Application Industry

Power facilities

Automotive

Elevator Industry

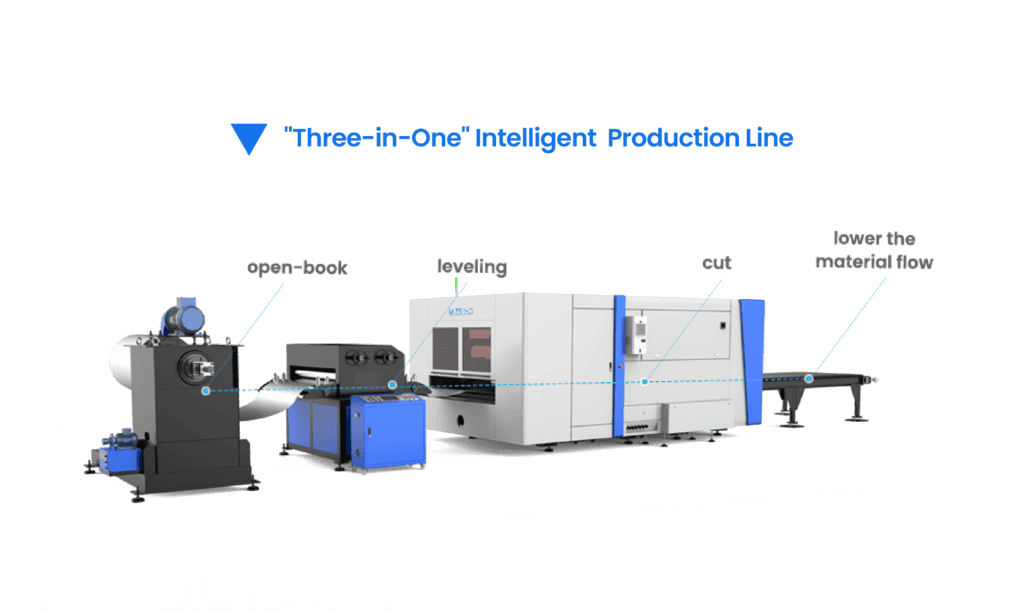

"Three-in-One" Intelligent Production Line

Upgrading from single sheet cutting to a “Three-in-One” processing production line integrates coil feeding, material leveling, and cutting into a single machine, significantly multiplying work efficiency.

High-Performance Core Configuration

Equipped with top-brand servo motors,quickly processes thin plates at speeds of several meters per minute, enhancing production efficiency and capacity, thus creating more value for the enterprise.

Super Intelligent Control System

Utilizing advanced nesting software and control systems, it is possible to pre-set processing files and material feed lengths, enabling continuous batch processing without the need for manual intervention during the process.

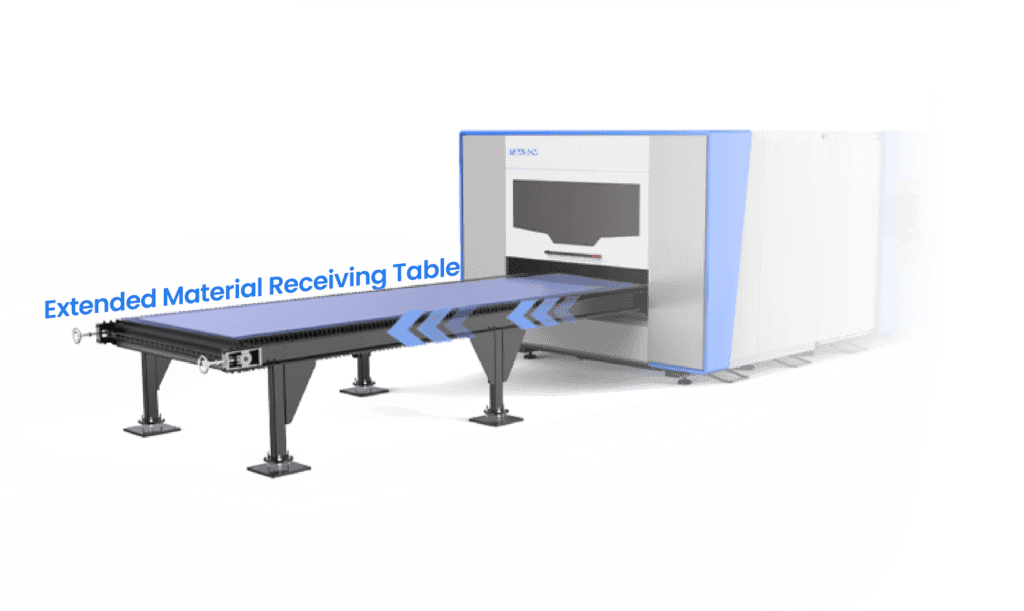

Extended Material Receiving Table

The extended pick-up table facilitates simultaneous cutting and material removal, eliminating the need for extra stops, and enabling the ultra-economic completion of medium to large-scale batch production tasks.

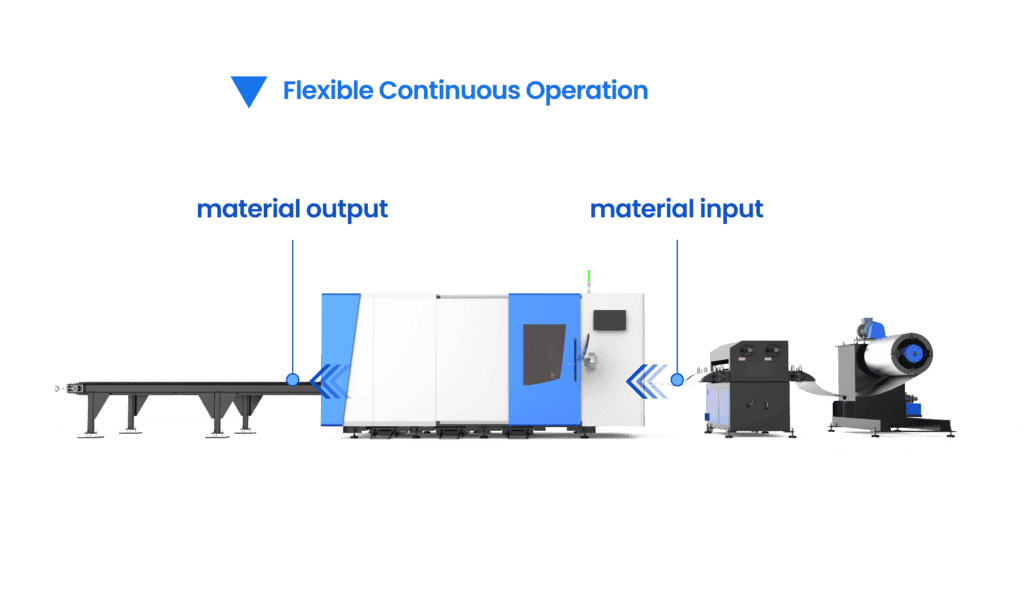

Continuous Cutting, Releasing Efficiency

With the coil feeding equipment transporting continuously, and simultaneous material input and output, ensuring superior continuous conveyance and seamless power cutting integration.

Equipment parameters

| SJ3 | |

|---|---|

| Laser Power | 1500W-3000W |

| Working Area | 3000*1500mm with extension platform |

| Max Speed | 120m/min |

| Max Acceleration | 1.2G |

| Positioning Accuracy | ±0.03mm/m |

| Repeated Positioning Accuracy | ±0.03mm |

| Dimension(L*W*H) | (With three-meter extension platform) 9150*3090*2200mm |