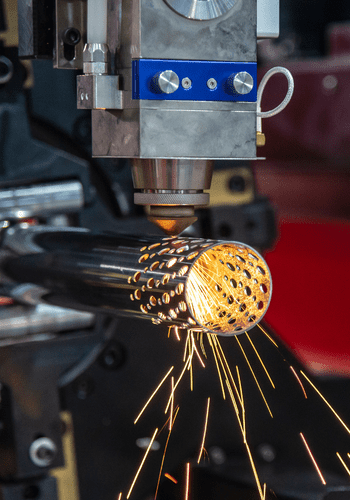

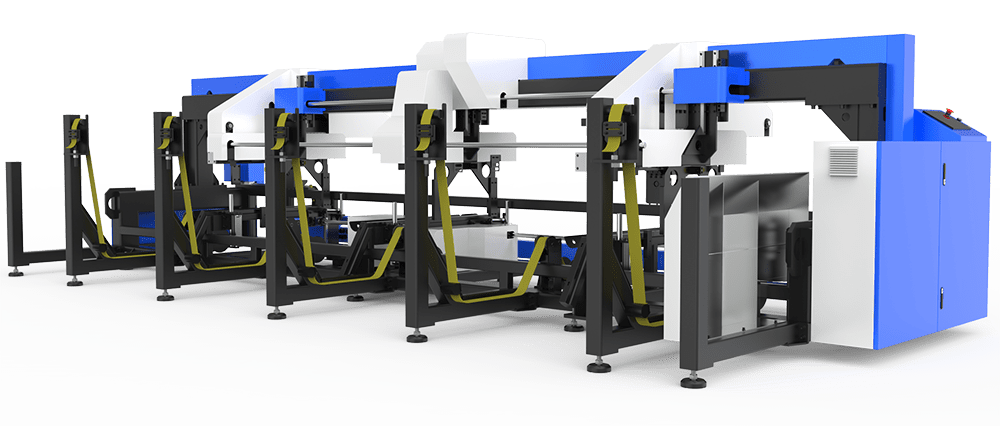

Small Tube Laser Cutting Machine

Baison’s small tube laser cutter is ideal for first-time users or as a supplementary machine for developing new customers or markets, whether you want to insource quality, produce at short notice with more flexibility, or create new markets and customers.

K Series Small Tube Laser Cutting Machine

Small Fiber Tube Laser Cutter Features

Small tube laser cutting machine with solid performance. With its advanced features, you can use them to increase your productivity and win more markets.

Super Processing Ability

Execute your exact design specifications precisely for standard or unique production requirements.

Cost-effective

Slashes your maintenance fees almost to zero and operation costs by a significant margin.

Servo Follow-up Support

The servo follow-up support system will ensure the stability and precision of cutting.

Shorter Processing Time

Carry out a large number of inputs in a significantly shorter time without sacrificing any accuracy and precision.

Easy to Operate

Our sophisticated software inputs complicated data entry and commands into simple buttons.

IP5X Lightweight Chuck

The equipment is extremely resistant to dust and shavings and capable of functioning at peak capacity without any disturbances.

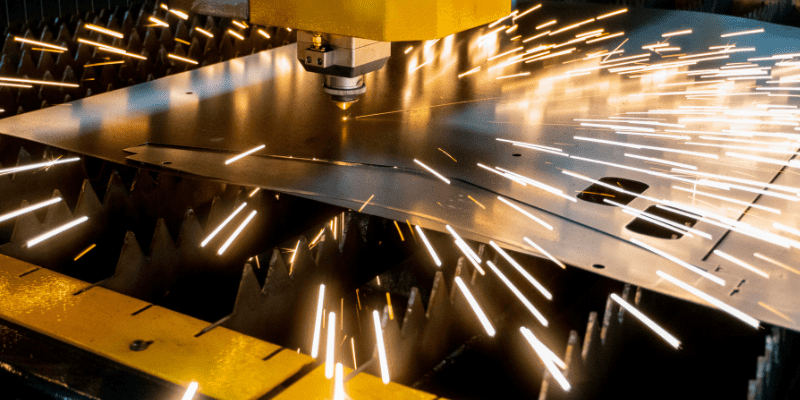

What Can The Small Tube Laser Cutter Be Used For?

The small tube laser cutter’s adaptability and wide range of features make it suitable for many applications, from the furniture industry to medical equipment manufacturing.

Storage Racks

Furniture

Gym Equipment

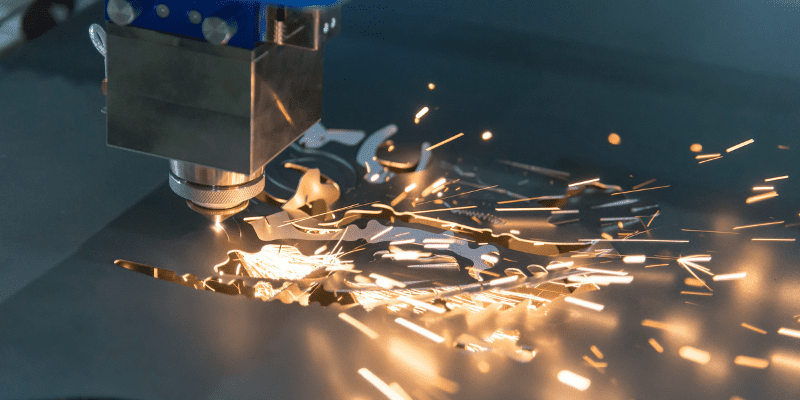

Numbers Don’t Lie

Fiber laser cutters cut up to 5x faster than conventional laser cutters with greater accuracy and precision. All while being easier to maintain(Half the operating costs). These numbers reveal the reason why.

| Model | K12 | K12C |

|---|---|---|

| Laser Power | 1500W-3000W | 1500W-3000W |

| Pipe Processing Range | Round tube: φ20~120mm Square tube: 20*20~120*120mm (When clamping a large square tube, the chamfer of the tube must be greater than R10mm) Channel steel: 8# (need to pay for the nesting software and professional fixtures) Angle iron: 8# (need to pay for the nesting software and professional fixtures) | Round tube: φ20~120mm Square tube: 20*20~120*120mm (When clamping a large square tube, the chamfer of the tube must be greater than R10mm) Channel steel: 8# (need to pay for matching material software and professional fixtures) Angle iron: 8# (need to pay for matching material software and professional fixtures) |

| Tail Length | 60mm | 60mm |

| Pipe Processing Length | 6500mm | 6500mm |

| Wall Thickness | 0.8-3mm | 0.8-5mm |

| Max Chuck Speed | 120r/min | 180r/min |

| Max Single Tube Loading Weight | 100KG | 80KG |

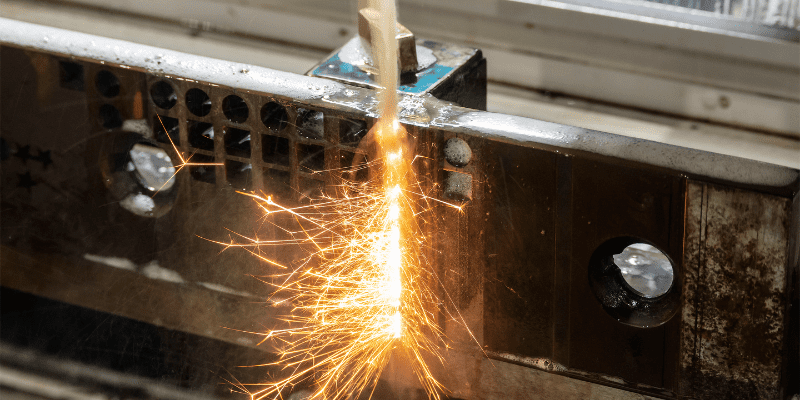

Quality Down to It’s Parts

We believe that a quality product boils down to the quality of its individual parts. That’s why our Laser Cutters are constructed of only the most powerful, resilient, and well-functioning parts

IPG Laser Source

IPG’s Lasers provide the Highest Total Power Output on the market with the widest beam mode range in an easily programmable multi-combination system.

Motovario Motoreducer

Designed to meet your particular production needs with minor servicing. These reducers provide your cutters with the highest lifespan/performance ratio in the most cost-effective way.

Ospri Laser Head

This head is designed to be lightweight, compact, and dustproof with a water-cooling feature. Able to channel up to 3000w, OSPRI Laser Heads are sharp, cost-effective, and resilient.

Yaskawa Servo Motor

Perform ultra-high speed and precise functions. Your laser cutter will perform at higher speeds than other cutters while maintaining the highest standard of precision.

Revolutionary Laser Cutting Software

All our laser cutters use TubePro, the latest in the tube and profile-cutting software. This software is the brain of the operations. Able to seamlessly integrate with other essential software such as Tubet, you will have access to the highest and fastest processing capabilities with our Small Tube Laser Cutters.

While easy to use, the TubePro software offers many functions that allow you and your team to execute complex designs optimized for precision and stability. Here are a few key features:

- TubePro adopts a look-forward strategy to control the laser head up and down in corner turning by calculating the lifting path via tube file in advance.

- Precision Corner Program, which includes gas pressure, laser peak power, and duty cycle, will improve and perfect corner production efficiency and quality.

- Center Auto Finder: allows laser cutter to offset tube deviation from the rotational center for high-precision cutting.

Resources and Articles

Below you can find some related articles which can help you know more about laser technology and its applications. We also have some cutting or welding tips for your reference.

20 Tips To Help You Improve the Laser Cutting Quality

What is Fiber Laser Cutting?

EDM vs. Laser Cutting: The Ultimate Difference Analysis

Add-on Loading Automation

Automated loading systems can automatically provide unprocessed material while you cut your work. Optimize your workflow to increase productivity. In addition, it can lower your operating costs by reducing the need for labor. And all these benefits at a fraction of the cost.

Ready to Get a Small Tube Laser Cutting Machine?

Make your work easier by using our machines. Send us your inquiry and our engineer will get back to you shortly.