Understanding the Capabilities of CO2 Laser Cutting

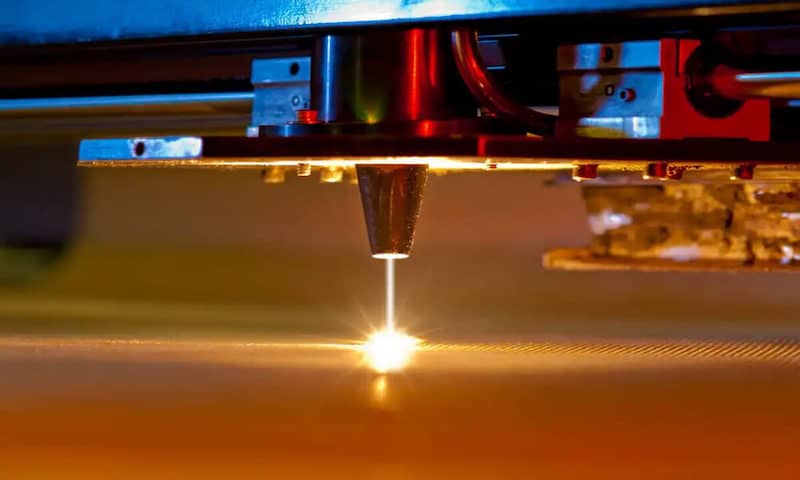

CO2 lasers possess impressive cutting abilities, enabling them to handle intricate and complex designs with exceptional precision. The laser’s power and the material’s thickness determine the cutting depth, allowing for varying levels of customization in different projects. This versatility makes CO2 laser cutting widely utilized across industries such as signage, packaging, automotive, and crafts.

The following list displays some key details about CO2 laser cutting.

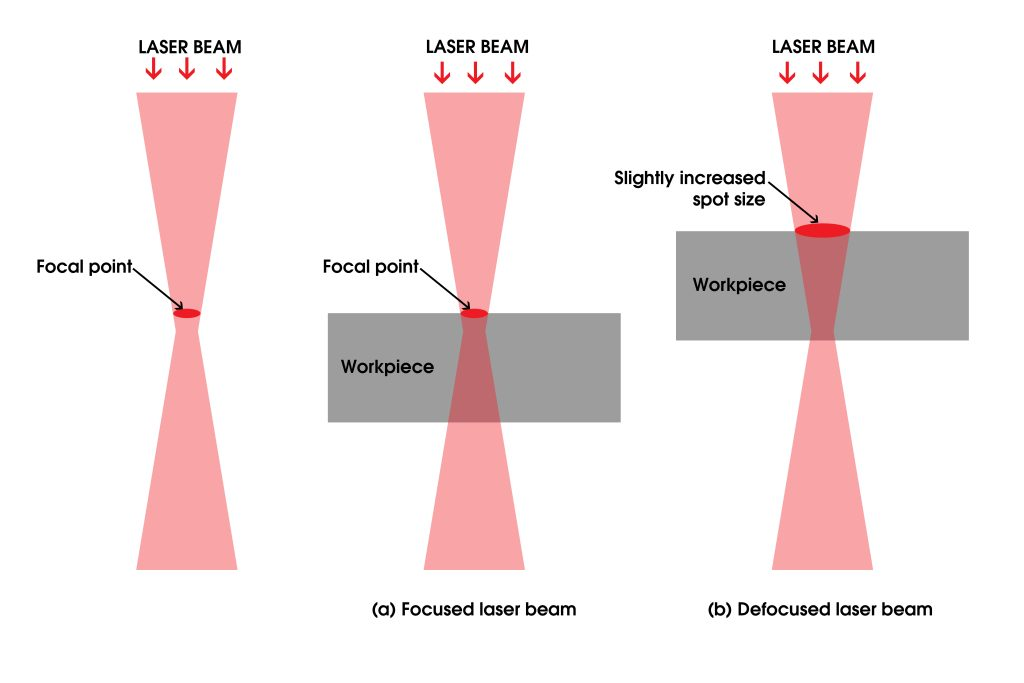

Cutting Depth: The depth at which a CO2 laser machine can cut depends on the material’s thickness and the power of the laser. Thicker materials may require multiple passes or higher laser power to achieve desired results.

Customization: With CO2 laser machines, you can create highly detailed and customized designs. Whether it’s delicate engravings or precise cuts, these lasers offer an excellent level of control over your projects.

Speed and Efficiency: CO2 lasers provide efficient cutting capabilities that allow for faster project completion. Their high-speed operation enables quick turnaround times without compromising on quality.

Industry Applications: CO2 laser cutting finds extensive use in various industries. For instance:

- In signage manufacturing, these lasers can effortlessly cut acrylic letters, shapes, woods, and various thicknesses.

- In packaging production, laser cutters enable precise die-cutting for boxes and containers. Laser engraving is also possible with a laser machine, allowing for intricate designs and patterns. The thickness of many materials being cut or engraved is an important factor to consider for optimal results.

- In automotive manufacturing, CO2 lasers assist in fabricating intricate parts with varying thicknesses.

- In crafts and hobbies, these lasers facilitate detailed laser engraving on various materials of different thicknesses.

With its high-energy beam, a CO2 laser has the power to vaporize or melt different materials, resulting in precise cuts with clean edges. Whether you’re working with paper, cork, or even chlorine strips, manufacturers have developed unique methods to ensure perfect results.

Factors Affecting CO2 Laser Cutting

CO2 laser cutting is influenced by several factors that determine the efficiency and effectiveness of the process. Understanding these factors is crucial for achieving desired results. Here are the key factors that affect CO2 laser cutting.

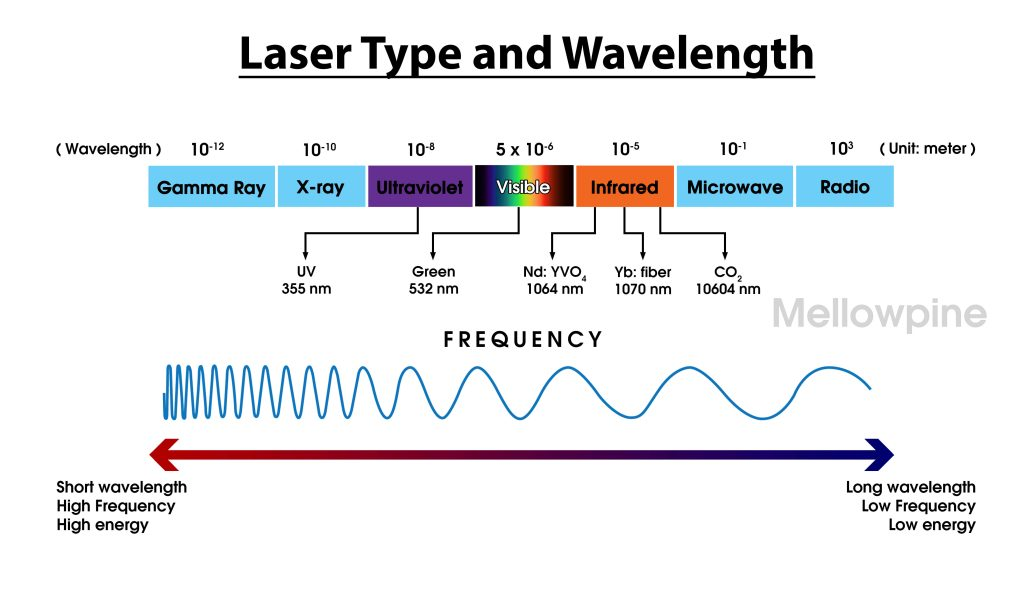

Wavelength and Power Levels

- CO2 lasers operate at a specific wavelength of around 10.6 micrometers.

- The power level of the laser beam determines the cutting speed and depth. Here is a guide.

- Higher power levels in laser cutters allow for faster cutting and laser engraving, but they may also result in more heat and potential material damage to the laser machine.

- It’s essential to consider that CO2 lasers are most effective for cutting materials up to a certain thickness. Beyond that point, other cutting methods may be more suitable.

Balancing laser cutter settings like power and speed when using a laser cutter is crucial to avoid damaging delicate materials or compromising cut precision.

Material Composition and Thickness

- Different materials have varying levels of laser absorption and reaction to heat.

- Materials with high carbon content, such as wood and acrylic, are generally easier to cut with CO2 lasers.

- Metals, on the other hand, require higher power levels and may have limitations in terms of thickness that can be effectively cut using a laser cutter.

- Materials with higher densities or complex compositions may require more precise adjustments in power and focus when using a laser cutter to achieve clean cuts without excessive charring or melting.

Absorption and Reflection Properties

- The ability of a material to absorb or reflect the laser beam affects cutting efficiency.

- Materials that absorb the laser energy well are easier to cut, while highly reflective materials can cause beam deflection and reduce cutting quality.

- It’s important to consider the surface finish and coating of the material, as they can impact laser absorption and reflection.

By considering the factors above list, laser operators can optimize their cutting parameters and select appropriate materials for CO2 laser cutting. It is essential to find the right balance between power levels, material composition, and laser beam interaction to achieve precise and efficient cutting results. You may need a definitive guide about choosing CO2 laser machines.

Range of Materials Compatible with CO2 Lasers

CO2 laser cutting is a versatile and precise method that can be used for cutting and engraving most non metal materials and other materials. Here are some materials that are suitable for CO2 laser cutting.

Organic Materials

- Wood and plywood: CO2 lasers can easily cut through various types of wood and plywood, making them ideal for creating intricate designs, signage, and custom shapes.

- Acrylic and plastic: These materials have excellent laser absorption properties, allowing for clean and precise cuts. CO2 lasers can be used to create intricate designs, prototypes, and even personalized items like keychains and jewelry.

- Leather and fabric: CO2 lasers can precisely cut and engrave leather, rubber, and fabric materials, offering customization and intricate detailing. This makes them suitable for applications such as fashion, upholstery, and accessories.

Inorganic Materials

- Glass and ceramics: CO2 lasers can be used to engrave and mark glass and ceramics, adding intricate designs and personalized touches to these materials. However, cutting glass and ceramics with CO2 lasers requires specialized techniques.

- Stone and marble: CO2 lasers can create detailed designs and engravings on stone and marble surfaces. They can be used for applications such as custom signage, home decor, and architectural elements.

- Metals (with certain limitations): CO2 lasers can cut thin sheets of metals like stainless steel and anodized aluminum, but thicker metals require higher power levels and may have limitations. Metal cutting with CO2 lasers is commonly used in industries such as automotive, aerospace, and jewelry.

Composite Materials

- Carbon fiber: CO2 lasers can cut carbon fiber materials with precision, making them suitable for various applications such as aerospace, automotive, and sporting goods.

- Fiberglass: CO2 lasers can cut and engrave fiberglass materials, providing accurate and clean results. This makes them suitable for applications such as boat building, automotive parts, and architectural models.

- Laminate: CO2 lasers can cut through laminate materials, allowing for precise shaping and customization. They are commonly used in industries such as furniture manufacturing, interior design, and signage.

Materials to Avoid for CO2 Laser Cutting

While CO2 lasers can cut a huge range of materials, there are some common materials that are unsuitable for this cutting method:

Reflective materials: Highly reflective materials, such as copper and aluminum, can reflect the laser beam and cause damage to the laser system. These materials require alternative cutting methods, such as fiber laser cutting or waterjet cutting.

Heat-sensitive materials: Materials that are prone to melting or warping under high temperatures, like certain plastics, may not be suitable for CO2 laser cutting. It is important to consider the material’s heat tolerance and select appropriate cutting methods accordingly. Like when polycarbonate is processed by a CO2 laser, it can produce toxic gas or catch fire. It is better suited for other methods like CNC milling.

Certain metals and alloys: Some metals, such as titanium and brass, require specialized laser systems or alternative cutting methods due to their high reflectivity or composition. These materials may need fiber lasers or other laser technologies for effective cutting.

It’s important to avoid using these materials in CO2 laser cutting processes as they can lead to undesirable outcomes such as toxic fumes, production of harmful gases, or difficulties in achieving clean cuts on reflective surfaces. By understanding the limitations of these materials, you can ensure safer and more efficient results when working with a CO2 laser cutter.

FAQs

What safety precautions should I take when using a CO2 laser cutter?

When operating a CO2 laser cutter, it’s crucial to follow the safety guidelines provided by the manufacturer. This includes wearing appropriate protective gear such as goggles and gloves, and ensuring proper ventilation in the workspace to prevent exposure to fumes generated during cutting or engraving processes.

Can I cut metal with a CO2 laser?

CO2 lasers are not suitable for directly cutting metals due to their wavelength limitations. However, they can be used for engraving metals or marking coated metal surfaces.

How do I determine the right settings of power and speed for different materials?

The proper settings of power and speed for the laser cutter depend on the material you’re working with. It’s recommended to conduct test cuts on scrap pieces to find the ideal combination of power and speed that achieves clean cuts without excessive burning or charring.

Can a CO2 laser cut through thick materials?

CO2 lasers have varying cutting depths depending on their wattage. While they can cut through relatively thick materials like wood or acrylic, extremely thick materials may require multiple passes or alternative cutting methods.

Conclusion

In conclusion, a CO2 laser cutting machine offers numerous benefits for various applications. By understanding the capabilities of CO2 laser cutting, you can make informed decisions about materials and designs. CO2 lasers are compatible with a wide range of materials. These versatile machines allow for intricate cuts and precise engraving on different surfaces.

CO2 laser machines offer excellent cutting and engraving capabilities while ensuring optimal performance. Whether you’re a hobbyist or a professional designer or manufacturer, investing in this technology can open up new possibilities for your projects.

Baison offers the best CO2 Cutting Machine

Our high quality CO2 laser cutting machines work around the clock to meet the needs of a wide range of designs and complex structures. Biason processes a wide range of materials with the highest precision and accuracy. We also have the laser engraver and laser cleaning machine for you to choose from.

If you’re looking to purchase a CO2 laser cutting machine or need further guidance on material compatibility or usage tips, don’t hesitate to reach out to Baison which specializes in laser cutting equipment. We can provide application evaluation tailored to your specific needs.