We’ll delve into how our welding solutions address common business pressures and set the standard for the future of welding. So, join us as we unpack how the technology turns welding processes into a sustainable competitive advantage that fuels your bottom line.

What is Handheld Laser Welding Machine?

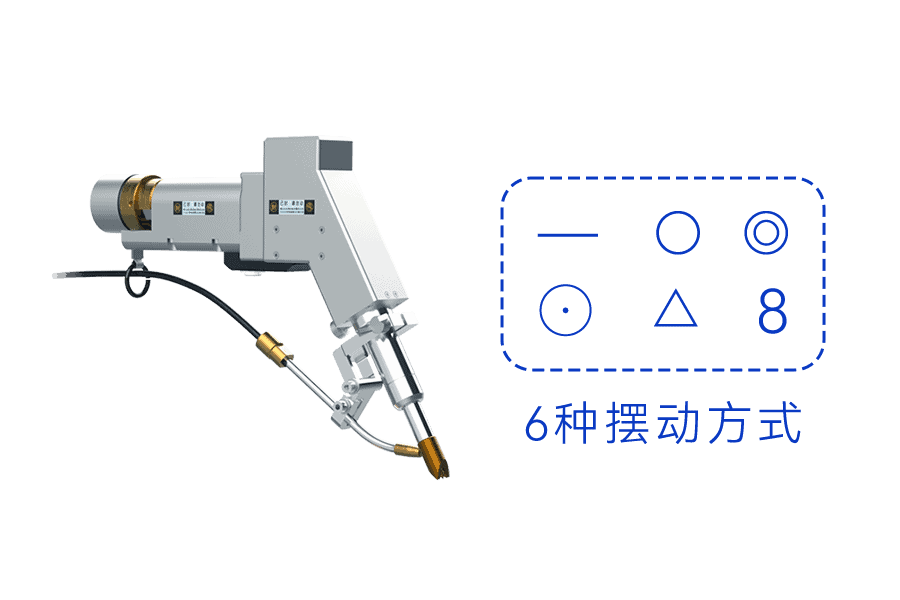

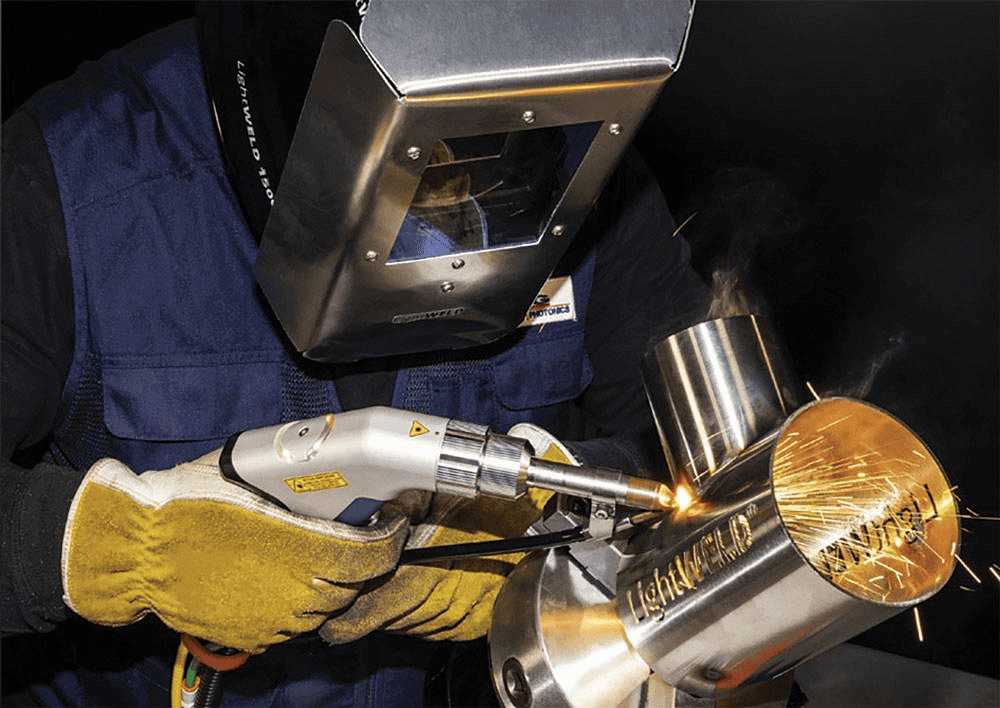

Handheld laser welding machines, characterized by their unmatched precision and efficiency, are redefining the fabrication process and enhancing productivity and quality across diverse industries. These machines’ ability to seamlessly fuse various materials, especially sheet metal, has led to a substantial reduction in labor costs and a boost in output. This versatile and user-friendly design is ideal for a broad spectrum of tasks, from large-scale assemblies to complex outdoor welding operations.

Moreover, these machines stand as a testament to technology integration and sustainability. Handheld laser welding machines, unlike traditional methods that generate harmful fumes and waste, provide a cleaner, more environmentally responsible alternative. This commitment to reduced environmental impact aligns with the global emphasis on sustainability, positioning these devices as an excellent business investment that also promotes responsible operations.

Advantages of Handheld Laser Welding Machine

You must be wondering how shifting from traditional argon arc welding to the more advanced handheld laser welding device can benefit your business. Well, there is more than just reason.

Here are some of the key advantages of the handheld laser welder:

- Environmental Protection: Laser welding is a clean process with little to no waste, contributing to a greener environment. Unlike traditional welding methods, it doesn’t generate harmful fumes or residue.

- Energy Efficiency: In an era where businesses strive for both economic and environmental sustainability, the handheld laser welding machine shines. Its high efficiency translates into reduced energy consumption. For instance, a furniture manufacturing plant, which often operates high-energy tools, can significantly decrease its energy bills and carbon footprint by integrating these laser welding machines into its production process.

- Minimal Distortion: When precision is paramount, as in manufacturing delicate components in the electronics industry, these machines are ideal. Utilizing a low heat input, they minimize the deformation of thin plates and materials, thereby preserving the original quality. This feature is especially valuable when working with thin circuitry or tiny mechanical parts where any distortion can lead to functional failures.

- Reduced Labor Costs: The speed and efficiency of the handheld laser welding machine bring considerable savings in labor costs. For instance, in a shipbuilding yard, where welds are numerous and large-scale, the machine’s faster welding speeds and reduced need for subsequent polishing and grinding can save countless man-hours, leading to substantial cost savings.

Comparison with Traditional Welding

To truly appreciate the efficiency of handheld laser welding machines, it is imperative to juxtapose them against conventional welding methods. This juxtaposition unravels the distinct advantages proffered by handheld fiber laser welders, spanning aspects like precision, rapidity, energy efficiency, and environmental sustainability. Let’s embark on a detailed exploration of these attributes.

Superiority in Precision

In the realm of welding quality, handheld laser welders hold a distinct edge over conventional TIG welding and MIG welding approaches. Leveraging the accuracy of laser beams, these machines assure minimal welding scars and cleaner, visually pleasing welds. The handheld laser welder ensures reduced weld splatter, decreasing the requirement for subsequent cleaning and guaranteeing a superior quality weld seam than tig welding.

Speed and Productivity

Handheld laser welding machines revolutionize operations with unprecedented speed and versatility in automotive and heavy machinery manufacturing. They drastically cut welding times and streamline handling diverse materials, boosting productivity. These machines, therefore, set a new efficiency benchmark in the industrial world.

Energy Efficiency

Energy consumption is another area where the handheld laser welding machine distinctly outshines traditional welding approaches. Designed for maximum efficiency, it utilizes less power for equivalent output, thereby contributing to environmental sustainability and minimizing operational expenses.

User-friendliness

In contrast to conventional welding methods, which demand substantial skill and experience, a handheld laser welder has a more manageable learning curve. The device’s intuitive interface and ergonomic design enhance user-friendliness, reducing reliance on skilled welders and consequently bringing down labor expenses.

Environmental Sustainability

Handheld laser welding machines are allies of environmental preservation. They operate with reduced energy, diminishing greenhouse gas emissions. Moreover, they generate fewer pollutants, such as weld splatter or fumes, compared to traditional welding methods. This makes them an optimal choice for businesses seeking low-cost, environmentally responsible welding solutions.

Tips to Choose a Handheld Laser Welding Machine

When you are in the market for a handheld laser welding machine, you’ll need to consider various aspects to ensure you make an informed decision. This process can be intricate due to the wide range of available models, each with unique features and benefits. Let’s see how we can make an informed decision.

Understand Your Welding Needs

First, define your welding requirements. What materials will you be welding? What’s the thickness of these materials? Once you know what’s required, it will be a lot easier.

Check the Machine’s Power

The power of the machine determines its capability to weld different materials. A higher-power machine will be able to weld thicker materials.

Consider the Machine’s Weight and Ergonomics

As the machine will be handheld, its weight and design are crucial for operator comfort. Look for a light machine with an ergonomic design to reduce operator fatigue.

Examine the Laser Beam’s Quality

The laser beam’s quality is paramount. A machine with a high-quality laser beam will ensure precise and efficient welding.

Ease of Use

The machine should have intuitive controls and easy-to-understand instructions. This will make it easier for operators to use the machine efficiently.

After-Sales Support and Warranty

Look for a machine that comes with good after-sales service and warranty. This will save you from unnecessary costs in the future.

Applications of Handheld Laser Welding Machine

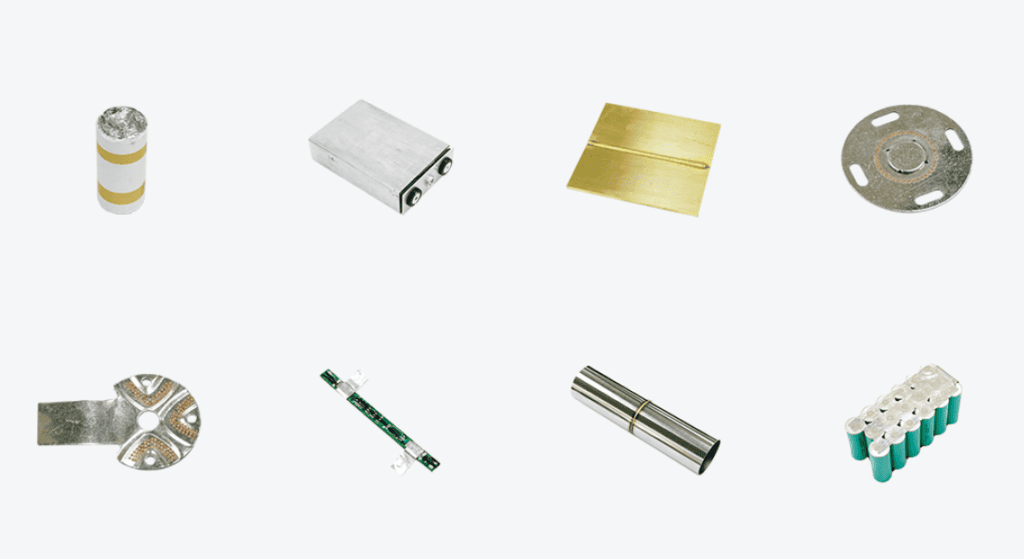

Handheld laser welding machines, due to their versatility and efficiency, have found applications across a wide range of industries. Their ability to deliver high-quality welds with minimal heat input and maximum environmental protection makes them a preferred choice. Here are some notable applications across various industries:

- Automotive Industry: Ideal for welding complex car parts, improving production speed and efficiency.

- Marine Industry: Used for repairs and fabrication of ship components due to its versatility and durability.

- Construction Industry: Provides precision in welding building components at a low cost.

- Furniture Manufacturing: Used for joining different types of welding metals in various furniture designs.

- Industrial Machinery: Enhances the production process by providing durable and firm welding.

- Energy Industry: Crucial in manufacturing and maintaining components of renewable energy systems.

- Medical Industry: Ensures precise, clean, and strong welds for medical equipment.

- Aerospace Industry: Delivers high-quality welds required for the stringent standards of aerospace applications.

Future Potential

The future potential of handheld laser welding equipment is immense. With superior speed, quality, and cost-effectiveness, these machines are becoming essential in various industries. Their ability to provide environmentally-friendly solutions, high energy efficiency, good welding quality, and low heat input positions them as a future leader in the welding industry.

These machines now consume less energy and have expanded applications, thereby becoming indispensable in many manufacturing and repair processes. Moreover, as industries pivot towards eco-friendly practices, the low environmental footprint of these machines enhances their appeal. Consequently, the future of these devices is set to see increased utilization, continual technological evolution, and an integral role in promoting sustainable industrial practices.

Conclusion

In conclusion, handheld laser welding machines offer a significant step forward in welding technology. They are efficient, precise, and cost-effective and contribute to environmental protection. Their application is broad, spanning various industries, from automotive to aerospace. As technology advances, their role is set to grow, providing sustainable solutions for a myriad of welding needs. We invite you to explore more resources on our website to better understand this transformative technology.

Dive Into the Future of Welding with Our Handheld Laser Welding Machine

Baison Laser is a global leader in providing advanced laser solutions. With a robust line-up of machines and dedicated service, we prioritize our customer’s needs. Explore more on our website or contact us today for any queries or support.