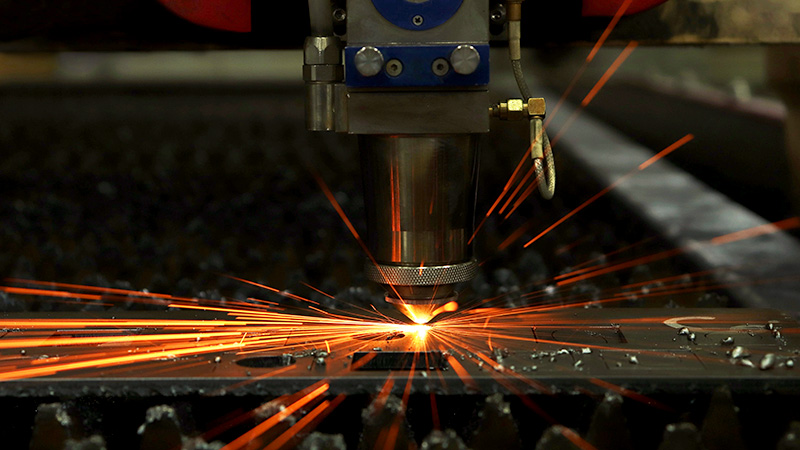

Fiber laser cutters are complex devices that strike a delicate balance between electrical power and cutting speed. Minor disruptions in the power supply can result in major issues such as poor cutting quality and material incompatibility. Understanding the reasons behind power drops is essential for long-term and continuous laser operations.

This article delves into the critical factors influencing laser cutter power drops and presents effective solutions.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a manufacturing tool for precise and accurate material cutting, marking, and engraving applications. It employs fiber optic technology to deliver a high-powered laser beam that easily cuts through metals and non-metals.

The key components include a fiber laser source, optic cables for laser beam transmission, a cutting head to focus the laser, and a CNC (Computer Numerically Controlled) system for precise control. Compared to traditional CO2 lasers, fiber lasers are smaller, more energy efficient, and last longer.

Today, you can find a fiber laser cutting machine in every industry, such as automotive, medical, aerospace, oil and gas, and construction, offering advantages like high cutting speeds, superior precision, and the ability to cut diverse materials with varying thicknesses.

| Attribute | Specification |

|---|

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

Importance of Maintaining Optimal Power in Laser Cutting

Optimal laser power is the key to an effective and efficient cutting process. As the laser power fluctuates, it disrupts the cutting process, resulting in material defects and ruining the workpiece.

Following are some key benefits of maintaining an optimal power flow in a laser cutting machine.

1. Consistent Cutting Precision

A steady and stable power draw will result in a consistent laser beam that makes precise and accurate cuts. Irregular power supply can compromise the laser cutting depth, affecting the workpiece’s final dimensions.

2. Good Cutting Speed

An inconsistent power supply will reduce the laser penetration power, forcing operators to decrease the cutting speed as compensation. A well-maintained and even power supply will ensure laser penetration stays the same at high cutting speeds.

3. Diverse Material Compatibility

Material compatibility is directly related to laser power supply. Softer materials will burn under sudden power spikes, and tougher metals will be unaffected if the power drops. Consistent laser power will ensure cutting effectiveness across various materials.

4. Minimizing Heat Affected Zone

Excessive power can lead to increased heat generation, resulting in a larger heat-affected zone (HAZ) around the cut. The heat input is controlled by maintaining optimal power, minimizing the impact on the material surrounding the cutting area.

5. Fiber Laser Longevity

Consistent power levels contribute to laser longevity. Power fluctuations will lead to increased wear and tear on components, reducing the overall lifespan of the fiber laser cutting machine.

4 Reasons and Solutions For Power Drop of Cutting Machine

Laser power drops can be difficult to identify and rectify. The culprit could be a dirty laser head or a damaged optical path.

Here are the four most common reasons for electrical power drop and their solutions.

1. Laser Overheating

Fiber laser cutting machines are compact devices that generate a lot of heat. During long continuous cutting sessions, the heat builds up to a critical point, and the safety mechanisms come into effect. It reduces the laser power supply and prevents further heating.

Solution

The cooling system of a fiber laser cutting machine is delicate. Go through the following steps to ensure it’s working properly.

- Keep the air vents clean and prevent dust build-up.

- Ensure the exhaust section of the cooling system isn’t being blocked.

- If you live in a particularly warm environment, you will need to invest in an AC unit.

2. Damaged Power Supply

The power drop can also be attributed to bad capacitors in the power supply. Over time, the components of a fiber laser cutting machine will wear down. This includes the electronics that control the electrical power supply.

Solution

Use an electricity usage monitor to determine the power drawn from the socket. For a fiber laser cutting machine operating at 1kW, you should see an excess of 10kW power draw. The additional power goes to the various components, such as the cooling system, the gas jets, and the CNC motors.

If you see a significant power drop, consult your laser cutting machine’s manufacturer for troubleshooting and replacement parts.

3. Bad Software

Modern fiber laser cutting machines have several conveniences, such as a smart temperature monitor, auto-focusing lens, pre-saved material cutting profiles, and dynamic power control. Firmware updates that improve digital security and introduce new features, often have software bugs.

Bad software updates can introduce problems in the machine’s power control system, causing power drops during the laser cutting process.

Solution

Have an electrician examine your laser cutter’s power supply. The power drop can be attributed to bad software if all components are undamaged and fully operational. Check if your laser cutting machine has a new firmware (software) update available. If not, your next step should be contacting the manufacturer.

4. Component Damage

Lastly, we have component damage as a reason for the electrical power drop. Damage can take many shapes and forms, including damaged optic lenses, cracker fiber cables, poor gas pressure, and more.

Component damage can mess with the laser cutter’s sensors. As a result, the machine restricts the power supply to prevent further damage.

Solution

- First, check if the auxiliary gas supply is operational. If your inert gas jet is blocked or damaged, it will cause the laser system to reduce the power supply.

- Next, check the laser beam focusing system. An unfocused beam is an indication of damaged lenses.

- Give the laser cutter a visual. Look for broken parts, gaps in the assembly, and general wear and tear.

- Call an expert technician to check and repair the laser cutter.

Ready to Get Your Own Laser Machines?

Boost your operations with Baison Laser's advanced, customized technology!

FAQs

1. What are the Major Causes for Laser Cutting Machine Power Drop?

Laser-cutting machine power drop can be attributed to overheating, damaged components, or software bugs.

2. Do Fiber Laser Cutting Machines Lose Power Over Time?

A fiber laser has a lifespan of 50k to 100k hours of usage. After that, the laser source degrades and draws less power from the socket.

3. How Much Power Does a Fiber Laser Cutting Machine Use?

A standard fiber laser cutting machine uses ten times the electrical power of the laser output. So, a 50W laser cutter will consume 500W of electrical power, and a 1 kW laser will consume over 10kW of electrical power.

Conclusion

Maintaining optimal power in laser cutting is paramount for achieving accurate, efficient, and cost-effective results. It ensures the machine’s reliability, extends its lifespan, and allows for consistent, high-quality cuts across various materials and thicknesses. Operators should manage laser overheating and regularly check for software updates. However, professionals should investigate and resolve severe issues relating to component damage.

Power-Up Your Laser Cutter with Baison!

Baison is the premier laser solutions provider for the global market. Our Laser Cutting Machines are built with the latest innovative fiber laser technology, ensuring a consistent power supply for years to come. We offer complimentary Customer Training sessions to help you maintain your laser cutter and maximize productivity.

Get started with our FREE Application Evaluation program and give your business a power boost. Contact us Now!