Material fabrication and cutting materials are essential parts of manufacturing industries. Saws have been used for the time unknown to cut the materials. They have evolved, and a traditional saw is replaced with a battery-powered one that cuts the material at high speed with better precision. Laser cutting machines have replaced traditional cutting methods and are preferred for their precision and accuracy.

In this article, we will compare Laser cutting vs. saw cutting. We will discuss the key differences and their advantages as well. Let’s take a look at laser cutting first.

What is Laser Cutting?

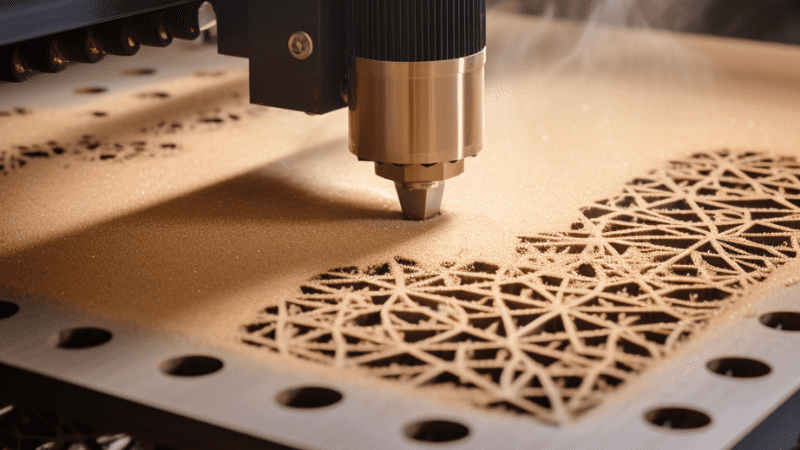

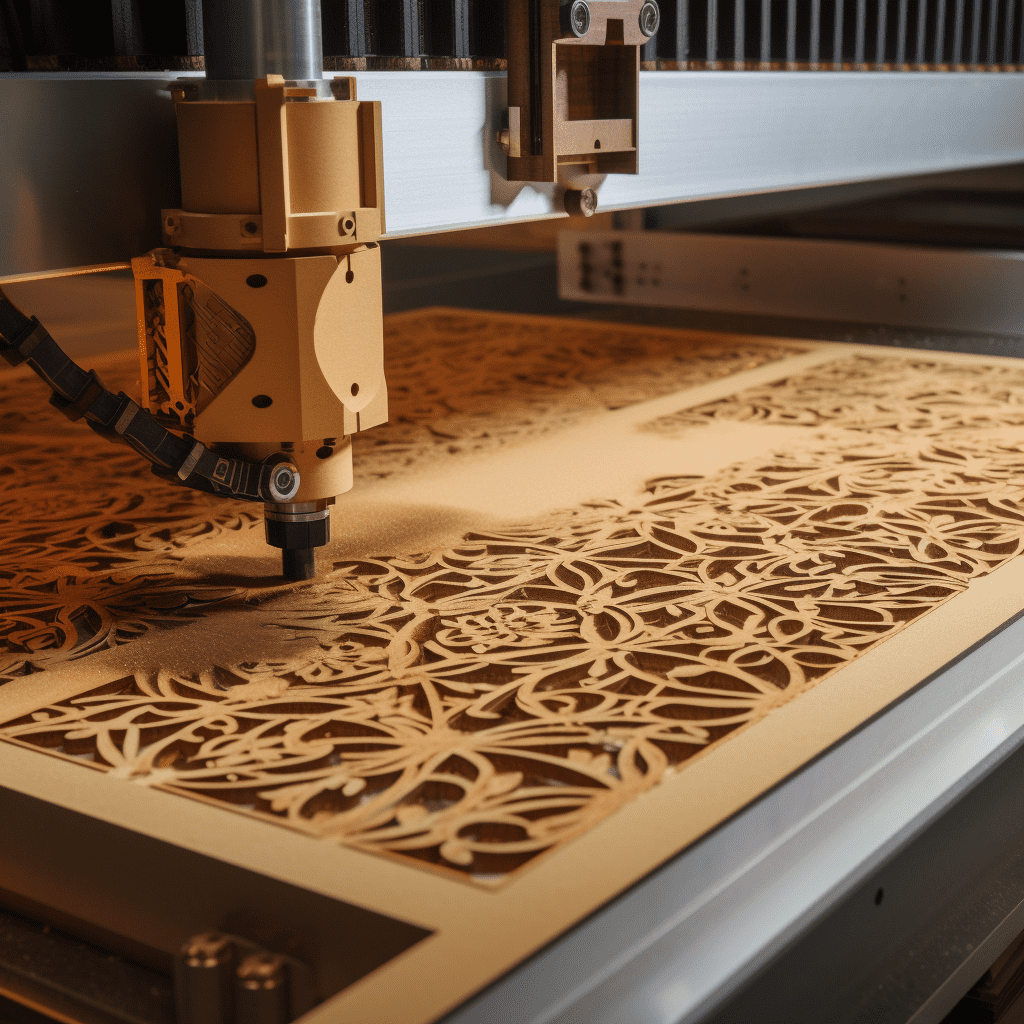

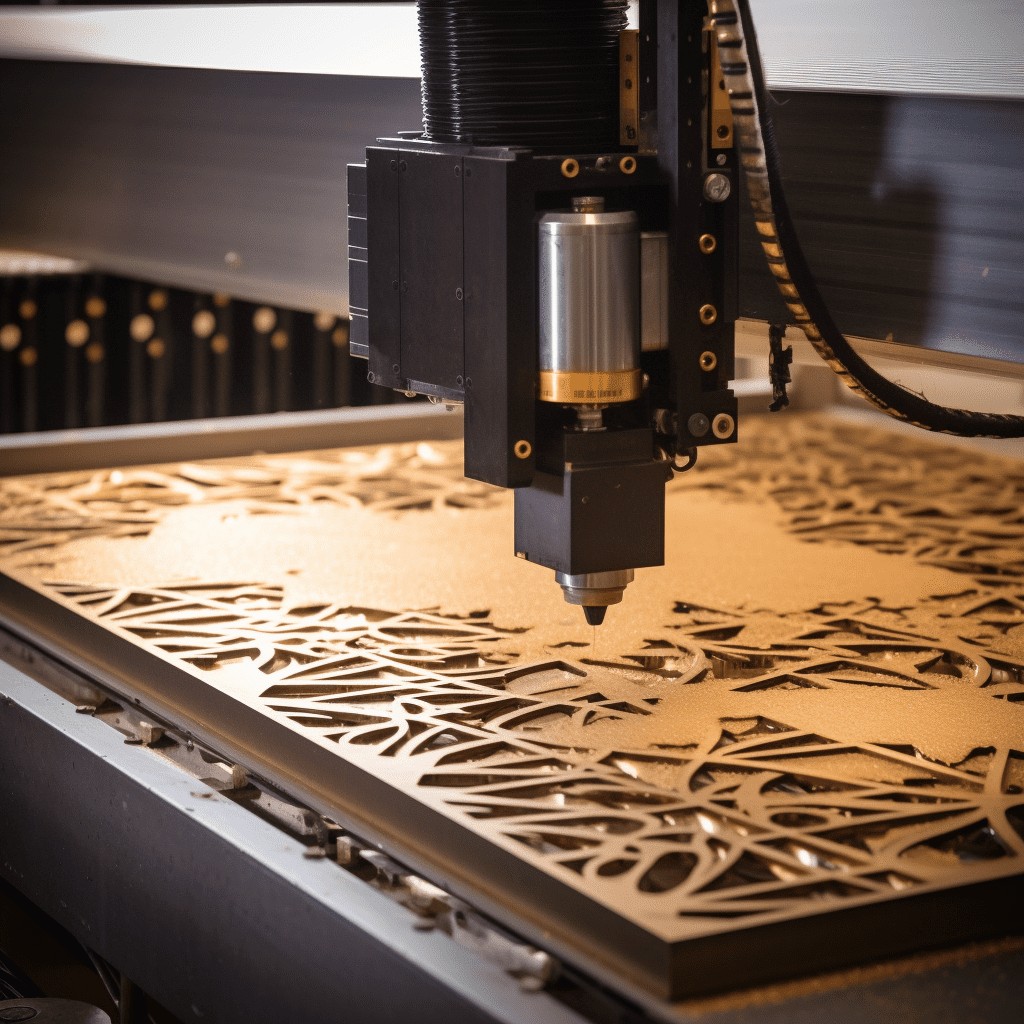

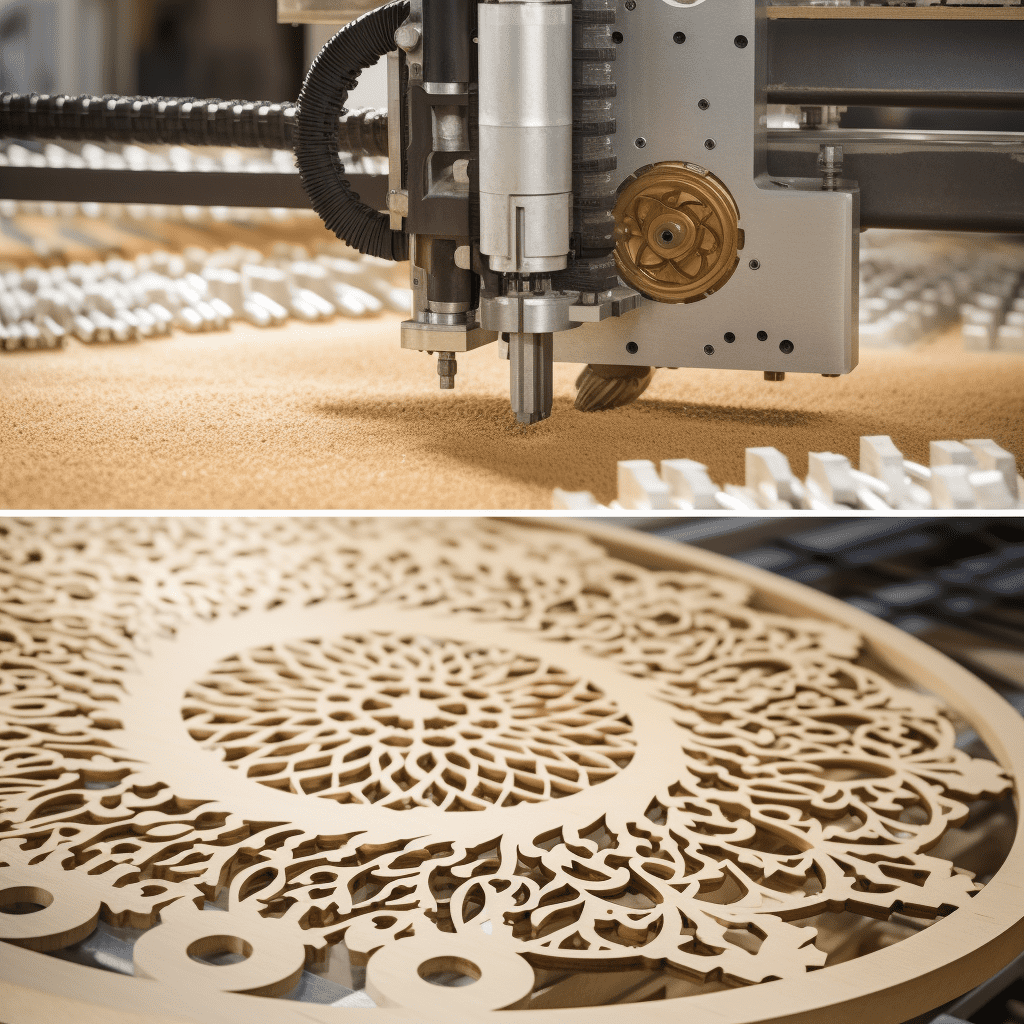

Laser cutting is using high-intensity laser-cutting equipment to cut material. The laser machine cuts through the material with narrow, high-intensity laser lights. The laser head directs the beam to the material through a series of lenses. Laser cutting is a thermal process in which a laser beam heats the material surface and causes it to vaporize.

A CNC system controls the movement of the beam. It’s like computer software that already has the design and moves the beam on a fixed pattern. Not only can it cut even intricate designs with precision, but it can handle many materials with equal precision.

Advantages of Laser Cutter

Here are a few advantages of laser cutting

Precision

Laser cutting machines are exact. They can cut even intricate designs with extreme precision. The good thing about laser cutting is that it can handle tough materials like steel and thin and delicate materials with the same precision.

Accuracy

Laser cutting is by far the most accurate way to cut different materials. The quality of the cut is also fine, with little to no finishing required afterward.

Versatile

Laser machines are not only versatile in handling different materials, but some of them can be used for welding, cutting, and engraving as well.

Programming Options

The laser machine has a separate CNC machine that directs the beam and follows the given pattern accurately.

Speed

Laser-cutting machines work at high speed. They are fast than almost all other cutting methods. The laser machines can even be fully automated. They can speed up the production process to a great degree.

Reduce Operational cost

Laser machines are expensive, but they save a lot of money once you buy them. They can produce more in less time, the quality of products is high, and they reduce manual intervention.

Reduce Waste

Laser machines cut material through a narrow beam. The beam affects only the interacted zone and does not affect the surrounding material or change its properties. This results in less scrap or material wastage.

Disadvantages of Laser Cutting

Although laser cutting technology has many advantages, there are also some disadvantages to consider, including:

High Initial Cost

Laser machines are expensive. The cost of laser cutting machines is higher compared to traditional cutting machines.

Limited Thickness

They may need to be more suitable for very thick materials. The maximum thickness that laser cutting machines can cut is usually around 1 inch. Thicker materials may take more time.

Safety and Environmental Concerns

Laser-cutting machines generate a lot of heat and radiation. This high-power beam can cause. There can be many safety and environmental hazards if the operator is not trained.

Material Limitations

Laser machines may not suit cutting highly reflective metals like copper.

Maintenance Costs

Laser-cutting machines require regular maintenance, which can be costly. Some of its parts, like the tube, nozzle, or lens, may need to replace from time to time which can be costly.

Not Portable

Laser machines are not portable and require floor space.

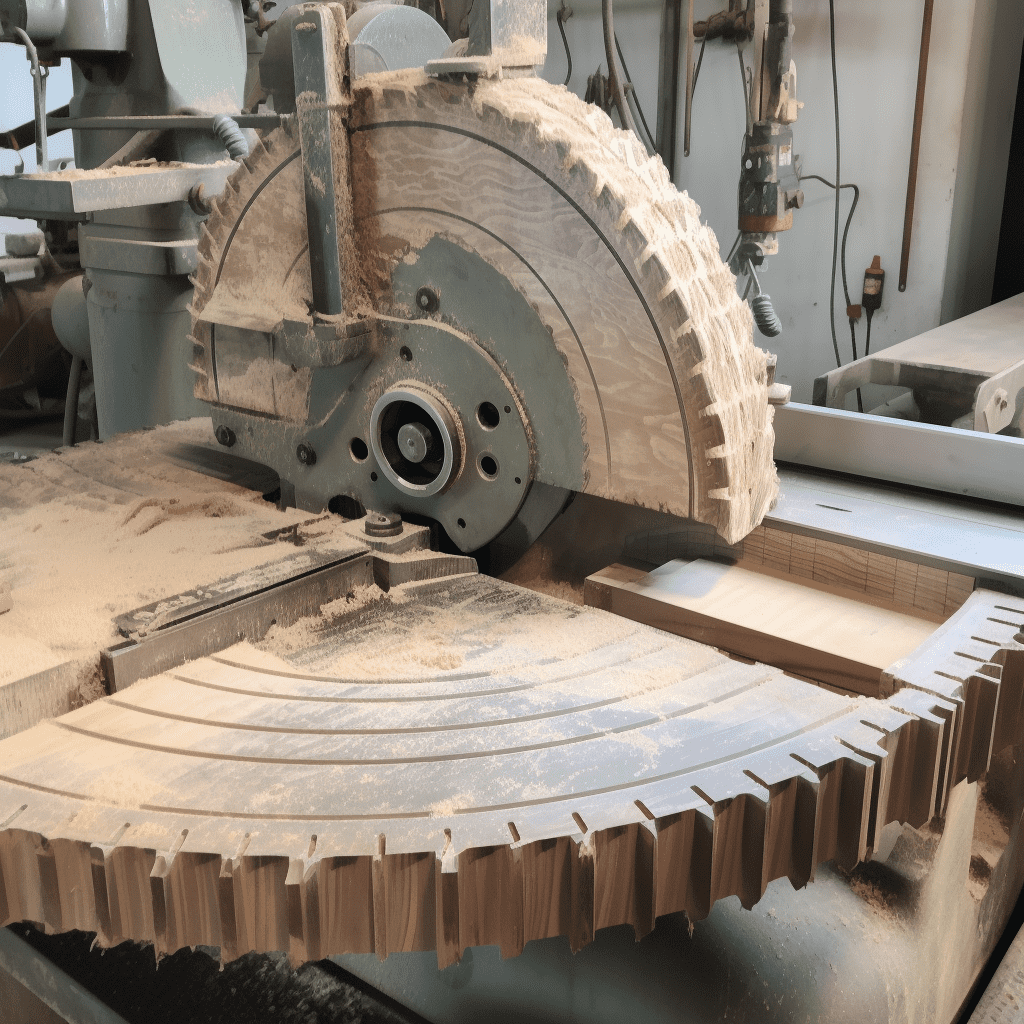

What is Saw Cutting?

Traditional saw cutting uses a saw to cut material. It consists of a tough blade to cut the material. They can be manual tools or are powered by batteries or electricity. Saws can cut plastic, wood, metal, and other materials. They come in different types, like jigsaw, circular, band, or chainsaw. Every kind of saw is suitable for different materials and types of cutting.

For example, a jigsaw moves the blade from back to forth; it is suitable for metal and wood cutting. A circular saw has a blade that spins rapidly. The band saw moves up and down, which is ideal for cutting curves and shapes. So the choice of Saw depends on the type of material, level of precision required, and type of cut.

Here we have explained different types of Saws.

Jigsaw: It has a reciprocating blade that moves up and down rapidly. It s ideal for cutting shapes and curves.

Band saws: It has a long continuous blade stretched between two wheels. It is used to cut wood or metal. It moves back and forth.

Circular saw: circular Saw has a sharp blade that spins around rapidly.

Table saw: It makes straight and long cuts in wood and other material.

Chainsaw: It has a chain with cutting teeth. You can use it to cut trees or huge blocks of wood.

Hacksaw: It has a thin blade and can cut metal.

Scroll Saws: The scroll saw has a sharp, thick blade that can reach tight spaces. It can cut intricate designs and curves with ease.

Advantages of Saw Cutting

Here are a few benefits of saw cutting:

Affordable price

Saws are a lot more affordable than any laser machine. In fact, there can not be a comparison for price.

Easy to Use

It’s a hand tool that is straightforward to use. The Saw is a tool that can be used for home repairs or DIY projects, even by individuals without formal training.

Compact and Easy to Carry

It is compact, and you can easily take it on sight.

Precision and accuracy

The precision and accuracy of saw cutting depend on the worker’s experience, knowledge, and practice. Even saws can give a clean and precise cut if the user knows how to use it, but overall finishing could be better than a laser cut.

Laser Cutting vs. Saw Cutting: Best Cutting Method

There is no comparison between the two types of cuttings. Saw is a hand tool, while laser systems are high-tech machines designed for industrial use. Both have their place and benefits. A laser machine may be an overkill for a DIY project. At the same time, a saw may be insufficient for industrial use. So each one has its advantages. Let’s compare both types of cuttings.

1. Work

Laser machines use high-powered beams to cut through materials. A saw uses a blade that repeatedly moves to cut material.

2. Type of Material

Both can cut through metal, wood, plastic, and other materials. Power saws can cut through all these materials. However, tough materials like steel or iron may take. They may not handle the thin and fragile material as well. Laser machines can cut both thick and thin material with equal ease.

3. Precision

Laser cutting machine offers superior precision and accuracy, far from what the hand or power saw can come. They offer intricate detail work and cut irregular shapes and complex designs.

4. Speed

Laser cutting is generally faster than saw cutting, especially when cutting complex shapes or multiple pieces. Saw cutting can be slower as compared to laser cutters.

5. Price

The laser machine is costly if we compare the price with an expensive saw. Especially for smaller jobs, a good saw can complete the job at less cost.

6. Safety

Both have safety issues. Laser machines are considered safe as they can be automated and may not require physical contact. Still, they emit high-powered beams, which, if not operated by trained staff, can cause safety hazards. Saw cutting is also dangerous if the operator is not trained or does not know how to use it safely.

7. Hands-off Cutting

Laser machines may require minimum human contact. They may need a workforce to load or unload material, but there is no physical contact during the cutting process.

8. Delicate and Intricate Cutting

Laser cutting is ideal for intricate and delicate work because of its precision and accuracy. The laser beam is focused on the cutting spot and does not affect or damage the surrounding material. This precision and accuracy are not possible with saw cutting. High-intensity light can be directed with high accuracy to cut through various materials. This level of precision means that the laser machine can easily cut intricate and delicate designs without damaging the material or distorting the shape.

9. Finish

Laser cutting offers a better finish than saw cutting. The material may need burring and post-processing after saw cutting.

Conclusion

Both Laser machines and saws are used for cutting materials. They both have their advantages. A laser machine is more precise and accurate, but a hacksaw or jigsaw can do the job easier for a small DIY project. Both are useful cutting methods; the choice depends on the specific application, budget, and use.

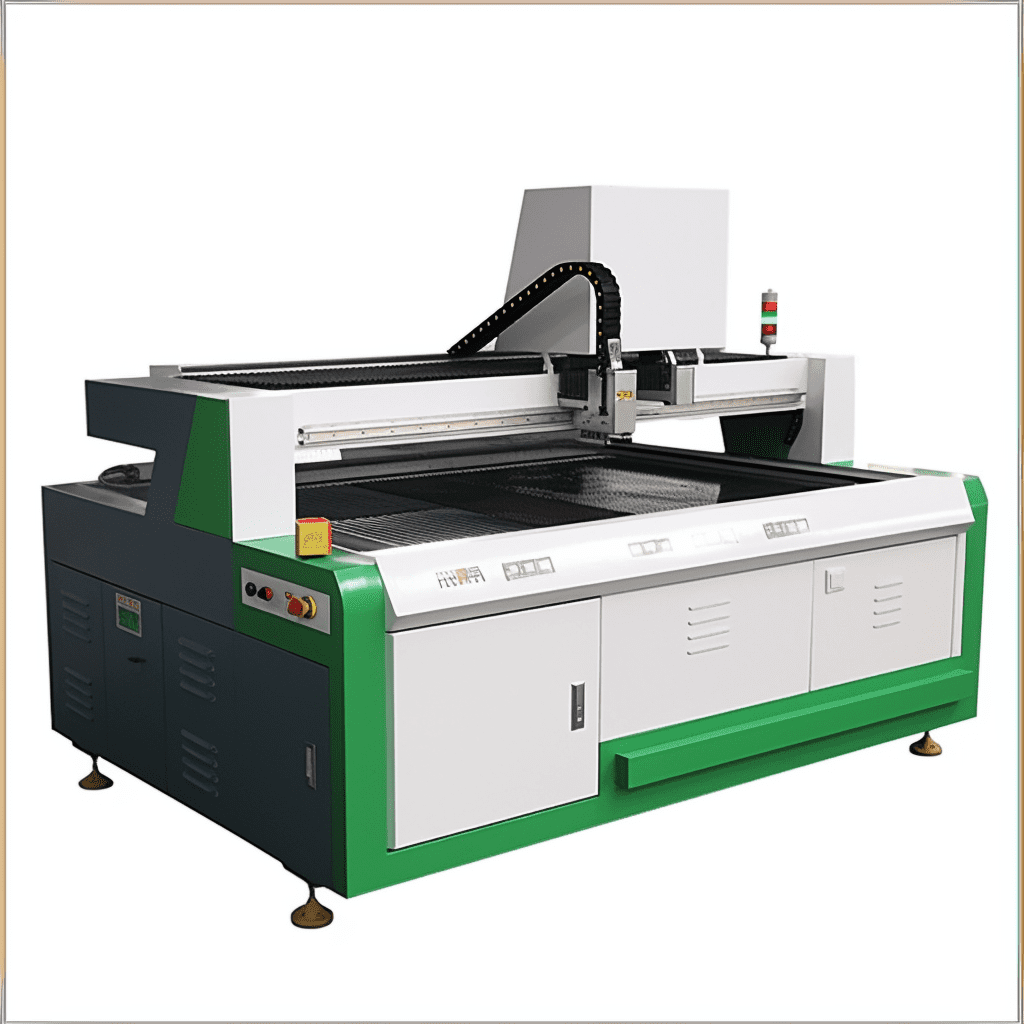

Baison offers high-quality laser machines for cutting. We offer machines that can be used for small businesses and high-powered machines for heavy industrial use. Our laser systems are efficient and user-friendly requiring minimum maintenance.

Upgrade your Cutting Needs with Baison’s Laser Cutting Machines

We offer laser machines for different applications. Contact us to know the details of our machines. Our customer care team is always there to answer your questions. We offer a free sample evaluation of the application to help you choose the best machine for your industrial needs.