Are you looking for the best laser engraver for your work? Then, you are in the right place.

Here we will discuss all the important aspects of the fiber laser marking system and how it best fits you. Medical, production, and other industries can use this machine for different applications. It’s also best for companies who are looking for higher efficiency. So, read further to learn more about the laser marking machine.

What is a Fiber Laser Marking Machine?

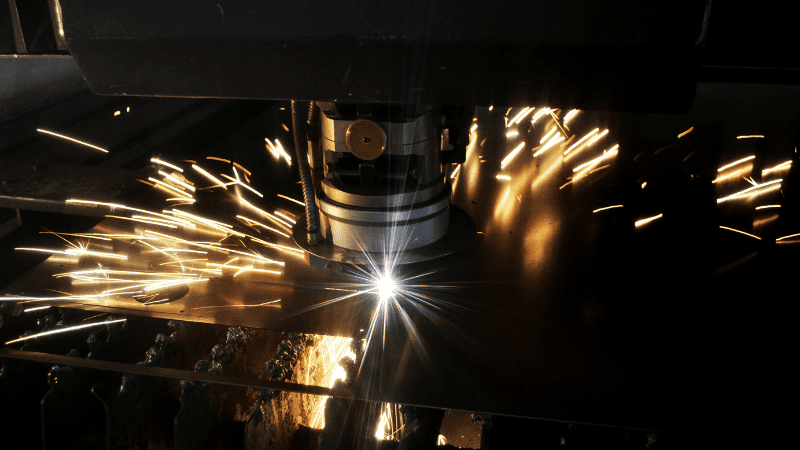

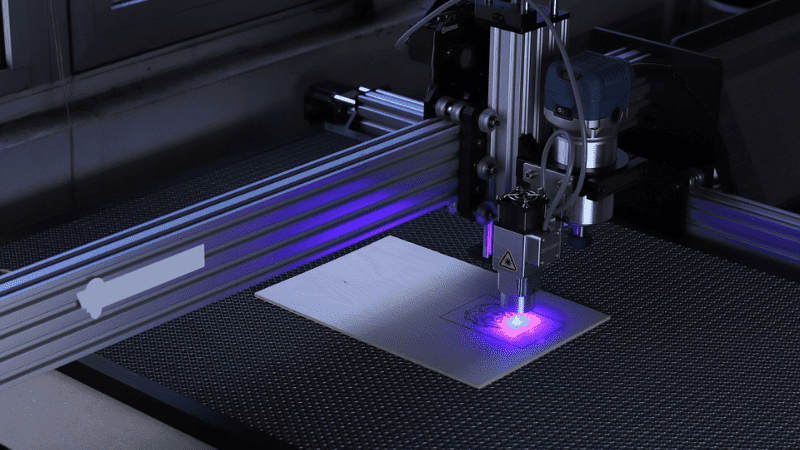

Fiber laser marking is a technique of leaving an impression on items with the help of a fiber laser of light.

The marking machine uses concentrated energy from light energy and turns it into a laser beam. This beam passes through an f-theta lens, which helps the light to focus on the whole plain. The concentrated laser beam creates distinct marks when passed over any surface. Note that different material surfaces absorb different wavelengths of light.

How do Fiber Laser Marking Machines Work?

Laser marking machines use a focused beam of light to mark the surface. When the light falls on the item’s surface, it changes the material’s appearance and properties.

This beam targets only a particular surface, allowing the laser marking system to create high-quality, precise, high-contrast marks that are easy to scan or read on virtually any surface. This feature makes machines ideal for applications where permanency and accuracy are important.

Advantages of Fiber Laser Marking Machines

1. Effectiveness

The fiber laser market makes marks that don’t fade due to environmental changes, time, or other elements. The marking effect is challenging to change and has a great anti-counterfeiting function. This is why fiber laser marking machines work great for automotive and other industries, where manufacturers must provide the exact design.

2. Non-contact Process

The energy carrier of fiber lasers is a beam of uniform wavelength. It doesn’t generate any mechanical stress while irradiating the surface of any material. This is why it doesn’t affect any mechanical properties of the material you use. It also eradicates noise pollution and chemicals. Therefore, the marks are tidy and clean.

3. High Quality and Precision

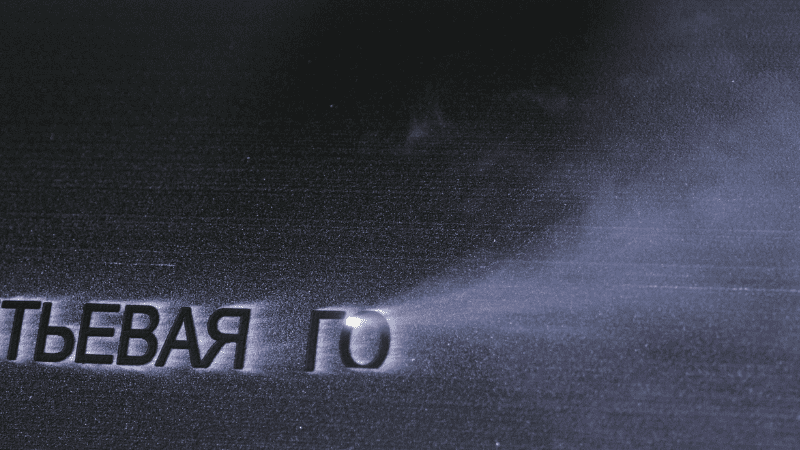

A fiber laser engraving machine is a highly precise engraving device. The machine uses high-precision laser technology to offer micro-level accuracy, ensuring accurate and fine engraving results.

Also, the beam output center of the device is 1064nm. The spot pattern of these machines is excellent, and the focused spot diameter is usually around 20um. Apart from that, the single line is thinner, and the divergence angle is 1/4.

Hence, it can offer ultra-fine and precise processing. When it comes to the marking quality of the device, the text information marked by the laser is permanent and clear and will not fall off or fade.

Comparing Different Marking Machines

I. Inkjet Printing Machines

Inkjet printing engrave marks on packaging and products by placing ink on the item’s surface. The inkjet coders virtually print on materials like wire, plastic, cable, metal, paper, glass, resin, and more. Manufacturers use it to print common symbols like lot numbers, dates, serial numbers, date codes, and barcodes. Inkjet printing is different from fiber laser marking machines.

The software present in the coder controls the jet to create print 1D and 2D marks. This allows the company to mark its packaging and products to track items permanently. This is also important to facilitate quick recall when necessary and meet regulatory requirements. Its ability to limit the risk of blurred or smeared printed codes, ensures these codes stay readable throughout the distribution and production process.

II. CO2 Laser Machines

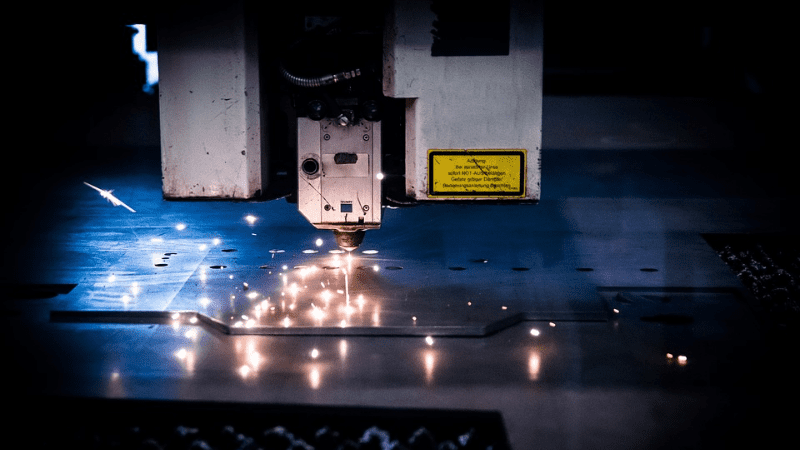

CO2 laser machines use sheet metal processing techniques that utilize an electricity-driven gas laser. It features a laser that cuts contours over different metal sheets such as stainless steel, steel, or aluminum.

This machine offers accurate results and allows you to work on complex designs. Hence, you have a lot of shaping freedom compared to other printing machines. These machines are also one of the oldest printing devices. In fact, its origin is traced back to the 1970s.

This cutter machine generates the laser beam in a sealed glass tube that includes gas like carbon dioxide. When the machines start, a high voltage passes through the tube and reacts with the gas particles, raising their energy that generates light. A particle with a strong light that is heated can be extremely strong enough to vaporize materials with hundreds of degrees Celsius melting points.

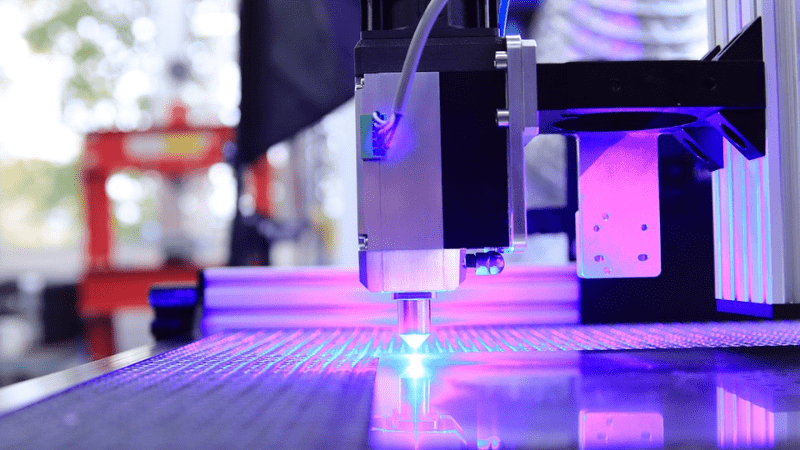

III. Green Laser Machines

These machines are made to mark highly reflective surfaces. Green laser machines also work best for highly sensitive substrates such as silicon wafers. It is designed to exhibit exceptional results and high precision. These machines feature 5-10 watts of power range. They are also ideal for soft plastics, integrated circuit chips, and PCB Boards. They are also used for marking or scribing Solar Cells of different material compositions.

Since the machine uses a 532nm wavelength, it provides greater absorption for different materials. It mitigates thermal energy, allowing the machine to mark substrates you can’t receive from the higher wavelength. Another advantage of this machine is that it can mark tight spot sizes of more than 10 µm.

Here’s an article on Fiber Laser vs. Green Marking Machine for your edification.

IV. UV Laser Machines

UV technology uses a band of the electromagnetic spectrum with a wavelength of 10nm to 400 nm. These are longer than X-rays but shorter than visible light. Additionally, long wavelength UV is different from ionizing radiation, as its photons don’t contain energy that can ionize atoms. But it can lead to chemical reactions that make substances fluoresce or glow. Therefore, UV’s biological and chemical effects are more than simple heating.

Also, most of the applications of UV radiation only occur due to its interactions with organic materials. UV laser marking machines are the result of this technology. They come with 355 UV laser wavelengths and can engrave different materials.

You can use them for cold marking applications, which don’t require heat from lasers. This machine can mark substances like glass, plastics, and ceramics without additives. Since they have a high-quality beam, these machines can micro-mark electronic microchips and circuit boards. Many manufacturers also use it for precise medical equipment marking and solar panels.

We have also prepared an article on fiber lasers and UV marking machines for you to learn more.

What to Consider When Choosing a Fiber Laser Machine

Choosing a suitable laser marking machine can make a huge difference to your production. It also determines the profitability of the project. Here are a few factors that you should consider when making your choice.

1. Material Compatibility

The first thing you need to consider is the type of material needed to engrave. There are two types of materials: non organic materials and organic materials. Organic materials are plastics, glass, paper products, and wood. You can use the fiber-cutting machine for both materials.

2. Marking Speed and Precision

The engraving speed is one of the main factors that you need to consider. The speed is directly proportional to the strength of the optical fiber power source. So, the more laser power, the higher the speed you can expect.

This means you need to choose a 30W laser, which can give you a deep engraving depth of 0.3mm with a speed of more than 4000 millimeters per second, offering you great results. Therefore, if you want to engrave at high speeds, you need to look for a fiber-optic laser with 30W. With this machine, you can also expect to get precise results.

3. Laser Beam Power

The more powerful the laser is, the faster the process will be. You need to determine your type of cycle time for the operation. If you need short cycle times, higher-power machines are the best option. But if not, you can opt for low-power laser engraving machines.

4. Ease of Use and Maintenance

The fiber laser marking machine should be easy to use. Whether a small business or a bigger corporation needs it, the simple and easy usage offers to speed up a deficiency in the production line department. It should have easy-to-understand features and a simple operating process.

Besides that, you need to consider maintenance. How many times do you need to asses or repair the machine? Do you need to perform regular maintenance and cleaning? And how much will it cost you? This will help you choose the right machine that is low maintenance.

5. Beam Quality and Electrical Connection

The laser with higher beam quality can engrave surfaces much faster, with improved quality, and with better resolution. Laser marker machines with better beam quality can generate a focused optical spot size down to less than 20 microns.

Like all the other electrical equipment, if the machine fails to meet the requirements of your locality, you might get charged for installing it. For instance, the “UL” certification is considered in the USA and CSA in Canada. Besides that, look at whether the machine’s electrical connection has any electrical restrictions. This helps you determine what precautions you need to take while using it.

Applications of Fiber Laser Marking Machines

Laser marking machines play an important role in many industries. Here are 4 of the most representative industries.

I. Packaging Industry

The product packages are labeled, which is done through laser marking. In fact, laser engraving is the preferred option for most manufacturers. The companies use the technology to engrave QR codes, bar codes, part numbers, serial numbers, logos, and trademarks on the packaging. Many traceability solutions can affect brands’ goals and success and ensure customer satisfaction.

II. Automotive Industry

Laser marking technology is the main tracking tool for auto component manufacturers. All plastic and metal vehicle components need a certain marking for their identification. The innumerable advantages of the fiber laser machine help companies create these markings with ease and speed.

III. Jewelry Industry

Laser marking devices are also commonly used to create complex designs on different types of jewelry, like earrings, necklaces, and pendants. Since this technology helps to engrave small areas yet provides precise results, you can manufacture beautiful and long-lasting jewelry with laser help.

IV. Medical Industry

Manufacturers that produce machines for medical purposes require permanent marks on steel, plastic, or other metal surfaces. Besides machines, they also need them for non-metal materials like packaging or labeling.

How to Maintain a Fiber Laser Marking Machine?

Laser equipment is inevitably subject to wear and tear during use. Maintaining the machine is necessary for the production process.

1. Cleaning and Maintenance Schedule

You need to regularly clean and maintain your machine. Weekly cut head, check the level of circulating water, and lubricate oil on the guide screw. You must also clean the lens, check the travel switch bracket, and clean the muffler filter. Try to set a daily maintenance and cleaning schedule to keep your machine in good condition.

2. Replacement of Consumables

You need to replace consumables in around one year. This helps your machine to work efficiently and offers promising results. If not replaced, it can impact the life span of your laser marking machine.

3. Regular Calibration and Inspection

We advise people to check the calibration regularly, at least within 6 months. You can do it early if you have used the laser levels roughly when they give you their specific accuracy level. Also, hire experts to inspect the machine regularly so you can repair it before it needs to be completely replaced.

4. Cooling System Maintenance

You need to replace the water regularly present inside the water cooler. In general, it’s best to replace it for at least one month. You also need to use distilled water for the water cooler or deionized water if there are no particular requirements.

Safety Precautions for Using a Fiber Laser Marking Machine

Although laser equipment is safe nowadays, there are some precautions to be taken when using it.

1. Durability and Safety Features

Make sure to choose a durable and long-lasting machine that doesn’t waste your money. You also need to look for laser systems with CE certification and a hermetically sealed beam path. These things ensure that your machine is safe to use.

2. Proper Machine Use

It’s important to understand how to use the machine to avoid accidents and problems. Therefore, read the operating instructions before you start to use it. Also, avoid direct exposure to a laser beam that can cause injuries.

3. Personal Protective Equipment

While using the fiber laser machines, you need to wear personal protective equipment. This includes safety goggles, gloves, and other things. This will help you avoid accidents during the operation.

The Significance of Fiber Laser Marking Technology for Businesses

Fiber laser marking solutions are best for manufacturers seeking ease of usage and maintenance. It also works great for companies with vast production lines, as you can use it for different materials. Also, this durable machine can go a long way if you use it with care and precautions. So, a fiber laser marking machine is perfect if you are looking for optimal features.

Conclusion

In a nutshell, machines that offer fiber laser markers are ideal for manufacturing that needs a simple marking process. It’s also ideal for someone who has used different printing and engraving machines but doesn’t get satisfactory results. With the higher marking depth, complex design capability, higher laser energy, and excellent precise results, fiber laser marking machines are best for you.

Get a Fiber Laser Machine and Resolve Your Problems

If you are looking for advanced technology for laser engravers, Baison Laser is here to help you. We provide the highest quality machines with the guidance and support you need to make the most of them. So, contact us and boost your production and sales.