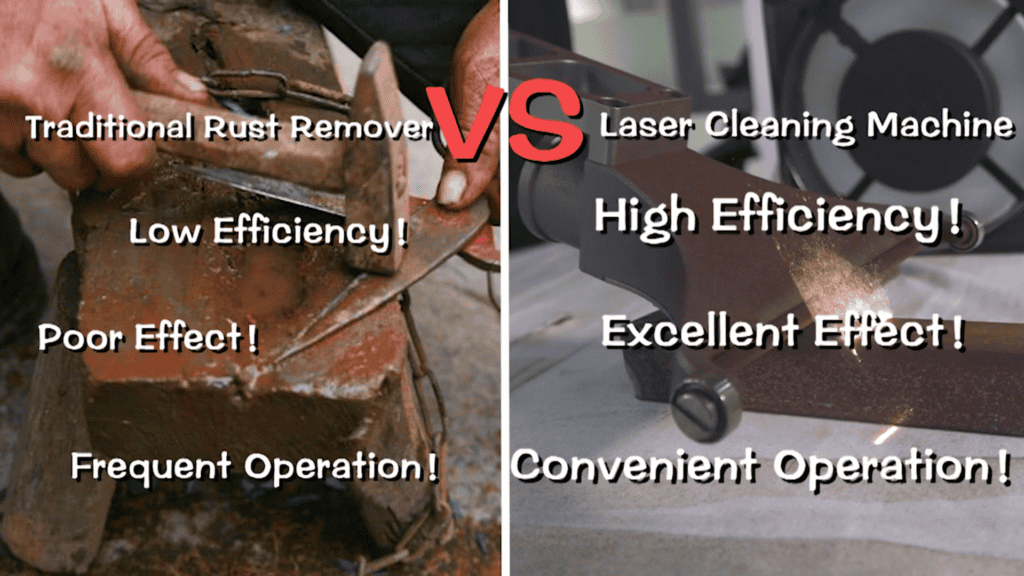

Industrial cleaning plays a key role in maintaining equipment quality and boosting operational productivity. Old-school cleaning methods like abrasive blasting (sand, walnut shells) and chemical treatments often cause problems. They can harm the environment, damage surfaces, and cost a lot over time.

This has opened the door for laser cleaning machines, a new solution that gives you precision, sustainability, and flexibility. Laser cleaning tech is catching on fast as industries look for green and effective options. These machines use powerful laser beams to strip away dirt like rust, paint, and grease without hurting the materials underneath.

Although the benefits are clear, the tech also has its limits. This guide helps decision-makers weigh the pros and cons of laser technology. It gives you the lowdown on this cutting-edge tool so you can make smart buying choices based on your company’s needs.

What Is a Laser Cleaning Machine, and How Does It Work?

Laser cleaning machines clean surfaces using laser ablation. This process aims a high-energy laser beam at the target area. Contaminants like rust, paint, oxides, or oils soak up the laser energy. This absorption heats them fast and evaporates the unwanted stuff without hurting the surface underneath.

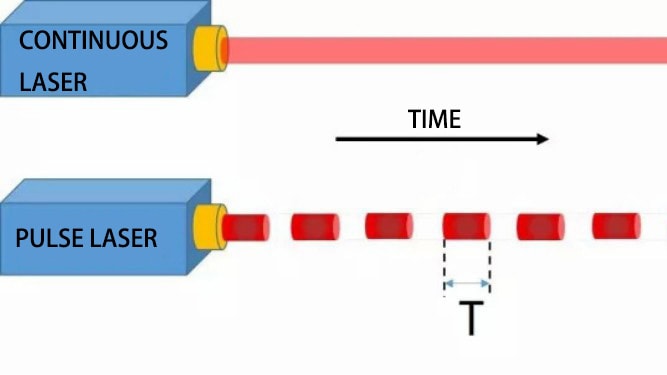

Cleaning uses two main types of laser systems: pulsed and continuous wave lasers. Pulsed laser cleaning machines send out short bursts of high-intensity energy. They work best for tricky jobs where you need to protect the surface. Continuous wave lasers give out a steady stream of energy. For larger cleaning projects, CW systems are your go-to options.

Laser cleaning machines have several key parts: a laser source that creates the beam, optics to focus and guide the laser, a scanner for exact movement on surfaces, and a cooling system to keep operations stable. Some machines also have fume extraction units to get rid of debris from cleaning.

6 Key Advantages of Laser Cleaning Machines for Industrial Use

1. Non-Contact, Precise Cleaning

The laser cleaning process gets rid of contaminants without touching the surface, which means they don’t harm the underlying material. The laser light targets surface contaminants, keeping the base material safe. Since it’s a noncontact process, laser cleaners are perfect for various industrial applications.

For example, in fields like aerospace and microelectronics, even tiny scratches can cause big problems. And unlike traditional methods, laser technology has unmatched cleaning speed. People have been using it to clean old, fragile objects for a while now. Laser cleaning is so precise that it can work on spots as tiny as a few microns. You can accurately control the beam and achieve the best cleaning effect.

2. Environmentally Friendly – No Chemicals or Waste

Laser cleaning systems clean without involving harsh chemicals, abrasives, or water, making it a green option compared to old-school methods. It creates very little secondary waste, often solid powder that’s easy to collect and recycle. So it’s getting popular as an environmentally friendly process for reviving metal surfaces, removing contaminants, paint removal, oil stains removal, and clearing other contaminants.

Laser cleaning technology also cuts down on environmental compliance costs and steers clear of pollution from chemical runoff or getting rid of dangerous waste. For companies, this leads to a safer workplace and helps them stick to tough environmental rules while keeping things running.

3. High Efficiency and Speed

Compared to traditional methods like media blasting or chemical cleaning, laser cleaning works are significantly faster and more efficient. For instance, studies show that laser systems can reduce cleaning time by up to 50% in production lines.

In real-world applications, this means higher productivity, as equipment downtime is minimized. The non-contact nature of laser cleaning also reduces the likelihood of rework or damage.

4. Lower Long-Term Operating Costs

Although laser cleaning machines have a higher upfront cost, their long-term benefits outweigh the initial investment. These systems require minimal consumables and low maintenance. With lifespans exceeding 10 years, the overall cost per use is significantly lower than traditional methods that rely on chemicals or abrasive materials. A lifetime cost analysis often reveals substantial savings as well as ROI for industries.

5. User-Friendly with Automation Capabilities

Modern laser cleaning systems feature intuitive touchscreen interfaces and programmable settings for ease of use. They can be integrated into robotic systems for automated production lines or used as handheld devices for manual tasks.

They’re flexible, safer, and more efficient than mechanical or chemical processes. Modern laser cleaning systems also come with operator safety features, such as enclosed laser beams, interlock systems, emergency stop buttons, and proper ventilation.

6. Versatile Applications Across Industries

Laser cleaners are highly versatile. They provide the most cost-effective rust removal across various industries:

- Aerospace: Efficiently removes coatings from aircraft components without compromising structural integrity.

- Automotive: Cleans rust from chassis parts with precision.

- Electronics: Safely cleans printed circuit boards (PCBs) without damaging sensitive components.

- Power Plants: Cleans turbine blades to maintain efficiency.

- Marine: Strips paint from ship hulls without causing surface damage.

6 Key Disadvantages of Laser Cleaning Machines and Considerations

1. High Initial Investment Cost

Laser cleaning machines have a higher upfront cost compared to traditional methods. Entry-level handheld systems can start at $5,000, while industrial-grade machines with advanced features may exceed $100,000. Payback periods typically range from 2 to 4 years, depending on application scale and efficiency gains. For example, a payback calculator might show that a $50,000 machine saves $20,000 annually in consumables and labor costs.

2. Safety Risks and Operator Precautions

Laser cleaning systems operate using high-energy beams that can pose safety risks if improperly handled. Most machines fall under Class 4 lasers. These lasers require protective eyewear, shielding, and trained operators to mitigate hazards like eye damage or burns.

Dirty laser optics can also pose a substantial threat to the machine and the operator. Compliance with industry standards such as CE, FDA, and ISO ensures safe operation.

3. Not Suitable for All Materials or Surfaces

Laser cleaning is less effective on porous materials like concrete or reflective surfaces like polished aluminum. It also struggles with thick layers of grease, barnacles, rubber, and certain plastics due to energy absorption limitations. In such cases, combining laser cleaning with mechanical or chemical methods can improve results.

4. Substrate Damage from Continuous Lasers

Continuous wave lasers can cause thermal damage to soft surfaces like thin metals or sensitive coatings due to high power. Pulsed lasers are better suited for delicate applications as they deliver controlled bursts of energy. Damage scenarios include warping of thin materials or discoloration of painted surfaces.

5. Environmental Limitations

Laser cleaning is unsuitable for flammable or explosive environments due to spark generation risks. Industrial settings like oil refineries or gas stations require alternative methods to prevent fire hazards. You should always make proper risk assessments and safety protocols when working near volatile substances.

6. Operating Requirements (Cooling, Temperature, Antifreeze)

Laser systems require stable operating conditions. In cold environments, antifreeze solutions prevent system damage during operation. Here’s how to maintain a water-cooled laser system:

- Replace the cooling water every 1–2 months to prevent impurities from accumulating. If the machine is unused for extended periods, drain the water completely to avoid stagnation.

- Opt for distilled or deionized water to minimize impurities that could form deposits on internal components. Avoid mineral water, as it contains metallic ions that can corrode the system.

- Clean or replace the filter element every 2 months under normal conditions, or more frequently in dusty environments.

- Maintain water temperature between 20–30°C depending on seasonal conditions. Use antifreeze in cold climates to protect the system during freezing temperatures.

- Regularly check hoses, fittings, and flow sensors for leaks or blockages that could disrupt cooling efficiency. Clean dust-proof nets weekly for better airflow around the chiller unit.

Comparison: Laser Cleaning vs. Traditional Cleaning Methods

| Category | Laser Cleaning | Sandblasting | Chemical Cleaning | Dry Ice Blasting |

| Contact-Free | Yes | No | No | Yes |

| Chemical-Free | Yes | Yes | No | Yes |

| Damage to Substrate | Minimal | High | Moderate | Minimal |

| Equipment Cost | $30,000–$250,000 | $5,000–$50,000 | $1,000–$10,000 | $10,000–$50,000 |

| Labor & Safety Needs | Low (automation-friendly) | High (protective gear required) | High (specialized training needed) | Moderate (minimal protective gear) |

| Environmental Impact | Minimal (no waste/emissions) | Moderate (dust/debris) | High (chemical waste) | Moderate (CO₂ emissions) |

| Cleaning Efficiency | 90–95% (fastest for precision tasks) | 70–80% (effective for large surfaces) | 75–85% (speed varies with chemical strength) | 65–75% (limited for thick coatings) |

| Maintenance Cost | $1,000–$3,000/year (low consumables) | $2,000–$5,000/year (abrasive media replacement) | $3,000–$8,000/year (chemical replenishment) | $1,500–$4,000/year (CO₂ pellet costs) |

| Estimated ROI | 2–4 years (high upfront cost offset by low operational expenses) | 1–2 years (low upfront cost but higher labor/consumables) | 6–18 months (low equipment cost but recurring chemical expenses) | 1–3 years (moderate costs balanced by reduced downtime) |

| Applications | Aerospace, electronics, automotive, heritage restoration | Metal surface prep, shipyards, heavy machinery | Industrial degreasing, paint stripping, oxide removal | Food processing, mold remediation, and machinery cleaning |

Which Type of Laser Cleaning Machine Should You Choose?

Pulse Laser Cleaning

- Best for: Precision tasks requiring minimal heat impact, such as cleaning delicate surfaces or detailed components.

- Cost: Higher upfront investment due to advanced control systems, typically ranging from $30,000 to $250,000.

- Applications: Aerospace (thin metals), electronics (PCB cleaning), and heritage restoration (artifacts).

- Advantages: Low heat generation, prevents substrate damage, and is ideal for intricate cleaning.

- Limitations: Slower cleaning speed and higher price compared to continuous systems.

Continuous Laser Cleaning

- Best for: Heavy-duty applications requiring fast throughput and large surface cleaning.

- Cost: More affordable, with prices ranging from $5,000 to $50,000.

- Applications: Shipbuilding (rust removal), automotive (paint stripping), and industrial machinery maintenance.

- Advantages: High cleaning speed, efficient for large areas, lower initial cost.

- Limitations: Generates more heat, which can damage sensitive materials; less precise than pulsed systems.

Real-World Use Cases and Success Stories

Here are a few real-world inspirations in laser cleaning:

CleanTech: This firm focuses on laser cleaning solutions for industry use. One standout job involved fixing up an old bridge in Germany. CleanTech’s laser tools took off years of rust and paint without damaging the bridge itself. This job cut about 30% off the usual repair costs.

Laser Cleaning Technologies: In 2021, this new company teamed up with a big plane maker to clean gunk off turbine parts. By using lasers to clean, they cut cleaning time by 90% and made surfaces better.

RoboClean: This company uses laser cleaning to maintain offshore oil rigs and cuts downtime by a lot. Their tech got rid of sea life and rust on the rigs and made them work 50% better. Using lasers also had less impact on the environment than old-school chemical cleaning.

Key Buying Considerations for Industrial Customers

- Required cleaning depth and material type

- Cleaning area size and frequency

- Budget range and ROI expectations

- Portability needs: trolley, backpack, robotic arm

- Service & support availability

- Certifications and compliance (ISO, CE)

Frequently Asked Questions (FAQ)

Q1: How much does a laser cleaning machine cost?

A1: Prices range from $5,000 for low-power handheld units to over $100,000 for high-power industrial systems, depending on power, features, and brand.

Q2: Can laser cleaning damage the base material?

A2: Improper settings or continuous lasers may cause thermal damage to sensitive surfaces.

Q3: What industries benefit the most from laser cleaning?

A3: Industries like automotive, aerospace, electronics, cultural restoration, and manufacturing see the greatest benefits from laser cleaning technology.

Q4: What power range should I choose for my application?

A4: Choose 50–100W for light-duty tasks, 200–500W for moderate industrial use, and 1000W+ for heavy-duty applications like shipbuilding or large-scale rust removal.

Q5: Are there government regulations for using lasers in cleaning?

A5: Yes, compliance with standards like CE, FDA, and ISO is required to ensure the safety and proper operation of laser systems.

Q6: Can I rent or lease laser cleaning equipment?

A6: Of course! Many suppliers offer rental or leasing options. Many even create a dedicated rental service.

Conclusion

Now you know about the laser cleaning machine problems as well as its good sides. If you compare the two, the pros far outweigh the cons. As long as you’re smart and safe about the system, there should be nothing much to worry about. Read our guide on Laser Safety Classifications for some very important details on safety categories.

Final Thoughts – Is a Laser Cleaning Machine Right for Your Business?

Couldn’t make up your mind yet? Why not let our experts assist you? Baison Laser is always happy to assist you with necessary details, insights, and tips. You can also request a demo and see if you like it!

Request a sample proofing. Or, if you’re already convinced, get a quote right away!