Application Industry

Exhaust duct

Elevator Industry

Auto Parts

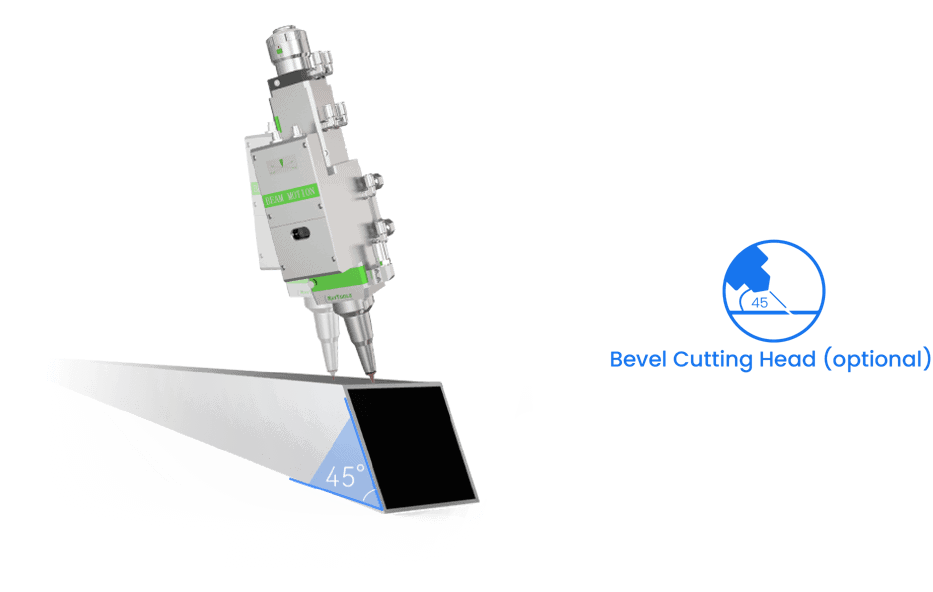

Excellent Bevel Cuts (*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams, etc.

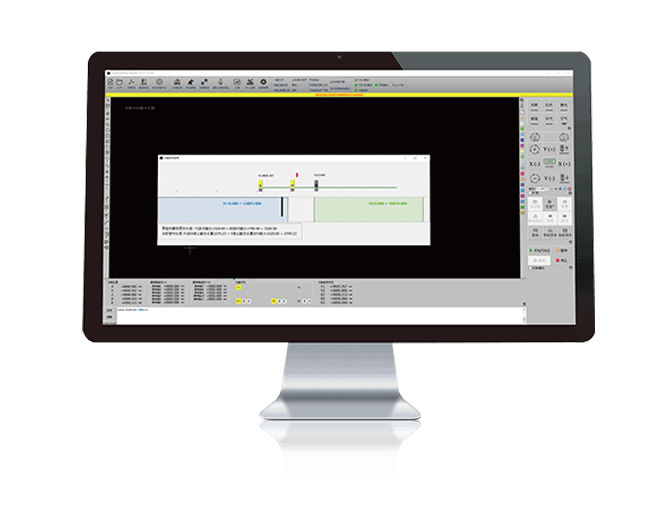

Intelligent Control System

The application of the tube cutting specific CNC system, which comes with a rich database of manufacturing processes, allows for simple and flexible operation, enabling one-click quick production.

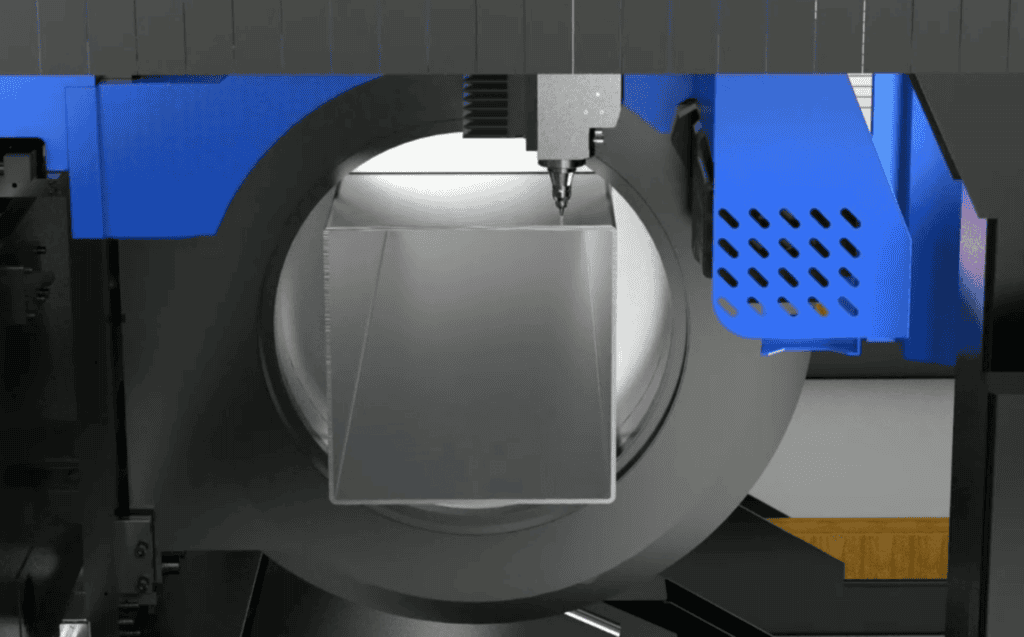

Zero-waste Processing

Patented structure design enables the cutting of entire pipes with zero waste, reducing waste of pipe materials and increasing material profits.

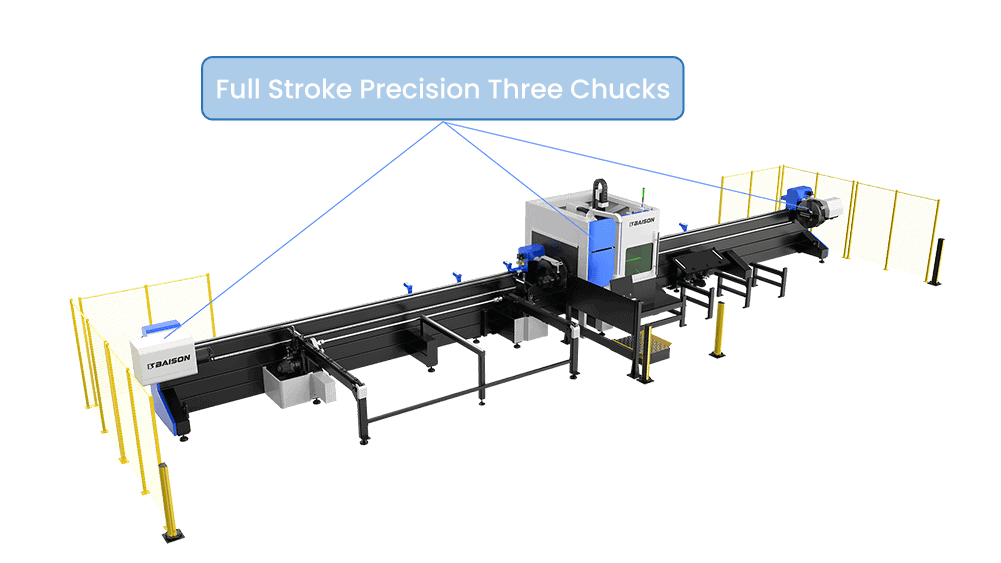

Full Stroke Precision Three Chucks

Supports stable clamping of large and heavy pipes, with a wider clamping range for the same specification chucks, stable operation, and high precision.

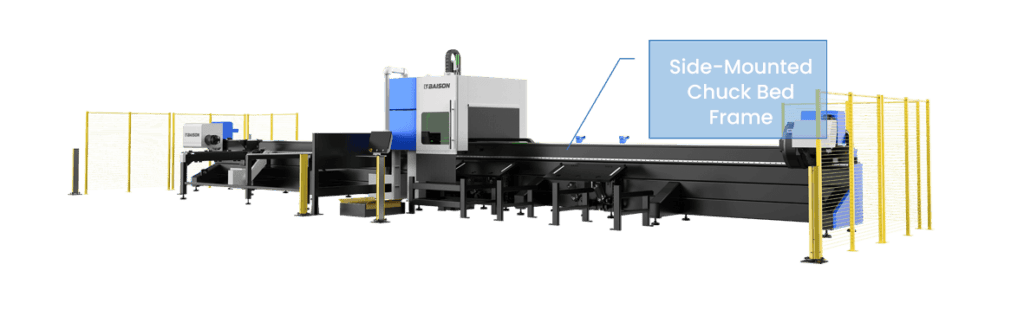

Side-Mounted Chuck Bed Frame

The high-strength bed is treated with high-temperature annealing, providing excellent rigidity and stable support for heavy pipes.

Equipment parameters

| V24ESS | |

|---|---|

| Laser Power | 3000W~12000W |

| Tubes can be processed | Round tube: φ10~240mm Square tube: 10*10~220*220mm (tube R angle greater than 30mm can be clamped 240mmx240mm) Channel steel: 22# (standard clamp) Angle iron: 10# (standard clamp) I-beam: standard clamp) H-steel maximum: 22# (standard clamp) |

| Tail length | 0 |

| Tube processing length | 6500mm |

| Max Speed | 80m/min |

| Max load capacity of single tube | 300kg |

| Dimension(L*W*H) | 14760*1935*2320mm |