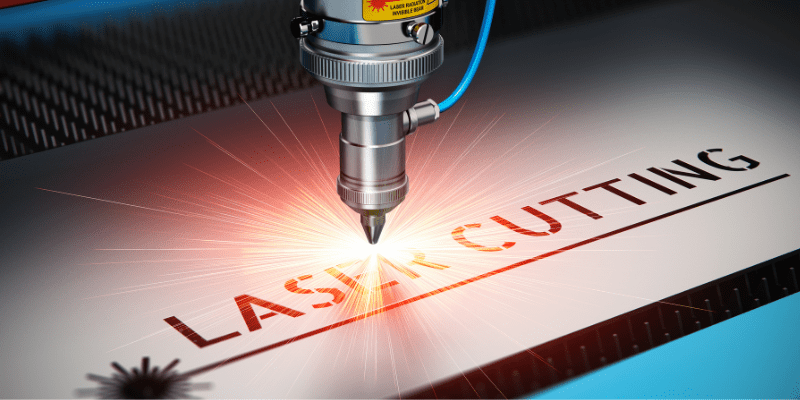

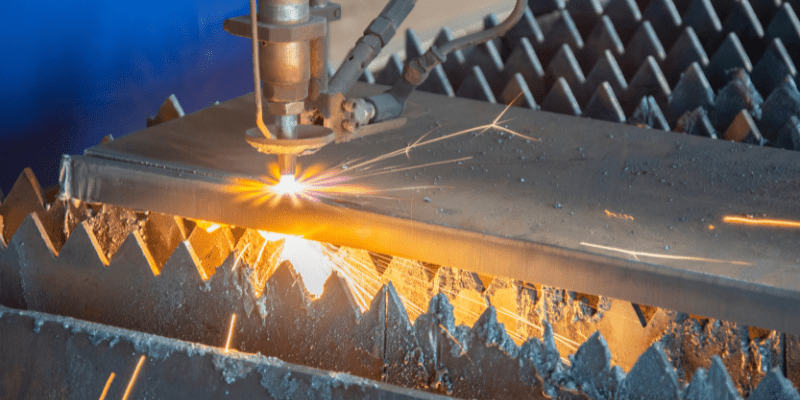

And the reasons for relying on this technology are numerous – Fast speeds, precision, and low costs are just some of the benefits anyone can gain from using such services! This leads us to ask questions about choosing a laser cutting service since these machines come in many sizes, shapes, and power outputs.

On top of that, there are so many different materials & one needs to pick the correct type of laser cutter suitable for that material!

So you must choose the right type of laser cutting service to enjoy the benefits of this technology! Today, we will take an in-depth look at all the factors you need to decide when choosing laser-cutting services.

Decide what you want to use your laser cutter for

Why do you need laser-cutting services in the first place? That’s an important question to ask, which will help you to choose the exemplary service for your needs…

A laser cutting machine can generally cut through various materials such as wood, plastic, metal, etc. Then there’s the question of material thickness. This is regarded to the fact that many kinds of laser-cutting machines can cut through different thicknesses…

So let’s look at each of these factors to help you decide what you want to use the laser cutter for:

Type of material

You can’t just use any laser cutting machine to cut through all materials. There are different types of laser cutting machines using other technology. So a particular laser cutting machine will be more suitable for a specific material!

So the first question that needs to be answered is what type of material you want to work with! Some of the materials which can be used for laser cutting include:

- Wood

- Acrylic

- Plastic

- Leather

- Metals

- Cardboard

- Fabric

- Rubber

For cutting & engraving wood, CO2 laser cutting machines are the best choice since the power settings can be easily adjusted. On the contrary, using fiber laser cutting machines for cutting wood is not recommended due to safety reasons and poor marks.

For cutting acrylic, the best choice is a CO2 laser machine due to the laser wavelength produced during the process. So if you plan to get a laser cutting service for cutting acrylic, you need to choose one that uses CO2 laser machines.

And if you plan to cut non-metallic material such as plastic, leather, rubber, and cardboard, then the obvious choice is the CO2 laser machine. The fiber laser cutters’ wavelength is 1.06um which is only ideal for metals. When non-metals are used with fiber laser cutting machines, the laser beam will not absorb or adequately absorb!

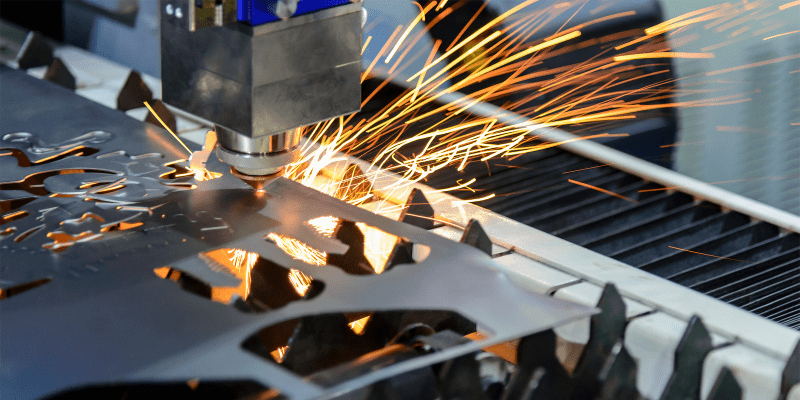

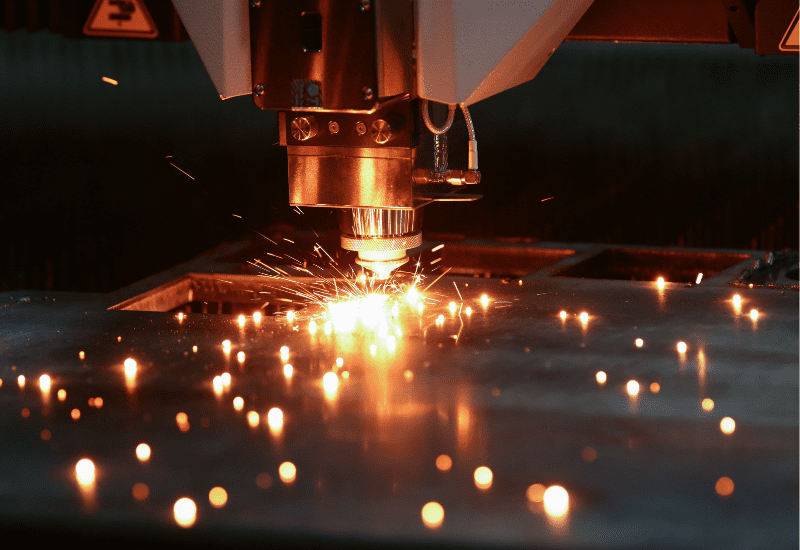

For cutting all non-reflective metals, you can use a CO2 laser without any problem. But when it comes to reflective metals such as aluminum, titanium, copper, and stainless steel, you need to use a fiber laser cutting machine!

The fiber laser cutters are specifically designed to handle reflective materials which can not be cut with a traditional CO2 laser cutter. When a CO2 laser cutter is used with reflective materials, the laser beam reflects from the material surface & thus can either damage the machine or the operator!

Material thickness

What’s the thickness of the material you want to cut? That’s also an important question that can help you to choose the right type of laser cutting service for your requirements.

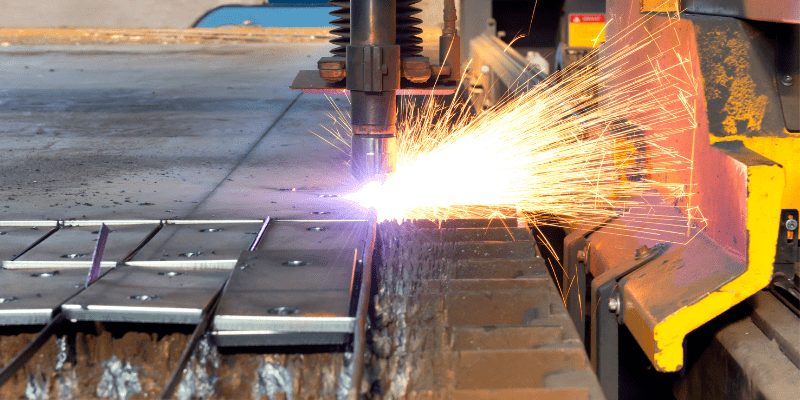

The capacity of a laser cutting machine to cut at different thicknesses depends on its power. A higher-power laser cutter can cut through thick material at a fast speed. On the other hand, a low-powered laser cutter will struggle with thick fabric or may even fail to cut it all.

So when looking for different service materials, always ask about the material thickness, which their machines can handle. Ideally, you should go with a service provider who uses high-power laser cutters as they will provide clean and efficient cuts. In addition, a high-power laser cutter also offers higher speed and can easily handle even thicker materials.

A typical laser cutter for small projects usually takes 25 to 80 watts. On the other hand, the laser cutters used for commercial and industrial purposes can be as high as 15,000 watts!

This blog discusses the laser cutting thickness limit: What is the Laser Cutting Thickness Limit for Different Materials?

Engraving or cutting

Do you only want to engrave on the materials, or do you want to cut them according to your specification? That’s also a valid and vital question that you need to answer!

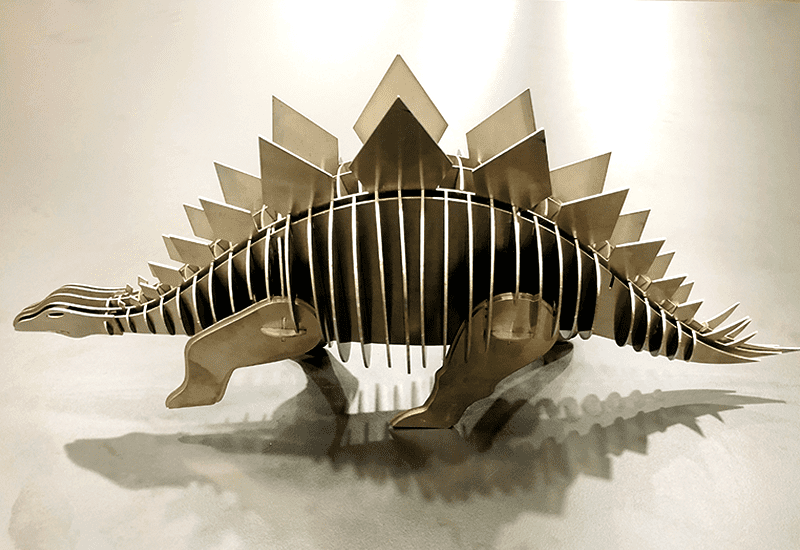

A laser cutter can be used for engraving and cutting – So it will all depend on what you want to achieve. For example, using a laser cutting machine to engrave wood, plastic, and metal is common.

Engraving allows you to create beautiful designs on different materials… You may already have seen wooden or metallic keyrings with customized names. They can also be made with laser cutters!

Do your research – compare prices, read reviews, and ask questions

Once you have decided what you want from the laser cutting service, the next step is to conduct proper research. This involves looking at different companies, comparing prices, checking reviews, etc.

Let’s look at different factors which will help you to do proper research so you can choose the exemplary laser-cutting service for your needs:

Compare Prices

Ideally, we all want the lowest price possible to save money. But when it comes to choosing the right type of service, you also need to consider the quality and experience.

Not everyone with a couple of laser cutters in his garage will be the right fit for your job! So when you compare the prices of different service providers, try to find a middle ground.

A service provider which is too expensive or too cheap should be discarded outright. For example, someone offering very affordable rates for laser cutting may be using low standard laser cutting machine or may cut corners to save costs.

Similarly, you wouldn’t want to go with a service that is too expensive. At the end of the day, you will have a limited budget and will want to get your cutting/engraving project done within that!

It would be wise to list different service providers along with their prices. This will help you to compare prices later on.

Read Reviews

After making a list of service providers which fall under your budget, you should move on to checking their reputation.

To read reviews, you can start by looking at their website… Many laser cutter service providers list their customer reviews on their homepage. However, one downside of this is that you can’t verify the trustworthiness or credibility of these reviews.

A better way is to check their Facebook or LinkedIn page and see what people say about them. Another way to check reviews is to type the company/website name + review in the Google search.

For example, ABC Laser Cutting Reviews (Replace ABC laser cutting with company/website name).

Ideally, you should pick a laser-cutting service with primarily positive reviews. A couple of negative or average reviews shouldn’t be a problem as long as most reviews are positive. But if a service provider has mostly negative reviews, you should remove that company from the list.

Ask Questions

It is always a good idea to ask questions about the laser-cutting process… So once you have compared prices and checked reviews of various service providers, the next step is to ask as many relevant questions as possible.

This will help you understand whether a particular service provider is right for your job. It will also help you to get an idea of whether they have the required expertise in the laser-cutting process or not!

Choose a service that has the right equipment and experience for your project.

The market is filled with different types and models of laser cutters. You must choose a service with relevant experience and the right equipment to complete your job.

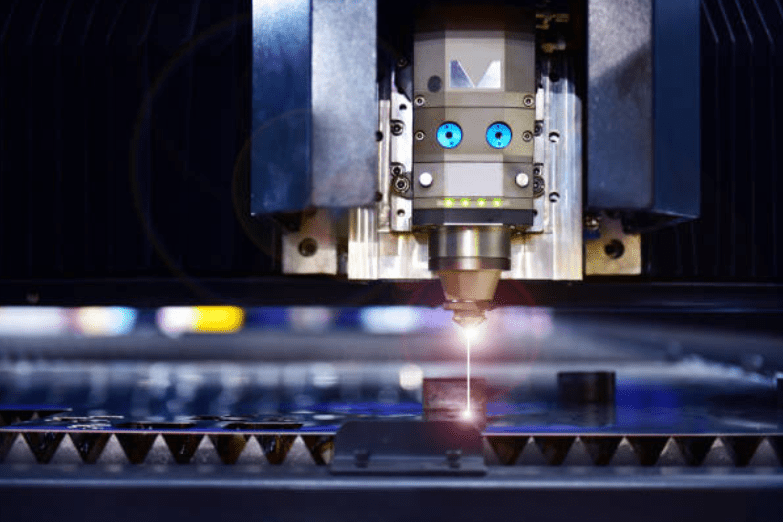

In general, a laser-cutting machine will fall under the following categories:

- CO2 laser cutter

- Fiber laser cutter

- Nd: YAG (crystal) laser cutter

In addition, these laser-cutting machines also come in different powers and sizes, such as 500W, 1000W, 2000W, and so on.

Ideally, you should go for a service provider which uses the latest laser cutting machine for the cutting and engraving operations. In addition, these machines must also have sufficient power to cut efficiently and quickly.

And last but not least, experience also matters a lot in this business. The last thing you would want is to hand over your project to someone who has just recently bought a laser cutting machine and has started offering their service.

When it comes to the finish quality and cutting/engraving according to specification, nothing can beat experience. In addition, an experienced service provider will also know which type of laser cutting machine will be ideal for which material or settings to choose.

Discuss your project with the service provider and make sure they understand your requirements

You can contact all the service providers that meet your criteria at this stage.

Not every laser-cutting project is the same, so you should pick a service provider who understands your requirements.

If a potential service provider is more interested in making you place an order rather than discussing your project, then that’s a bad sign!

A good laser cutting service provider will take their time to discuss your project in complete detail. It is only after understanding your requirements that they will agree to take on the project.

When discussing your project with a potential company, make sure to tell the following details:

- What type of material do you want to use, and what is the material thickness?

- What type of shape/design do you want from the laser-cutting process?

- Do you need a simple cutting job or a more complex engraving?

- How many pieces of cutting/engraving do you want?

- What’s their preferred file format for sending the design?

Be as detailed as possible so that the service provider can better understand your project details and what you want to achieve through this process!

Most service providers usually have a dedicated page on their website where you can contact them and discuss project details. In addition, many service providers also provide live chat so that potential customers can reach them.

But if both options are unavailable, you can also rely on sending the good-old email and wait for their reply.

Get a quote and timeline for the project, then approve or amend as needed

Once you have conveyed your project details to multiple service providers, wait for them to give you a quote and an estimated timeline.

The prices mentioned for laser cutting or engraving on most service provider websites are just a baseline. The actual cost will depend on the job’s complexity and how long it will take to cut/engrave on your preferred material. This means that the final quote for your project will be different than what’s mentioned on the web pages.

Besides the price, another factor is the timeline for the project’s completion.

If a service provider is giving you a timeline of several months, you should discard them immediately! I mean, laser cutters are known for being fast & if it takes several months to get your project done, then what’s the point of all of this anyway!

A good service provider will give you a more reasonable timeline after looking at the scale and complexity of your project. Once again, you need to pick the one which offers the quickest turnaround time.

After getting a quote and timeline, you can either approve the project or make amends to change the prices and delivery date.

Ensure you have all the files and information you need before starting the project.

The laser cutting machine requires a file to cut or engrave a design on the required material. This file includes the exact composition or shape and can be prepared on a computer.

Upon reading the file, a laser cutter starts engraving or cutting according to the provided information. In general, you can use the following files in a laser-cutting machine:

- Raster File

- CAD File

- Vector File

- 3D Design File

Before the laser-cutting service provider can begin working on your project, ensure you have a laser-cutting file ready. You can easily create these files through vector or image editing software. And if you need more expertise to create the design you want, you can hire a third party to make these designs for you.

Ideally, the best file format for a laser cutter is the vector file since it can be expanded/stretched without losing the image quality. On the other hand, raster files can quickly lose their image quality when developed since they are bound by pixels.

Conclusion

So the next time you need to find a suitable laser-cutting service for your project, remember to follow all the abovementioned steps. They will help you find exemplary service that matches your budget and timeline while also delivering high quality!

The only way to get all the benefits associated with laser cutting technology is to find the right type of service provider. If you think about it, choosing an inexperienced provider may lead to a monetary loss or even a loss of time if they fail to cut according to your design. In addition, not having experience with different materials could also lead to poor quality cuts or even damage to the material.

So make sure you do your due diligence before deciding on a particular service provider. Doing so will help you to save money and time while also enjoying the benefits of this fantastic technology.

Need to buy a fiber laser cutting machine?

Over the years, Baison Laser has earned a reputation for being a quality supplier of laser-cutting equipment. And it doesn’t matter which industry you belong to; we can cater and deliver our equipment based on your specific needs.

So if you are looking for a trusted and well-known supplier of laser cutting machines, feel free to request a quote. We also offer free sample proofing and free application evaluation for interested parties. And if you have any inquiries about our process or a question related to our laser cutter machines, feel free to contact us today!