Due to market varieties, choosing a suitable laser machine for marking and engraving challenges beginners. These tools are handy in the aerospace, device manufacturing, and automotive industries.

Understanding these machines’ differences, advantages, and features aids your selection for different applications.

This article will discuss fiber lasers and UV marking machines in-depth. Before selecting these tools, you’ll also learn their advantages and factors. Let’s get started.

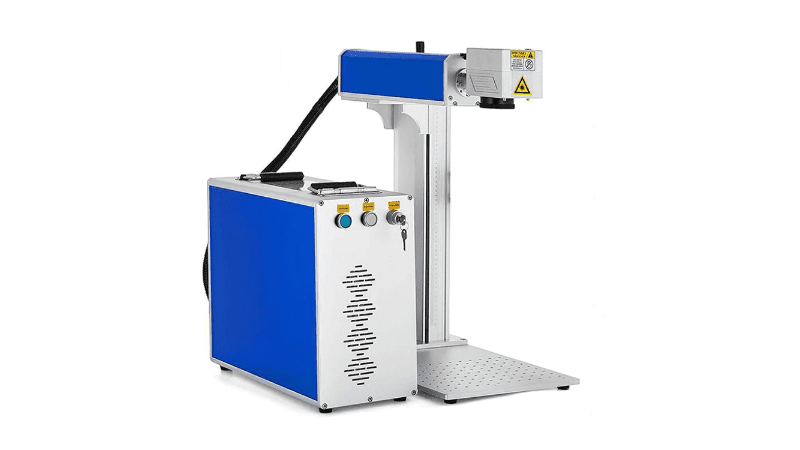

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine is an industrial equipment used to engrave different materials with good beam quality. The non-thermal process damage technology generates high-intensity waves utilizing a fiber optic cable. It can etch ceramics, plastics, and metals.

Computer software controls the laser beam to create precise text, patterns, and designs on the material. The high light intensity ensures the marks are highly durable and don’t cause heat damage. These machines offer excellent versatility, accuracy, and speed.

Advantages of Fiber Laser Marking Machine

Long lifespan, high precision, and accuracy are benefits of a fiber laser marking machine.

- High Precision and Accuracy. The fiber-optic cable transporting the beam from the fiber laser source to the cutting head ensures precision. It delivers excellent accuracy due to the machine’s high energy output in a smaller spot size.Additionally, the laser medium minimizes the heat-affected zones, reducing distorting or warping.

- Long Lifespan. Fiber lasers can remain functional for 10 to 20 years with adequate care and maintenance. Their lifespan depends on the frequency of use, material, and quality of their construction.

- Wide Range of Materials. These machines are versatile and usable in many industries on ceramics, glass, plastic, and metals. The tools offer precision and produce excellent, detailed markings ideal for different applications.

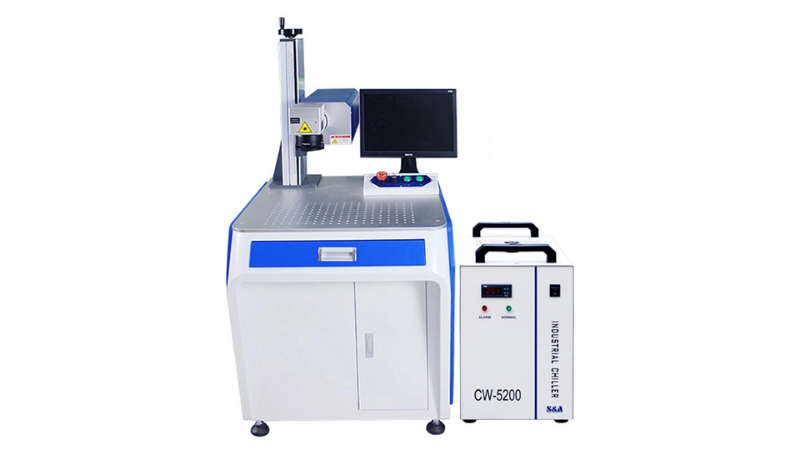

What Is a UV Laser Marking Machine?

An ultraviolet (UV) laser machine is a device that creates permanent marks on glass, metals, ceramics, and plastics. The tool’s wavelength is shorter, enabling it to produce accurate and precise markings.

The UV laser machine is perfect for applications requiring high-efficiency resolution markings. Its shorter wavelength (150 to 400 nanometers) makes it appropriate for heat-sensitive materials without thermal deformation.

UV lasers can mark a metal material across manufacturing lines with a high absorptive wavelength (355 nm). The absorption rate enables the machine to perform cold marking without adding heat stress to the materials.

Advantages of UV Laser Marking Machine

There are various benefits of using the UV laser marking system. Some of them include the following:

1. Ideal for Marking Organic Materials

While a UV laser system is highly effective at engraving ceramics, plastic, and metals. It can also mark organic materials and is usable on paper, leather, and wood. However, it requires careful optimization and testing of the settings.

2. High Marking Speed

The standard wavelength laser machines offer high marking speed due to their high-intensity ultraviolet spectrum light beam focusing on small areas.

Unlike MOPA fiber lasers, these tools have a short wavelength, helping them achieve excellent resolution and accuracy. The speed depends on the machine’s power, design complexity, material type, and thickness.

3. Cold Processing

This UV laser machine benefit marks surfaces using a focused light beam without generating heat. It does not damage or deform the material, which is ideal when working with sensitive materials like electronics or plastics.

Fiber Laser vs. UV Marking Machines

The differences between these machines are enormous. Below are a few:

1. Laser Beam Quality

A fiber laser beam quality is higher than that of UV marking machines. Its diameter is smaller, which enables detailed and precise marking.

UV laser marking machines achieve high precision and accuracy levels and can engrave metallic and non-metallic items. Choosing between both devices for your projects depends on the specific application needs and material.

2. Marking Speed

The marking speed of UV marking and fiber laser machines depends on the material you’re engraving.

Fiber lasers mark materials faster than UV machines because they offer higher power outputs. The material design complexity also impacts the processing speed. Delicate patterns take extended periods, regardless of your device type.

3. Materials Compatibility

UV marking and fiber laser power machines have varying material compatibility because of their wavelengths.

Fiber lasers wavelength is around 1,064 nanometers and is typically used to mark plastics and metals. UV marking machines’ wavelength is shorter and around 355 nanometers, ideal for engraving softer items like ceramics and glass.

UV marking machines can mark objects without warping or thermal damage, making them perfect for heat-sensitive materials. Fiber laser light is ideal for highly reflective marking on plastics or metals without chemical and physical changes.

4. Lifespan and Maintenance

The lifespan and maintenance of UV marking and fiber laser machines vary by component quality, environmental conditions, and usage frequency.

Fiber lasers typically have a longer lifespan than UV marking machines because they have fewer moving parts and a robust design. Both device parts need periodic replacement and routine cleaning for maintenance.

Fiber lasers require less maintenance than UV marking machines and have a longer lifespan.

What to Consider when Choosing Laser Marking Machines

The factors to consider before choosing a laser marking machine are as follows:

Compare Different Laser Marking Technologies

CO2, fiber, UV, and MOPA are different laser marking machines. Below are their technological differences:

1. CO2 Laser Marking Machines

Carbon dioxide (CO2) lasers are tools based on gas technology using seal tubes with molecular gas as a marking source for non-metallic surfaces. They’re ideal for leather, foil, acrylic, plastics, glass, and wood.

CO2 laser sources have low intensity but can achieve high-speed marking on non-linear crystals and precious metals in a solid state.

2. Fiber Laser Marking Machines

Fiber laser machines use a beam of light to engrave or mark metallic and non-metallic materials. They’re perfect on ceramics, metals, plastics, and other materials.

These machines create precise text, patterns, and designs with high light intensity while offering versatility, speed, and accuracy.

3. UV Laser Marking Machines

UV laser machines use a highly absorbent wavelength (355 nm) technology to mark different material types permanently. You can engrave various plastics, ceramics, metals, and glass parts with the device.

UV lasers are ideal for industrial applications requiring high-resolution markings.

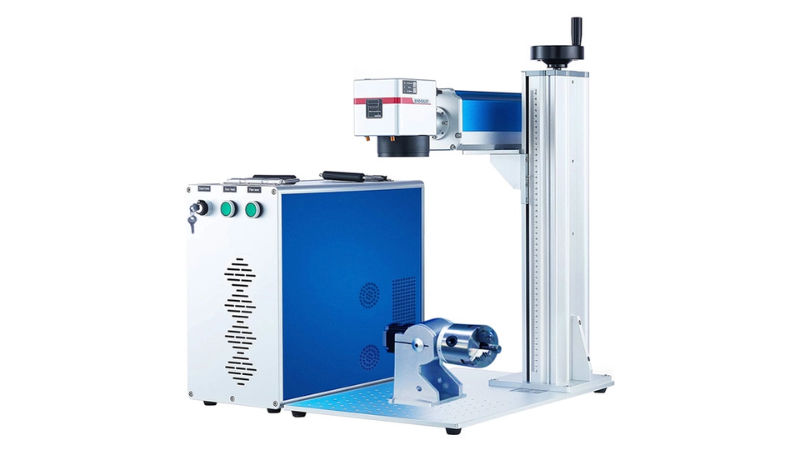

4. MOPA Laser Marking Machines

The Master Oscillator Power Amplifier (MOPA) laser machines use this innovative technology to mark any surface material. The laser engraving light energy can etch plastics and nickel alloys without mechanical deformation.

MOPA laser marking machines are handy for industrial engraving in the electronics, medical, aerospace, automotive, and oil and gas sectors.

Evaluate the Marking Software and System Features

Examining the laser marking machine software and system features before selection is essential.

1. User-friendly Software Interface

Evaluating laser marking machines’ user-friendly software interface before selection is crucial as it significantly impacts the production process efficiency.

A user-friendly interface makes creating precise marking and machine navigation easier for operators. A poorly designed intersection contributes to errors and slows down production.

2. Customizable Marking Parameters and Settings

Examining laser machine settings and customizable marking parameters enables you to tailor the machine to achieve a certain contrast level.

Since all laser machines don’t offer similar system features, consider evaluating the settings and marking parameters. It ensures that you get the required customization level for your projects.

3. Data Connectivity and Integration With Other Systems

Evaluating these features is crucial because modern manufacturing systems rely on real-time communication and data exchange. It requires interoperability and compatibility with different devices to produce desired marking results.

Data connectivity is essential for optimizing and monitoring machine performance. Data integration enables customization in manufacturing processes with greater flexibility. You can create customized workflows that improve productivity with these features.

4. Laser Safety Features

Considering laser machines’ safety features before purchase is crucial because they radiate at dangerous levels. It can cause severe burns or eye damage to users if not appropriately managed.

You’ll ensure the machine adheres to industry regulations such as IEC, OSHA, and ANSI standards by evaluating its safety features. Ensure the device has emergency shut-off switches, in-built interlock systems, and proper warning labels.

Choose a Reliable and Trustworthy Supplier

Another essential factor to consider before selecting a laser marking machine is the supplier. A salesperson without an in-depth understanding of the products they’re selling is not ideal for you.

Buy from reliable, trustworthy suppliers that can recommend the best products for your projects.

Why Should You Choose the Right Laser Marking Machine

Choosing the right laser marking machine is crucial for various reasons. It can affect your marking quality, and a suitable device produces clean and precise results.

Another reason to choose the right tool is that some materials require different laser machines. You may need a fiber laser machine when marking metals and CO2 equipment for plastics.

Consider a device with multiple techniques that can seamlessly engrave, deep mark, and etch.

Conclusion

After learning which is better between fiber and UV laser marking system, choose the best tool. The ideal equipment should have a long life span, offer high precision, and be usable on various materials.

Buy a High-quality Fiber Laser or UV Marking Machine from Baison Laser

Buy fiber laser and UV marking machines with excellent security, data connection, and integration from the best producers. Baison Laser is your go-to source for the best equipment.

Contact us today for a consultation, and we’ll provide premium products that meet your needs.