Industrial cleaning is a hectic task. Cleaning stubborn stains, paint, or rust is a huge challenge in several industries. Traditional methods are time-consuming and often damage the surfaces. In addition, some techniques release hazardous substances.

Laser cleaning machines offer a safe, quick, and effective solution for industries. This advanced technology is transforming numerous industries all over the world. In this blog post, we’ll share the ins and outs of laser cleaning. It will help you understand why laser cleaning machines are the future of industrial cleaning. Let’s get into it.

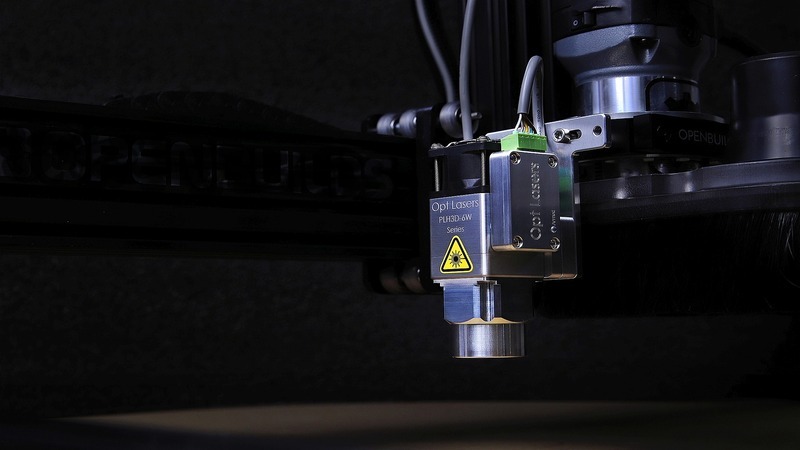

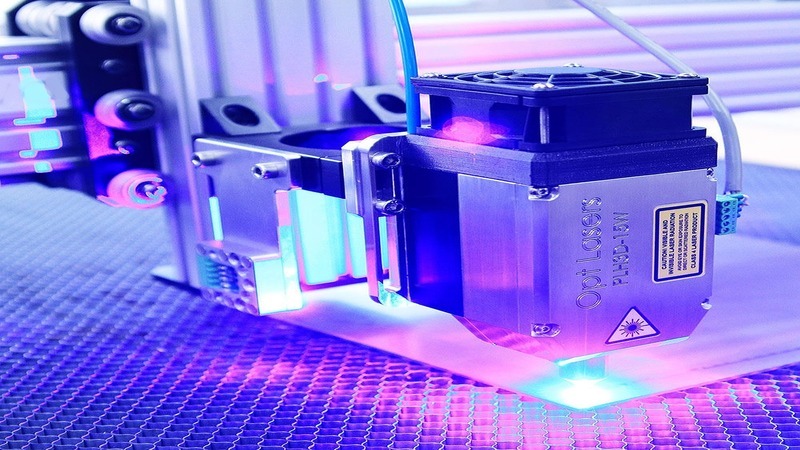

What is a Laser Cleaning Machine?

A laser cleaning machine is a modern device. It utilizes a high-energy, focused light beam to remove various unwanted substances from a surface. Whether you are dealing with contaminants, coatings, or impurities, a laser cleaning machine can remove all of them.

Most traditional cleaning approaches rely on abrasive chemicals or harsh techniques. They ruin the materials’ surface. Laser technology offers an efficient alternative to this. It targets only the unwanted layer. The process is non-contact, which is why it doesn’t damage the base material.

How Do Laser Cleaning Machines Work?

Laser cleaning machines employ the process of laser ablation. In this method, a high-energy laser beam is directed at the targeted surface. The laser beam contains numerous focused laser pulses. The focused laser beam heats and vaporizes the undesirable surface.

The laser cleaning machine targets only the unwanted layer. It doesn’t impact the base material. The absence of physical contact between the equipment and the surface makes it safe.

Types of Laser Cleaning

Laser cleaning machines are based on laser cleaning technology. Laser machines employ one of the following three cleaning methods:

Dry Laser Cleaning

Dry laser cleaning involves the direct elimination of contaminants from a surface. The laser beam vaporizes the dirt or any unwanted layer. It is the most common laser cleaning technique. It’s not only simple but also effective.

You can use dry laser cleaning for metal surfaces, moldy spots, and machinery components. This method involves no toxic chemicals or water residue. It presents a low-maintenance solution for industrial cleaning. It is also ideal for sensitive surfaces and artwork.

Wet Laser Cleaning

Wet laser cleaning employs a liquid dielectric for cleaning various surfaces. A liquid layer is evenly spread on the surface to be cleaned. A laser beam is applied to eliminate stains and contaminants.

The liquid layer absorbs a part of the laser heat. It prevents the base material from thermal damage. As the laser heats the liquid layer, microbubbles form in it. They expand and collide with the contaminants. It detaches the contaminants from the surface and cleans it.

For wet laser cleaning, the liquid dielectric must be inert to the contaminants. If the contaminants or the base material, it can lead to undesirable chemical reactions. This laser cleaning is best for high-damage-risk scenarios. It is effective for composites, ceramics, plastics, or coated surfaces. It provides excellent control, preventing surface oxidation and deformation.

Laser + Inert Gas Cleaning

This laser cleaning employs a continuous flow of inert gas during laser ablation. The combination of the flow of inert gas and the laser beam is a great solution for eliminating unwanted materials.

Nitrogen, helium, or argon are commonly utilized in laser cleaning. These gases prevent oxidation of the base material. In addition, they remove vaporized particles and debris instantly.

Laser inert gas cleaning is acknowledged for attaining high-purity results. It is ideal for aerospace, defense, and medical device manufacturing.

Why Laser Cleaning Machines Are The Future of Industrial Cleaning?

The rise of laser cleaning technology marks a revolutionary shift in industries. It ensures safety as well as efficiency. The following are the reasons why laser cleaning machines are considered the future of industrial cleaning:

Eco-Friendly Cleaning

Today, sustainability has become a global practice. Laser cleaning machines perfectly align with the green manufacturing goals.

Traditional cleaning methods employed in industries rely on harsh chemicals. These chemicals react with the contaminants and generate toxic waste. The waste is difficult to dispose of. It often poses serious environmental hazards.

In contrast, laser offers an environmentally safe solution. It acts on the unwanted particles and eliminates them. It doesn’t involve any toxic chemicals. Moreover, laser cleaning machines do not release any harmful waste. It means no contaminated runoff and no chemical exposure for workers.

Opting for laser cleaning means aligning a company with sustainability regulations. The European Union has issued the RoHS Directive (2011/65/EU). These restrictions are made to limit the release of certain hazardous chemicals. Laser cleaning allows you to comply with these environmental standards.

Safety in a Challenging Workplace

Safety is a major concern in an industrial environment. Laser cleaning machines offer a significant upgrade over conventional methods. These devices promise a safer workplace in a sensitive workplace.

Enclosed laser heads and an interlocking mechanism contribute to preventing accidents. The ventilation system ensures the continuous elimination of vaporized contaminants. It prevents the formation of a hazardous atmosphere.

Temperature sensors monitor the temperature of the machine. The water cooling system in some laser cleaning machines helps maintain an optimal temperature.

The capability of laser machines to work remotely allows you to work remotely. It also minimizes the exposure to a hazardous environment. Operators can clean the surfaces away from the worksite.

Precision and Speed

Industrial applications demand work at a fast pace with accuracy. Laser cleaning devices are acknowledged for their precision. You can fine-tune the machine’s power, pulse frequency, and focus depth. These features allow you to access microscopic spots and clean them effectively.

The focused beam targets the spot where it is needed. The short, pulsed laser provides bursts of energy. This targeted ablation vaporizes only the contaminants. The substrate surface remains intact.

The laser machine also has outstanding speed. It can operate at a speed of 50 square centimeters per minute. The cleaning speed can be further optimized by adjusting pulse repetition rates and scan patterns. The combination of precision and speed makes it the best alternative to conventional techniques.

Automation

Automation is becoming the norm for today’s industries. Where everything is automated from simple initiations to complex operations, it’s not in laser technology. Laser cleaning machines have a fantastic potential to be automated.

You can also integrate them with Industry 4.0. The International Society of Automation has declared Industry 4.0 as the future of smart manufacturing. It allows you to program the machines with custom cleaning parameters. It ensures repeatable and error-free results.

Several advanced models of laser cleaning machines come with AI-driven control algorithms. This system automatically adjusts the cleaning parameter based on the condition of the surface. It also contributes to optimizing energy efficiency and cleaning effectiveness.

Versatility Across Industries

The laser cleaning technique is adaptable across various industries. It is also usable for numerous materials.

Automotive Industry

In the automotive industry, a laser machine is used for cleaning weld seams. You can also use them for removing coatings. In addition, they enable you to prepare different surfaces for bonding or adding paint.

Aerospace Industry

The aerospace industry demands accuracy in every sector. A small mistake can lead to costly damage. A laser cleaning removes oxides from engine components and composite surfaces. Besides, they ensure the structural integrity of various surfaces.

Electronics and Semiconductor industry

In the case of electronics and semiconductors, you have to work at the microscopic level. Laser cleaning offers ultra-precision. You can use it to eliminate a micrometer-thin oxide layer. The machine is also usable for removing residues from wafers and connectors. Controlled energy flow and a focused beam make it perfect for delicate materials.

Heavy Machinery Industry

The heavy machinery sector also leverages laser cleaning machines. Shipbuilding, power generators, and the railway industry rely on them for maintenance. They also use the machine for rust removal and paint stripping on large metal components.

Heritage Conservation Industry

The heritage conservation industry is also utilizing laser cleaning. Cleaning ancient sculptures and historic artifacts is safer with a laser machine. Traditional methods may abrade delicate surfaces. A slight damage to any aged material can ruin its worth. Laser cleaning operates at the micro-level and eliminates pollutants.

Cost-Effective in the Long Run

The cost of machinery makes a significant contribution to the overall operational expenses. Laser machines are quite expensive. You need a hefty investment to purchase them. However, once you get a laser cleaning machine, you can save a lot on operational costs.

Conventional tools are less expensive than laser cleaning machines. However, they need frequent maintenance. Moreover, their operational costs also add up over time. Continuous need for consumables and waste management elevates the overall cost in the long run.

In contrast, laser machines last for more than 1000 hours. They are durable and require minimal maintenance. Moreover, they are energy efficient. These factors make it a cost-effective solution for industries. Minimal waste production and high productivity also contribute to a better return on investment.

FAQs

What is the future of laser technology?

The future of laser technology is expanding. With the growth of quantum computing, laser techniques have become more refined. The advancement in AI-based control and compact laser modules is making lasers faster and more energy-efficient. Industries are shifting toward green and contactless laser solutions for various purposes.

What are the advantages of laser cleaning?

Laser cleaning offers numerous advantages, including non-contact operations, energy efficiency, and high precision. Minimal waste generation and environmental safety also make it an eco-friendly choice. Moreover, it reduces maintenance costs and operator risks.

What are the industrial applications of lasers?

Lasers are used extensively in industries for cutting, welding, engraving, and cleaning. They are crucial for high precision, repeatability, and efficiency in manufacturing processes. Their adaptability to different materials and integration with automation systems make lasers indispensable tools.

How has laser cleaning technology improved?

Laser cleaning technology has significantly improved with the development of fiber lasers, advanced optics. It is a non-contact and waste-free solution. Modern laser machines come with AI-based feedback. It allows precise control over cleaning depth and intensity.

What is the importance of lasers in modern industry?

Lasers are essential in modern industry. They enable high-precision, high-speed, and contamination-free manufacturing. By offering automation compatibility, lasers contribute to smart manufacturing and sustainable production practices. They also minimize material waste, energy use, and downtime. This helps industries achieve both economic and environmental efficiency.

What are the 5 applications of lasers?

The application of lasers includes laser cutting, welding, engraving, cleaning, and in medicine.

- Lasers are used to cut metals, plastics, and composites with extreme precision.

- High-powered lasers fuse materials together quickly and smoothly. They create strong, durable joints in manufacturing and construction.

- Lasers permanently mark products with serial numbers, barcodes, or designs without physical contact.

- Laser cleaning removes rust, paint, and contaminants from surfaces without using chemicals or abrasives.

- In medicine, lasers are used for surgeries, vision correction (LASIK), and the sterilization of instruments.

Conclusion

Industrial cleaning has always been an essential part of maintaining equipment efficiency. A laser cleaning machine offers an effective and precise solution for industrial cleaning. Their eco-friendly and chemical-free operation not only reduces environmental impact.

In addition, they are cost-efficient and adaptable across various industries. These features make it a fabulous solution for modern production lines. As technology is advancing, laser cleaning stands out as the future of industrial maintenance.

If you are looking for industrial cleaning, go with a durable laser cleaning machine. Baison offers the best laser cleaning machines for industries. So, investing in a laser cleaning machine and make your project efficient.

Explore Laser Cleaning Machines With Baison

Choosing a reliable manufacturer of laser machines is necessary for ensuring quality, precision, and long-term performance. A trusted brand like Baison provides advanced technology backed by strong technical support. We offer premium-quality laser cutting, welding, engraving, and cleaning machines. You can explore our laser products. So, get an instant quote and explore our fantastic laser machines.