Automation in Laser Tube Cutting: Is It Worth the Investment?

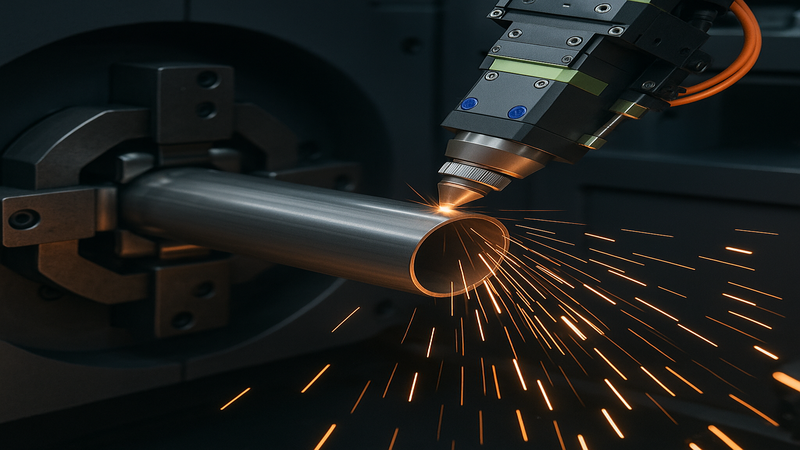

From aviation to pharma, automation has profoundly impacted all sectors. The implementation of automation in laser cutting, particularly in manufacturing, is also becoming popular. This article examines whether automation in laser cutting is worth it or not. Also, it discusses the components of automation to help you make an informed decision. So read on and make a wise choice:

What Does Automation Mean in Laser Tube Cutting?

In simple words, automation refers to the use of computer-operated systems. This is done to perform tasks that would otherwise need intense human effort.

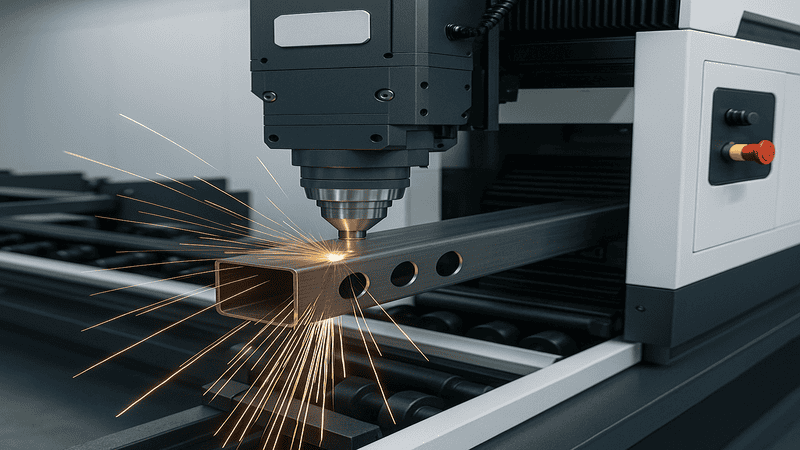

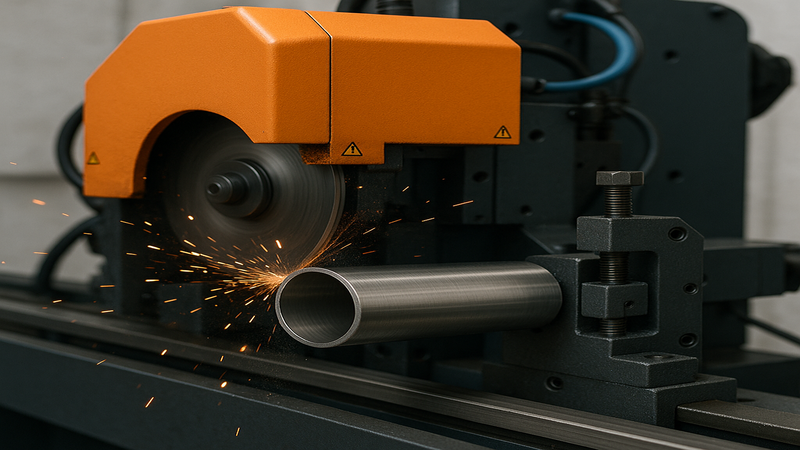

In laser tube cutting, automation is used to load and unload metal tubes. Also, automation accurately positions the tubes for cutting. Automation in laser cutting is highly beneficial, especially in hazardous zones.

Automation guarantees a seamless and efficient workflow. It minimizes the chance of human error. All processes are conducted without any human involvement, thus saving time. In laser cutting, various types of automation are used, including:

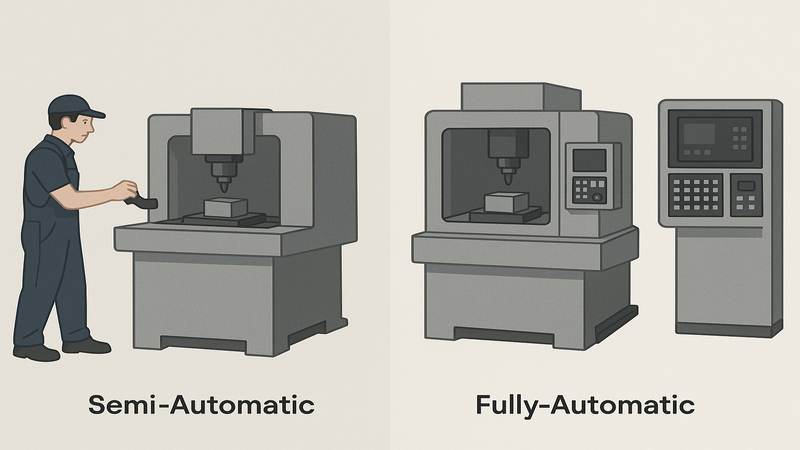

- Semi-Automatic

- Fully-Automatic

- Robotic arms

- CNC control

The semi-automatic systems are designed to help operators in some parts of the process. In this type of automation, manual input by the operator is required. Thus, the task cannot be completed by machines alone. Semi-automation can be considered the entry point into automation.

In a fully automatic system, machines perform the entire cutting process, from loading to unloading, on their own. This type of automation offers high efficiency and excellent productivity.

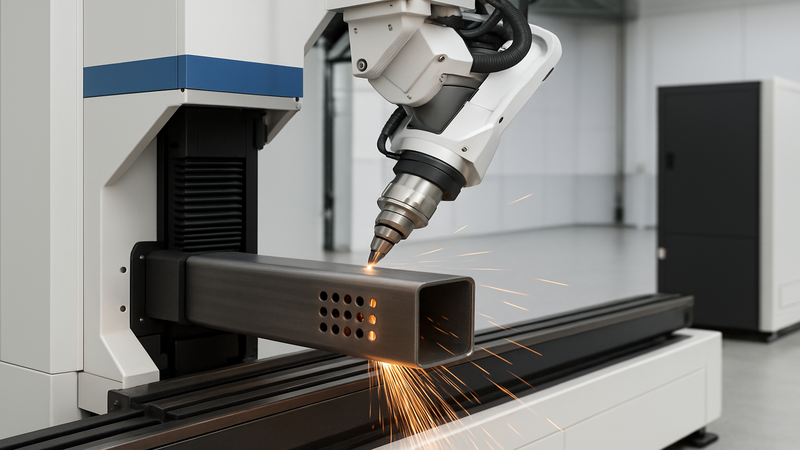

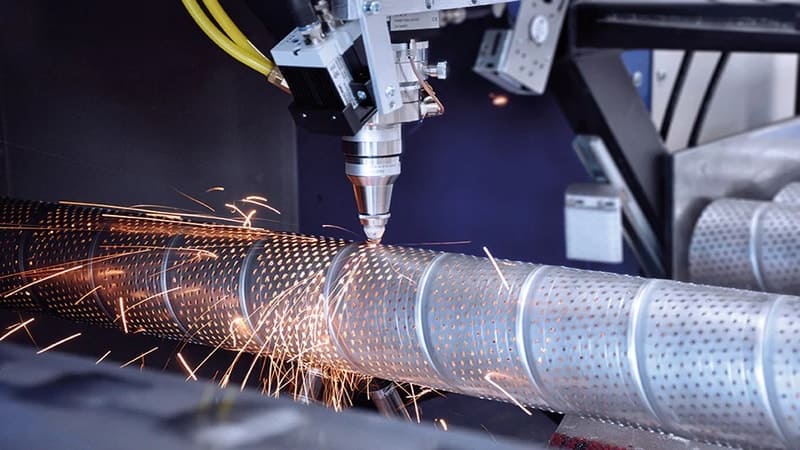

On the other hand, the robotic arms are integrated into many critical and advanced systems. This enables easy handling and sorting of tubes, particularly after they have been cut. Using a robotic arm is linked with improving the speed and accuracy of the cutting process.

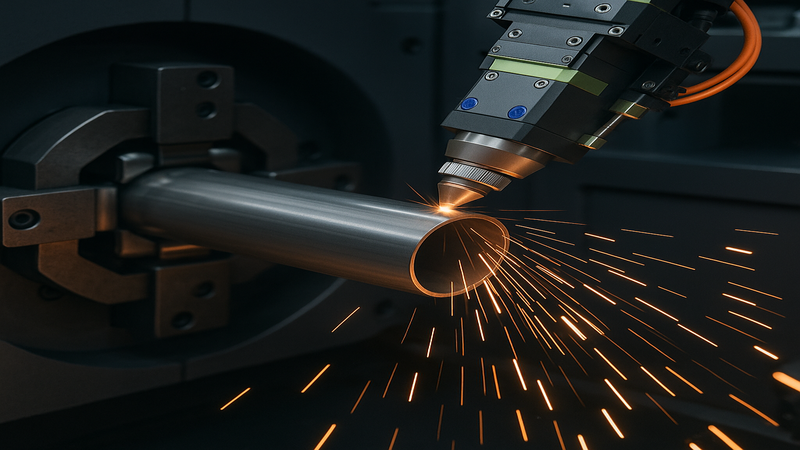

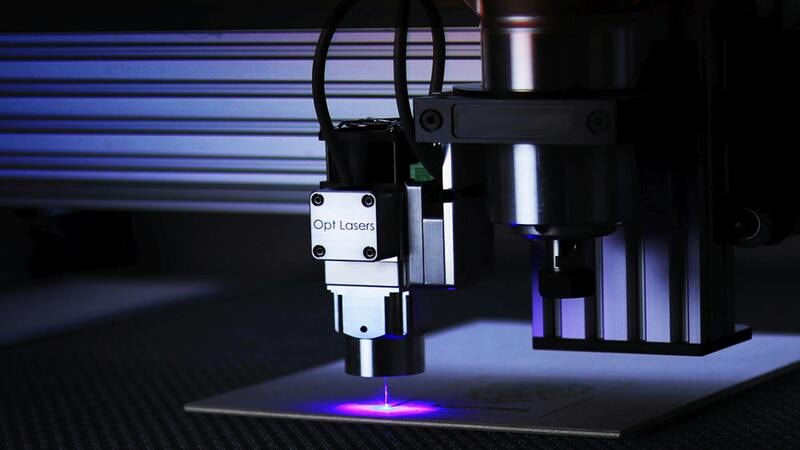

CNC control systems enable operators to program cutting paths and parameters in manufacturing processes, ensuring precision. CNC control systems are compatible with CAD/CAM software, enabling real-time modifications.

Businesses can tailor their automated processes according to specific needs. For example, companies can switch from a fully automated system to a semi-automated system easily when required.

Key Components of an Automated Laser Tube Cutting System

Automated laser tube cutting systems are composed of several equipment components. All these components work together to improve the performance and efficiency of the laser-cutting process. Given below are the key elements of an automated tube laser cutting system, discussed in detail:

Automatic Loading Systems

The first key component of the automated laser tube cutting system is the automatic loading system. The automatic loading system includes bundle loaders and machinery.

These leaders automate the process of loading raw materials into the machine. This system reduces the time and manual handling hazards associated with loading.

Automatic Positioning and Centring

The automatic positioning and centring process involves the use of sensors and an intelligent clamping system. These systems align the tubes perfectly before the tube cutting begins. The perfect alignment of tubes before cutting increases the accuracy of the cutting process.

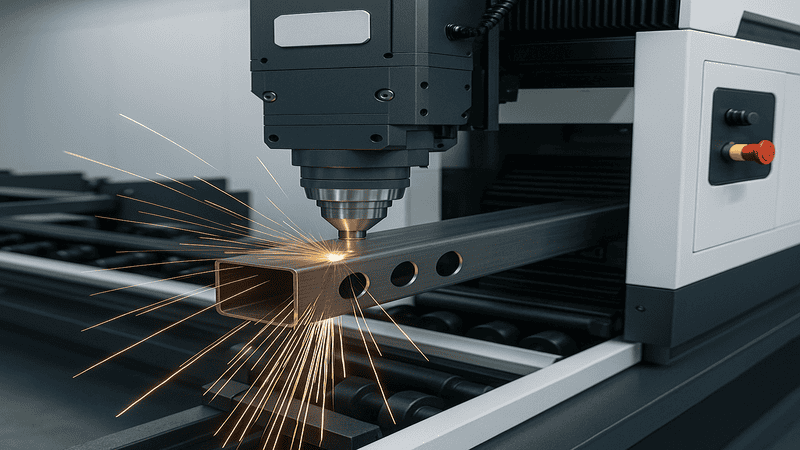

Integrated CNC Cutting Control

CNC cutting control is an essential component of the automation system. The cutting process is integrated with CAD and CAM software.

The CNC cutting tool allows a smooth flow of data from design to actual process. The operators can import designs from CAD software and make real-time adjustments easily.

Automated Unloading and Sorting

Automated unloading and sorting are done using robotic arms and conveyors. This component ensures that the finished parts meet the parameters defined earlier. The automated unloading and sorting system also reduces the need for manual sorting. Additionally, it facilitates a smooth workflow.

Benefits of Automation in Laser Tube Cutting

The benefits of automation for all industrial processes are not to be underestimated. These laser cutting automation benefits compel procurement teams to shift to an automated system.

The following are the most common benefits of integrating automation into your cutting process. These benefits will compel you to automate your other crucial operations, such as laser welding and laser marking.

Increased Cutting Speed and Better Output

Once programmed, the machine can run continuously, delivering the same consistent result. The machine also reduces the downtime between batches. The faster loading of tubes and the absence of human intervention in the entire process increase speed and are linked to better output.

Reduced Labour Dependency

Another benefit of switching to automated laser tube cutting is that reliance on labour can be reduced. The tube cutting machine with auto loading/unloading minimizes labor dependency.

Shifting to automation helps reduce labor costs as well as associated training costs. Additionally, some automated machines run overnight without supervision, thereby helping to save time.

Enhanced Accuracy and Repeatability

The next benefit of an automated laser cutting system is that it delivers consistent results. Using automation, the risk of human error in alignment can be eliminated. Consistent results can be achieved in large-scale production runs by utilizing automation.

In simple terms, the programmed system reduces the risk of errors, thus delivering results that are more accurate and precise. In many cases, using an automated laser cutting system even eliminates the need for grinding and smoothing the edges.

Optimized Material Usage

Advanced systems efficiently cut the tubes. Doing this not only guarantees the best result but also optimizes material usage.

The waste material generated by the automated cutting system is less than that generated by the manual cutting methods. This is the reason why automated systems maximize the utility of each tube.

Improved Workplace Safety

While working with laser cutting or laser marking, workers are exposed to the sharp laser beam, which can be hazardous to their eyes. Similarly, while loading and unloading the heavy tubes, workers are at risk of physical injuries.

Automation eliminates the need for workers to carry heavy and dangerous materials, thus reducing the risk of injuries. Therefore, automation is a key factor in workplace safety.

Is Automation Always Worth It? Factors to Consider

Regardless of the benefits of automation, people often question, Should I automate laser tube cutting? Well, the factors below will help you in deciding whether automation in laser cutting processes is a good idea or not:

Production Volume

It can be said that firms involved in high-volume production benefited the most from the automated cutting system. The higher the production volume, the better the return on investment.

Automation guarantees cost savings and profitability gains. Although the initial cost of setting up an automated system is high, the benefits it offers in the long run justify the investment.

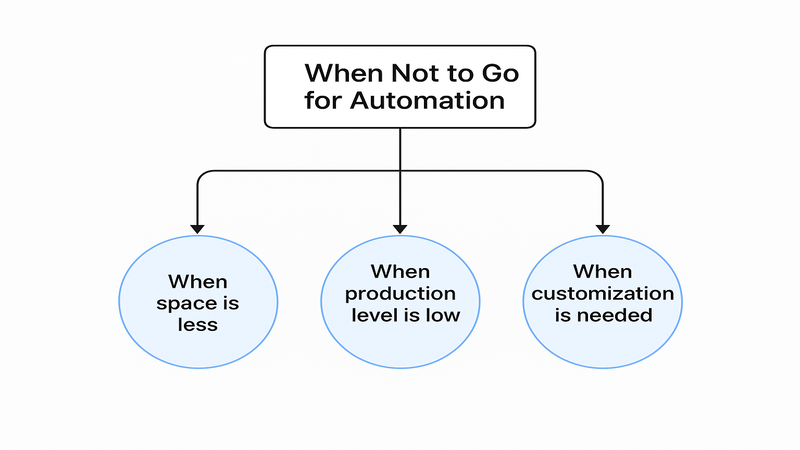

Therefore, if you need to produce in bulk, automated systems are the best option for you. However, if your production volume is low, the initial cost cannot be covered, and as a result, automated systems are not worth it for this level.

Part Complexity and Customisation

Machines are programmed to perform repetitive tasks. If you have to perform repetitive tasks, then automated systems are ideal for you.

If you need continuous change or require customization, automation may not be the best fit for your needs. Simply put, if you need to cut tubes in the same way repeatedly, it’s advisable to invest in an automated system.

Labor Costs and Availability

If you are carrying out pipe-cutting and tube-cutting operations in regions where labor is limited, you need to invest in automated systems. The automated system reduces the need for physical labour, thereby helping to save labour costs.

Even if the labor cost is low and labor is available, the automated systems will help you reduce the expenses in the long run.

Floor Space and Infrastructure

The last factor that determines whether automated laser tube cutting is beneficial for you or not is the infrastructure. Computerized systems require more space. In some cases, these systems also need the infrastructure to be modified.

Therefore, if you are short on space, it is not advisable to switch to an automated system for cutting pipes. The table given below summarises the factors that should be considered while deciding whether automation is worth it or not:

| Factor | Impact on Automation Decision |

| Production Volume | High production volume justifies automation through better laser tube cutting systems, ROI |

| Part Complexity | Standard parts benefit more; custom work may still require manual intervention. |

| Labor Costs & Availability | High labor costs or shortages favor automation |

| Floor Space & Infrastructure | Automation systems require extra space and power upgrades |

Cost vs. ROI: Does Automation Pay Off?

CNC tube laser cutting with automation systems, as well as all other automated systems, can be expensive. The high cost associated often makes procurement managers question whether the automation pays off or not.

To make an informed decision, ensure that you compare the initial costs and the return on investment. The initial cost depends on the system’s features. For example, if you have opted for the semi-automated system, you may incur costs of USD 50,000.

Alternatively, if you have opted for a fully automatic system, which also includes robotic arms, the initial cost may even exceed USD 500,000. Depending on your budget, you can choose the automation system.

In the initial stages, it is advised to set up a semi-automatic system. Once you have reaped financial benefits from that system, you can upgrade to a fully automatic setup.

Although the initial cost may be higher, the long-term benefits make installing these systems a worthy investment. Reduced labor costs, faster processing, and better output all result in increased profitability.

In many cases, the large to medium-volume firms often achieve a return on investment within 1-3 years. This timeframe can even be reduced if the system eliminates manual processes completely or if the profit is exceptionally high.

For instance, a fabrication company invested in a $150,000 automated tube-cutting system. It reported a 25% reduction in labor costs and a 40% increase in productivity over the first 20 months. With a 36% decline in material wastage, the system covered its initial cost in just two years.

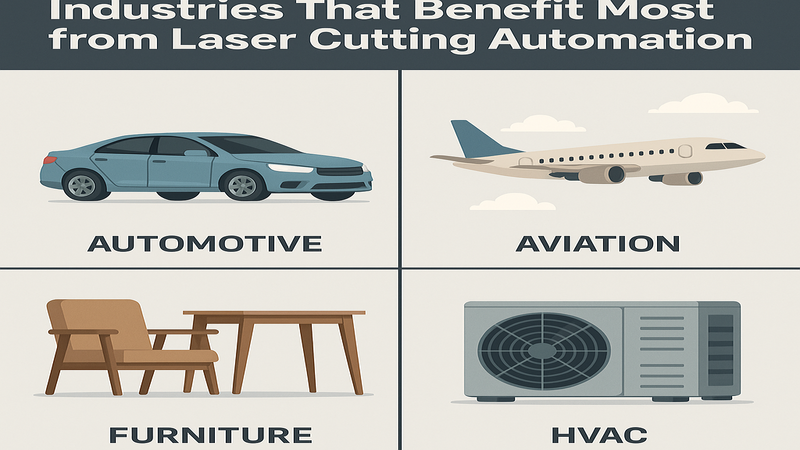

Industries That Benefit Most from Laser Cutting Automation

As discussed earlier, automation is transforming the operations of nearly all industries. Industries that rely heavily on accuracy and precision benefit the most from the use of automation.

Here, we will discuss the five industries that have taken advantage of laser cutting in automation the most:

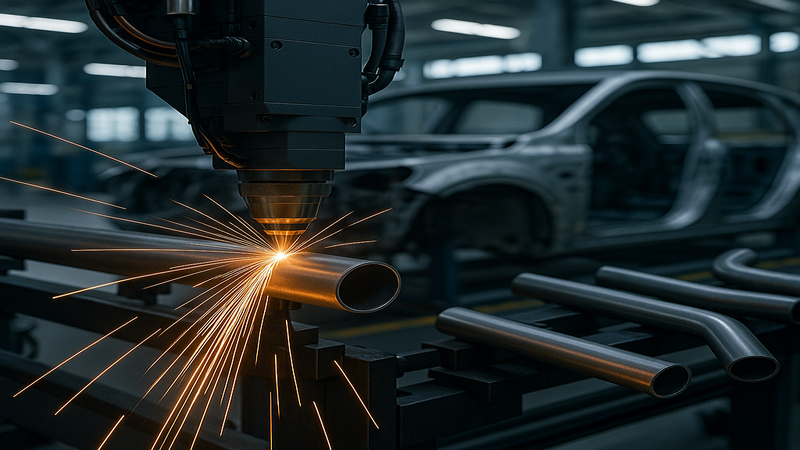

1. Automotive Sector

The importance of automation in laser tube cutting in the automotive sector cannot be understated. The repetitive and high-volume production makes automation in this sector extremely important.

In the automotive industry, parts such as exhaust systems and chassis reinforcements require consistent quality. This can be achieved only by using automated systems. Automation in laser cutting ensures that cuts are precise, thereby contributing to overall safety and precision.

2. Furniture and Fixtures

You might have noticed that furniture often has tiny cuts that are too close to each other. In furniture, precise cuts are necessary to enhance both the design and functionality of the piece.

Automated systems in furniture manufacturing result in delivering consistent cuts. This also speeds up production, especially for in-demand items such as frames, bases, and supports.

3. HVAC and Tubular Structures

In the HVAC industry, the consistency of pipe sizes and accurate angles is essential. Utilising automation in HVAC systems ensures optimal performance and maintains consistent airflow.

Automated laser tube cutting offers the precision required for ductwork and framework. In short, we can say that automation reduces the risk of all possible errors in the HVAC system.

4. Aerospace and Aviation

In aerospace and aviation, precision is not just a requirement but a necessity. In aerospace, the tubes are subject to extreme stress, pressure, and temperature.

The automation in laser tube cutting ensures a tighter tolerance. The tighter tolerance guarantees safety and reliability.

5. Medical Sector

In the medical sector, many diagnostic tools and surgical instruments use tubes. These tubes must be highly precise; otherwise, they can pose a threat to patient safety. To ensure safety and reliability, the medical sector must shift from a manual system to automated laser tube cutting.

Best Practices for Implementing Automation in Laser Tube Cutting

Ensuring the successful implementation of automation requires following some practices. These practices include, but are not limited to:

- If unsure of the success, start with semi-automation. If you are satisfied with the results, switch to a fully automated system.

- Always choose a reliable vendor that provides efficient support, software integration, and training.

- Ensure that you maintain your automation system regularly.

Final Verdict

Whether semi or fully automated with robotic arms, automation offers multiple advantages. The benefits of automating laser cutting include improved efficiency and reduced waste material.

Multiple factors influence whether automation is worth it or not. So, companies must evaluate their production needs before making any decision.

What are you waiting for? Transform your laser cutting operations by setting up an automated laser tube cutting machine now.

Baison Laser – Trusted Experts in Laser Cutting, Welding & Cleaning Solutions

Baison Laser is here to help you find the best fiber laser cutting solution for your firm. With our innovative technology and skilled employees, we are here to meet all your needs. Owing to our unmatched R&D capabilities, we are the top manufacturer of fiber laser systems.

Just contact us now, and we will share an instant quote for your requirements.

FAQs

Q. What is the main disadvantage of laser cutting?

The main disadvantages of laser cutting include the high initial cost. The initial cost is high, but it can be recovered. Another disadvantage of laser cutting is that it may not work well on thick materials.

Q. How to tell if a laser tube is going bad?

You can tell that the laser is malfunctioning by noticing certain signs. These signs include reduced cutting power, inconsistent quality, and slower cutting speeds. Strange sounds and overheating also indicate that the laser is going bad.

Q. What are the three types of laser cutting?

The three types of laser cutting are CO₂, fiber, and crystal (YAG/YVO₄) laser cutting. CO₂ lasers are best for non-metals. Fiber lasers are good at cutting metals with precision. Alternatively, crystal lasers offer high power for specialised industrial applications.