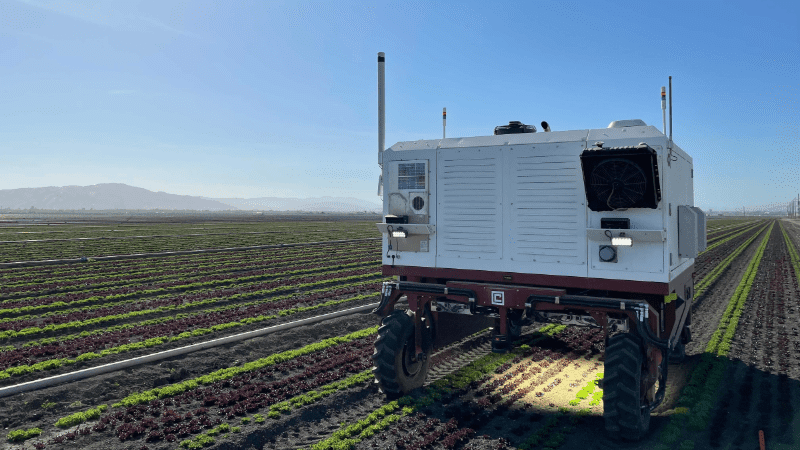

Various equipment, tools, and vehicles are used in farm]ing and agricultural production. These machines are designed to make farming operations more efficient, increase yields, reduce labor costs, and improve crop quality.

Laser-cutting machines have widely replaced the traditional cutting method in the manufacturing industry. They offer the precision and accuracy that these extensive machines need.

This article is all about using laser cutting machines for agricultural machines. We will discuss what laser cutting is, how it is a superior cutting method to traditional methods, and how it can cut production costs and increase production.

What is Laser Cutting Technology?

A laser-cutting machine uses a laser beam to cut metals like sheets, tubes, and other materials. The machine uses a high-power laser beam to vaporize or melt the material.

Laser machines use the CNC or computer design file, and the beam moves according to the specific instructions from the design file. This means accurate design and less material loss during metal fabrication.

Laser machines have cutting heads on the mobile mechanical system, which moves rapidly. The laser beam can cut metal materials, drill holes, engrave designs, or weld components. Besides the cutting process of metal and other materials, laser beams are used for laser welding, drilling holes, and engraving.

Laser Cutting Techniques for Agricultural Machinery Manufacturing

Laser cutters come in different types. Each has specific use and advantage and is useful for different materials.

CO2 laser cutting

CO2 laser-cutting machines use a gas mixture of carbon dioxide, nitrogen, and helium to generate a high-powered beam of infrared light. They are good for cutting plastic, ceramic, wood, and rubber.

Fiber Laser Cutting

Fiber Laser cutting machines are more advanced in technology than CO2 cutters. They also use a focused laser beam generated by a fiber optic laser. The beam is amplified by light and is sent through a fiber optic cable to the cutting head.

Compared to CO2 machines, a fiber laser cutting machine has a narrow beam that makes it more precise. It also consumes less energy and can cut thin materials with high precision. Fiber laser cutters can be more expensive than CO2 cutters, but the running cost is less as no resonant gas is required.

YAG Laser Cutting

Yag Laser YAG (yttrium-aluminum-garnet) laser cutting is another type of laser cutting technology. In these cutters, the laser beam is generated by exciting the crystal with a flashlamp, which causes it to emit a high-energy light pulse. The laser beam is then focused and directed onto the material. It melts ad vaporizes the material with the intense, heated beam.

YAG lasers are typically used for cutting metals, especially those with high melting points, such as stainless steel, titanium, and other alloys. YAG lasers can also cut ceramics, plastics, and other materials. YAG lasers are suitable for cutting thick metals and other materials that are difficult to cut with fiber or CO2 lasers.

What is the Importance of Efficient Agricultural Machines?

Efficient and smart machines are important in agriculture, like any other field. These machines help in cutting time and labor. Automated machines can speed up the harvesting and processing of crops. These machines reduce the need for manual power. Machines can replace labor which reduces cost as well as increase crop output. Superior cutting tools can lead to damage to crops or trees.

Then there are energy-efficient machines in the agricultural industry that can decrease the carbon footprint of farming. Overall, efficient machines can increase the corp output and profit for farmers. Efficient machines also reduce the risk of injury for operators.

Benefits of Laser Cutting Technology in Agriculture

Here are a few benefits of using laser-cutting machines:

Improved Precision

Laser cutters work with a computerized design; a narrow beam cuts materials with high precision. This leads to precise cuts. The narrow laser beam gives precise cuts and can work on the most intricate designs effortlessly. The parts of agricultural machines need to fit together while manufacturing, which makes the precision of laser cutting more advantageous.

Increased Efficiency

A laser cutter works much faster than traditional cutting methods. It can increase the output ten times more without adding extra costs. The fully automated machines reduce manual intervention.

Reduction in material waste

The laser beam is very narrow, and the heat-affected area on the metal surface is accurate. There is no risk of affecting the metals.

Customization

Laser cutting machines offer full customization, essential for manufacturing different parts of machines and tools.

Safety

Laser machines are safer than other machines. They do not require any manual contact with the material being cut, reduce the possibility of accidents,

Versatility

Laser cutters can cut almost all types of materials. They can process all thick or thin metals, plastic, glass, ceramics, and composites.

Reduced Production Cost

Laser machines are automated and require less manual work. That saves on labor. They are also accurate and precise, which means quality production of sophisticated machinery parts. They also have a fast turnaround time and can produce more parts in much less time.

Factors to Consider When Laser Cutting for Agricultural Machinery

Here are a few factors to consider while working with industrial laser cutters:

Material Selection

Laser cutters can handle many materials, but the power control must be adjusted according to the material you are working on. You may need high power while working on thick metal and plastic. In the same way, cutting very thin material with high power may not give very fine results.

Laser power

As with material selection, laser power must be adjusted to suit the thickness and type of material. Agricultural machinery components are usually made of steel, alloys, aluminum, and other metals. So the laser power should be adjusted accordingly. Thin metals or plastic may easily be cut with low-power lasers.

Design and Complexity

The parts of machines have complex designs. These intricate designs. And the number of cuts should be considered while adjusting the speed of the laser machine. Simple cuts take less time, while intricate designs take longer and more power.

Laser Beam Focus

The focus of the laser beam must be adjusted according to the material’s thickness to ensure it cuts all the way through. For example, the laser beam should be focused deeper into the material for thick materials.

Laser Beam Quality

Laser beam quality can be adjusted to suit the thickness of the material. Laser beam quality refers to the spatial distribution of the beam’s intensity and phase. It can affect efficiency ad cut quality. You can adjust the laser beam shape and size from the resonator’s design or use beam shape optics like mirrors or lenses.

Safety Considerations

It is important to take care of the following safety considerations while working on laser machines.

- Wear personal protective gear

- Keep the area ventilated

- Make sure all laser-cutting equipment is selected according to your needs

- Make sure laser machines are kept in a restricted area

- Inspect the machine regularly and perform maintenance

- Make sure the focusing lens beam is directed at the cutting material

- Ensure all staff working with these machines are properly trained and understand the potential danger of laser machines

Applications of Laser Cutting in Agriculture

- Tractors: Tractors and trollies are used for tilling, plowing, and planting fields. They are also used to load crops and send them from farms to the market or storehouses. There is extensive use of sheet metal and other materials in tractors.

- Harvesters: Harvesters are also an essential part of farming. They also have tough metal parts.

- Planters: Manual cutting tools or planters. Despite all the machines, tools are still an essential part of farming. They are made up of hard metal material.

- Irrigation systems: This can include watering systems, sprinkle heads, and other parts made of different materials.

- Sprayers: Farming requires different types of sprays to spread fertilizers, pesticides, and herbicides to crops.

- Hay balers: They are essential machines for balling hay for livestock.

- Livestock equipment: Farming animals are part of the agricultural system. Different equipment is needed for livestock and to process milk and other dairy products.

Final Words

Laser cutting has been increasingly used to manufacture agricultural components due to its high precision, efficiency, and versatility. With laser cutting, manufacturers can produce agricultural components that are more precise, durable, and cost-effective than traditional manufacturing methods.

Laser cutting can also mark and engrave agricultural components, providing essential information such as product identification, manufacturing date, and batch number.

Speed up the Manufacturing of Agricultural Machinery With Our Laser Cutters

Laser cutting has revolutionized the manufacturing industries indeed. Baison is your one-stop for selecting all types of laser machines for different industries. Our laser cutting machines come with state-of-the-art technology that can sheet metal, galvanized steel, or any other material with precision. These laser machines are environmentally friendly, and we have different laser-cutting machines.

Contact us if you are unsure which of our laser-cutting machines suits your industrial needs. We offer free application evaluation.