This post will explore the advantages of fiber laser cutting machines, discuss how they can be applied in metal fabrication, and provide practical tips for successfully integrating this cutting-edge technology into your operations.

How Does Laser Cutting Process Work?

The fiber laser cutting process can be easily understood through these straightforward steps:

- Design preparation: Make a digital design of the desired shape or pattern using design software like CAD.

- Machine configuration: Transfer the design to the laser cutting machine’s software and adjust settings like cutting speed, laser strength, and material type.

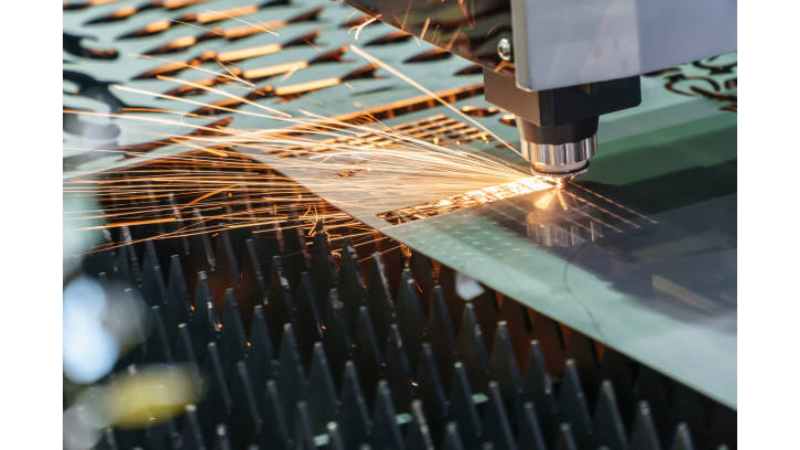

- Material setup: Place the metal sheet or workpiece on the machine’s cutting bed, ensuring it is level and secure.

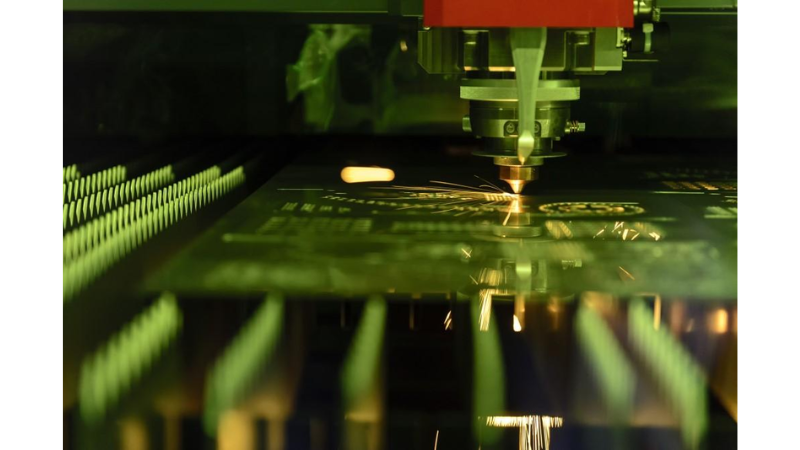

- Laser initiation: Activate the laser, generating a high-intensity light beam, and direct it at the material’s surface.

- Cutting action: The laser beam melts, burns, or vaporizes the material following the specified pattern. The machine’s software guides the laser head’s movement to trace the design precisely.

- Gas assistance: An assist gas, like nitrogen or oxygen, is blown at the cutting zone to clear away molten or vaporized material and maintain a clean cutting edge.

- Completed cut: When the cutting process is finished, the machine stops and deactivates the laser beam.

- Finished product: Gently remove the cut piece from the machine, examine it for quality and precision, and perform any necessary post-processing tasks, like cleaning or deburring.

What Role Do Laser Beam and Cutting Head Play in Fiber Laser Cutting Machines

We can break down the roles into two different categories:

Laser Beam in Fiber Laser Cutting Machines

The laser beam is a vital component of fiber laser-cutting machines. It generates the high-intensity light required to cut through various materials. In a fiber laser cutting machine, the laser beam is produced within the fiber optic cable and directed toward the material surface.

The focused beam has a high energy density, enabling it to melt, burn, or vaporize the material with precision and speed. The laser beam’s characteristics, such as its wavelength and power, determine the machine’s cutting efficiency and the types of materials it can process.

Cutting Head in Fiber Laser Cutting Machines

The cutting head is another crucial element of fiber laser cutting machines. It serves several essential functions, including:

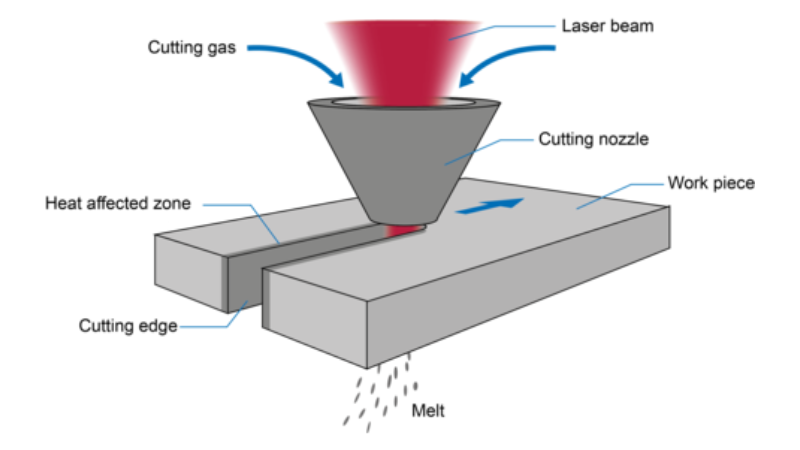

- Focusing the laser beam: The cutting head contains a lens or a series of lenses that concentrate the laser beam onto a small spot on the material’s surface. This focusing action increases the energy density of the beam, enabling it to cut through the material more effectively.

- Controlling the assist gas: The cutting head directs the assist gas, such as nitrogen or oxygen, onto the cutting area. The assist gas helps to remove molten or vaporized material from the cut, ensuring clean and precise edges.

- Movement and positioning: The cutting head is attached to a motion system, such as a gantry or a robotic arm, which allows it to move along the X, Y, and Z axes. This movement system enables the cutting head to follow the designated path accurately, ensuring the final cut piece matches the original design.

Together, the laser beam and cutting head work to provide precise, efficient, and high-quality cutting in fiber laser cutting machines. Look at this blog to learn how to choose cutting heads for your business.

What Factors Affect the Laser Cutting Process

A few key aspects can impact the laser cutting process, affecting the overall performance and quality of the final cut. These crucial factors are:

- Material thickness and kind: The material’s thickness and type play a significant role in how effective the laser cutting will be. Generally, thicker materials need more laser power and slower cutting speeds. Different materials, like metals, might be more suitable for laser cutting than others, such as wood or plastic.

- Laser beam focus and quality: The laser beam’s focus and quality are essential for achieving clean and efficient cuts. A properly focused beam with high energy density cuts materials more effectively, resulting in better edges and reduced waste. Maintaining the laser’s focus and beam quality throughout the cutting process is critical for the best results.

- Assist gas pressure and cutting speed: The assist gas pressure and cutting speed also influence the laser cutting process. Higher gas pressure helps clear molten or vaporized material more effectively, leading to cleaner cuts. However, too much pressure might cause the material to warp or become distorted. The cutting speed must be well-balanced to ensure accurate cuts without sacrificing efficiency. A slow cutting speed can cause too much heat, potentially damaging the material, while a fast cutting speed may lead to incomplete cuts or less precision.

Advantages of Fiber Laser Cutting Machines in Metal Fabrication

Fiber laser cutting machines present numerous benefits in metal fabrication, making them a go-to choice for various applications. Some of the primary advantages include:

- High precision and low operating cost: Offering both high precision and cost efficiency, fiber laser cutting machines are an intelligent investment for businesses in the metal fabrication sector. Their energy efficiency and reduced maintenance requirements contribute to their overall cost-effectiveness.

- Cutting a range of precious metals with accuracy: Capable of handling various precious metals like gold, silver, and platinum with exceptional precision, fiber laser cutting machines are particularly valuable for industries such as jewelry and luxury goods that demand intricate designs and precise cuts.

- Easily cutting through thick plates and stainless steel: The power and capability of fiber laser cutting machines allow them to effortlessly cut through dense materials, including thick metal plates and stainless steel. This feature makes them suitable for diverse metal fabrication tasks that require cutting through heavy materials.

- High-powered laser beam and precision cutting ability: Generating a high-intensity laser beam, fiber laser cutting machines enable precise cutting of multiple metals. This precision ensures the final product closely aligns with the original design, resulting in high-quality outcomes.

Applications of Fiber Laser Cutting Machines in Metal Fabrication

Here are three specific applications within the metal fabrication field:

Automotive industry

Fiber laser cutting machines are essential for manufacturing various parts and components in the automotive industry. They are used to create intricate shapes, such as gears, brackets, and engine components, with high precision and accuracy.

Additionally, fiber lasers can cut through lightweight and high-strength materials like aluminum and stainless steel, which are commonly used in the automotive industry to improve fuel efficiency and vehicle performance.

Fiber laser cutting machines are employed in producing body panels and structural components, ensuring tight tolerances and smooth edges, which contribute to improved aerodynamics and reduced wind noise.

Steel fabrication

In the steel fabrication industry, fiber laser cutting machines are used for processing a wide range of steel products, including structural beams, pipes, and sheet metal. Their easy cutting through thick steel plates makes them popular for this sector. Furthermore, the clean and precise cuts produced by fiber lasers minimize the need for additional finishing processes, saving time and resources.

Fiber laser cutting machines are utilized in the construction industry for fabricating steel frames and beams with high precision, ensuring the structural integrity and stability of buildings.

Fitness equipment

Fiber laser cutting machines are widely used in the fitness industry. They are used to cut and shape metal components for gym machines, such as weight plates, pulleys, and support structures. The high precision and accuracy of fiber laser cutting machines allow manufacturers to create durable and reliable fitness equipment that can withstand regular use and heavy loads.

Fiber laser cutting machines help produce intricate designs for weight stack plates used in resistance training machines, ensuring smooth and consistent performance during workouts.

How to Choose the Right Fiber Laser Cutting Machine for Your Project

Choosing the right fiber laser cutting machine for your business is crucial to achieving the desired results. It’s essential to understand the factors that impact the performance and efficiency of the machine. Here are some key points to consider when selecting a fiber laser cutting machine for your project:

Adjusting Settings for Different Materials

Different materials require specific adjustments to the fiber laser cutting machine’s settings to ensure the best results. Factors such as cutting speed, laser power, and focus must be optimized according to the material’s thickness and type.

Select a machine that offers easy-to-use controls and presets for various materials to simplify this process and enhance overall efficiency.

Tips for Best Cutting Quality and Speed

To achieve the best cutting quality and speed, it’s essential to consider the following tips:

- Maintain the correct focus distance: Ensure that the laser’s focal point is accurately positioned on the surface of the material being cut.

- Optimize cutting speed: The cutting speed should be adjusted according to the material and thickness to balance cutting quality and productivity.

- Use the appropriate assist gas: Depending on the material, use the correct assist gas, such as nitrogen or oxygen, to improve cut quality and reduce the heat-affected zone.

Care and Maintenance of Fiber Laser Cutting Machines

Proper care and maintenance of your fiber laser cutting machine will ensure its longevity and optimal performance. Some essential maintenance tips include:

- Keep the machine clean: Regularly remove debris and dust from the machine and its components.

- Inspect and clean the optics: Regularly check the laser optics for signs of wear or contamination and clean them as needed.

- Lubricate moving parts: Follow the manufacturer’s guidelines for lubricating the machine’s moving components to reduce wear and ensure smooth operation.

Advancements in Fiber Laser Technology and Metal Fabrication Industry

Fiber laser technology advancements have introduced numerous benefits and opportunities to the metal fabrication industry. Here’s a fresh look at how these innovations are transforming the sector:

- Customization possibilities: Fiber laser cutting machines allow businesses to provide tailored solutions to clients, cutting complex designs with precision and catering to unique customer needs with high-quality, bespoke products.

- Encouraging collaboration: Rapid growth in fiber laser technology has fostered a collaborative environment within the industry. Companies partner with research institutions, tech developers, and other stakeholders to explore new applications, optimize processes, and develop innovative solutions.

- Exploring new markets: Fiber laser cutting machines’ versatility and efficiency enable businesses to venture into new markets and industries, diversifying their product offerings, expanding their customer base, and creating new revenue streams.

- Workforce development: Integrating fiber laser cutting machines into metal fabrication highlights the importance of employee development and upskilling. Businesses invest in training programs to ensure their workforce stays current with technology trends and best practices.

- Accelerating digital transformation: Fiber laser technology has sped up the digital transformation of the metal fabrication industry. The integration of fiber laser cutting machines with CAD software and digital tools streamlines workflows, enhances data-driven decision-making and optimizes operations.

Conclusion

In conclusion, fiber laser cutting machines have revolutionized the metal fabrication industry, offering unmatched precision, speed, and versatility. As businesses continue to embrace these advancements, the possibilities for innovation and growth are endless.

We hope this blog post has provided valuable insights into the benefits and applications of fiber laser cutting machines in metal fabrication.

Unlock Your Metal Fabrication Potential with Baison Laser

Upgrade your business’s cutting methods and tap into the full potential of fiber laser cutting machines. Request an instant quote today and let our team of experts at Baison Laser help you transform your metal fabrication capabilities.