This blog post will discuss using a pipe-cutting machine to cut angled pipes. We’ll cover everything from choosing the suitable machine to setting it up and making the cut. By the end of this post, you’ll have the knowledge and confidence to make perfect cuts on any angled pipe using a pipe-cutting machine.

What are Pipe Cutting Machines?

Though hand-held pipe-cutting machines are suitable for a small plumbing job or a DIY project for industrial use, we need better precision, speed, and efficiency. Pipe-cutting machines are special machines that cut and shape pipes of various sizes and materials. They are commonly used in manufacturing, construction, plumbing, and other industries requiring precise cuts.

Common types of pipe-cutting machines:

Different types of pipe-cutting machines are available, and each has its method of operation. However, most machines use a blade or cutting wheel to remove material from the pipe. The machine may also have clamps or other mechanisms to hold the pipe during the cutting process securely.

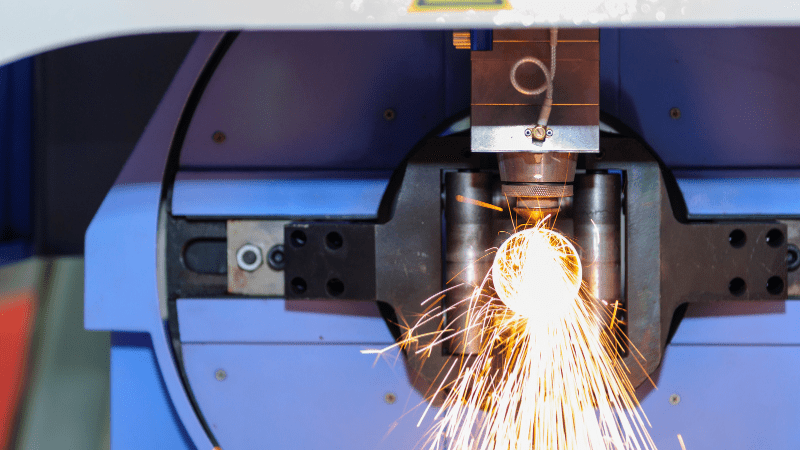

Abrasive Cutting Machines

They use a high-speed rotating blade or cutting wheel coated with abrasive material (diamond particles) to cut through the pipe. However, these machines can be noisy, causing hearing problems for the laborers. They also generate lots of amount of debris and dust. There are also many safety hazards associated with these machines.

Cold Cutting Machines

These machines use a hydraulic or pneumatic system to power a cutting blade that shears through the pipe without generating heat or sparks. This method is limited to cutting pipes made of sensitive materials like plastic or fiberglass and may not suit metal pipes. They also have a limited cutting range.

Plasma Cutting Machines

These machines use a plasma torch to generate a high-temperature plasma arc that melts and cuts through the pipe. They are good for metal and alloy pipes. These machines offer exact cuts with little to no deviation from the intended cut line. They work with speed, but it works slower if we compare the speed to a laser cutting machine. They use a thermal cutting process that involves melting the metal, which can take longer than the non-contact cutting process used by laser machines.

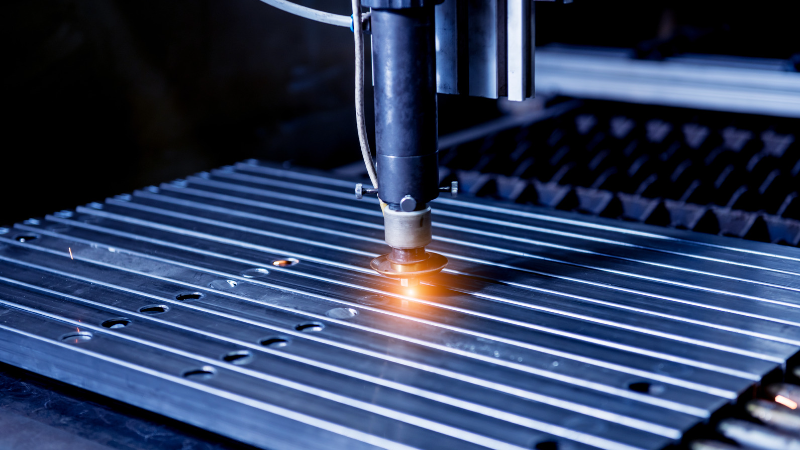

Laser Cutting Machines

These machines use a focused laser beam to cut through the pipe. This method is precise and can cut complex shapes or patterns. They are the most precise ones and rapidly replace old cutting methods due to their better finish and higher output rate.

For more types of cutting machines, you can read the article we’ve written before: 3 Types of Laser Cutters You Need to Know.

Why is it Important to Cut Angled Pipes with Great Finish?

Even a small plumbing job on any construction site is incomplete without an angled pipe. A precise cut ensures the pipe fits properly with other pieces, and the structural design depends on its precise cutting. That makes an angled cutting machine even more critical. Here are a few reasons why angled cuts are so important.

- Aesthetics: An angled pipe with a clean and precise finish looks more visually appealing than a rough cut or uneven finish. This is especially important for visible or exposed pipes in a finished product or project.

- A rough cut or slightly uneven finish leads to leaks, poor alignment, and weak joints. It can not only ruin the aesthetics but can endanger lives and property.

- A precise cut saves time, energy, and material as well. A rough cut or uneven finish may require additional time and effort to correct or additional material to compensate for the poor fit.

Overall, cutting angled pipes with an excellent finish is important for both functional and aesthetic reasons and can lead to a safer, more efficient, and visually appealing end product.

What Safety Measures to Consider while Using a Pipe-Cutting Machine?

Here are some safety considerations while using a pipe-cutting machine:

- Ensure you wear proper protective gear, including safety goggles, gloves, and a face shield. This will protect you from debris that may fly off during cutting.

- Before starting the machine, make sure it is in good working condition. Check the blades to ensure they are sharp and not damaged. Also, ensure the machine is properly grounded to avoid electrical hazards.

- Set the cutting machine to the appropriate angle for your cutting pipe. Make sure the machine is calibrated correctly and set up according to the manufacturer’s instructions.

- Make sure the pipe is securely clamped in place before you start cutting. It will prevent the pipe from moving or shifting during the cutting process, which can lead to accidents.

- Make sure you use the right blade for the job. A blade that is too small or not designed for cutting angled pipes can break or cause accidents.

- Use the machine according to the manufacturer’s instructions and follow proper cutting techniques. Do not force the blade through the pipe or exceed the machine’s cutting capacity.

- After using the cutting machine, make sure to clean up any debris or scraps from the work area to avoid tripping hazards.

What is the Process of Cutting Angled Pipes with Pipe Cutting Machine

Cutting angled pipes with a pipe-cutting machine typically involves the following process:

- Choose the appropriate cutting machine: Select a pipe cutting machine suitable for the type of pipe you want to cut and the cut angle you need. It largely depends on the type of material, Its length, and thickness.

- Secure the pipe: Use clamps or vices to securely hold the pipe on the machine’s bed or work surface.

- Adjust the machine: Set the cutting angle and depth on the machine according to the specifications of the pipe and the desired cut.

- Start the cutting machine and allow it to reach the appropriate speed and cutting depth.

- Slowly and steadily feed the pipe into the machine’s cutting blade, ensuring that the blade is cutting at the correct angle.

- Remove the cut pipe: Turn off the machine and remove the cut pipe from the clamps or vices.

- Inspect the cut: Check the angle and quality of the cut to ensure that it meets your requirements.

- Repeat the process for additional angled cuts on the same pipe or other pipes if necessary.

What Should We Do After Cutting the Pipe

After the angled pipe is cut from the cutting machine, you should follow these steps:

- Inspect the cut end of the pipe to ensure that it is straight, smooth, and free of burrs or sharp edges.

- If necessary, use a deburring tool or sandpaper to remove any burrs or sharp edges from the cut end of the pipe.

- Measure the length of the cut pipe to ensure that it is the correct size for your project.

- Use appropriate tools and safety equipment if you need to cut or modify the pipe.

- If you are ready to install the pipe, ensure that the pipe is properly aligned and connected to other pipes or fittings as necessary.

- If you are not ready to install the pipe immediately, store it in a clean, dry, and protected location to prevent damage or contamination.

- Dispose of any waste material from the cutting process appropriately, following local regulations and guidelines.

Advantages of Buying a Cutting Machine

Pipe-cutting machines are designed to cut pipes quickly, accurately, and efficiently. Here are some advantages of using pipe-cutting machines to cut angled pipes:

Precision and Accuracy

Pipe-cutting machines are designed to cut pipes with high precision and accuracy, ensuring the cuts are clean, straight, and accurate. This is especially important when cutting angled pipes, as any deviation from the required angle can result in faulty connections or a weak joint.

Time-saving

Pipe-cutting machines are incredibly fast, allowing you to cut multiple pipes in a short amount of time. This can save significant time compared to manual cutting methods, which can be tedious and time-consuming.

Cost-effective

Pipe-cutting machines can help reduce material waste, as they can cut pipes with minimal waste, saving you money on material costs. Additionally, their speed and efficiency help reduce labor costs by reducing the time required to cut pipes manually.

Improved Safety

Pipe-cutting machines are designed to be safe, with features such as guards and emergency stop buttons to prevent accidents. It makes them safer than manual cutting methods, which can be dangerous, especially when cutting angled pipes.

Versatility

Pipe-cutting machines can be used to cut a wide variety of pipes, including angled pipes, with ease. This makes them a versatile tool for various applications, from plumbing and HVAC installations to metalworking and construction projects.

Conclusion

Overall, pipe-cutting machines are excellent for cutting angled pipes, offering precision, speed, efficiency, cost-effectiveness, safety, and versatility. A laser-cutting machine may cost you more upfront but increases productivity and quality.

Baison offers several pipe-cutting laser machines covering small to big industrial needs. High-Output Fiber Laser Tube Cutting Machines are versatile for every sized option. We have small tube laser cutting machines for the heavy-duty machines used in industrial manufacturing. Besides our tube-cutting machines, we have multi-function laser cutting machines or sheet and tube-cutting machines that cut through sheet and metal pipes and tubes with uncompromising precision for complex industries.

Revolutionize Your Pipe Fabrication with Baison’s Laser Cutting Machines

Our machines are specifically designed to cut pipes and angled pipes with precision and speed, saving you valuable production time and reducing material waste.

Investing in our laser-cutting machines will improve your production process and increase the quality and consistency of your products. If you are not sure which one suits your industrial needs, help us evaluate, as we offer free evaluation. With our technology and dedicated customer support team, you can trust that you’re making a smart investment in the future of your business.

Don’t wait any longer to upgrade your pipe fabrication process. Contact us today to learn more about our laser-cutting machines and how they can benefit your business. We offer a free evaluation to help you choose the best machine that suits all your needs.