Modern fiber lasers are the result of a collective effort of a hundred years worth of research and development. These laser systems have gone from industrial-grade tools to widespread everyday machines used by hobbyists and small business owners in just a few short years.

This article provides an in-depth look into fiber laser technology, its inner workings, applications, and benefits.

Let’s dive into it.

What Is Fiber Laser Technology?

Fiber laser technology uses an optical fiber cable made of silica glass as the gain medium to boost the strength of the laser.

The optical fiber is exposed to a high-intensity light source, and as light rays pass through the cable, they refract internally and get amplified.

Additional reflectors at the end of the fiber cable further reflect and amplify the laser beam.

The wattage of the light source determines the strength of a fiber laser. High-wattage lamps pump light into the gain medium, which leads to greater laser penetration.

Due to the flexibility of fiber laser systems, it has seen widespread adoption in the manufacturing industry. Except for fiber laser cutting machines, fiber laser is commonly used for welding, making, cleaning, and drilling metals, as well as non-metals.

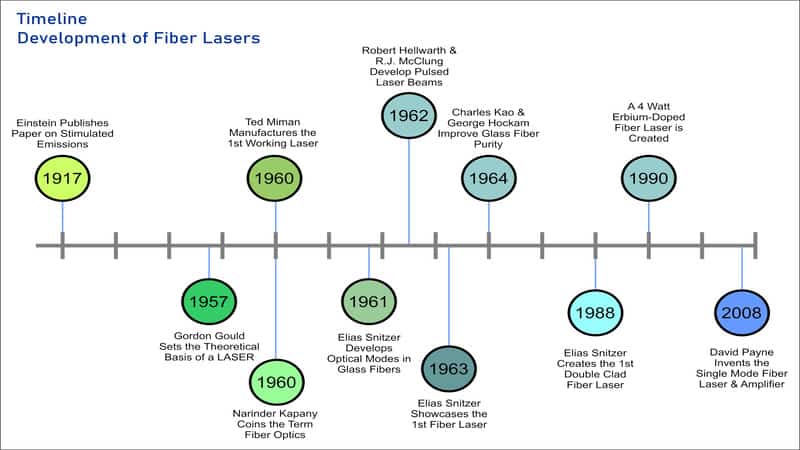

The Fascinating History of Fiber Laser

The invention of the modern fiber laser is a complex and fascinating story that spans nearly a hundred years and with the collaboration of over a dozen scientific minds. Albert Einstein’s 1917 research into simulated light emissions became the basis for modern lasers. Einstein proposed the theory that photos of light can trigger atoms to release other photons.

Four decades after Einstein (1957) published his paper, Gordon Gould presented the basic structure of visible light amplification.

Gould was the first person to use the acronym for the technology in his work notebook, calling it a LASER: Light Amplification by Stimulated Emission of Radiation.

While Gould formed the basis of the laser, Ted Maiman went on to construct the first functional laser.

Just a few years after Maiman’s achievement, Elias Snitzer, who was then working on fiber optics, created a system to combine the two technologies, creating the first fiber laser system in 1963.

Optical fibers were still very difficult to fabricate in the 60s, and without high-quality fiber cables, the fiber laser would not be competitive to gas power lasers.

Over the next 30 years, several scientists, including Snitzer, would improve the design and introduce high-purity optical fibers, double-clad fiber, and rare earth metal doped fiber cables.

In the late 2000s, Italian company Salvagnini would finally bring a fully functional fiber laser cutting machine to the market. Since then, fiber laser cutting machines have been rapidly and steadily improving to overtake CO2 laser cutting machines.

Following the sale of the first fiber laser cutter, improvements in manufacturing technology, CNC performance, and fiber optics have further enhanced the capabilities of fiber lasers.

How Do Fiber Lasers Work?— an Easy-to-follow Guide

Modern laser beams are a commutation of years of research and decades of improvements in the manufacturing process.

Many see fiber laser systems as a complex and daunting technology. But the basic operating principles are very easy to understand.

Here we break down the basic steps involved in fiber laser operation.

Step 1 Initiating the Light Source

The first element of a fiber laser is the light source. Modern fiber lasers use a semiconductor diode for illumination. Higher wattage will result in a high-power fiber laser, but at the cost of excess heat generation at the light source.

A robust cooling system is necessary when dealing with high-output power concentrated in such a small space.

Lasers used for manufacturing in industrial environments are incredibly powerful, and a standard light source is often insufficient for such systems.

Some fiber lasers bypass the overheating issues by using multiple smaller pump laser diodes to fill the optical fiber cable with light.

Step 2 Pump Light into the Optical Fiber Core

Once your light source is initialized, it must be directed toward the optical fiber cable. As light exits the diode source, it scatters in all directions.

Hence opaque thicker materials surround the diode to prevent the light from escaping in unwanted directions. Then the only exit point for the light would be in the direction of the optical fiber.

The process of directing more and more light into a single optical fiber is called pumping.

However, the optical fibers are prone to light leakage as well. If you pump light into a naked fiber, most of the energy will dissipate to the surrounding. So the fibers must be clad in a thin and flexible material, preventing light leakage and improving the fiber’s refractive index.

The fibers combine with cladding material to form a cable, and the cable’s core is the optical fiber.

Step 3 Light Is Converted into a Laser Light Beam

When light enters the fiber cable, it is still too weak and unfocused. But as the light packets (photons) pass through the fiber, they are refracted internally and concentrated. Light continuously bounces inside the fiber until a laser beam is formed.

Step 4 Laser Light Is Amplified Internally

Even after forming the laser light into a cohesive beam, the power output is still relatively low. So the laser must now be amplified until the beam quality improves significantly. Amplification occurs in three ways.

- First, fiber optic cables are doped with rare earth metals that get excited by the laser light and release more photons. These extra photons provide additional energy to the laser beam.

- Next, the fiber cable is coiled to increase the internal refractions of the laser light exponentially.

- Finally, reflective mirrors at the end of the cable run prevent light from returning to the laser diodes or prematurely exiting the optical fiber.

Step 5 Wavelength Management

An optional step for optimizing fiber laser output is to control the wavelength (frequency) of the final beam. The stimulated emission from molecules is at varying wavelengths and can affect the quality of the laser output. To control the beam output, fiber Bragg gratings are needed.

Fiber Bragg gratings are a series of deflectors constructed inside the optical fiber that block unwanted wavelengths of light and only allow the desired ones to pass through.

Step 6 A Lens System Shapes and Focuses the Laser Light

After the laser diodes pump light into the core of the fiber-optic cable and a laser beam is formed, it is strong enough to melt or even cut materials. But at this point, the light is too unfocused, and the spot diameter of the laser is too large.

A series of high-quality lenses shape the laser beam into a smaller point (spot) and help manage other laser parameters like the focal length. Higher-quality lenses result in better beam quality.

Step 7 Electronic Deflectors Change the Direction of the Laser Light

After passing through the gain medium and the lenses, the laser beam is ready for any application. But controlling the position and direction of the laser beam is still a challenge.

The solution is a set of electronically controlled deflectors (mirrors) at the end of the laser beam. As light hits these deflectors, a computer-controlled system changes the angle of the deflector to control the fiber laser’s direction.

The sensitive parts inside the fiber laser cavity aren’t designed to be moved around. Using this method, the fiber laser can stay stationary while moving only the laser beam.

7 Key Benefits of Fiber Laser Machines for Your Business

Here is a brief list of the most important benefits that fiber laser machines bring to the table.

High Precision

One of fiber lasers’ most significant improvements over the older CO2 lasers is the incredible laser precision. This higher precision is achieved by the combination of smaller spot diameter and advancements in CNC (computer numerical control).

Fiber lasers can now accurately and precisely move to a 1000th of an inch. (0.001 in. or ~25 microns).

Energy Efficiency

Laser electrical efficiency is measured based on the difference between power drawn from the wall socket and the power output of the laser beams.

Fiber lasers are incredibly energy efficient and can convert up to 35% of the input electricity into laser energy. This is slightly higher than neodymium lasers and nearly twice the efficiency of CO2.

Compact Size

A significant contributor to size reduction for fiber lasers is the lack of a laser tube. Older CO2 lasers use a bulky glass tube that houses a gas mixture used as the gain medium.

Additionally, using energy-efficient diode lasers to pump light into the laser medium leads to smaller cooling systems inside the fiber laser cavity.

Finally, the ability to coil the fiber cable inside the machine has led to higher-power fiber lasers in the same smaller package.

Versatility

Fiber lasers are versatile tools that can be deployed to different manufacturing systems. For example, a fiber laser cutting machine can also laser engrave and mark.

By reducing the focus of the laser beam or using pulsed fiber lasers, you can decrease the energy output and use the laser for non-cutting applications.

Outside the manufacturing sector, fiber lasers are used in medical equipment, engineering measuring tools, and many more.

Long Lifespan

Another excellent selling point for fiber lasers is their long life and durability. A standard fiber laser is designed for over 30,000 hours of operation.

This is nearly 15 times longer than a traditional gas-powered laser machine. Due to their high durability, fiber lasers also require less frequent maintenance.

Material Compatibility

Fiber lasers are primarily recommended for metalwork. You can cut, mark, clean, engrave, and drill through sheet metal and even thicker plates using fiber lasers.

However, fiber lasers provide limited compatibility with non-metals. Limited compatibility means the laser can engrave and mark but will struggle to cut the material.

You can use lower-power fiber lasers for marking and cutting textiles, leather, wood, etc.

Lower Operational Costs

Fiber laser machines offer significant savings through higher energy efficiency, lower power consumption, and maintenance-free operation.

Your annual cost per part will be considerably lower in the long term than traditional gas-powered laser solutions.

5 Amazing Applications of Fiber Lasers

Non-manufacturing laser applications are best suited to low-powered diode lasers. Although fiber lasers are used in medical fields, Nd: YAG lasers dominate that field.

Because the high power output by fiber lasers can reach upwards of tens of kilowatts, they are favored for their manufacturing capabilities. Here are five of the most common fiber laser applications.

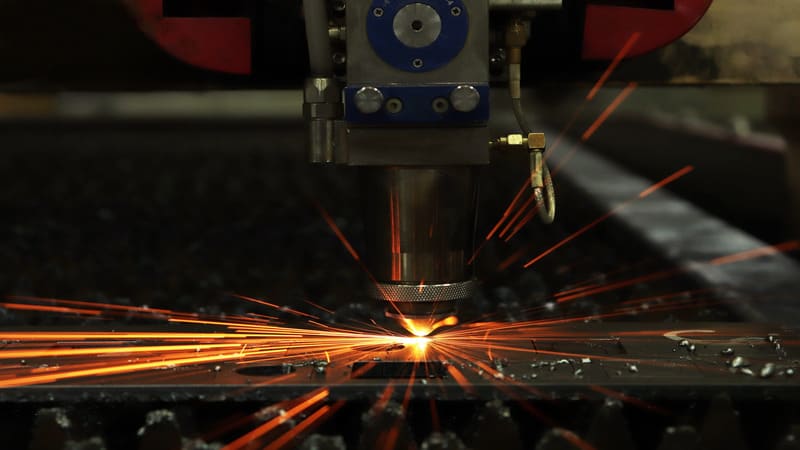

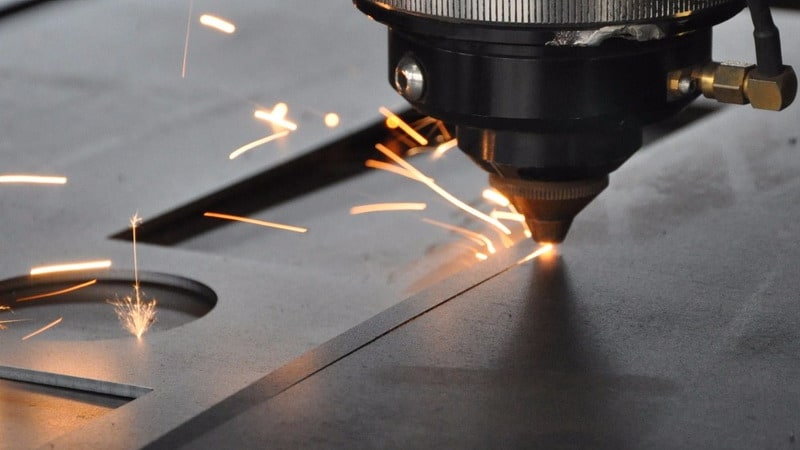

Laser Cutting

Metal cutters are one of the most widespread applications for fiber laser systems. Most modern metal manufacturing involves the manipulation of sheet metal, metal tubes, or thin metal plates.

Moreover, fiber laser cutting excels at dealing with those exact types of materials. Laser-cutting machines vary based on the laser beams’ power output, the machine’s size, and automation capabilities.

Higher beam quality is necessary for precision cutting. Hence high, quality lenses should be used and cleaned regularly.

Laser Engraving

Fiber lasers can quickly and accurately carve letters and complex designs into products that will last as long as the product is in use.

A major use case of laser engraving comes from combining CNC laser systems with design software to allow users to create detailed and complex patterns on any number of surfaces.

Laser Marking

Low-power fiber lasers are excellent options for marking components and products. They can quickly impart product details and safety instructions onto a component with high precision and clarity.

Laser marking is often used to draw company logos and brandings onto the final product.

Large-scale factories use fiber laser marking machines to impart serial numbers and batch numbers into small components such as memory chips, PCBs, and car chassis. Before choosing a suitable fiber laser marking machine, learn about it in detail.

Laser Welding

Fiber laser welding is a high-precision welding technique used to join two thinner sheets of material with minimal weld marks. Additionally, it is possible to weld plastics using low-power or pulsed lasers.

Laser welding is more expensive than traditional TIG or MIG welding and is typically reserved for specialized applications like microscopic welds, precious metal welding, etc.

Laser welding is an excellent alternative to other sheet metal joining methods like rivets as it produces a more flush finish. Similarly, laser welding is preferred for joining non-metals when air-tight joints are required and glue (or adhesives) is not viable.

Laser Cleaning

Fiber lasers are also used for cleaning up the edges and surfaces of metals. Rusted iron pieces can be cleaned using a fiber laser in a few seconds compared to sanding. Laser cleaning also yields a better surface finish.

Lasers can also clean up weld marks and metal burrs from other manufacturing processes. Laser cleaning is less common in general manufacturing due to its higher initial cost.

Cleaning is primarily concerned with laser power and consistency. Beam quality and focus are secondary factors for this process.

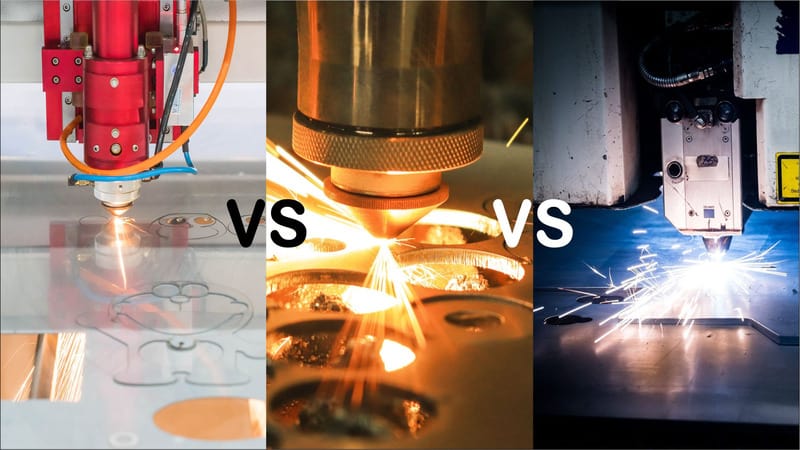

Fiber Lasers vs. CO2 Lasers vs. Nd: YAG Lasers

So far, in this article, we have only focused on fiber lasers. However, two more laser systems are currently available that are popular and, in some cases, better than the fiber option.

CO2 predates fiber lasers by half a century and is a tested and trusted option. Nd: YAG is similar to fiber lasers and a somewhat newer technology that is still being researched. This section compares the three technologies and highlights their respective advantages.

Technology

- CO2 is an older laser technology that uses high-voltage electric current to excite gas molecules, generating photons inside the glass mixture tube. These photons are then amplified into a laser by two outer reflectors.

- Nd: YAG (neodymium-doped yttrium aluminum garnet) lasers pump light into a neodymium crystal which acts as the laser medium. When you pump light into the crystal, the excited impurities generate photons (stimulated emission).

- Fiber lasers pump light into an optical fiber cable which acts as a laser medium and amplifies the light internally due to its high refractive index.

Pricing

Laser costs range from a few hundred dollars (USD) all the way up to a million. Gas lasers are the cheapest at $2,000 for a beginner unit, while entry-level fiber and YAG models start around the $15,000 mark.

The initial investment into gas lasers is considerably low, but the maintenance cost can start to add up.

CO2 lasers are best suited for low-volume production runs. In such situations, a lower life span and poor energy efficiency can be justified by the significant reduction in upfront costs.

Size

CO2 lasers are bulkier because of the large and heavy gas mixture tube used for photon generation. As you directly pump light into a fiber and YAG lasers, there is no need for the photon-generating glass tube.

Fiber laser machines occupy less space and maintain a higher beam quality.

Efficiency

The biggest power draw of a laser system is the light source, as it is necessary for amplification.

Since both fiber and YAG lasers use energy-efficient lamps to pump light into the laser medium, they have a higher overall efficiency leading to lower operating costs.

Semiconductor lasers that use diodes have the highest efficiency, upwards of 60% but only at 5-10W of power.

At this range, semiconductor lasers are only helpful for marking and cutting plywood or fabrics.

Life Span

The lifespan of CO2 lasers is the lowest among all laser technologies as the gas mixture tube degrades over time and needs to be replaced after 2,000 hours of operation.

Contrarily, Fiber lasers can operate at their high (peak) power all day and still maintain their long lifespan. Neodymium lasers share a similar lifespan to single-mode fiber lasers.

Reliability

Modern optimizations have led to increased reliability of all laser systems. Generally speaking, a solid-state laser and a gas laser will have the same level of reliability in optimal operating conditions.

However, in hazardous situations like factory floors or chemical processing plants, gas lasers will have lower reliability due to the fragile nature of the glass laser tube.

Material Compatibility

CO2 lasers have the most diverse material compatibility as they can be used on metals, plastics, polymers, wood, and more. They are only limited by highly reflective metal surfaces like bronze or copper, as most of the laser energy is reflected off the surface.

YAG lasers have reasonably high metal material compatibility but are only compatible with some ceramic non-metals.

Fiber lasers are the best of both worlds as they have a near-universal compatibility with metals, including highly reflective surface ones and decent non-metal compatibility.

INSERT TABLE

What Type of Fiber Laser Machine Is Best for Your Needs?

Fiber laser machines are a versatile, flexible, and cost-effective solution for small to medium-sized businesses. However, it is crucial to buy a machine that is best suited to your needs.

Especially since fiber laser machines have a higher initial investment cost, choosing a suitable machine for your business can significantly reduce your ROI (return on investment) period.

Here are the major factors you must consider before buying a fiber laser.

Laser Application

Outline your primary use case for a fiber laser. Getting a fiber laser cutter would be a smart business decision if you primarily work on sheet metal fabrication. You benefit from the diverse metal compatibility.

Laser cleaning, marking, and welding machines are uni-task tools that are designed for only one purpose. If you cannot fully utilize these machines on a regular basis, then its best to avoid them.

Machine Size

Although fiber laser machines are small and compact, they still need ample breathing room.

You should have enough clearance around the machine for good airflow so the laser doesn’t overheat.

Additionally, you should have enough roaming space so someone doesn’t accidentally bump into the machine while it’s operational.

You must also consider decent ventilation when cutting plastics or certain hazardous materials that can generate dangerous fumes.

Laser Power

High-power fiber lasers are mostly reserved for cutting thick blocks of metal. Most industries won’t benefit from a 10kW solid-state laser.

Laser marking requires the least amount of power, while engraving, cleaning, and cutting will require varying levels of power based on operating conditions.

Avoid high-power lasers if they don’t provide significant benefits to your business.

Cost Overtime

A solid-state laser, like a fiber one, will generally cost more at the initial purchase than a CO2 one.

However, fiber lasers have lower operating costs due to their excellent efficiency, even when hitting high-power targets.

Fiber lasers are also considered maintenance-free because of their exceptionally long lifespan.

Operating Mode

Lasers can operate in two modes depending on the application.

- Continuous Wave Mode: In this mode, the photons will exit the machine in a continuous wave, and the laser bombards the surface of the workpiece non-stop. Continuous wave operation can also lead to burn marks on the edges of the workpiece.

- Pulse Mode: In this mode, the photons exit the machine in short bursts called pulses. Pulsed fiber lasers shoot less energy into the workpiece and reduce the chance of unwanted melting or warping. The pulse durations of the laser determine the pulse energy of a laser. Longer durations will result in more energy output.

Production Capacity

Most lasers utilize a stationary work bed. The size of the bed limits the production capacity of fiber laser machines.

A larger bed size would be necessary for larger businesses that need quick turnaround times, but it won’t be viable for mass production.

Aside from bed size, some fiber laser cutters utilize a coil feed system.

Here, the main fiber laser body is attached to a sheet metal decoiler that continuously feeds metal to the machine.

The coil-fed laser system differs from a traditional sheet metal system and is typically reserved for high-volume and low-complexity production runs.

Conclusion

Fiber laser systems started as an unverifiable theory in the mind of Einstein and slowly grew into one of the most innovative modern tools today. These lasers are versatile tools crucial to several industries, including metalwork, robotics, surgery, and more. Highly regarded for their small footprint and efficiency, fiber laser machines are now more affordable than ever before.

Furthermore, the broad material compatibility of fiber laser systems has given them an edge over other metal fabrication processes.

Get a High-Quality Fiber Laser Machine Today!

Baison is a long-term manufacturer of precision laser cutting machines. Our best-in-class fiber laser systems are shipped globally to over 100 countries across the globe.

We offer value-added services like pre-purchase application evaluation and a thorough operator training program.

Our catalog includes powerful and robust Fiber and CO2 laser machines. A successful business needs quality tools. Get the Best Fiber Laser Machine Today!