Fiber laser cutting has been the go-to manufacturing process for companies worldwide. Others rarely match its precision, accuracy, cost, and efficiency. However, the coil-fed laser cutting machine has proven superior in several industrial applications with its continuous material feed.

Continue reading to learn about the several benefits of coil-fed fiber laser cutting.

What is Coil-fed Laser Cutting?

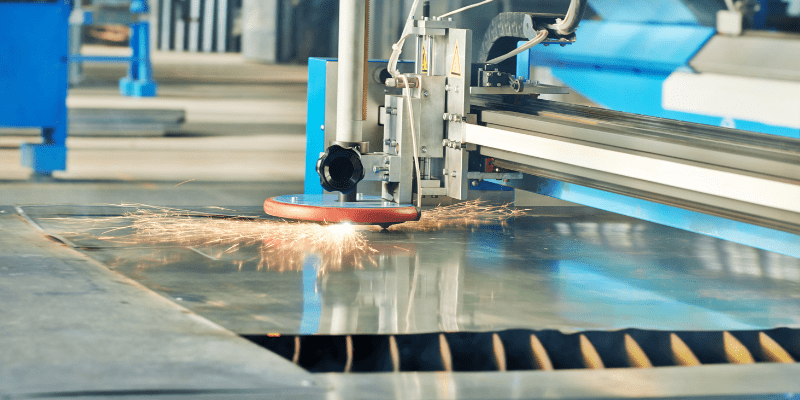

Coil-fed laser cutting machines have an open-style cutting bed that allows continuous metal sheets to pass through. A Decompiler slowly unwinds the metal sheet off the coil while a straightener feeds it to the cutter uniformly.

The continuous sheet metal supply keeps the laser cutting machine fed until the coil runs out. Hence, a coil-fed laser cutting machine is preferred for large-volume productions. Coil-fed machines support sheet metal thicknesses up to 6mm. After 6mm, the material is officially categorized as a plate.

A laser is a high-intensity light beam focused through an optical fiber. The spot diameter of the laser beam starts around 10,000 μm (10mm or 0.39 in) and goes all the way down to an impressive 15μm (0.0006 in.). As a result, fiber laser cutting systems are incredibly powerful and can outperform almost all other means of fabrication. The coil width of the coil-fed laser cutting depends on the particular laser cutting machine and its functions.

Do You Have Any Questions?

Let Us Solve Your Problem

7 Benefits of Coil-fed Laser Cutting

Laser cutting machines cater to various manufacturing processes. However, coil-fed units are uniquely designed and can adapt to all applications. The following advantages show the versatility and practicality of the coil-fed laser cutting system.

1 – Waste Material is Minimized

Sheet metal cutting operations are a delicate balance between desired shape and area availability. After processing the sheet metal, you are left with leftover waste that is very difficult to manage. A coil-fed fiber laser cutting machine massively helps with waste material reduction.

- Coil-fed lasers provide a longer canvas that can facilitate larger designs.

- Once a shape is cut out of the sheet metal, the remaining waste material can be coiled onto another stock and later sent for recycling.

- Careful orientation of designs can further increase the efficiency of cutting operations.

Higher-end models use an intelligent vision system that can accurately identify the edges of the metal sheet and keep the designs within range. In addition, a laser vision system can detect potential cutting errors early in production.

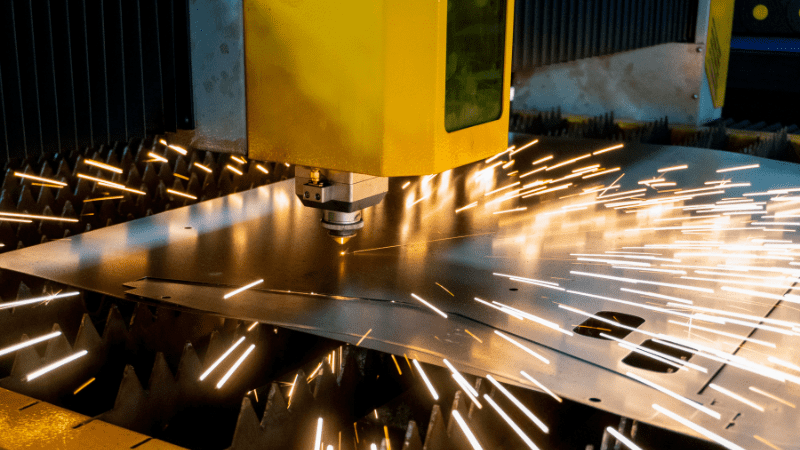

2 – Faster & Smoother Production Lines

A significant amount of time is wasted between production cycles. Workpiece (sheet metal) loading and unloading times can often take longer than the actual cutting process. A continuous coil system keeps the laser cutter fed and the production line moving.

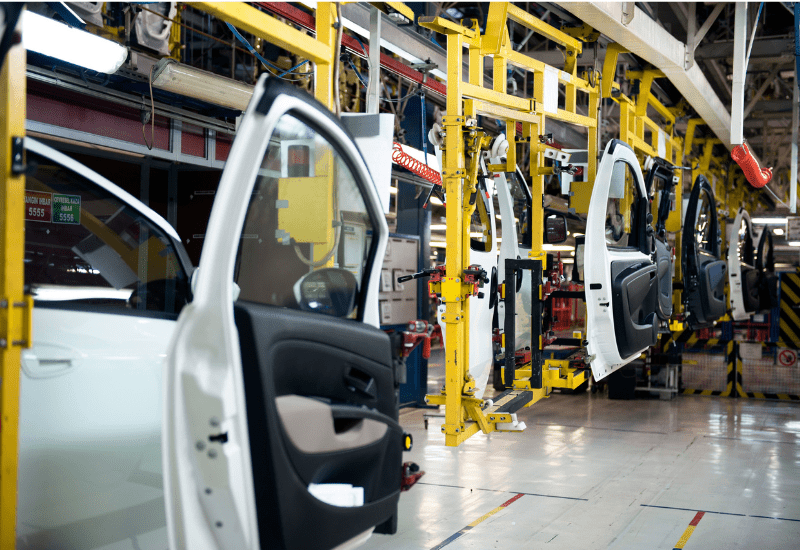

Laser cutting technology is incredibly fast and precise. The bottleneck in production lines comes from manual material loading and machine maintenance. Coil-fed laser cutting is ideal for swift manufacturing and is often used in the automotive industry.

3 – Fully Automated Laser Cutting

Most fiber laser cutting machines can be easily automated to deal with large-volume manufacturing. However, the limiting factor of manual material loading remains. On the other hand, coil-fed laser machines are fully automated, from material feed to waste management.

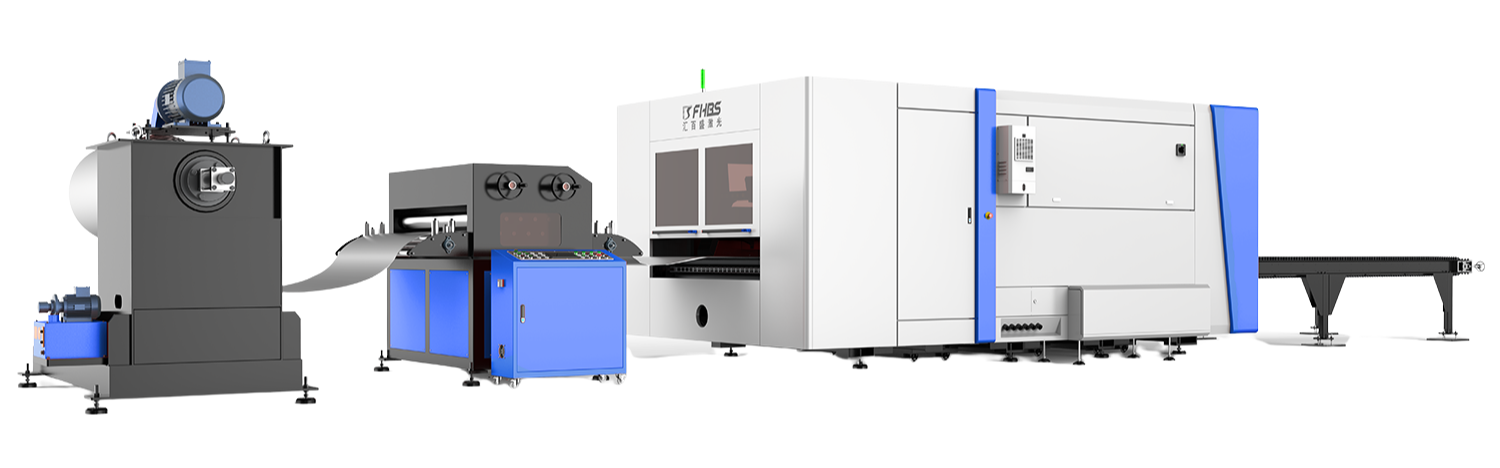

A typically coil-fed laser system involves five distinct parts working in harmony.

- A Decoiler handles the metal coil processing.

- A Paper Scrap Recoiler handles the paper waste.

- A Straightener removes any bends in the sheet.

- The Laser Cutter processes the coil material.

- Another Recoiler handles the waste material sheet.

Metal coils come with a paper spacer lined between the layers. As the metal coil unrolls, the paper spacer comes with it and needs to be rolled (coiled) onto another spool.

In a fully automated system, the operator only needs to load the coil onto the decoiler. Afterward, the production cycle will continue independently of the operator until the job is finished or the system runs out of raw material. Additionally, a coil-fed machine frees the operator to continue working on other projects ensuring maximum efficiency on the production line.

4 – Lower Processing Costs

Coil-fed cutting is also considerably more cost-effective than other methods of processing sheet metal. Fiber laser systems are very efficient from a power consumption perspective. So you’re already saving a significant amount in annual operating costs.

Additionally, coil-fed cutters provide an increase in time efficiency for material processing. Faster loading times, quicker cutting speeds, and optimized production cycle times reduce the general cost of manufacturing.

5 – Wide Material Compatibility

Fiber lasers have a reasonable level of material compatibility. You can cut various raw materials like metals, non-metals, and composites. However, coil-fed lasers are designed to handle sheet metal rolls.

Here is a brief list of the most popular metal options.

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- & Other Alloys

Additionally, you can process treated metals with a fiber laser if needed. Several treated materials, including anodized, coated, painted, galvanized, and metal-plated sheets, are compatible with this technique.

6 – Modular Assembly Design

As discussed above, coil-fed laser systems are broken into five distinct modules. And the entire system can still work even at the loss of two modules. The paper recoiler and the waste (processed) sheet recoiler help smooth the process but are not strictly necessary.

This modular design ensures that the laser cutting operations can continue with a limited capacity if a supporting part breaks down. Maintenance and repair costs are also reduced with the modular approach.

Fiber lasers have an overall lower maintenance requirement than their CO2 counterparts. Therefore, with a modular design, you are not bound by the maintenance requirements of other assembly parts.

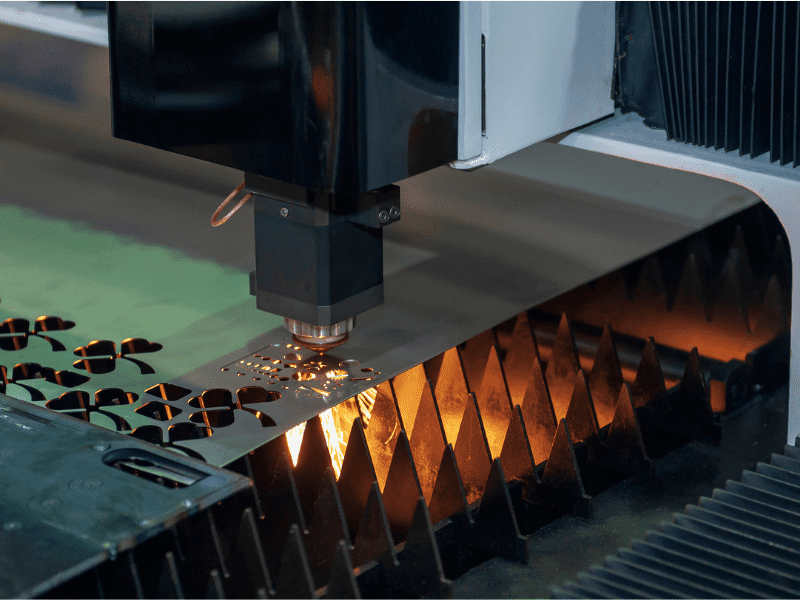

7 – High-Quality Finish

The fiber laser at the core of a coil-fed machine is incredibly precise. It makes clean cuts in the metal at high speed. Among the many advantages of this process, speed and accuracy are undoubtedly the most impressive. The supporting equipment of a coil-fed system is designed to further enhance the main advantages of fiber laser technology.

Unlike traditionally machined metals, laser cut parts don’t generate swarf (metal chips) during manufacturing. Thus, there is no need for deburring parts after the finished parts leave the laser cutter.

Do You Have Any Questions?

Let Us Solve Your Problem

Coil-Fed Laser Cutting Applications

Coil-fed laser cutting systems can handle all manner of sheet metal processing. Therefore, any task that can be accomplished with a fiber laser system can be more effectively executed with a coil-fed laser process.

The following is a brief list of the most popular applications of coil-fed laser cutting.

1. Coil-Fed Laser Blanking

Blanks are simple geometric shapes cut out of a sheet of metal. A coil-fed laser blanking line utilizes continuous feed to quickly produce several hundred blanks out of a single metal coil. These blanks are sent to partners who manufacture the end product.

Almost every large-scale factory buys blanks from an external supplier instead of starting its laser blanking line. A majority of coil processing takes place at some laser blanking line. Most businesses cannot justify the investment cost of a fiber laser cutting machine. The other applications on this list mainly utilize laser cut blanks in their production systems.

2. Fabrication of Automotive Parts

The automotive industry is full of several interconnected production systems that work together to create a single vehicle. One such system is the coil-fed laser blanking system, which makes the aluminum veneer, electrical cabinets, and small engine parts.

3. Electronic Enclosures

Electronic enclosures are one of the biggest markets for laser cut parts. Whether we are discussing ventilators for the medical industry or computer cases for servers and desktops, the odds are they were made using a laser cutting machine.

Coil-fed laser blanking produces flat planes in the correct size, which are bent, cut, and riveted into an enclosure.

4. Medical Equipment

Aside from metal enclosures, coil laser systems make several miscellaneous medical equipment such as metal table tops, scalpels, etc.

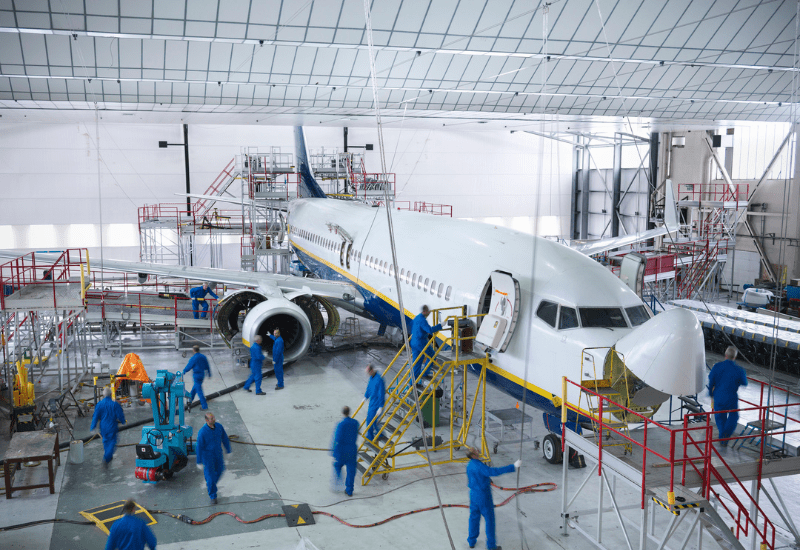

5. Aerospace Applications

The aerospace industry uses coil laser cutting machines for various custom projects, like electric shielding, aircraft body parts, or small engine components.

6. Brackets & Hinges

Coil Fed Laser compared to traditional methods is excellent at producing high-performance precision brackets and hinges.

7. Kitchen Utensils

Some kitchen equipment like knives starts as laser cut blanks which are later shaped, sharpened, and polished into a blade.

Here we have compiled some tips to help you get better coil-fed laser cutting results.

Do You Have Any Questions?

Let Us Solve Your Problem

Conclusion

Coil-fed laser cutting machines are excellent for a wide range of applications. The addition of an automated coil feed boosts overall productivity and reduces production times. Fiber lasers are compatible with several different materials. But coil feed systems limit them to sheet metals, producing more efficient production.

Get a Coil-Fed Laser Cutting Machine from Baison!

Baison is a top-tier fiber laser system manufacturer. Our expertise, attention to detail, and unwavering commitment have allowed us to serve over a hundred countries and regions for more than two decades.

We are confident that our stacked product lineup will accommodate your manufacturing needs. Get an Instant Quote Now!