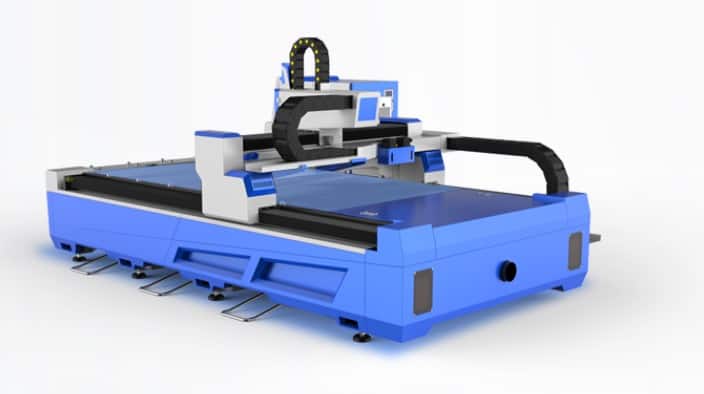

What are Laser Cutting Machines?

Laser-cutting machines are essential for businesses seeking to improve their manufacturing capabilities. These machines utilize laser technology to efficiently and accurately cut various materials, providing a precise solution for multiple industries.

How Laser Cutting Machines Work?

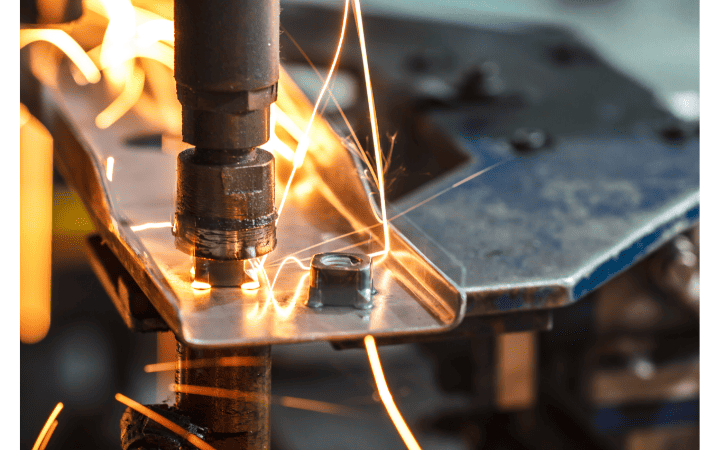

A laser cutter uses a highly concentrated laser beam to melt, burn, or vaporize materials, allowing for precise and clean cuts. In the laser cutting process, the laser beam is generated by a resonator and directed onto the workpiece through mirrors and lenses. The intense heat from the laser beam creates a narrow kerf, enabling intricate cuts with minimal material wastage.

The cutting process is controlled by computer numerical control (CNC) systems that follow a pre-programmed design, guiding the laser along the desired cutting path. Laser-cutting machines are widely used in various industries for their accuracy, versatility, and efficiency in processing a wide range of materials, including metals, plastics, wood, and more.

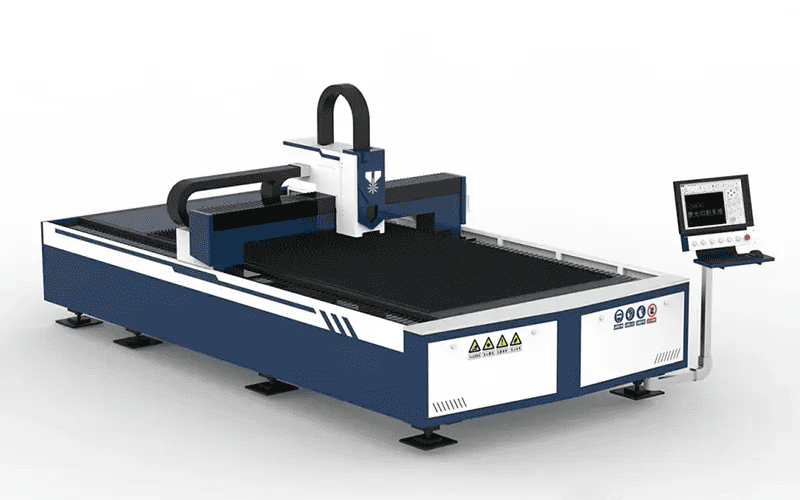

Types of Laser Cutting Technologies

A wide variety of laser cutting technologies are available on the market, including CO2 lasers, fiber lasers, and diode lasers. CO2 lasers are commonly used for engraving and cutting non-metallic materials such as wood and acrylic. Fiber lasers excel at cutting metal surfaces with high precision, making them ideal for industrial applications. These laser cutters are popular options in the industry.

Materials Compatible with Laser Cutting Machines

A laser cutter, also known as a diode laser, is versatile equipment for engraving and cutting a wide range of materials. From metals like stainless steel to substrates such as leather and glass, these cutters offer compatibility with various materials. Different laser cutter models may have limitations on certain materials or thicknesses they can effectively work with.

Understanding Capabilities and Limitations

When choosing laser-cutting equipment for your business, it is important to understand the capabilities and limitations of this equipment. Factors such as power level, work area size, cutting speeds, and edge quality should be considered based on your specific needs. Manufacturers’ technical support services are crucial for smooth operations with cutters and engraving equipment.

By comprehending how laser cutters, also known as cutters, function along with their diverse technology options and material compatibility range, you can make an informed decision when selecting the right laser-cutting machine for your business. These machines are capable of engraving various materials and require specific equipment to operate effectively.

What are Economical Laser Cutting Machines?

Economical laser engraving equipment is cost-effective for businesses looking to optimize their budget without compromising quality. These machines offer several advantages over ordinary laser cutters, making them popular in various industries. With their efficient beam and spacious work area, they provide a reliable solution for businesses in need of precise engraving capabilities.

Definition and Characteristics of the Economic Laser Cutter

- Affordable price range: Economical laser cutter comes at a fraction of the cost compared to their high-end counterparts. These engraving machines offer impressive cutting power and efficiency, making the cutting process quick and precise. The key to their effectiveness lies in the powerful beam they emit.

- Excellent build quality: Despite being affordable, these laser cutters and engravers maintain excellent build quality. They are durable and long-lasting, making them a great investment for anyone in need of fiber laser engravers or fiber laser cutting machines.

- Wide variety of features: Laser engravers and fiber laser cutters offer a wide range of features and capabilities, including high-precision cutting, engraving, and material compatibility. These laser cutter machines are known for their advanced technology and versatility.

Compared to Ordinary Ones

- Lower initial investment: Small businesses and business owners with limited budgets can access affordable engraving machines and cutters without breaking the bank. The price range of this laser equipment is suitable for those looking for cost-effective options.

- Reduced maintenance costs: Economical engraving machines often have lower maintenance requirements, resulting in long-term savings. The equipment’s cutting head, powered by fiber technology, contributes to the overall efficiency and durability of the machine.

- Energy-efficient operation: These affordable laser cutters are designed with focused laser systems to consume less power while delivering excellent results, helping businesses save on energy bills. This piece of equipment is a fiber laser cutter.

Industries Where Economical Machines are Commonly Used

- Small businesses in the manufacturing sector can benefit from affordable laser cutters. These laser cutters, such as the Glowforge equipment, are equipped with powerful software that allows for precise cutting in metal fabrication or woodwork processes.

- Small business users: Startups or entrepreneurs looking for an entry-level option find economical laser cutters and equipment ideal for their needs, such as the Glowforge. These machines offer the power and capabilities required to get started in laser cutting.

- Customization services: Industries like signage making, leather crafting, or personalized gift production can utilize affordable laser technology effectively. Laser cutters, such as the Glowforge, provide the power and precision needed to create unique designs on various materials including metal.

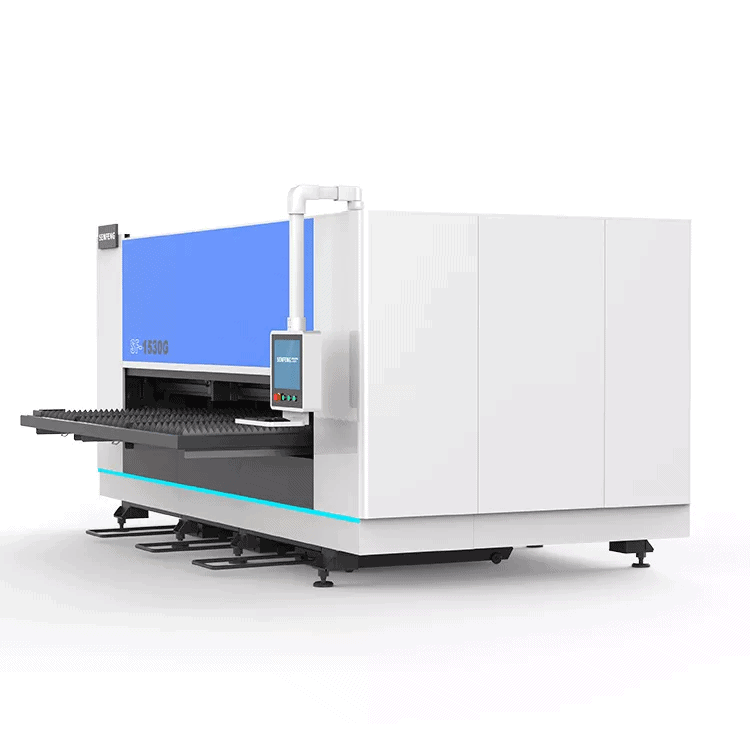

What are Ordinary Laser Cutting Machines?

Ordinary laser cutting machines, such as the tool and Glowforge, are commonly used in various industries and are known for their advanced features and capabilities. These machines offer high-performance cutting of metal, engraving, and compatibility with different materials, making them suitable for various applications.

Definition and Characteristics of the Ordinary Laser Cutter

Advanced technology: Ordinary laser cutting machines, such as the Glowforge and Xtool, are equipped with state-of-the-art power, enabling precise and intricate cutting and engraving.

High-end build quality: These laser engraving machines are built with robust materials and components, ensuring durability and reliability even in demanding industrial settings. With their focused laser systems, they can also be used as laser marking machines, providing precise laser marking capabilities. Whether you need a cheap laser cutter or a high-performance machine, these laser engraving systems deliver exceptional results.

The Glowforge machine has an extensive feature set, including automatic focus adjustment, advanced motion control systems, and multiple cutting modes. It is an ordinary laser cutter that offers a comprehensive range of features in the power area.

Compared to Economic Ones

Higher initial investment: Due to their advanced technology and superior performance, ordinary laser cutting machines like the Glowforge cutter generally come with a higher price tag and require more power to operate in a larger area.

Maintenance expenses for focused laser systems, such as cheap laser cutters, may include regular maintenance and calibration to ensure optimal laser power. These costs can contribute to higher long-term expenses associated with fiber laser machines.

Power consumption: Ordinary laser cutters may consume more energy compared to economical options, resulting in higher energy bills. However, using the Glowforge machine can help reduce power consumption as it is designed to be efficient and uses only a minimal amount of energy, approximately X mm peruse.

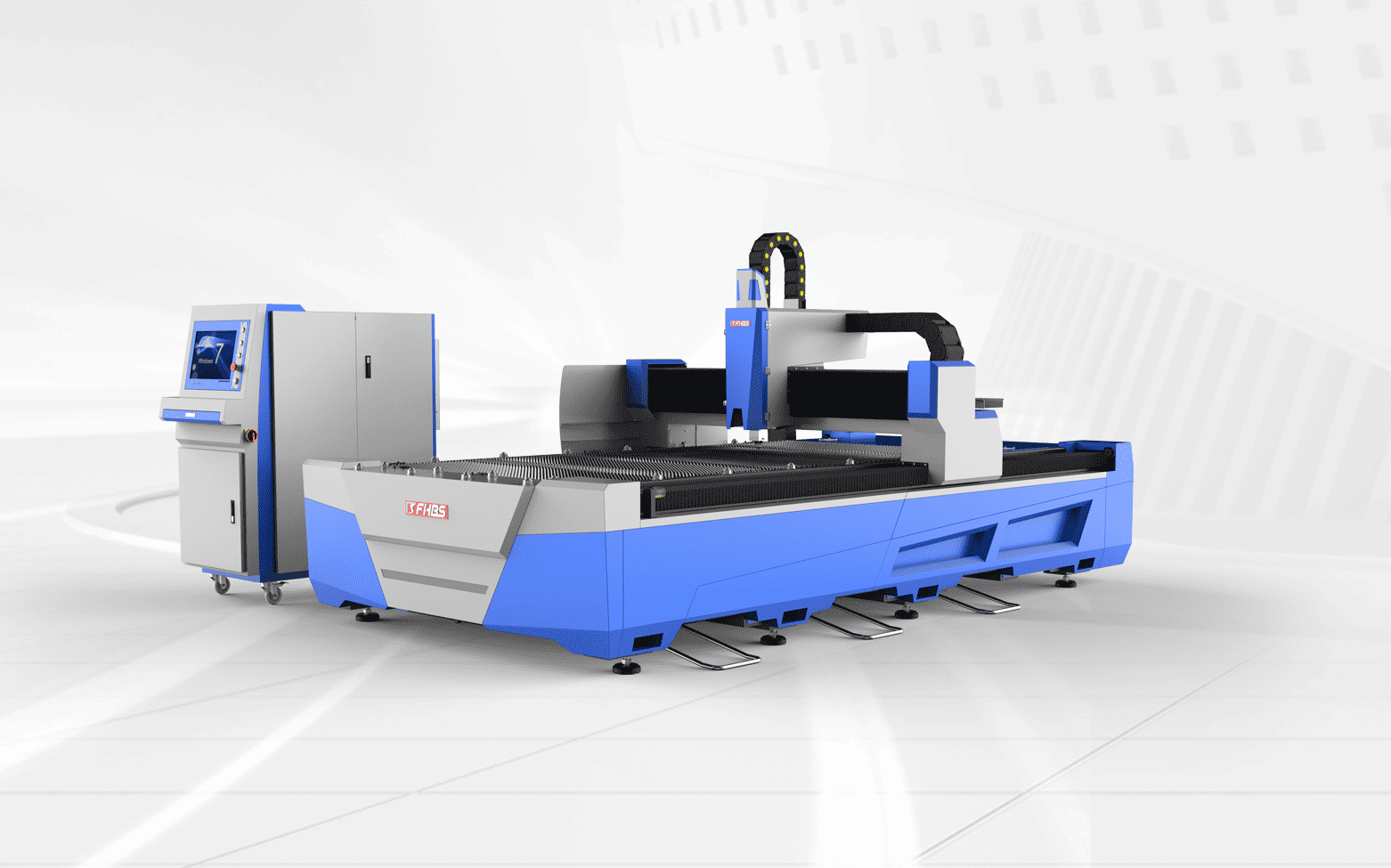

Industries Where Ordinary Machines are Commonly Used:

Large-scale manufacturing industries use high-end laser cutters for their precision and efficiency in mass production. Automotive, aerospace, and electronics rely on these machines for their power. Glowforge is one such laser cutter commonly used in these industries.

Specialized applications: Certain industries that require intricate and complex cutting, such as jewelry making or medical device manufacturing, benefit from the advanced capabilities of the Glowforge laser cutter. Its power and precision make it the ideal tool to use for these specific tasks.

Factors to Consider in Choosing the Right Laser Cutting Machine

When choosing between economical and ordinary laser-cutting machines, there are several factors to consider based on your specific requirements. Here are the key factors to take into account: the power of the cutter and how to use it effectively.

- Budget: Determine your budget limitations and consider the initial investment required for the machine. Economical laser cutter generally comes at a lower price point compared to ordinary ones, making them more suitable for businesses with limited budgets.

- Performance and Features: Assess your production needs and the level of performance and features required. Ordinary laser cutters often offer advanced capabilities, such as higher precision, faster cutting speeds, and more extensive software integration. Economical machines may have fewer advanced features, but can still provide satisfactory results for certain applications.

- Material Compatibility: Consider the types of materials you need to work with and ensure that both economical and ordinary laser-cutting equipment are compatible with them. Verify the machine’s specifications and capabilities for cutting and engraving different materials, such as metals, plastics, or wood.

- Work Area Size: Evaluate the size of the workpieces that you will be handling and ensure that the chosen laser cutting machine provides an adequate cutting area to accommodate them. This factor applies to both economical and ordinary machines.

- Maintenance and Operating Costs: Examine the maintenance requirements and associated costs of the machines. While economical laser-cutting equipment may have lower initial costs, it may require more frequent maintenance and consumable replacements. On the other hand, ordinary machines might have higher initial costs but could offer better durability and potentially lower maintenance expenses.

- Energy Efficiency: Consider the energy consumption of the machine. Both economical and ordinary laser-cutting machines can vary in terms of energy efficiency. Opting for an energy-efficient machine can help reduce long-term operating costs.

- Support and Warranty: Check the manufacturer’s reputation for providing reliable customer support and after-sales service. Evaluate the warranty period offered for the machine, as this can provide peace of mind in case of any unforeseen issues.

- User Skill Level: Assess the skill level required to operate the laser cutting machine. Some ordinary machines might have more complex controls and require skilled operators, while economical machines often have user-friendly interfaces suitable for beginners or those with limited experience.

- Industry and Application: Consider the specific industry you are in and the intended application of the machine. Determine whether the features and capabilities of either an economical or ordinary machine align with your industry requirements.

By considering these factors, you can make an informed decision between an economical and ordinary laser cutter that best suits your budget, performance needs, materials, maintenance requirements, and overall business goals.

FAQs

Q: How do I determine which type of laser-cutting machine is suitable for my business?

A: When choosing between economical or ordinary laser cutting machines, consider factors such as your budget constraints, production volume requirements, desired level of precision needed for your applications, and the material types you work with regularly.

Q: Are there any ongoing costs associated with owning a laser-cutting machine?

A: Yes. Apart from the initial investment in a new laser machine, ongoing costs may include maintenance, replacement parts for laser machines, electricity consumption for the laser engraving machine, and operator training for the laser cutter machine.

Q: Can an economical laser cutting machine handle complex cutting tasks?

While economical laser cutter machines may have certain limitations compared to ordinary ones, they are still capable of handling a wide range of cutting tasks effectively. However, for highly intricate or demanding applications, an ordinary laser cutter machine might be more suitable.

Conclusion

In conclusion, selecting the appropriate laser-cutting machine for your business requires careful consideration of various factors. Key factors to consider include your business needs, budget, production volume, material requirements, and desired precision level. Economical machines offer a cost-effective solution suitable for small businesses with limited budgets, while ordinary machines provide advanced features for complex cutting needs, albeit at a higher cost.

If you are not sure which machine is right, click here and we will help to find the one that’s perfect for you. Ready to take your business to the next level with the right laser-cutting technology? Get started now and invest in your success with a reliable and efficient machine!