In today’s fast-paced manufacturing environment, businesses must continually adapt and innovate to maintain a competitive edge. The fiber laser cutting machine is one groundbreaking innovation that has taken the manufacturing world by storm. The heart of this advanced technology is the automatic feeding manipulator, an essential component that significantly improves efficiency and productivity.

In this comprehensive post, we’ll dive into the world of automatic feeding manipulators for fiber laser cutting machines, exploring their importance, components, advantages, and applications.

What Is an Automatic Feeding Manipulator?

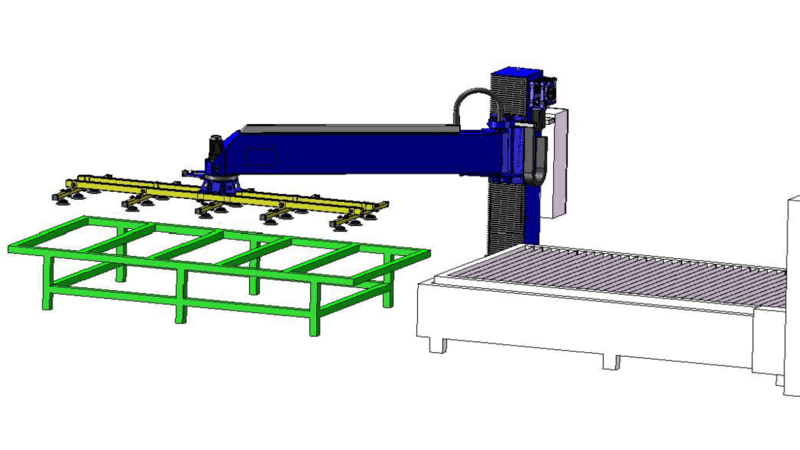

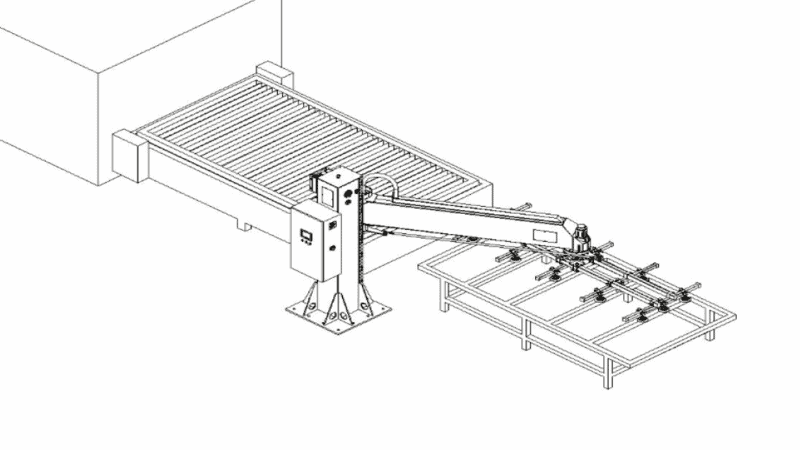

An automatic feeding manipulator is a state-of-the-art robotic system specifically designed to facilitate the loading and unloading of materials in a fiber laser cutting machine. The manipulator automates the entire material handling process, ensuring seamless and efficient cutting operations with minimal human intervention.

Consequently, it plays a significant role in increasing production speed, precision, and overall efficiency. This makes it a must-have addition for businesses looking to enhance their manufacturing capabilities and stay ahead of the competition.

Components of Automatic Feeding Manipulator

The automatic loading and unloading robot comes in various cutting machines in different forms. However, in fiber laser cutting machines, its key components are:

Automatic Loading and Unloading System

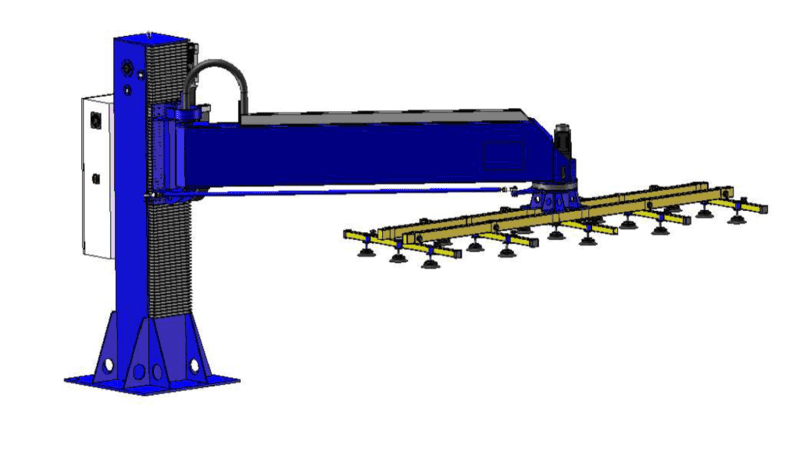

This innovative system lies at the core of the manipulator’s functionality. It comprises a series of conveyors, clamps, and sensors that work in tandem to ensure the smooth and accurate transfer of materials onto and off the cutting table.

With this great automation, the system drastically reduces the risk of human error and minimizes downtime.

Bed for Feeding and Placing Metal

The solid bed is included for stacking and organizing sheet metal within the loading and unloading system. It ensures the optimal placement of materials for cutting, streamlining the overall cutting process and maximizing productivity.

Cooling Accessories for Safeguarding Lens

Cooling accessories, which primarily include the collimating and focusing lenses, are added to maintain the cutting head and laser beam’s temperature. They prevent overheating and ensure the longevity and reliability of the cutting machine, safeguarding your investment.

Chasing Aperture for Repositioning Accuracy

The chasing aperture component helps maintain the laser beam’s position accuracy while cutting materials of various thicknesses. Most laser-cutting machine manipulators have a 35 mm aperture, preventing stray light interference.

Touch Screen Control System for High Flexibility

This user-friendly interface empowers operators to monitor and control the entire cutting process effortlessly. With its intuitive design and robust functionality, the touchscreen control system offers unmatched flexibility and ease of use, making it an invaluable asset for any manufacturing operation.

Advantages of Automatic Feeding Manipulator

The automatic feeding manipulator is the latest technology that is significantly gaining popularity in the laser cutting machine industry due to its various benefits and pros. So notable ones are listed below:

High Efficiency and Utilization Efficiency

By automating the material handling process, the manipulator significantly increases the overall efficiency of the cutting machine and reduces downtime. This translates to faster production rates and lower costs, giving your business a competitive advantage.

Effectively Protects from Human Interference and Stray Light

The manipulator’s smart design shields the cutting area from external light sources, ensuring optimal cutting conditions. This protection is vital for maintaining the highest level of precision and quality in your cutting operations.

High-speed and High-Precision Cutting

Thanks to the advanced components of the manipulator, cutting speeds and precision are greatly enhanced. This results in improved product quality, making your business more attractive to customers and increasing your market share.

Complete Automation of Production Line

The manipulator makes the laser cutting or any other process fully automated. All the assembly line processes, from feeding, uncoiling, leveling, cutting, and unloading, are done robotically, eliminating material waste.

Corrosion Resistance and Lightweight

The manipulator is constructed using corrosion-resistant materials i.e., Aluminum and steel, which guarantee durability and ensure longevity in harsh industrial environments. Moreover, its lightweight design makes it easy to install, maintain, and relocate as needed.

Effectively Reduced Labor Intensity

With minimal human intervention, the feeding manipulator significantly reduces labor requirements and the risk of workplace injuries. This saves on labor costs and creates a safer work environment for your workers.

Coolant System for Long Working Time

The integrated coolant system helps maintain the ideal operating temperature, prolonging the working life of the cutting machine. This reduces maintenance costs and ensures a reliable, cost-effective solution for your business.

Flexibility with Customized Programming

An automatic feeding manipulator can be programmed to handle different types of materials and products, making it a versatile and flexible solution for a wide range of manufacturing and production processes.

Applications of Automatic Feeding Manipulator

Being technologically advanced equipment, the feeding manipulators have automated and revolutionized many industries. You may find its applications in the following industries:

Carbon Steel and Pipe Cutting

The manipulator’s versatility makes it suitable for cutting various materials, including carbon steel and pipes. This opens up new possibilities for businesses looking to expand their product offerings or enter new markets.

Elevator Manufacturing

Automatic feeding manipulators can handle and position doors for assembly, ensuring that they are aligned correctly and securely attached to the elevator frame

Manufacturing of Household Appliances

It can be used in the manufacturing of household appliances to handle and assemble various components of the appliances, such as plastic parts, metal parts, and electronic components.

High-power Laser Cutting

The automatic manipulator can also handle both bottom layers cutting and high-power laser cutting applications. This makes it an incredibly versatile solution for meeting diverse cutting needs across different industries.

Laser Power and Focusing Speed Requirements

This automated system can accommodate various laser power and focusing speed requirements, ensuring optimal cutting results for every project. This adaptability allows you to cater to a wide range of client needs, further solidifying your reputation for quality and precision.

Conclusion

The automatic feeding manipulator for fiber laser cutting machines has truly revolutionized the manufacturing industry. Its advanced components and capabilities have significantly improved efficiency, precision, and productivity while reducing labor intensity and risk. As a result, businesses can enjoy better cutting quality, reduced downtime, and a stronger competitive edge in the market.

If you’re interested in implementing an automatic feeding manipulator in your manufacturing process or upgrading your existing fiber laser cutting machine, Baison is the perfect solution for your business needs. At Baison Laser, we develop state-of-the-art fiber laser cutting machines to cater to all your manufacturing and cutting needs.

Discover the Perfect Solution for Your Business with Baison

Request a quote, get free sample proofing, or receive a free application evaluation to learn more about Baison fiber laser cutting machines and automatic feeding manipulators.

Don’t hesitate to contact us today, and our team of experts will be more than happy to guide you through the process of selecting the ideal solution for your business.