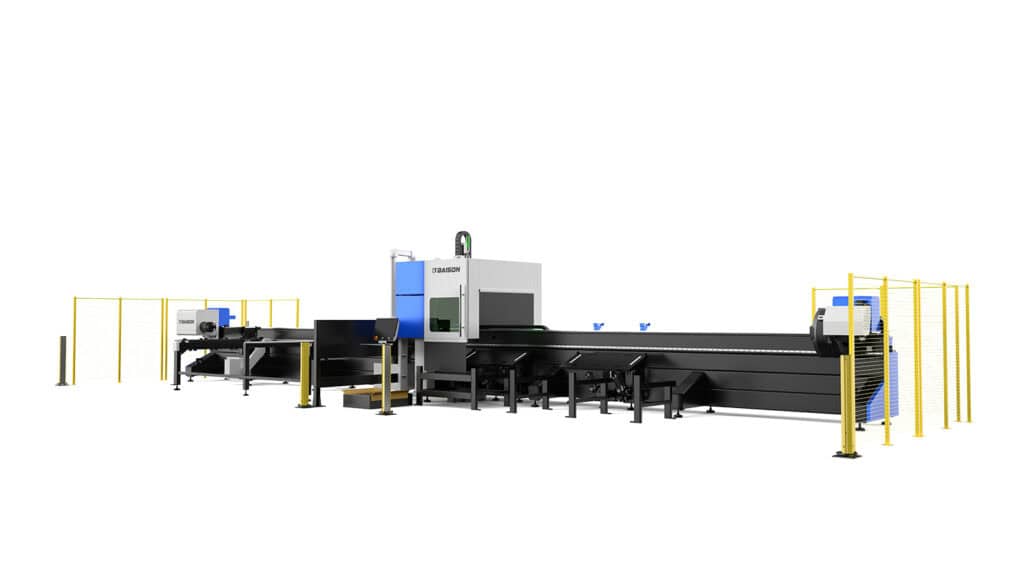

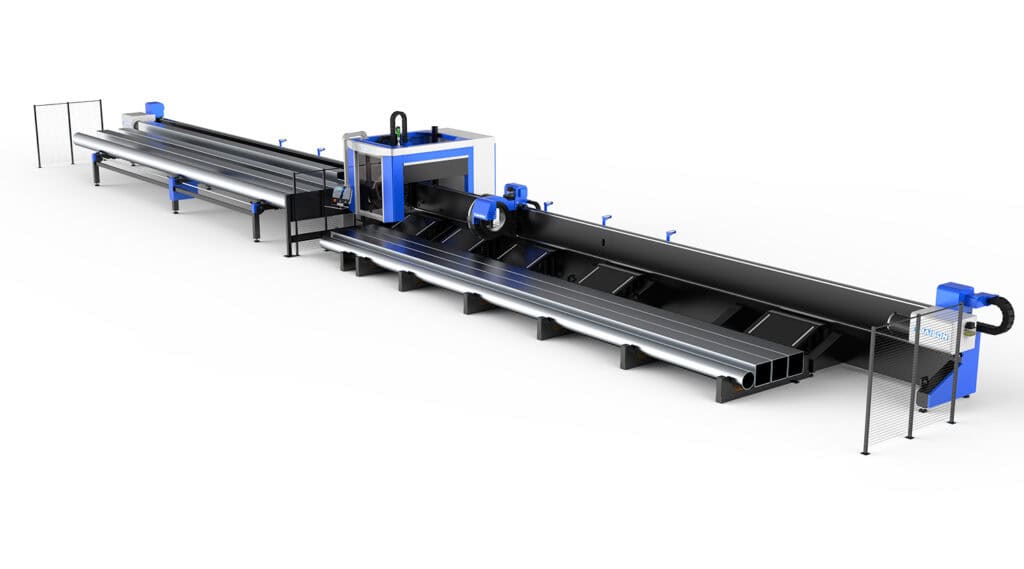

Heavy Duty Tube Laser Cutting Machine

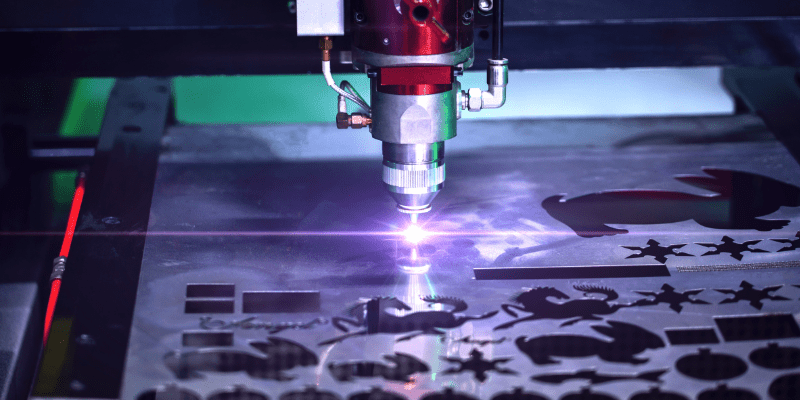

The heavy-duty laser tube cutting machine is perfect for those in the manufacturing and fabrication industries. With its high feed rates and flexible processing, this machine can handle even the most strenuous jobs quickly and easily. Whether working with thin or thick materials, the heavy-duty tube-cutting machine is up to the task.

Heavy Duty Tube Laser Cutting Machine

V Series Two-chuck

V36

1000kg Load Capacity

3000W-12000W

Tube Range φ 0.39″ -14.17″ (10-360mm )

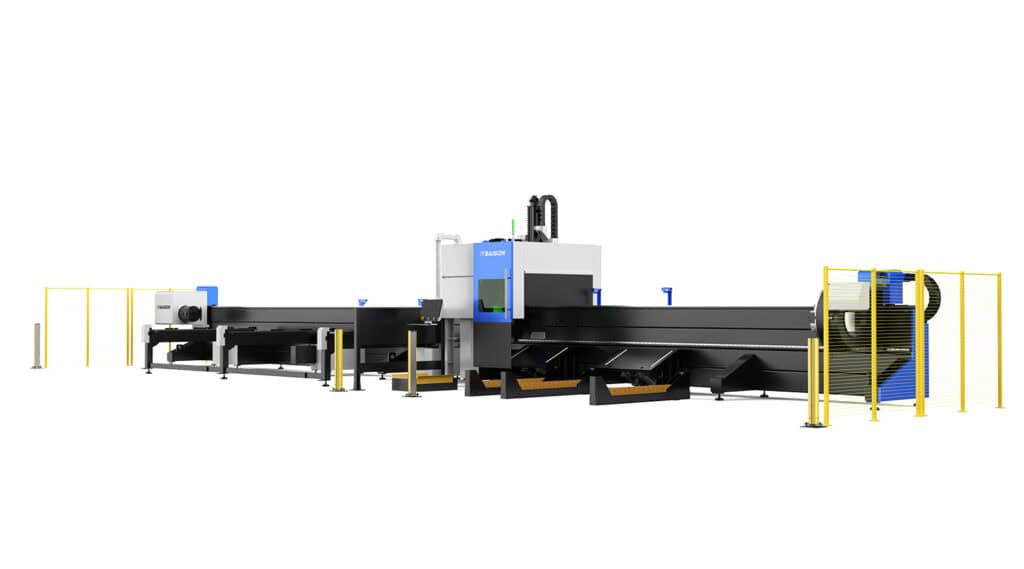

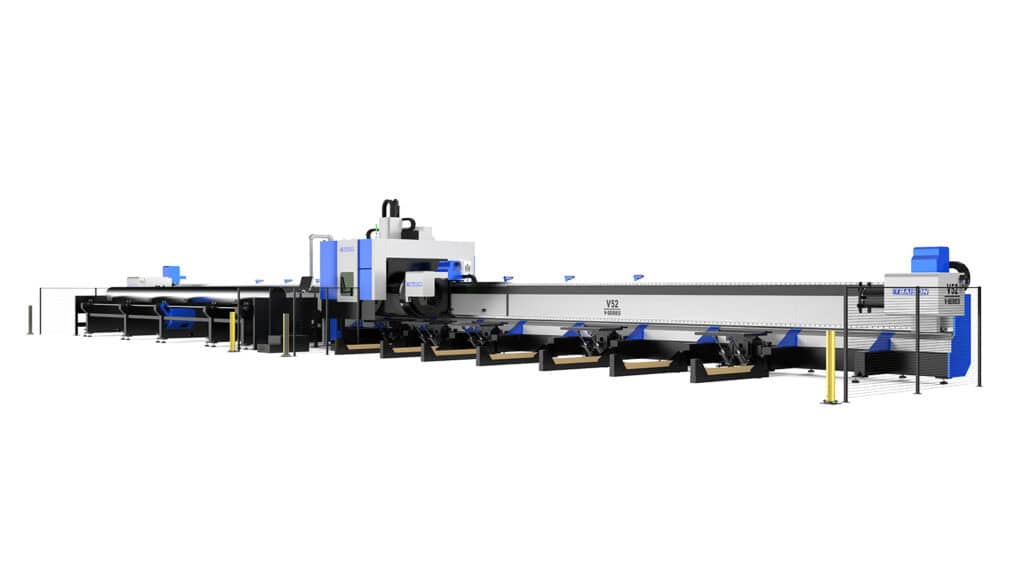

V Series Three-chuck

Loading: 29.53′(9000mm), Unloading: 19.69′(6000mm)

3000W-12000W

Tube Range φ 0.79″ -14.17″ (20-360mm )

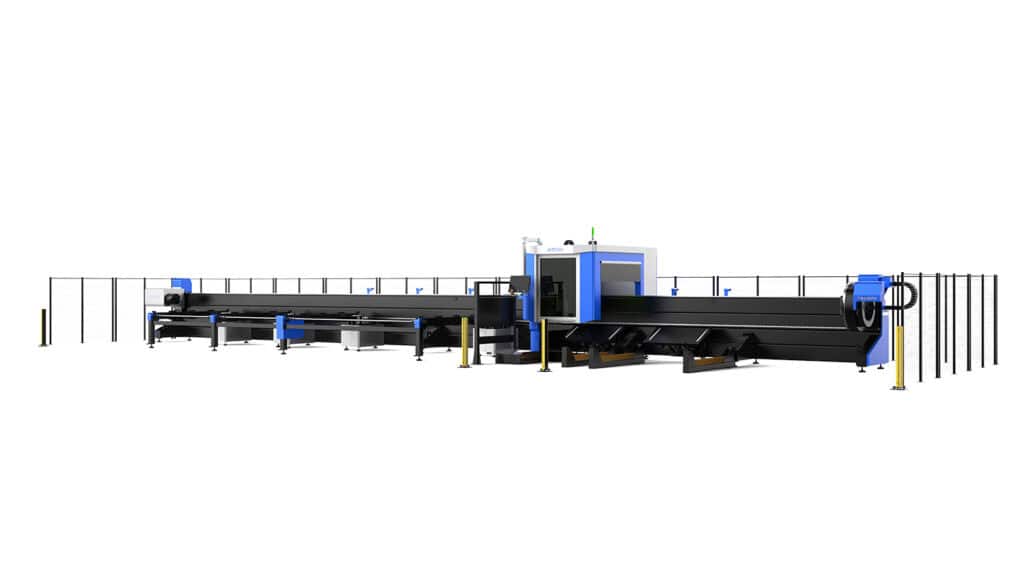

Loading: 39.37′(12000mm), Unloading: 19.69′(6000mm)

3000W-12000W

Tube Range φ 0.79″ -14.17″ (20-360mm )

Loading: 39.37′(12000mm), Unloading: 29.53′(9000mm)

3000W-12000W

Tube Range φ 0.79″ -14.17″ (20-360mm )

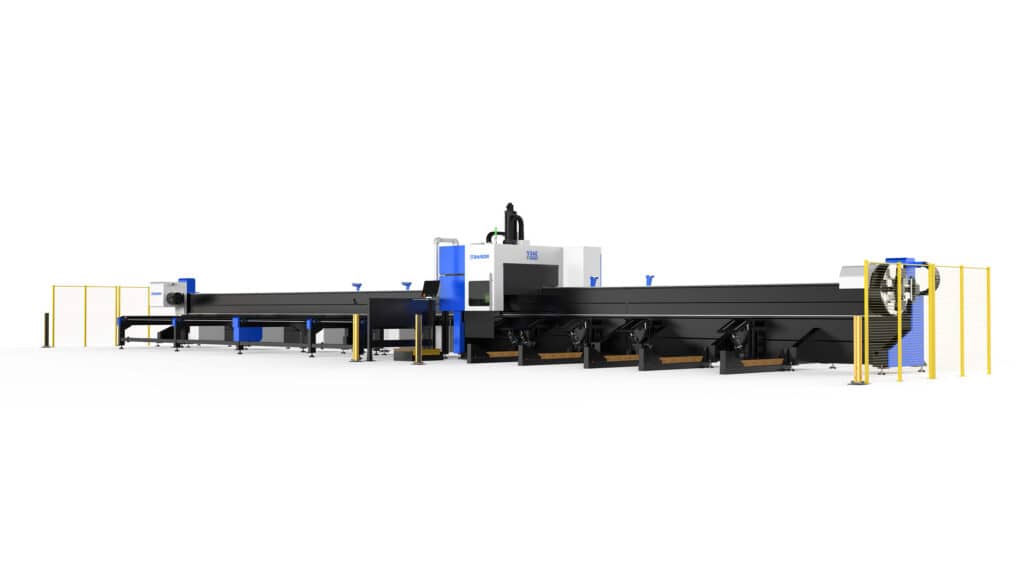

V Series Four-chuck

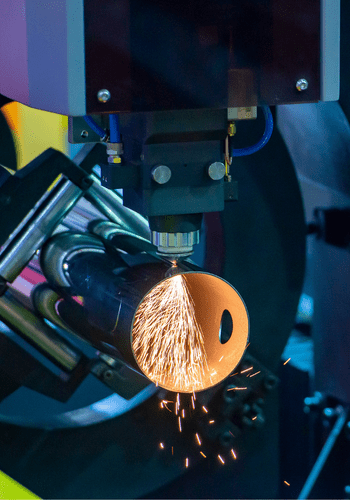

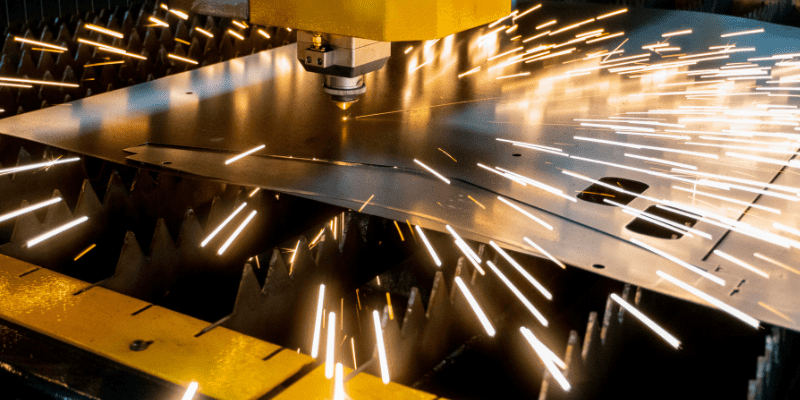

A Full Line of Features Designed to Meet the Most Challenging Tasks

If you’re looking for a fiber laser cutting machine that can handle the most challenging jobs, then the heavy-duty fiber laser metal tube cutting machine is a perfect choice.

Diameter of Up to 500mm/19.68in

Suitable for thick metal cuts and heavy-duty applications. One machine cuts all sizes of tubing

High-quality Bevel Cuts

Allows for more refined end products and more accuracy, no matter smaller or bigger components.

Up to 4 Heavy Duty Chucks

It guarantees durability and robust performance over prolonged periods of use.

Length of Up to 12000mm/472.44in

It gives you the freedom to carry out more extensive operations and get larger sheets of metal cut in less time.

Easy to Operate

Allow all your existing staff to operate advanced equipment without needing to hire a specialist.

Automatic Loading and Unloading

Minimize labor work and redirect your staff to more important tasks with flawless loading and unloading technologies.

Versatile Solutions Suited To Your Needs.

If you’re looking to expand your opportunities and pivot into new industries, or you’re looking to create higher quality products of your current range, our heavy-duty tube cutting equipment can fit right into your facility.

Transportation Pipeline

Oil Refinery Equipment

Bridge Construction

Powerful Machines That Allow For Unmatched Efficiency

Our solutions grant you new opportunities to scale your production lines. With experts with over 20 years of experience in the field, we’ve designed technology and machines that can be customized and suited to your needs.

| Model | V36 | V24ESS | V36ENS | V36ETS | V36ETN | V36UTT |

|---|---|---|---|---|---|---|

| Laser Power | 3000W-12000W | 3000W-12000W | 3000W-12000W | 3000W-12000W | 3000W-12000W | 3000W-12000W |

| Pipe Processing Range | Round tube: φ20~360mm Square tube: 20*20~350*350mm Tube R angle greater than 25mm can be clamped 360mmx360mm) Maximum channel steel: 35# (standard clamp) Maximum angle iron: 10# (standard clamp) (greater than 10# need to pay for professional tooling clamp) Maximum I-beam: 35# (standard clamp) Maximum H-steel: 345*345mm (standard clamp) | Round tube: φ20~240mm Square tube: 20*20~220*220mm (tube R angle greater than 30mm can clamp 240mmx240mm) Channel steel: 22# (need to pay for professional fixtures) Angle iron: 10# (need to pay for professional fixtures) I-beam: 22# (need to pay for professional fixtures) H-steel maximum: 22# (need to pay for professional fixtures) | Round tube: φ20~360mm Square tube: 20*20~350*350mm (tube R angle greater than 25mm can clamp 360mmx360mm) Maximum channel steel: 35# (standard clamp) Maximum angle iron: 10# (standard clamp) (greater than 10# requires professional tooling clamp) Maximum I-beam: 35# (standard clamp) Maximum H-beam: 345*345mm (standard clamp) | Round tube: φ20~360mm Square tube: 20*20~350*350mm (tube R angle greater than 25mm can clamp 360mmx360mm) Channel steel maximum: 35# (standard clamp) Angle iron maximum: 10# (standard clamp) (greater than 10# need to pay for professional tooling clamp) I-beam maximum: 35# (standard clamp) H-steel maximum: 345*345mm (standard clamp) | Round tube: φ20~360mm Square tube: 20*20~350*350mm (tube R angle greater than 25mm can clamp 360mmx360mm) Maximum channel steel: 35# (standard clamp) Maximum angle iron: 10# (standard clamp) (greater than 10# needs to pay for professional tooling clamp) Maximum I-beam: 35# (standard clamp) Maximum H-steel: 345*345mm ((standard clamp) | Round tube: φ20~360mm Square tube: 20*20~350*350mm (tube R angle greater than 25mm can clamp 360mmx360mm) Maximum channel steel: 35# (standard clamp) Maximum angle iron: 10# (standard clamp) (greater than 10# need to pay for professional tooling clamp) Maximum I-beam: 35# (standard clamp) Maximum H-steel: 345*345mm (standard clamp) |

| Tail Length | 160mm | 0mm | 0mm | 0mm | 0mm | 0 |

| Pipe Processing Length | 6500mm | 9000mm | 12000mm | 12000mm | 12000mm | 12000mm |

| Wall Thickness | 0.8-10mm | 0.8-10mm | 1-12mm | 1-12mm | 1-12mm | 1-16mm |

| Max Chuck Speed | 107r/min | 106r/min | 60r/min | 60r/min | 60r/min | 60r/min |

| Max Single Tube Loading Weight | 1000KG | 400KG | 1000KG | 1000KG | 1000KG | 1000KG |

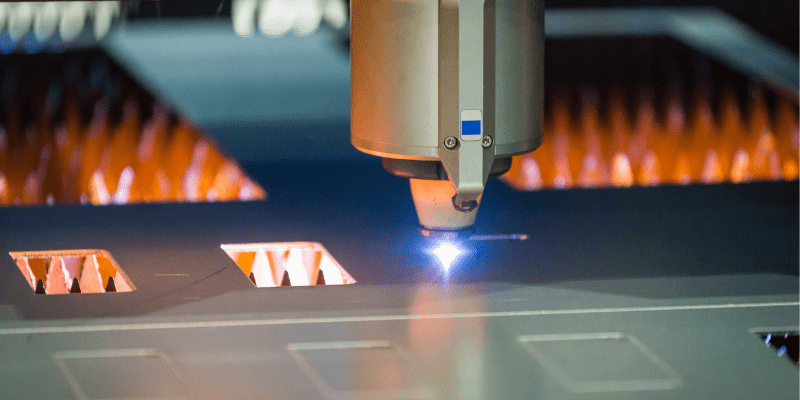

Top Notch Hardware For Consistent Results

Our laser cutting machines feature the most durable and powerful components on the market, and allow you to maintain the same cutting results over prolonged periods of time and years of operation.

IPG Laser Source

Our machines are built to be assets, not liabilities, so we use only the market’s most durable, sustainable, and consistent laser generators.

Motovario Motoreducer

To provide our clients with stable, balanced lasers that are always on track, we partner with Motovario, the gold standard in gears and motors.

Ospri Laser Head

Our Ospri Laser Heads help you keep the same quality of production even after prolonged use by maintaining precision cuts and consistent results.

Yaskawa Servo Motor

A Yaskawa Servo Motor drives and controls our lasers with accuracy, efficiency, and little heat, optimizing maintenance budgets.

Software Solutions That Make Your Most Ambitious Projects a Lot Easier

Baison tuber laser cutting machine uses the Cypcut TubePro operating system, one of the world’s leading laser tube cutting machine control systems.

TubePro is a professional tube-cutting machine that can be used to produce different shapes of tubes with ease. It has been designed for both standard and special production needs, seamlessly integrating into TubesT nesting software so you will not have any difficulties using it on your next welding project!

With this software, you can monitor the performance of our laser machines, ensure your projects are going smoothly, and accurately measure the timeframe of producing multiple units.

- Accurate, accessible metrics to measure performance.

- Remote control functions to maintain smooth operations.

- User-friendly interface that’s easy to operate.

Tube Laser Cutting Resources & Knowledge

Over the past two decades of laser machine production, we have accumulated a lot of experience and cutting skills. We can provide our customers with solutions to various daily problems.

3 Types of Laser Cutters You Need to Know

How to Prevent Dross in Laser Cutting?

20 Tips To Help You Improve the Laser Cutting Quality

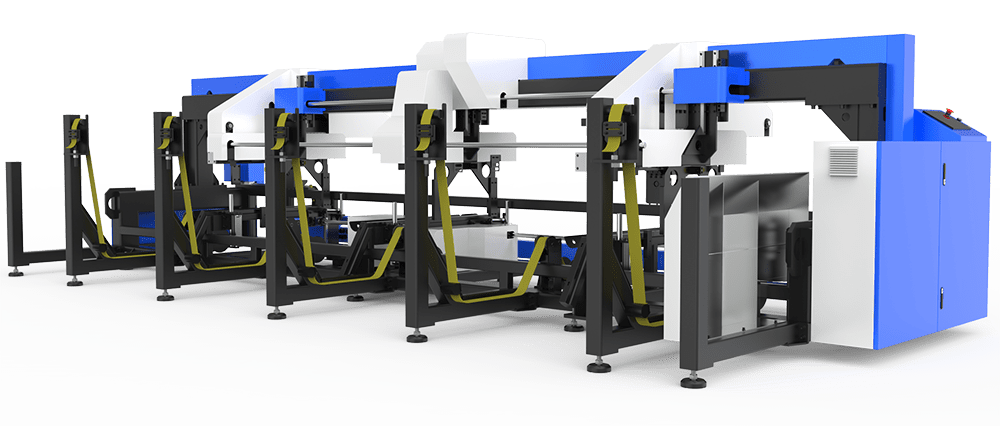

Auto Tube Loading System

You can reduce your setup time with the auto tube loading unit. The functional bundle space automatically provides material, and it’s also possible to set up a machine in front of you so that everything is customized for how much product comes through on any given day – making production faster than ever!

Looking to Boost Your Productivity Today?

Our professionals will help you from start to finish, contact us today and let us walk you through our services in more detail.