The current world has made a revolutionary change in many aspects. Industries became more efficient with the help of innovation and technology. These indeed turned impossible to possible. Just like that, industrial operations have been more advanced with the help of laser-cutting technology.

Have you ever imagined heavy materials could easily be cut simply with the help of light? Well, advanced laser-cutting technology turned the imagination into reality. Now, manufacturing industries are more proficient and productive, thanks to laser-cutting technology!

While discussing laser-cutting technologies, you must know that there are different types. The two most popular technologies are – Fiber laser and CO2 laser. While they all follow the same mantra of cutting things, there are notable differences between these two technologies.

So, what are the basic differences? Which one suits your needs best? Spare a few minutes and find out!

Laser Technologies Overview

Laser cutting is an indirect process to cut materials with a laser light beam. At present, it has earned quite a popularity in industrial sectors for its accuracy, flexibility, and speed. There are many types of laser cutting technologies.

The two most popular types nowadays are CO2 laser and fiber laser systems. Each of them offers some exclusive advantages depending on the materials and preciseness.

CO₂ and fiber lasers have a typical implementation process, known as ablation, to cut through the material. Ablation is a process of removing material through vaporization that helps to create a clean and sleek cut.

Besides a few similarities, each laser type has specialized applications, but both play significant roles in many fields and make the cutting process faster and more reliable for different materials.

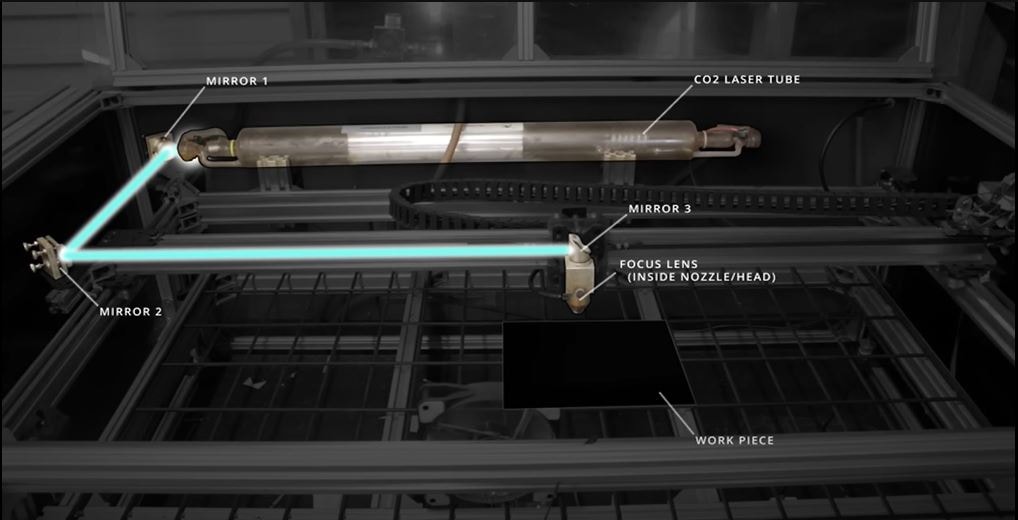

CO2 Laser System

Like its name, CO2 lasers operate through a gas mixture mainly ruled by carbon dioxide gas. It uses a gas laser to create a powerful laser beam to cut through the thick materials. It can easily be cut through various materials like – plastic, metals, wood, and textile products. It can be an excellent choice because of its extensive and extraordinary use in various fields.

Fiber Laser System

On the other hand, Fiber lasers function through fiber optic cable, which creates a highly efficient laser beam. The laser beam can cut through thin materials while delivering proficiency, speed, and sleekness. It saves energy expenses and is highly appreciated in industries like electronics and jewelry.

CO2 Laser vs Fiber Laser: Performance Comparison

CO2 and Fiber lasers surely have some uniqueness that differentiates them. To have a proper understanding, let’s follow the given chart of comparison between CO2 and Fiber lasers-

| Feature | CO2 Laser | Fiber Laser |

|---|

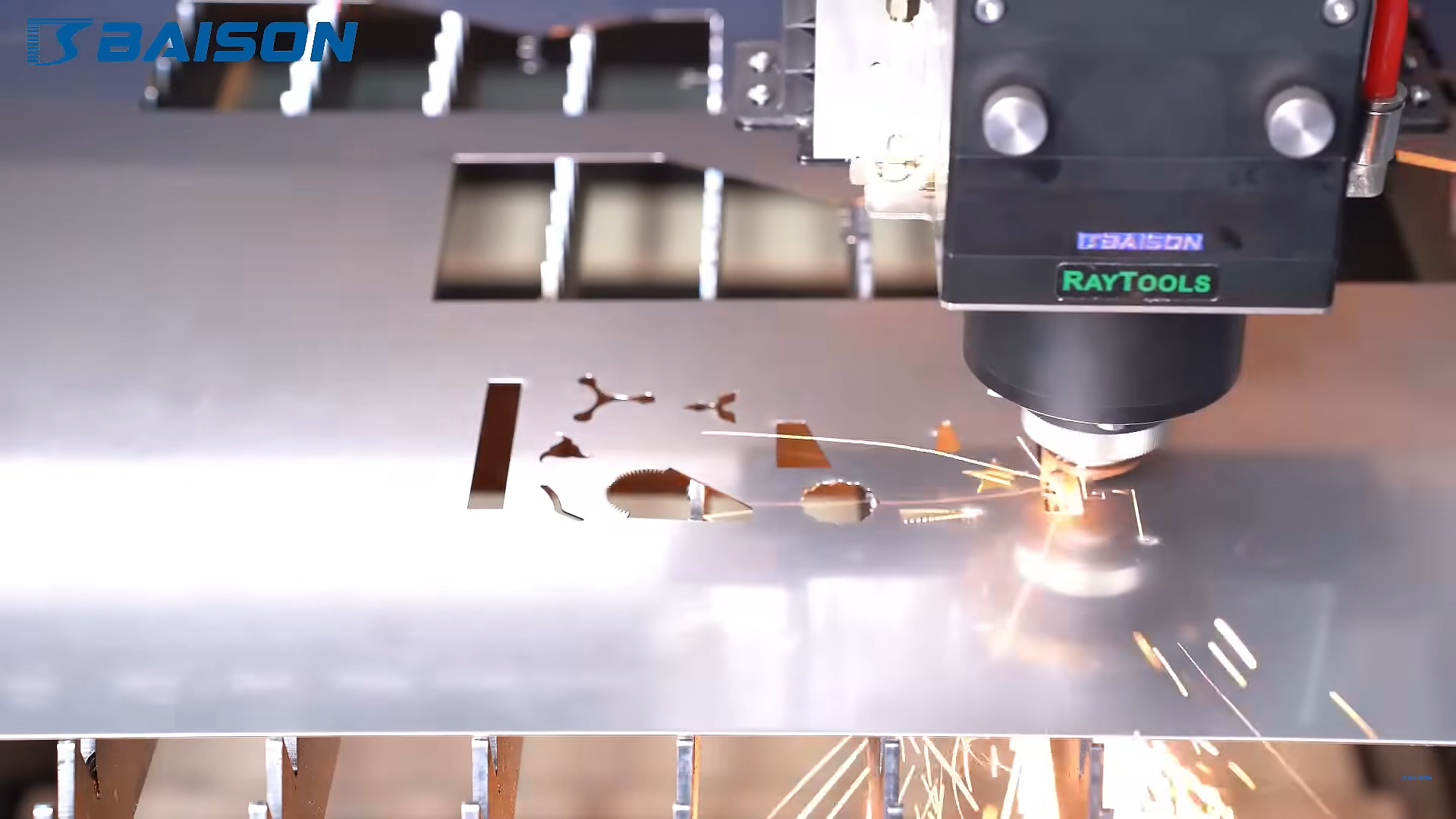

Fiber Laser Cutting Machines and Equipment

Fiber laser cutting machines use the heat of a fiber laser to melt and remove the selected material. This creates a smooth and clean cut with high precision. Fiber laser cutting machines have become a significant part of the industry. Fiber optic cable creates laser beams that deliver high-precision cutting with excellent proficiency.

Besides, fiber optic cable delivers a laser beam that works with high precision and consumes less energy. This power source is also very cost-effective. It is well-known for its low maintenance quality, which ensures the machines’ longevity.

A well-built fiber laser cutter can last from 50,000 to 100,000 hours of operation. Furthermore, fiber laser cutting machines can easily cut objects with a depth of less than 5 mm efficiently and precisely. This quality makes them ideal for cutting thin materials.

Many types of fiber laser cutting machines are used in different sectors for different purposes. All the fiber laser cutters work by following the steps one by one. These Steps are-

- Generating a laser beam

- Efficiently guiding pump light through the optical cable

- Light amplification

- Laser focusing

- Reaction of materials.

Industry Applications and Material Compatibility

CO₂ and fiber laser cutting technologies have significantly excelled in their respective fields. Each of them carries unique qualities that have expanded their range of use. Compared to some of the other cutting methods, laser cutting gives you a decent edge in productivity.

CO2 Lasers can perfectly cut through any material, metal or non-metallic components. Though they can cut any material, CO2 lasers are exclusively suited for non-metallic materials such as various plastics, wood, acrylic, paper, leather, and fabric. Manufacturing industries related to non-metallic applications widely use CO2 lasers for this quality.

These machines are used in various industries, such as the energy sector, arts and crafts, textile industries, Tannery Industries, food and beverage industries, etc. Also, non-ferrous materials like copper and aluminum can be easily cut quickly and efficiently based on their thickness.

However, fiber laser cutting machines work intensely with any material. This proves the versatility of fiber laser cutters. The fiber laser cutting machine operates through a fiber optic cable that can deliver a high-energy beam.

This high-energy beam is the principal component to ensure the machine’s high proficiency, accuracy, and speed for cutting metals. Despite being able to cut any metal at any thickness, fiber lasers are best suited to cut of 20 mm or less.

Any metal, be it ferrous or non-ferrous, such as carbon steel, stainless steel, aluminum, copper, titanium, steel, brass, or other reflective metals, can be excellently cut by a fiber laser cutter.

Various industries widely use fiber laser cutting machines, such as medical, advertising, automotive, aerospace, jewelry, fitness equipment, kitchenware, military, agricultural equipment, and sheet metal processing factories.

Cost Considerations

We have learned about all the qualities and applications of both machines in detail. Now, let’s see how much they cost for implementation, operation, and maintenance. We need to consider both machines’ overall costs to choose and evaluate the perfect laser-cutting machine.

Let’s help you choose the right one.

Upfront or Initial Cost

Between the advantages of fiber lasers and CO2 laser cutting machines, fiber lasers carry a higher upfront cost than CO2 lasers. The prices vary according to the features, per watt of power, degree of automation, etc. The more advanced, upgraded version you choose, the higher the price. So, you can say the implementation process will cost you significant money.

In contrast, the upfront cost of a CO2 laser cutter is less than that of a fiber laser cutter, but the maintenance cost of CO2 lasers is very high compared to that of fiber lasers. It has more moving parts than a Fiber laser cutter. Also, the glass and lens need regular cleaning alongside the gas refill, which increases the machine’s maintenance cost.

Maintenance Cost

You can have a guaranteed lifespan with the fiber laser cutter. Fiber laser cutting machines are pretty reliable and durable. Their maintenance is not so complicated or pricy. So, the overall maintenance cost is not so high apart from the upfront cost. This longevity ensures energy and money savings.

CO2 laser systems’ laser tube requires frequent replacements and it alone can cost nearly $500. The other parts don’t come cheap either.

Energy Consumption and Efficiency

In contrast to CO2 laser cutters, fiber laser cutters have low energy consumption ability and a high efficiency rate. This increases the lifespan of fiber laser cutters 10 times more than CO2 laser cutters. Fiber lasers offer over 90% efficiency, which results in significant cost savings, whereas CO2 lasers are only about 5 to 10% efficient.

Considering both machines’ facts, the fiber laser cutting machine seems more cost-effective despite its upfront expense.

Setup and Operation

In laser cutting technology, every type has unique qualities that help stand out from each other. Those traits expanded the possibility of their use in various fields. Both fiber laser cutters and CO2 laser cutters differ in terms of setup and operation in addition to those different qualities. In contrast to CO2 laser-cutting machines, fiber laser-cutting machines are much easier to set up.

The design of the fiber laser cutter is quite simple and has fewer parts. So, it takes less time to set up and operates very quickly. This reduces idle time and increases machine productivity. On the other hand, CO2 laser cutters include complex design and setup, which is quite time-consuming. After installation, the machines also require operation time, which maximizes idle time.

Also, fiber laser cutting machines require less maintenance than CO2 laser cutting machines. CO2 laser cutters need regular gas mixer refills and other maintenance, which fiber laser cutters don’t require. The complex design and implementation have raised the regular maintenance of CO2 laser cutters.

In contrast, fiber laser cutters have less complex designs, minimizing the need for regular maintenance or gas refills. This also made the machine energy efficient compared to CO2 lasers.

Furthermore, fiber laser cutting machines deliver higher energy efficiency while consuming less power than CO2 lasers. This quality raises the performance quality of fiber lasers. This energy efficiency makes fiber lasers more eco-friendly and promotes sustainability.

Besides, in terms of precision and speed, fiber lasers excel in both fields than CO2 lasers. In particular, CO2 lasers create a rough edge when cutting thin metals. The fiber laser’s focused beam helps deliver a sleek and smooth cut on thin materials with the highest accuracy and precision.

Combined with high-speed and precision fiber lasers, they can complete the given task faster than CO2 lasers.

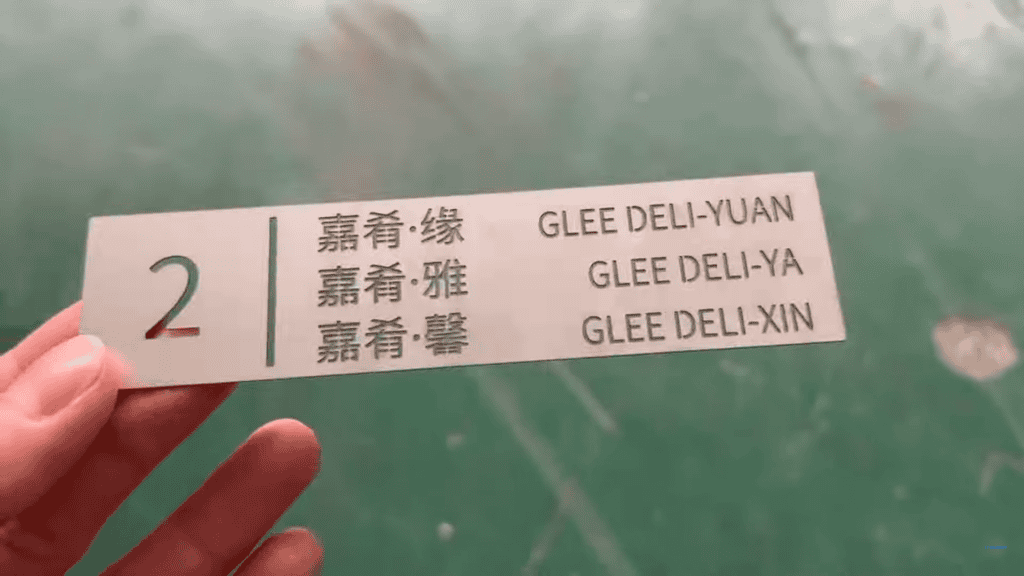

Marking and Engraving Capabilities

Fiber and CO2 lasers have excellent capability in cutting, marking, and engraving various materials. Both of them can cut any material, be it non-metal or metal. Yet, they show excellence in cutting certain types of materials.

While fiber laser works better to mark, cut, or engrave metal, especially reflective ones, CO2 lasers are perfect for marking, cutting, or engraving non-metallic materials. Materials like textiles, wood, or cardboard are the specialty of CO2 lasers. On the other hand, shiny and reflective metals like steel, brass, titanium, etc., are fiber lasers’ specialty.

Moreover, fiber lasers can create very small focal diameters. So they are perfectly suitable for permanently marking serial numbers, barcodes, and data matrices on metallic components. For this quality, industries like- aerospace, automobile, and electronics choose fiber lasers for marking purposes to ensure accuracy.

In contrast, the long wavelength of CO2 lasers delivers smooth and perfect marking on non-metal and soft materials without any defect. This quality has made CO2 lasers a top choice in industries that work with packaging, fashion, and organic materials. They use CO2 laser cutting machines to engrave logos, designs, and patterns on the materials accurately and perfectly.

Laser Cutting Considerations

By now, you must have gathered a clear idea of which laser-cutting machine suits which type of job. You also become aware of all the qualities of each of the machines. Now, it’s time to choose between CO2 and fiber laser cutters. Your choice ultimately depends on the specific application and other requirements.

To choose the right one, consider what material you need to process. Material type is the primary factor in choosing between CO2 and Fiber lasers. As we already know, CO2 works best with non-metallic materials, and fiber lasers are best for working with metallic components. You need to consider this fact at first.

Then, the precision level and speed should be considered. Fiber laser works faster and has the highest precision than CO2. So, you need to consider this fact too.

Don’t forget about the operating cost, which is also crucial to implementation and maintenance. Compared to CO2 lasers, Fiber laser cutting machines offer high precision and low operating costs. This helps with huge cost savings, making them an attractive option for many industries.

So, you need to consider the overall expenditure of both machines to choose the right one. This way, you can save on expenses while having the best outcome.

Choosing the Right Laser Technology

Now that you have considered all the main points, it’s time to choose the right laser technology. To choose the right laser technology, you must evaluate your needs, purposes, and limitations. This will help you ensure your business’s production goal by choosing the best laser-cutting technology.

Before choosing the suitable machines, you must decide what material will be processed. You can choose fiber laser cutting machines if your business mainly works with thin or reflective metal. Fiber laser cutters’ precision level, speed, and operating costs are top-notch. So you can make detailed, intricate cuts and achieve highly accurate outcomes with the fiber laser cutter.

On the other hand, CO2 lasers are better suited to cut thicker materials. If your business is related to dealing with non-metal or non-ferrous materials, you can opt for CO2 lasers. The ability to deliver top-quality results in cutting thicker materials has widened the use of various components. So, you can choose CO2 lasers for cutting non-metal materials.

Conclusion and Recommendations

With advanced laser technology, fiber laser technology has gained great global recognition. Superior technology, high-speed benefits, almost half of the operating costs, and three to four times greater throughput than CO2 lasers are all essential factors that have made fiber lasers gain market share day by day.

Both fiber laser and CO2 laser technology have shown excellence in their positions. Their exceptional qualities have proved their value in different fields worldwide.

For the most precise fiber laser cutting services, reach out to Baison Laser, an industry leader in highly accurate fiber laser services. With more than 20 years of experience and 300+ patents, we serve over 100 countries and regions. At Baison Laser, we have the most advanced and diverse set of laser cutting for’ beasts’ purposes.

State your needs; get a quote today!