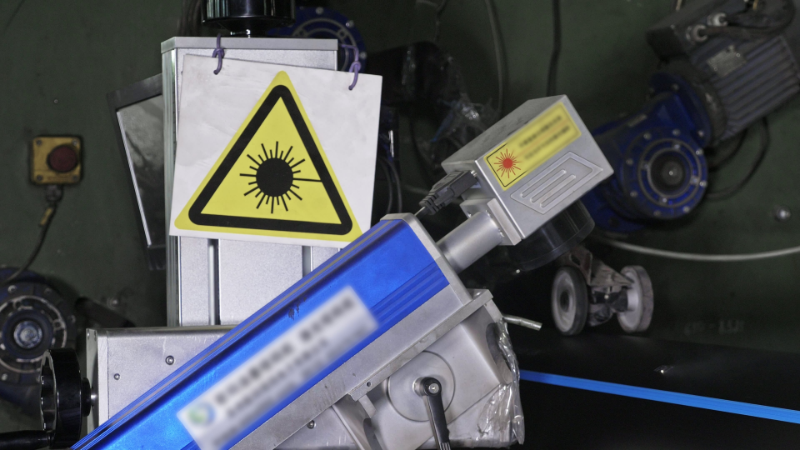

You can use laser engraver software to complete the design for laser engravers. By utilizing computer-controlled software and different lasers like CO2 lasers for plastics and fiber lasers for metals, laser marking offers versatility and accuracy in engraving and cutting workpieces, creating high-quality markings on a wide range of materials. And it is strongly advised to always follow laser safety protocols and use laser safety glasses.

Benefits of Laser Marking Machine Over Laser Engraving Machine

A laser marking machine and a laser engraving machine are used interchangeably but both are different. You can click here for a detailed comparison. It has several advantages over a laser engraving machine, making it an ideal choice for various applications. Here are the key benefits.

- Faster processing speeds: Laser marking machines are typically faster than laser engraving machines, allowing for high-speed marking of products or materials. This makes them ideal for large-scale production or high-volume marking requirements.

- Higher precision and finer details: With their focused laser beams, laser marking machines provide superior precision and finer details in the marking process. This ensures that intricate designs and small text can be accurately marked onto various materials surfaces.

- Minimal waste or debris: Laser marking is a non-contact process, which means there is no physical contact between the laser beam and the material being marked. Unlike engraving, laser marking does not remove any material from the surface being marked. As a result, there is not only minimal waste or debris generated during the process but also eliminates the risk of damage or deformation to delicate or sensitive materials. This makes laser marking a cleaner and more environmentally friendly option.

- Versatility with materials: Laser marking machines are highly versatile and can mark a wide range of materials including metals, plastics, glass, ceramics, and more. This flexibility allows businesses to use a single machine for various projects without needing separate equipment for different materials.

Overall, laser marking machines provide faster, more precise, versatile, and durable marking solutions compared to laser engravers. These advantages make laser marking machines a preferred choice for a wide range of industries, including automotive, electronics, medical, aerospace, and more.

Applications of Laser Marking

The laser marking process is extensively used in various industries for a wide range of applications, such as product branding, serialization, coding, and even for creating decorative patterns or designs on materials. Here are some of the most common applications of Laser Marking:

Automotive Industry

Laser marking is widely used in the automotive industry for various purposes. It is commonly employed for part identification, allowing easy tracking and identification of components. Traceability codes and serial numbers are laser marked on engine parts to ensure accurate documentation and quality control.

Electronics Industry

Laser marking is a vital process in the electronics industry for marking metal components with identification codes, logos, and other essential information. This technique enhances brand recognition and ensures product authenticity, making it a valuable branding tool.

Medical Industry

Laser marking is widely used in the medical industry to mark medical devices with important information. It creates precise surface markings on metal, such as lot numbers, manufacturing dates, and regulatory symbols. These identifiers are crucial for tracking instruments throughout their lifecycle, ensuring proper maintenance, and preventing mix-ups during surgeries.

Jewelry Industry

Laser marking is used in the jewelry industry to mark precious metals and gemstones with identification marks, logos, or personalized engravings. This adds value to the jewelry and helps in authentication.

Packaging Industry

Laser marking is used to mark the surface of metal packing materials with information like batch numbers, expiry dates, and barcodes. This helps in efficient inventory management and product traceability.

Overall, Laser Marking is an effective and versatile process for engraving and cutting metal materials. It has a wide range of applications in various fields. Laser marking is increasingly being adopted by businesses of all sizes to enhance branding, serialization, coding, decoration, and quality control processes, and to effectively manage their operations. By harnessing the power of lasers, these industries enhance productivity, improve quality control measures, and streamline their operations.

Factors to Consider When Purchasing a Laser Marking Machine

When purchasing a Laser Marking Machine, there are several important factors to consider to ensure that you make the right choice and get the best possible performance from your machine. Here are some of the most important factors to consider.

Laser type

There are different types of lasers used in laser marking machines, such as fiber lasers, CO2 lasers, and UV lasers. The choice of laser type depends on the material to be marked and the desired marking quality.

Marking speed

The marking speed of a laser marking machine determines how quickly it can mark the desired patterns or texts. Laser speed setting is also important as it will affect the level of precision for your laser cuts. It determines the movement speed of the laser head. For engraving and cutting of thin material, the speed is usually set (close) to the maximum. Consider the production volume and engraving speed requirements when choosing a machine.

Power Output

Choose a laser marking machine with sufficient laser power output to effectively use laser engraving materials or mark different workpieces. The power output of the machine determines its ability to cut or use different materials effectively. At low power, the flammable materials such as wood, cardboard, the edges of the cut may burn rather than vaporize. It is crucial to select a machine that can handle the level of intensity needed for your desired engraving or marking applications.

You can click here to see the impact of different marking speeds and powers on the laser marking process.

Material Compatibility

Ensure that the laser marking machine you choose can effectively mark the materials you work with. Different laser machines have varying capabilities. Plastics, glass, and more. Consider the type of materials you frequently work with and verify that the machine is compatible.

Marking Area

When choosing a laser marking machine, it is crucial to consider the size of the engraving area that you require for your products or components. Laser marking machines are available in different sizes, so it’s important to select one that offers an adequate marking area for your specific needs. Make sure to take into account the dimensions of your products or components to ensure they fit within the machine’s designated workspace.

Software and Connectivity

Look for a laser marking machine equipped with user-friendly software and compatibility with other systems. The laser engraving software should allow you to easily design and control your markings, providing flexibility in creating custom designs or patterns. Consider connectivity options such as USB or Ethernet ports for seamless integration into your existing workflow.

By considering the above factors, you can make an informed and educated decision when purchasing a Laser Marking Machine. It’s important to research and compare different machines and suppliers, to ensure you get a machine that meets your needs, fits your budget, and provides you with the best performance and productivity.

Where To Find The Best Deals On Fiber Laser Making Machines?

Looking to find the best deals on fiber laser marking machines? Here are some tips to help you get started:

- Research online suppliers and manufacturers that specialize in laser marking machines. Look for reputable companies that offer a wide range of options, including fiber laser engravers and CO2 laser cutters.

- Trade shows or exhibitions often provide an opportunity to see laser marking machines and other laser equipment in action. Besides, Take your time to browse different websites and online marketplaces to find the best deals. Consider factors such as power output, marking speed, and laser engraving software compatibility when choosing a laser marker for your laser engraving projects.

- After-sales services are crucial to complex laser machines, so a company that offers such a service is a plus. That way, you can ask them for specific customization in the machine that can help you increase production.

By following these steps, you’ll be well on your way to finding the best deals on fiber laser making machines. Whether you’re setting up a maker space or starting a new business venture, investing in quality equipment to get started with laser is crucial for achieving precise and efficient results.

FAQs

Q: How long does it take to mark an item using a laser marker?

A: The marking time depends on factors such as the complexity of the design, material type, and laser power. However, laser marking is generally a quick process that can be completed in seconds or minutes. You need a list of laser engraving ideas to practice your skills and instructions on the software part to bring out the best of the machine.

Q: Is laser marking environmentally friendly?

A: Laser marking is an eco-friendly solution as it does not require the use of consumables like ink or solvents. It produces minimal waste and has low energy consumption compared to other traditional marking methods.

Q: Can I create a custom raster engraving design or logos with a laser marker?

A: Yes, laser marking machines allow for the creation of custom designs, logos, serial numbers, barcodes, and other personalized markings. Our Fiber Laser Metal Marking Machines are able to laser etch stunning and intricate designs onto your metal and hard plastics. The software used with the machine enables easy customization and flexibility in design options.

Conclusion

In conclusion, laser marking machines are a powerful tool for resolving your marking needs. With their precise and efficient technology, these machines offer numerous benefits over laser engraving machines. Laser marking provides permanent and high-quality marks on a wide range of materials, making it suitable for various applications across industries.

When purchasing a laser marking machine, it is essential to consider factors such as power output, and engraving speed. By carefully evaluating these aspects, you can ensure that you invest in the right machine that meets your specific needs. By investing in a high-quality laser marking machine, you can enhance productivity, improve profit, and achieve consistent and accurate markings.

Baison Laser Provide The Best Laser Marking Machine Solutions

To find the best deals on fiber laser marking machines, it is recommended to explore reputable suppliers and manufacturers. Baison is such an enterprise that manufactures premium quality laser marking machines for you. You can learn laser engraving basics, laser engraving project ideas and even a laser cutting machine to improve your laser engraving results here. Contact us now to request a system quote and get yourself a top-notch laser marking machine to streamline your operations and elevate your marking capabilities!