What Is CNC Laser Cutting Machine?

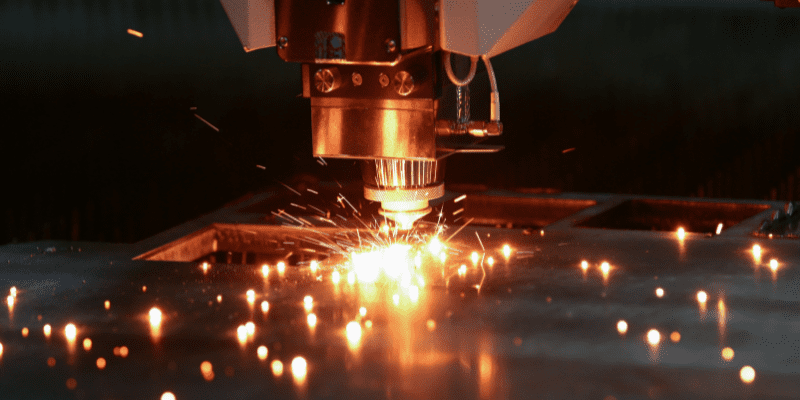

A CNC laser cutting machine is a piece of technology that vaporizes, melts, or otherwise progressively removes material using laser beams as the primary cutting tool. Computer numerical control, often known as CNC, is a technology that enables a machine to employ optical, an assist gas, and a navigation system to guide and center a laser beam onto the material.

They are pretty well-known for their exact cuts. Even though laser cutting has existed for many decades, CNC has introduced not long ago and is used by many. CNC depends on a computer program to perform its functions, much like any other system technology. This system does the cutting by executing several G-Code operations in sequence.

How Does a CNC Laser Cutting Machine Work?

The operation of the laser cutting machine happens by focusing a powerful laser beam, which gets controlled by computer numerical control (CNC) in the direction of the material. The laser beam gets navigated with the help of the optics and the CNC. There are other navigation methods, such as collimation, adaptive optics, and constant beam length axis. CNC laser-cutting machines depend on CNC’s functionality to deliver instructions to conduct the cutting sequence.

In addition to being a non-contact, thermally based technique, the CNC laser cutting process is also a very efficient method for laser cutting. A laser-focusing lens and a nozzle are both incorporated inside a laser head, which is the component responsible for carrying out this process. The combination of these things produces a concentrated laser beam. After that, computer numerical control (CNC) regulates the motion sequence, enabling you to form the material according to the design of your choice.

Types of CNC Laser Cutting Machines?

It is possible to categorize different types of CNC laser cutters according to the state of the operating laser medium. Therefore, when it comes to different kinds of CNC lasers, the most common are: the CNC Fiber Laser, the CNC CO2 Laser, and the CNC Crystal Laser.

These specific laser cutters use computer numerical control (CNC) technology to supply you with the incredible finishing you need on the cut. Here is a list of the following types you can get in the market.

- CNC Plasma Cutting

- CNC Laser Cutting

- CNC CO2 Laser Cutting

- CNC Crystal Cutting

- CNC Flying Optics Machines

- CNC Neodymium-doped yttrium aluminum ganet.

The few types of laser-cutting technologies that are now accessible across the industry are summarized above. However, the three primary CNC machines are:

CNC Fiber Lasers

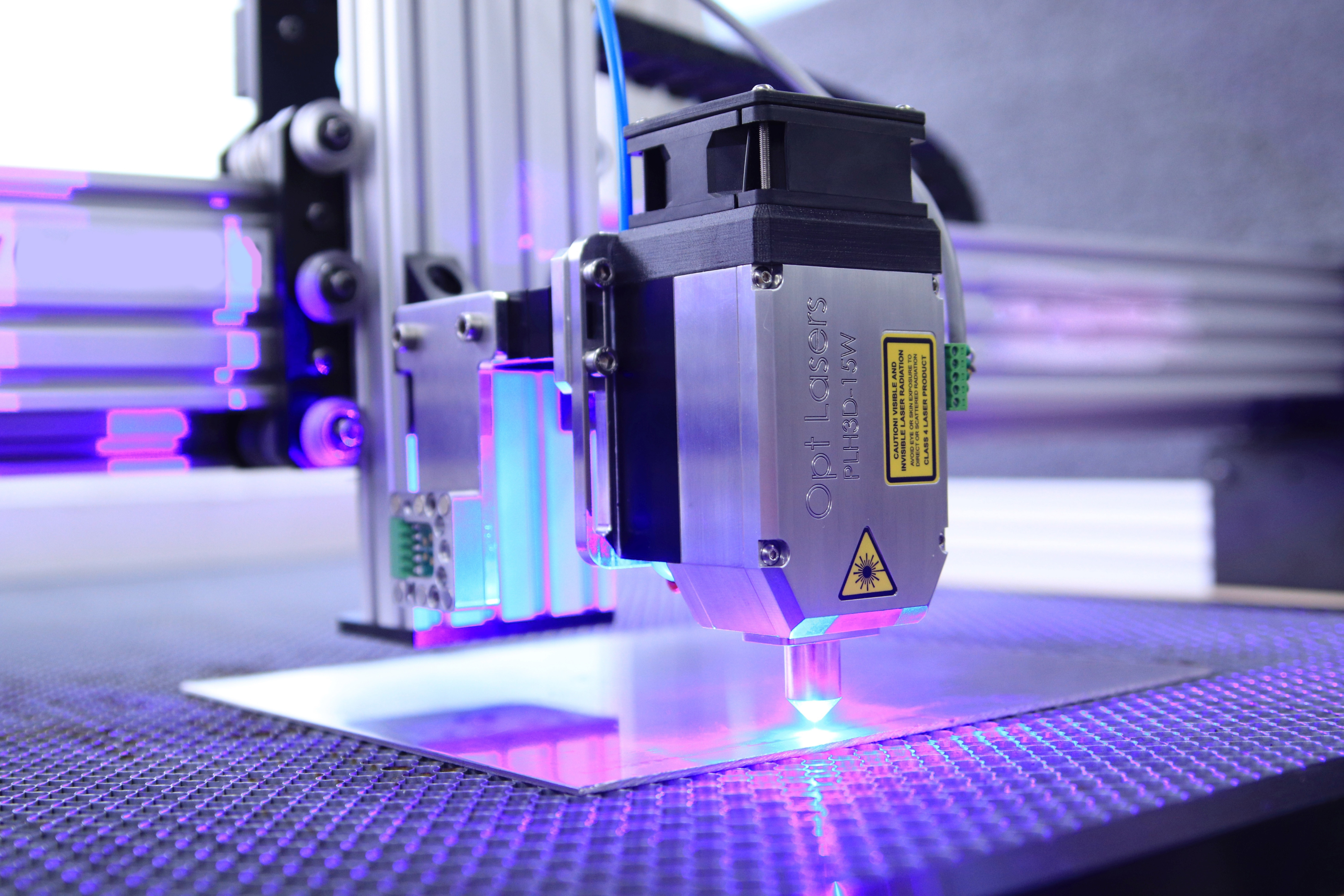

This laser machine uses a method that generates a powerful laser beam by using a stack of diodes to produce the laser power. The laser’s ability to be precise and consistent results from the beam getting concentrated utilizing a fiber optic cable. This machine uses computer numerical control (CNC) to improve the cutting accuracy and ensure the laser beam moves in the correct direction.

CNC CO2 Laser

This laser machine uses carbon dioxide as the active laser medium in their machine. CNC technology often uses them, improving the lasers’ accuracy and precision. Given its high power output and excellent efficiency, this laser gets heavily utilized in the industry. This machine is ideal for cutting thin sheet metal or anything else with a thickness of fewer than 10 millimeters.

CNC Crystal Laser

In a CNC crystal laser, the high-powered output gets generated by the beams that come from the crystal. Neodymium-doped yttrium aluminum garnet and neodymium-doped yttrium ortho-vanadate are examples of the materials used in constructing these machines. These machines use CNC technology, guaranteeing the precision and the shape produced. Therefore, crystal lasers have a higher intensity than other forms of lasers. They can also cut through various materials, including carbon steel, aluminum, and thin metal sheets.

Difference Between the CNC Cutting & Laser Cutting

Both are different from one another due to the presence of certain features that set them apart. The primary distinction is in the way in which they operate. The term “friction” refers to the interaction of the tool being used to cut the material, and it is the driving force behind the CNC cutting process.

On the other hand, the procedure used for laser cutting is the opposite. When laser cutting, the equipment directs intense laser beams onto the substance. Compared to CNC laser cutting, laser cutting takes place without the machine ever coming into contact with the material.

The pricing is also another point of differentiation between them. Because of the higher level of technology, a CNC machine will be 10% more costly than a laser cutting machine. Due to this, if you run a small creative company and need a wide variety of cutting tools, you should consider investing in a CNC machine. Laser cutting is the method of choice for industrial applications since it simply requires a predetermined set of forms, and there is a high demand for production.

CNC Laser Cutting Machine Applications

CNC laser machines offer various applications in manufacturing, including engraving, large-scale cutting production, 3D printing, medical usage, and the textile industry. These machines get utilized in multiple industries because of their highly efficient process and technology. In addition, since CNC technology has been accessible, many businesses are deciding to use such cutters. The following are some of the most prevalent uses for laser cutting that are currently available:

Medical Usage

The medical industry makes significant use of laser cutters in various applications. Moreover, with the recent advancements in CNC machining technology, laser cutting has become more critical in this segment of the economy. Because of its excellent efficiency and massive volume, the medical industry finds it highly efficient to work with CNC Laser technology.

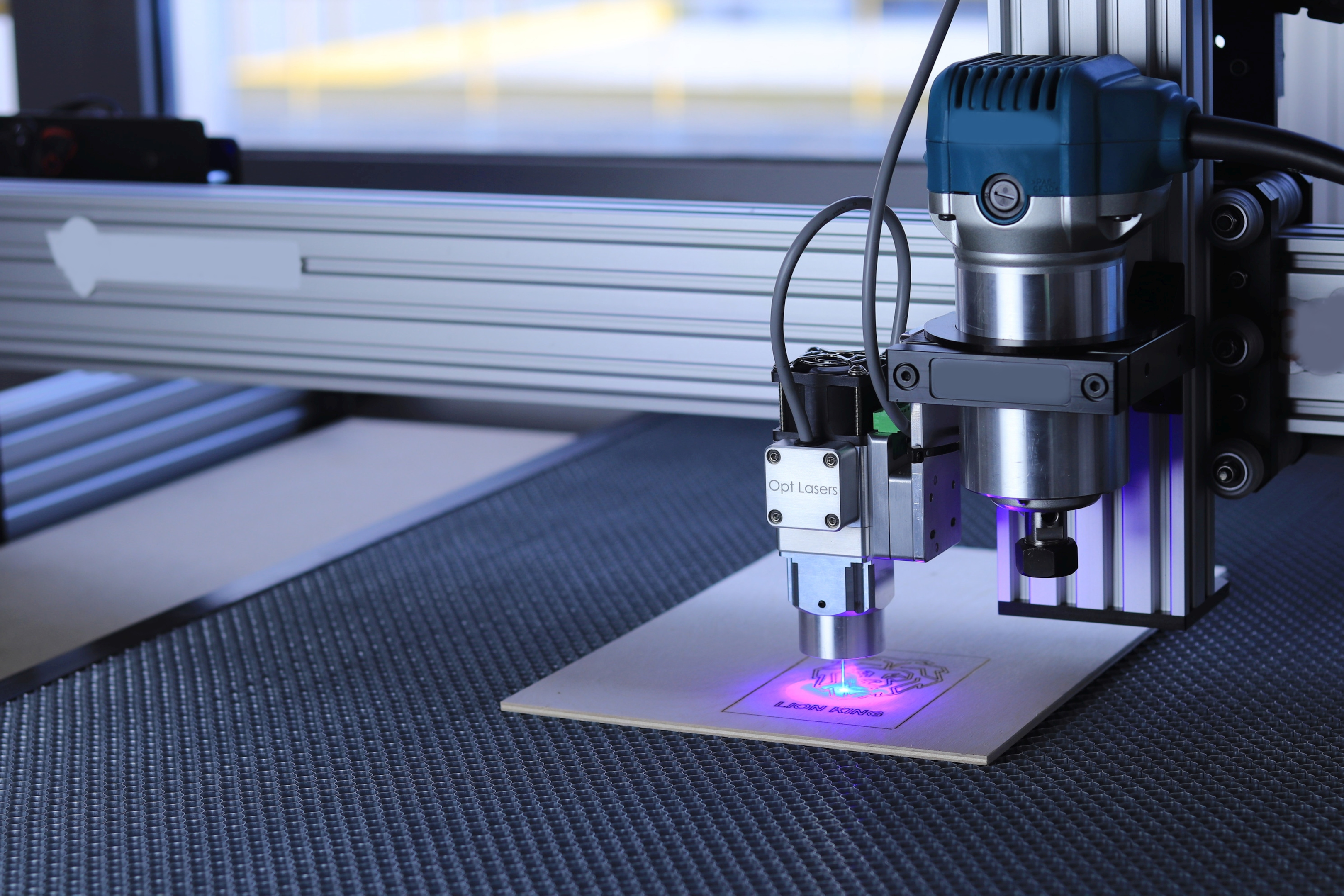

Engraving

Due to the high precision and accuracy required in engraving and marking, most companies use such lasers. In this application, computer numerical control (CNC) technology uses features to specify the material’s engraving or marking. With the assistance of these CNC laser cutting equipment, you can operate on even the tiniest thing possible.

3D Printing

Printing objects with 3D technology is the construction method of the future. The development of 3D printers and the rising demand for them have led to the use of CNC laser cutting machines in producing these devices. Devices known as 3D printers are those that are modified to make use of laser technology. You can cut through various materials and patterns with CNC laser cutting integrated into the printing machine.

Workshop

As a result of their versatility and ability to operate with a wide variety of equipment, these machines are also an ideal choice for small workshops. Due to this, there is a significant and growing demand for CNC lasers in workshops. They cut various materials and objects into multiple forms and dimensions. They have the opportunity to be more creative when working on projects.

Textile Production

The textile industry has seen a substantial expansion as a direct result of the development of CNC laser cutting technology. Using this technology has resulted in a reduction in the workforce, which has led to an increase in profit. In industries with a high need for more design and printing, CNC technology gets used to a large extent.

Aerospace Industry

The aerospace industry demands that components be manufactured with high precision since they get used in various machinery and aircraft. The components used must have an extremely high level of accuracy and cannot have any form of flaws or holes in them. In this kind of work, the consequences of even the most minor error could be quite severe; for this reason, CNC machining gets strong recommendations.

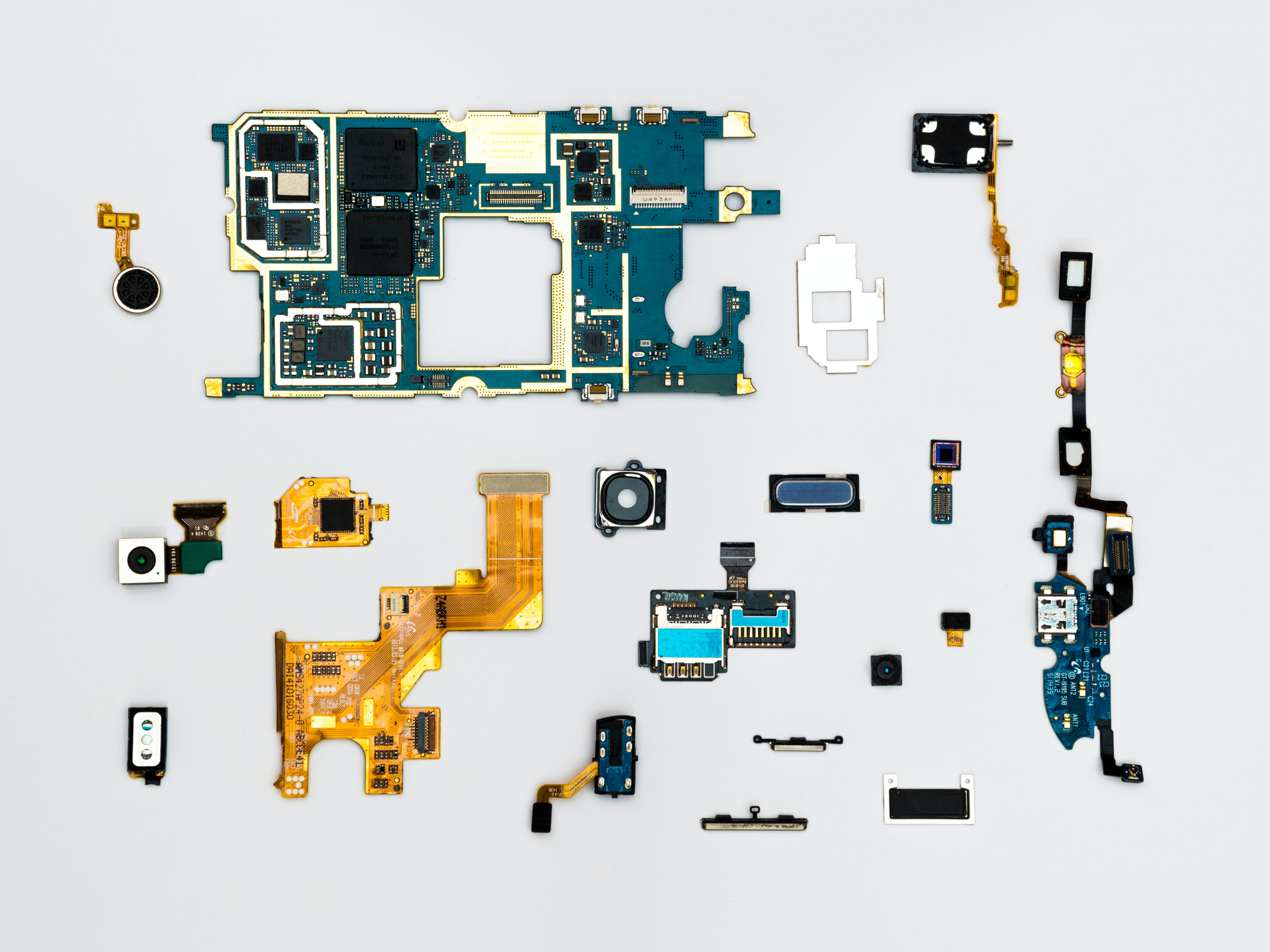

Electronic Industry

The electrical components utilized in contemporary gadgets are becoming lighter and smaller as technology advances; nonetheless, assembling these components and producing them requires high precision and accuracy. You might come into components that need you to work with little 10mm components at some point. Therefore, several businesses have CNC machines installed in their workplaces.

The Benefits of Using a CNC Laser Cutting Machine

Compared to a traditional laser cutting machine, the quality of work produced by a CNC laser cutting machine is regarded as superior. It is due to the many benefits of being safer, more precise, and, most importantly, more accurate.

These machines provide several benefits that are not available with other options for various reasons. Using a CNC laser cutting machine has several advantages, some of which are detailed below.

- Automated Machine: CNC is a term that stands for computer numerical control. It indicates that the laser cutting machines that use CNC technology execute a series of pre-programmed automated procedures to complete the cutting process without any involvement from a human operator. Since the entire process of the machine is automatic, it is much more efficient and profitable. In addition, since an automated machine performs the cutting, the quality and accuracy of every cut are exceptionally high.

- Flexible: Almost any laser cutting gets done with the same equipment without needing adjustments. The machine is capable of cutting through a wide variety of forms and sizes with a single setting. In addition, because of advancements in CNC technology, you don’t even have to move the machine at all while you’re using it. Simply enter the required measurements and features into the computer, and the machine will take care of the rest.

- Precision: When using CNC, there is no need for concern about the final piece’s accuracy. CNC laser cutting machines can create more detailed designs and make holes as tiny as 2 millimeters in diameter. These get completed using a laser beam with high-power output and great precision and accuracy.

- Reduces Distortion: You are required to use your hand while operating standard laser equipment, which results in the material getting distorted and the substance getting contaminated. However, since CNC technology reduces the possibility of material deformation and contamination; therefore, it is well suited for use in the medical industry.

- Cost Saving: These CNC machines have a very minimal need for power, which is one of the most amazing aspects of their technology. Compared to other laser-cutting machines, the overall operating costs of these devices are quite moderate.

- Complex Design: Since it uses CNC, the machine can precisely cut through various intricate patterns while exhibiting no inaccuracy. The machine gets used to cleanly cut tiny holes and components in metal while also removing any burrs or dross that may be present.

Tips for Choosing the Suitable CNC Laser Cutting Machine for Your Business

Laser technology has benefited various business sectors, making it one of the most ground-breaking and inventive pieces of modern technology. It is essential to comprehend which laser-cutting equipment suits your needs.

There are a variety of CNC laser cutting machines available, and selecting the appropriate one could be a time-consuming and challenging process. As a result, we have covered some of the most important factors you need to consider while looking for the ideal CNC laser for your business.

Requirements

You should always make sure to analyze your requirements before purchasing any kind of laser cutter. It is essential. Look into the reasons for your necessity for a laser machine. Are we talking about a large-scale or a small-scale operation here? The answers to these questions will give you a completely transparent comprehension of your requirements. Make sure you know what you will use it for before investing in a CNC machine.

Software Compatibility

Software compatibility gets included with each CNC laser-cutting machine that you purchase. However, the most significant issue is the kind of software used. If you acquire a laser machine with a lower price point, you will be obligated to use the build software included with the equipment.

When you buy a high-end laser machine, it will come equipped with features that enable you to utilize third-party software like Adobe or CAD. These abilities will be included in the purchase price. Experimenting with the various patterns the machine can cut opens up additional creative possibilities for you. Therefore, when buying, make sure your need for software compatibility.

Spacing

Laser machines might take up a significant amount of space depending on the type. When purchasing laser equipment, most of us overlook the significance of spacing. Due to this, the work location will either become too congested or too empty. Today’s laser-cutting machines are available in every conceivable size and form, making it quite simple to choose the one that suits your space. However, with increased size comes more power; hence, selecting the appropriate powered laser is essential when buying laser-cutting equipment.

Ensure Quality

Laser machines can be quite pricey; thus, when investing in such costly equipment, it is essential to ensure the product’s high level of quality. Today, many businesses have responded to the growing demand for laser cutting machines by beginning production of laser cutting machines in a variety of designs and shapes.

Due to growing competition levels, more and more items are counterfeit or duplicated. It is essential to examine and inspect everything thoroughly while shopping for affordable machines. If you are just starting, we recommend investing in machinery from well-known companies manufacture.

Cooling & Ventilation

If you are in charge of a powerful CNC laser cutter machine, you must ensure that you have an adequate cooling and ventilation system. The enormous power output of any large laser equipment tends to cause it to get extremely hot very rapidly. As a result, it is essential to ensure the machine has an effective ventilation system and a cooling mechanism.

Budget

When purchasing a CNC laser machine, you must be aware of several different aspects. Be sure to have a predetermined budget in place for your company before purchasing a CNC laser machine. It is incredibly simple to spend more than required.

Always make purchases based on how they benefit your company and its productivity. A few factors, such as maintenance costs, new tools, and equipment, could be required in the future, which add to the machine’s total cost. When planning to get a laser device, it is essential to keep all of these aspects in mind.

Final Verdict

Without a doubt, CNC laser machines make dealing with materials more creative and enjoyable. Their very effective and efficient procedures enable them to be more versatile. With the technology available, users can now cut through materials of all forms and sizes with great accuracy and precision. If you are still unsure about the CNC machine procedure, please contact us for more assistance.