This article will discuss chucks in laser-cutting machines. We will discuss what it is, how it is used, different types, benefits, and all there is to know about it. Before we become specific about chucks, let’s take a look at what is a laser-cutting machine.

What is Laser Cutting?

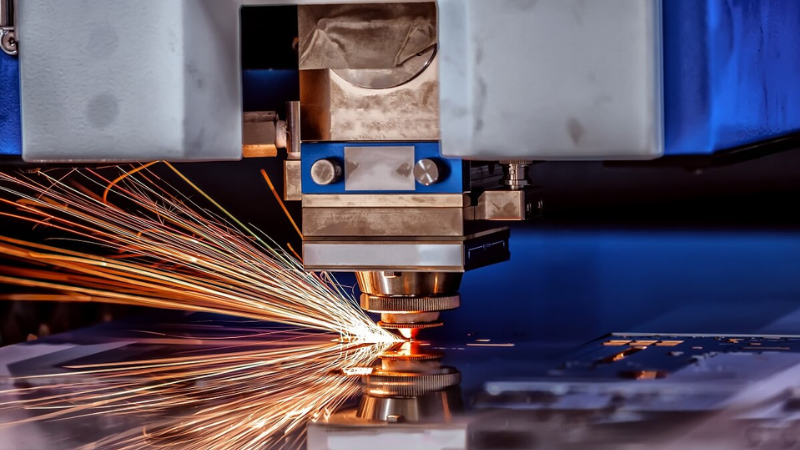

Laser cutting is the technology of cutting material with high precision. The programmed computer numerical control directs the laser beam. As software directs the beam, it moves accurately following the design.

The powerful laser power can cut through hard material and thin plates and wires with equal precision. The focused beam has high power that produces heat and vaporizes the material where it is directed.

The stimulation of lasing material creates the laser beam with the help of electrical discharge or gas. The beam is further amplified by passing through a lens or mirror until it becomes a powerful coherent monochromatic light.

Beam is focused on the desired spot of the base material. The CNC system controls how the beam travels on the material; thus, it can cut, engrave, drill, and follow any intricate pattern.

What is a Laser Chuck?

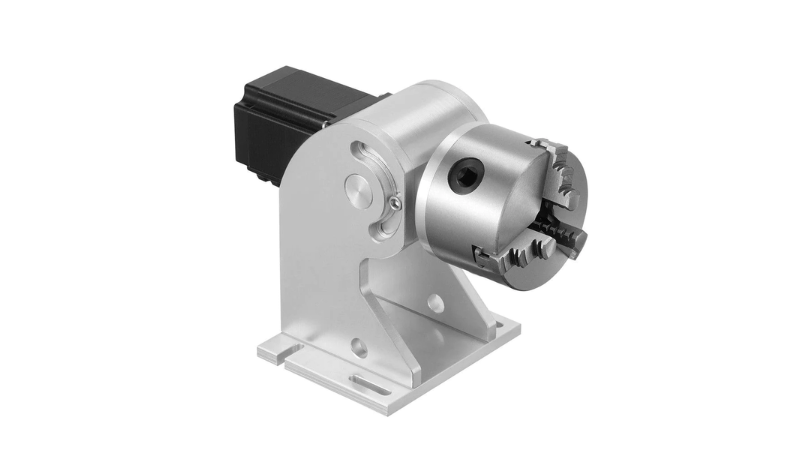

Chuck is part of a laser-cutting machine. Its purpose is to hold the cutting material in place. It keeps the material secure on a level surface. Even with a laser engraving machine, the material must be held in place while the beam works. And it may also involve moving the material or rotating it while it is working.

So basically, a chuck keeps the cutting material in place while the processing; Laser cutting deals with tubes and pipes that need to stay in place while the laser cutting machine is working. It can hold both big tubes and thin plates and sheets depending on the chuck you use for the machine.

How does Laser Chuck Work in Laser Cutters?

Chuck comes in different kinds. A laser tube cutting chuck comes as a vacuum table or a mechanical clamping system that keeps the material in place. Now the type of chuck determines how it works. A mechanical chuck keeps the material using physical force, and a vacuum table uses suction power.

The chuck ensures the material remains in the right position while cutting so that cuts are precise and even. The chuck can hold several materials, including pipes and tubes of all types.

What are the Key Components of a Laser Cutter?

Here are the different components of a laser cutter

Laser Source

The source of how a laser beam is generated. It can be a gas laser-like CO2 Fiber Lasers or solid state.

Optics

Optics are the beam delivery system, like mirrors and lenses used to deliver the beam.

Cutting Bed

The surface where the material is to be placed.

CNC controller

The computerized program directs the beam onto the material for cutting or engraving.

Control System

It manages the laser output power, speed, and direction of the laser beam.

Exhaust System

The system removes the fumes and gases generated from the cutting process.

Cooling System

It prevents the optics and laser generator from overheating.

How Do Laser Chucks Work With the Cutting Head?

The chuck is either a flat surface with suction power or mechanical clamps to hold the material in place. It has holes on the surface. The material is placed on the chuck surface. When the machine is active, the suction holes keep the material in place.

The laser head is part of the machine that directs the beam on the surface. It moves on the material according to the programmed instructions. Chucks can also be adjusted to suit different types and sizes of materials. So it’s important to choose the right cutting head for your needs.

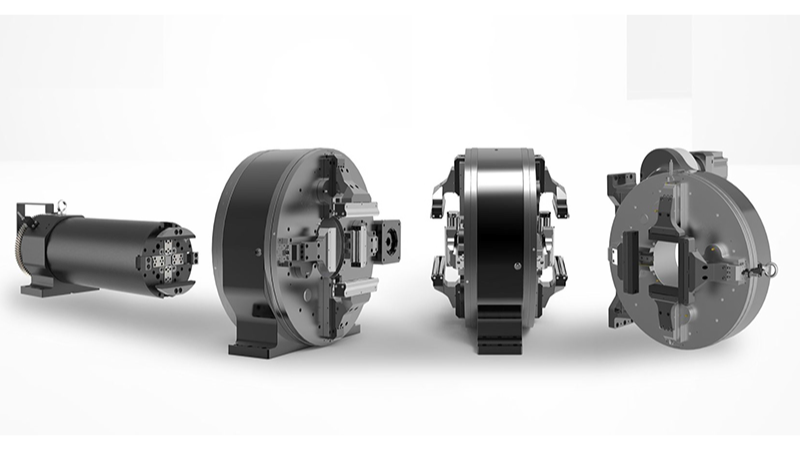

Different Types of Laser Chucks

Let’s take a look at different types of chucks:

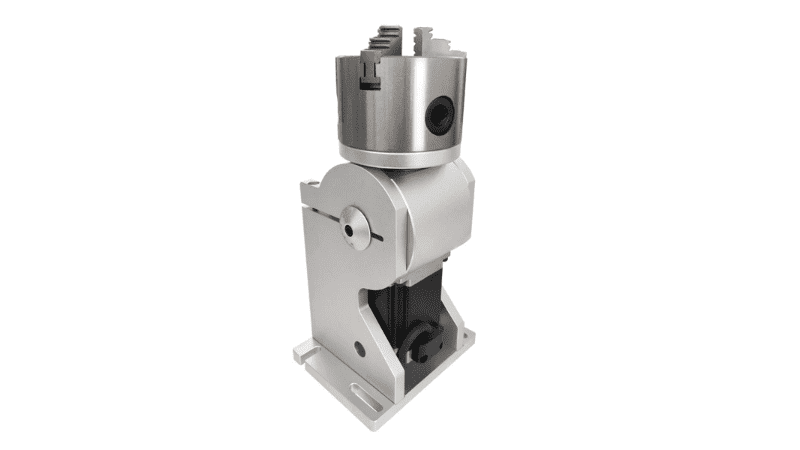

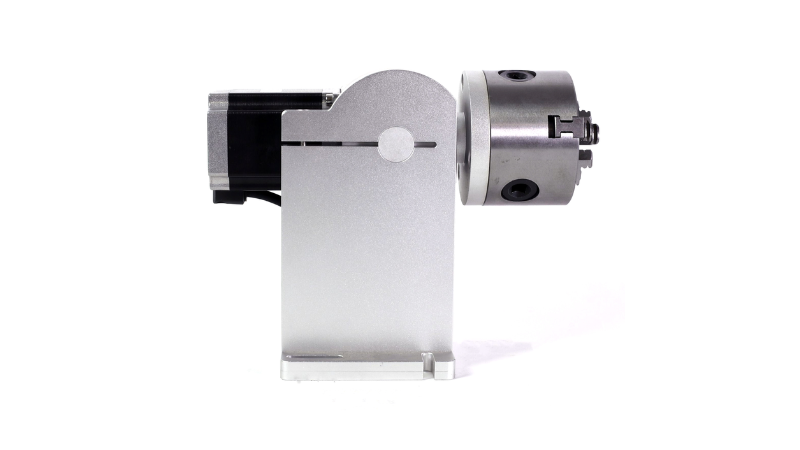

Three-jaw chuck

The chuck has three jaws that move in unison to grip the object. It is commonly used for simple and small workpieces like rods, tubes, and cylinders. They may only work for larger or lighter workpieces.

Four-jaw chuck

It has four independently moving jaws allowing greater flexibility in holding irregular shapes or non-symmetrical objects. It is also suitable for holding thin materials like ceramics or wall tubing.

Collet chuck

This type of chuck uses a collet to hold the object being worked on. Collets are available in different sizes and shapes to accommodate various objects.

Magnetic chuck

This chuck uses a magnetic field to hold the object being worked on. They are made of high magnetic permeability like iron or steel. Magnetic force is generated by a magnetic field or electromagnets.

Vacuum chuck

This chuck uses a vacuum to hold the object being worked on. It is commonly used in woodworking and plastic fabrication.

Pneumatic chuck

This chuck uses compressed air to clamp the object being worked on. It is commonly used in automated manufacturing processes.

Hydraulic chuck

These chucks use hydraulic power to actuate and disengage the material.

How to Choose a Chuck?

Here are a few things to consider while choosing the chuck for laser cutting machines:

Type of laser Machine

For example, fiber lasers require a different chuck than CO2 lasers.

Material to be cut

The cutting workpiece should also be considered while selecting the chuck. It can be flat, tubular, or have a delicate material.

Thickness of Material

Chuck should be able to hold the material in place. So the thickness of pipes, tubes, and workpiece should be considered as whether it fits in the chuck.

Accuracy requirements

The required precision should also be considered while selecting the chuck.

Cost

The high-end chucks that offer better precision are more expensive.

Other Tools vs. Chuck

Let’s compare the chuck with other tools that work the same but are used for different materials and sizes of workpieces.

Roller vs. chuck

Roller and chuck are both used in laser cutting machines. Both have the same purpose of keeping the workpiece in place. However, rollers are used to hold and move the material while the laser beam works to ensure the material is cut from all sides evenly.

The roller uses flexible materials like cloth, plastic, and paper. They also fed the material into the Cutting machine continuously. They hold the material in place and move it forward.

Chucks, on the other hand, hold rigid materials in place. They keep the material in place and make sure it remains stationary. Using a roller or chuck depends on the type of machine and what material it is processing.

Collet vs. chuck

Both collect, and chuck is used in laser cutting machines and have the same purpose of holding the material in place. A collet is a type of clamp that holds the material by compressing around its circumference. Collets usually work on small-diameter objects like tubes, wires, and rods.

Collet is often used in the type of material that need high precision. Chuck, on the other hand, are used for workpiece with large diameter. They also provide a secure grip on heavy sheets and metal plates.

The Importance of Laser Chucks in the Laser Cutting Process

Laser chucks play a vital role in the laser cutting machine. It not only holds the cutting material in place securely. The cut’s precision and the end product’s quality largely depend on keeping the workpiece in place.

The laser chuck is programmed to match the size and shape of the material. Laser chuck uses the vacuum to create suction, holding the workpiece in place. It provides a level surface for the workpiece. Laser chucks are designed for laser machines. They are resistant to heat and damage that laser light may cause.

Keeping heavy tubes in place securely is also important for safety overall. Also, the laser chucks in the laser system have features to improve the machine’s efficiency.

Final Words

Laser machines are far superior when we compare their precision and efficiency with the other cutting means. As it holds the workpiece, Chuck is important in any cutting, drilling, or engraving machine.

The workpiece can be a heavy tube with thick galvanized material or a thin metal strip depending on the application. Different chucks are used for different types of material, and choice should depend on the machinery and the metal thickness.

Upgrade Your Manufacturing Game with Baison’s Laser Cutting Machines

Baison offers top-of-the-line laser cutting machines with various sizes for different scales in the industry, with laser chucks to choose from. Our machines can handle any cutting job with precision and efficiency.

Whether you’re working on a small DIY project or a large-scale production run, our laser-cutting machines are the perfect tool for hard and delicate materials. Our machines are easy to operate and feature advanced technology that delivers consistent, high-quality cuts.

Contact us to learn more about our laser cutting, welding, or engraving machines. We offer Free application evaluation if you need clarification on which system your industry needs.