The unparalleled laser technology has become an imperative component of several industries. From manufacturing to food and healthcare, this technology has immense applications. However, the effectiveness of laser technology is significantly affected by the quality of the laser beam.

In this blog post, you’ll explore the process of measuring laser beam quality. You’ll also learn about ways to improve the laser beam quality. So, let’s dive into it.

Understanding Laser Beam Parameters

Several parameters characterize a laser beam. Here are some of the commonly used parameters for estimating laser beam quality:

1. M2 Factor

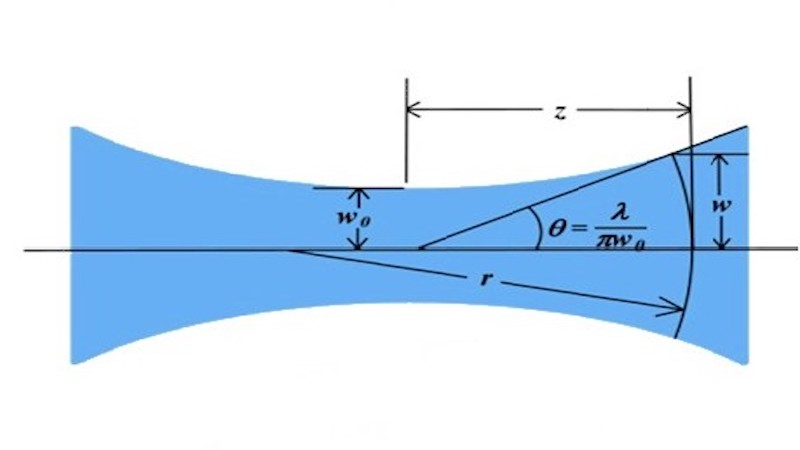

It is a significant parameter for determining the quality of a laser beam. This factor compares the shape of the Gaussian beam. According to ISO Standard 11146, the value of the M2 factor is:

M2 = πw0θ/λ

Here, w0 indicates the beam waist, θ represents the divergence angle of the laser, and λ denotes the lasing wavelength.

You can derive the divergence angle of a Gaussian beam by using the following equation:

θ = λ/πw0

Incorporating the divergence angle in the equation for the M2 factor enables you to calculate the value of the M2 factor accurately. After inserting the divergence angle, the final equation for M2 becomes:

M2 = πw0/λ×λ/πw0

If the value of the M2 factor comes out to be 1, it represents a diffraction-limited Gaussian beam. If the value of the M2 factor comes out to be larger than 1, it indicates the deviation of the laser beam from the ideal Gaussian beam. However, you can’t achieve a value of M2 factor less than 1.

The calculation of the M2 factor is necessary for applications where the laser beam is focused on a spot. The value indicates the effectiveness of the focus of the laser beam. The lower value of M2 shows that the spot is intense and effectively focused.

ISO 11146 standard suggests recording five beam-radius measurements at variable positions in near and far fields along the propagation axis. In some cases, the cross-section at a particular plane may appear like a Gaussian distribution; however, the actual beam propagation differs significantly from a Gaussian beam. In such scenarios, the laser beam has a greater divergence angle.

2. Beam-Parameter Product (BPP)

The beam parameter product (BPP) is another significant parameter for estimating the quality of the laser beam. As per ISO 11146 standard, BPP is calculated as a product of the beam radius and the half-angle beam divergence. The beam radius measurements are taken at the beam waist, and the half-angle beam divergence is determined in the far field.

The following equation shows the relation between BPP and M2 factor:

BPP = M2λ/π = πw0θ

The equation shows that the beam parameter product is directly proportional to the M2 factor. It means that a laser beam with a larger BPP value is not like a Gaussian beam and has a worse quality. λ/π is the minimum value that you can achieve. It corresponds to an ideal Gaussian beam.

3. Power in The Bucket

According to Spiedigitallibrary, this parameter is commonly utilized in high-power laser applications and materials processing. It is used for determining beam quality and propagation. Power in the bucket refers to the amount of laser power that is delivered into a cone. It is calculated in angular units λ/D that are referred to as “buckets.” Here, λ represents the wavelength of the laser beam, and D shows the characteristic size of the initial beam.

Due to a lack of industry standards for this parameter, it is generally measured as vertical or horizontal beam quality. The following equation represents vertical and horizontal beam quality:

Vertical Beam Quality = √Ideal Power in Bucket/ Actual Power in Same Bucket

Horizontal Beam Quality = Actual Beam Radius at a Given Power/ Ideal Beam Radius at the Same Power

Like the other two parameters, low power in the bucket represents a high quality of the laser beam.

Do You Have Any Questions?

Let Us Solve Your Problem

Why is It Important to Understand Laser Beam Quality?

The laser machine is a paramount equipment for several industries. The accuracy of the end product in these fields relies on the quality of a laser beam. Here is an overview of the significance of understanding laser beam quality:

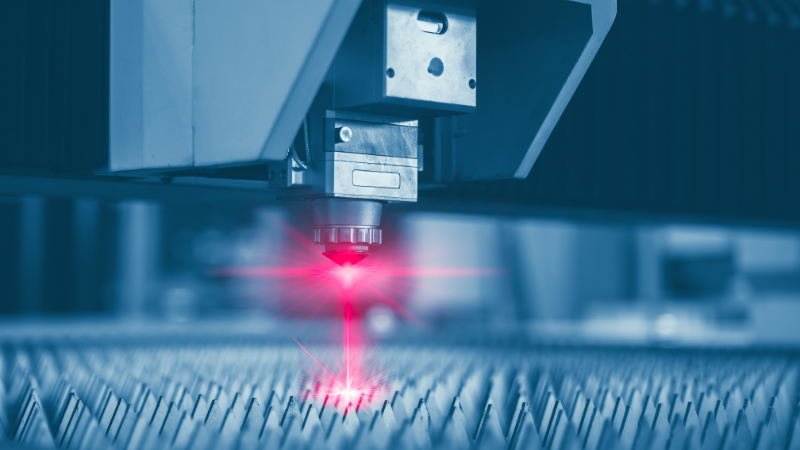

1. Impact on Laser Cutting

Laser cutting involves cutting hard and sensitive materials using a high-energy laser beam. A high-quality laser beam with less divergence and a sharp focal point helps you gain precise cuts. In contrast, poor beam quality damages the material, leading to material wastage.

A better-quality laser beam produces clean cuts with minimum rough edges. It minimizes the requirement for post-processing, minimizing the overall laser cutting costs and efforts. You need to spend less time and money on post-processing procedures. It saves you considerable cost and time.

2. Impact on Laser Marking and Engraving

Laser marking is another popular technique used in several industries. The quality of the beam ensures consistent and refined engraving. It also helps you achieve detailed marking. Moreover, low divergence angles offer concentrated beams, resulting in effective vaporization of the material.

The mode of the laser beam also impacts the quality of a laser marking. A laser beam with Gaussian mode offers a more concentrated and sharp beam than flat-top mode. The beam shape is another factor that influences the results of laser marking.

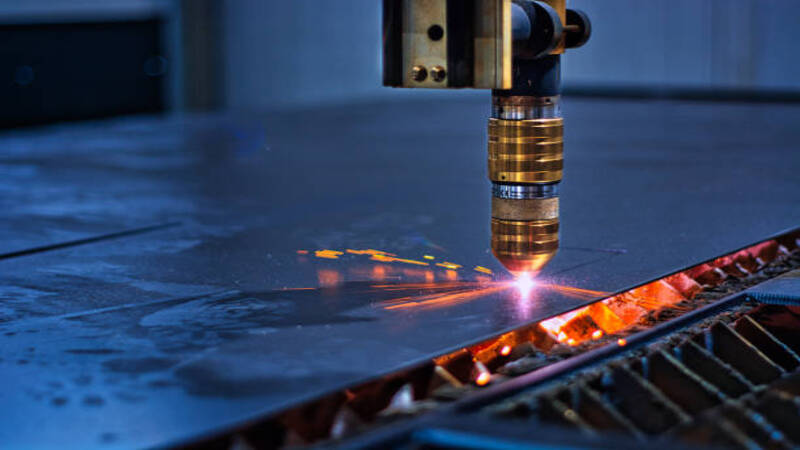

3. Impact on Laser Handing

A laser creates a high-energy beam that can melt and vaporize the material. A high-quality laser machine generates a precisely focused beam. It minimizes the risks of material damage and material wastage.

Employing optimized laser beam widths becomes necessary while dealing with expensive materials to maximize efficient usage of the material and the safety of the final product.

4. Impact on Results

Understanding the quality of a laser beam enables you to optimize the laser machine to obtain particular results. As the quality of the beam affects the results, you can minimize the defects and inconsistencies in the final products. It enables you to improve customer satisfaction by offering desirable results.

Factors Affecting Laser Beam Quality

Several factors affect the laser beam quality. The following are some prominent factors that influence the quality of the laserbeam:

1. Laser Diameter

The laser beam diameter defines the beam’s size perpendicular to its propagation direction. Laser beam radius is also used in place of laser diameter. Laser diameter is the beam’s transverse extension. However, most laser beams, including Gaussian beams, do not have well-defined boundaries. Laser professionals set a particular standard to determine the diameter of laser beams.

The value of 1/e2 is used to determine the diameter of the laser beam. According to the Coherent, 1/e2 is 13.5% of the maximum intensity of the laser beam. The boundary of the laser beam is considered the point when its intensity falls below 1/e2 to its peak value. A short beam diameter enhances the energy density of the laser beam. A larger beam diameter increases the chances of beam clipping, and you need additional costs to avoid this issue.

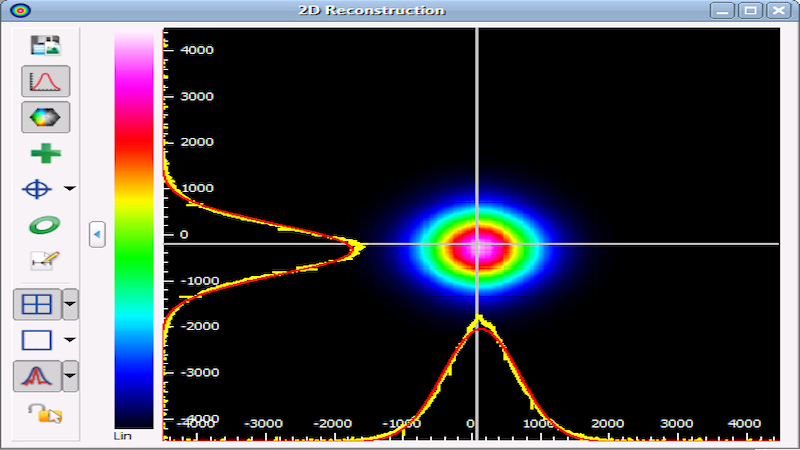

2. Beam Profile

The beam profile of a laser beam indicates the spatial distribution of its intensity. Two types of beam profiles are common. One is a Gaussian beam profile, and the other is a flat-top beam profile.

However, no laser beam is perfectly Gaussian or flat-top in practical scenarios. The fluctuations in the laser machine make the laser beam different from a Gaussian or flat-top beam. You can use the M2 factor to determine the difference between a real laser beam and an ideal Gaussian beam.

3. Divergence

Beam divergence indicates how much a beam expands as it travels away from the laser beam waist. The divergence is caused by diffraction and is a major problem when employed over long distances. Various applications where the targeted object is hundreds of meters apart from the beam source.

The divergence depends on the laser beam’s wavelength and waist. A greater beam wavelength has a greater divergence angle. Greater laser beam waist corresponds to lesser divergence.

4. Beam Stability

Beam stability also affects beam quality. It represents the variation in different beam parameters over time. A stable laser beam maintains its orientation, shape, intensity, and position over time. The stability of the laser beam is necessary for various applications.

Various aspects affect the laser beam stability. It includes the stability of the laser source, thermal and mechanical stability of various optical components present in the path of the laser beam, and surrounding conditions.

Do You Have Any Questions?

Let Us Solve Your Problem

Techniques and Tools for Measuring Laser Beam Quality

Several tools and techniques have been developed for accurately measuring the laser beam quality. The following are some commonly used techniques and tools for measuring the quality of a laser beam:

1. Lens

A lens is a crucial tool for measuring and analyzing the quality of a laser beam. It enables you to focus the beam at the required position. A standard lens is used whose properties are known to determine the position of the beam waist conveniently. Understanding the position of the beam waist enables you to measure the beam diameter at the perfect distances to calculate the M2 factor accurately.

2. Beam Profilers

Beam profilers are specially designed equipment for capturing and analyzing the spatial intensity distribution of a laser beam. Among various techniques beam profilers use, knife-edge and camera techniques are the most common.

Knife-edge techniques employes slit or spinning blades to cut the laser beam before it reaches the power meter for detection. The intensity of the laser beam is measured as a function of time. The algorithms assist in the reconstruction of the original beam profile.

The camera technique directly illuminates a camera sensor. The laser beam is directed to a flat diffuse surface, and a lens directs the light onto a CCD (charge-coupled device). It enables you to create beam profiles of large-diameter beams.

3. Ruler

You don’t need any special tool to measure the distance accurately when measuring the laser beam quality. A ruler is used for this purpose. The main objective of using a ruler is to establish the correct distance between the sensor and the focal point.

5 Tips for Improving Laser Beam Quality

Improving the laser beam quality is crucial for obtaining desired outcomes. Here are some tips to improve laser quality:

- Use a high-quality laser source that has excellent stability and minimum noise. Effective mode control of the laser source is also necessary to establish higher power and better laser beam quality.

- The quality of optical components, including lenses, mirrors, polarizers, or fillers, also affects the quality of the laser beam. High-quality optical components allow you to maintain beam shape, size, and orientation.

- Creating custom beam patterns is another way to improve laser beam quality. Active and passive beam-shaping devices are best for establishing customized beam patterns.

- Proper monitoring and adjustment of a laser beam is also an effective way to create a better-quality laser. Feedback and control systems can significantly contribute to maintaining and adjusting the beam.

- According to Optica, the coherent combination of lasers in the Michelson cavity can efficiently improve the quality of the laser beam.

Do You Have Any Questions?

Let Us Solve Your Problem

FAQs

1. What are the parameters of laser beam quality?

Several parameters determine the laser beam quality. It includes beam diameter, beam profile, divergence, and beam stability. In addition, the beam quality factor is another prominent parameter for measuring laser beam quality.

2. How do I choose a beam?

You need to choose the size of the beam depending on the distance it needs to cover. Also, choose the load your beam has to support. Moreover, considering the material properties, it will target to choose the right beam.

Conclusion

The demand for high-quality lasers is escalating with the effective use of lasers in various fields. The quality of laser beams has become a paramount feature for obtaining the desired products. The increasing use of lasers in precision-demanding fields, like medical science, also harbors the demand for quality lasers. Accurate measurement of a laser beam’s quality parameters can significantly improve the results.

Baison Laser offers the best-quality laser machines with excellent laser quality. Its laser cutters, markers, and cleansers enable you to fabricate desired products. So, check the quality of the laser beam and improve it before starting your project.

Get a High-Quality Laser With Baison Laser!

The quality of the laser determines the quality of the beam. Baison Laser offers you excellent laser machines that generate high-quality laser beams. Contact us today and get a new, high-end laser.