The world’s top laser generator manufacturers create and supply high laser systems that offer top-notch cutting solutions to businesses in the metal cutting industry. Among them are Messer and Trumpf in Germany, Mazak and Tanaka in Japan, Salvagnini in Italy, and the Swiss Company, Bystronic.

If you are looking for the best laser technology for your business, this article is exclusively for you. I’ll give you the top 10 global laser generator manufacturers and why you should choose from this list when purchasing. Let’s get to the details!

Top 10 Laser Generator Manufacturers

Here’s a tabled summary of our top 10 global laser generator manufacturers.

| Rank | Company Name | Country | Year Established | Unique Feature |

| 1 | Trumpf | Germany | 1923 | Multipurpose laser systems (welding, cutting & surface treatment |

| 2 | Bystronic | Swizerland | 1964 | Digitalized sheet metal processing |

| 3 | Amanda | Japan | 1980 | High-precision beam delivery and accurate motion |

| 4 | Mazak | Japan | 1919 | Innovative laser-cutting solutions |

| 5 | Prima Power | Italy | 1977 | LASERDYNE Smart Techniques |

| 6 | Messer | Germany | 1898 | Powerful laser-plasma combination |

| 7 | Salvagnini | Italy | 1963 | Switzerland |

| 8 | Mitsubishi | Japan | 1870 | Laser machines with fast CNC control units |

| 9 | Tanaka | Japan | 1917 | High-power machines for cutting large metal plates |

| 10 | GWeike | China | 2004 | Beyond Manufacture-combining, digitization with technological evolution |

Trumpf

Trumpf is a household name in the laser machine industry. The German company has a 100-year history of successful machine manufacturing, making it one of the global giants in machine tool production.

Over the years, the industrial machine production company has opened subsidiaries in countries like the US, China, and the UK. Its machine production has two main divisions:

- Machine tools

- Laser technology

The Laser technology division manufactures laser systems that can perform multiple metal processing tasks, including metal cutting, metal surface treatment, and laser welding.

The company manufactures different types of high-cutting efficiency lasers, including:

- CO2 lasers

- Direct diode lasers

- Optical fiber lasers

- Active mirror or disk lasers

- Lasers with ultrashort/short pulses

- Laser marking machines

- Extreme ultraviolet drive lasers

If you plan to include laser cutting in your business operations, Trumpf laser generators are an excellent option.

For example, the Trumpf TruFlow CO2 laser machines have a power spectrum of 2kW-20kW, providing a broad scope for material type and thickness selection.

Their TruFlow fiber laser cutting machine can perform welding, cutting, and surface treatment of 2D and 3D dimensional pieces effectively and in a cost and energy-efficient manner.

Bystronic

The name Bystronic was coined from the first letters of the 3 founders of the company in 1964. In today’s laser cutting machine manufacturing industry, Bystronic is synonymous with excellence in digitizing sheet metal processing.

The Swiss company has multiplied its production locations in more than 30 countries. In addition, it has created subsidiaries in countries like the US, UK, Italy, Germany, China, and South Africa.

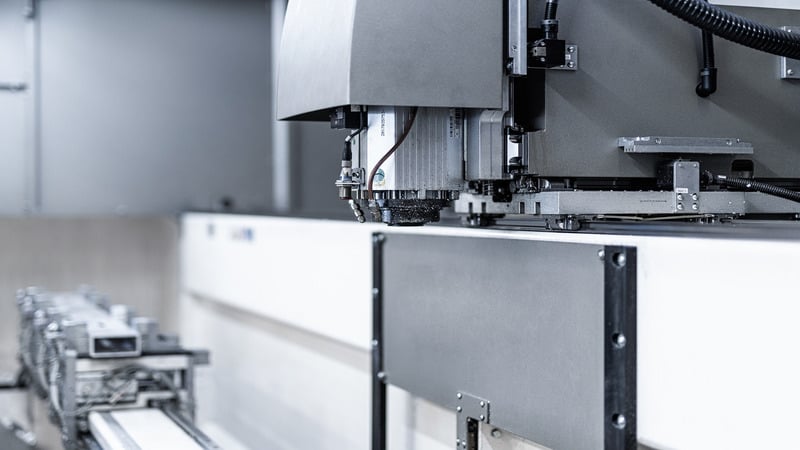

Apart from standing out as an expert in manufacturing laser cutting machines, Bystronic has also proven to be the ‘Xpert Pro’ in press brakes.

These metal folding machines use automation software to simplify complex metal bending processes and guarantee high-quality performance.

Bystronic’s laser-cutting machine models combine intelligence, performance, and process optimization to ensure the success of your business.

This is true of ByCut Star. The laser cutter machine has surpassed the company’s 3kW-20kW power laser cutting machines to provide high cutting speed and a whopping 30kW cutting power lasers for aluminum, steel, and stainless-steel metals.

AMADA

The Japanese company, AMADA, has found its spot among global producers of quality equipment and superior sheet metal processing machinery.

The company made its debut in laser cutting machine production in the 1980s with the LC-644, a simple laser cutting machine with 1500-watt cutting power.

AMADA provides metal cutting solutions with advanced CO2 laser and fiber laser cutting systems today. The fiber laser cutting machines function at high speeds with laser power heads of 3-12kW.

AMADA has major manufacturing facilities in the US (AMADA America. INC.), Canada, and Mexico.

The Company’s business vision is to produce the next generation of laser-cutting machines and, therefore, respond to the production needs of every metal-cutting business. That way, your business can benefit from production efficiency and maximize profitability.

AMADA has optimized its CO2 and fiber laser-cutting machines. That means the laser technology used in these machines offers high speed and flexibility, and you can use them to cut any type of metal. Besides, their beam delivery is top-notch, and their motion is seamless.

All these feature work to bring quality to your business. With superior cuts and lower costs, productivity shoots up.

The Company’s ENSIS Series Fiber Laser and REGIUS 3015 AJ Linear Fiber Laser series are its most efficient laser cutting systems. Laser cutting machines in the ENSIS & REGIUS Series run at 3000 to 12000-watt cutting power.

Mazak

Yamazaki Mazak Corporation is a Japanese company that has made a name for themselves in the machine manufacturing industry.

Its American, UK, and Russian subsidiaries are simply known as Mazak. The company also has subsidiaries in Asia, including the Yamazaki Mazak Co., Ltd in China.

Since its foundation in 1919, Mazak has climbed the ladder to become a giant among key global laser-cutting machine manufacturers. Its metal processing solutions fall under these categories:

- Hybrid Multi-tasking and multi-tasking

- Turning

- 5-axis

- CNC Controls

- Automation systems

- Milling

Although Mazak’s technology solutions extend to all these functions, the Company is also a world leader in innovative laser-cutting solutions. Their laser cutting machine solutions vary in type and process to include:

- 2D & 3D laser cutting machine

- Pipe/tube laser cutting machine

- Pre-owned laser-cutting machine

The last category is optimal for startups without large budgets but looking for high-quality performance.

Mazak’s laser cutting machine options start from a 4kW cutting power to a 15kW cutting power.

Their OPTIPLEX 3015 NEO laser cutting system is one of the company’s most powerful productions. The laser cutter has excellent beam shape and diameter control and is available in 4,7,10, and 15kW levels.

Prima Power

Prima Industrie is the predecessor to the company now known as Prima Power. The Italian company started in 1977 by creating high-tech machines. Two years later, they manufactured their first fiber laser cutting machine.

In 2018, the company bought Finn-Power, a move that led to changing its name and selling all its products under the Prima Power brand.

The company also made great expansion strides by opening new subsidiaries in Russia, India, Turkey, Australia, Brazil, UAE, and Korea.

Prima Power is a major global player in sheet metal processing machinery. Its laser cutting technology produces competitive machine products, including:

- Laser drilling machines

- Laser welding machines

- Fiber laser cutting machines

- Laser equipment

Prima Power’s credibility in the fiber laser cutting industry has been boosted by its Laserdyne processing systems. These systems stand out for their efficiency in speed, accuracy, and lower costs.

Further, Prima Power has achieved hi-tech sheet metal processing by introducing smart techniques. The laser process control technique integrates the control of the laser beam, motion, and process sensor to provide high quality and greater productivity.

Among Prima Power’s latest addition to their advanced laser machinery is the 2D Laser Genius+. The fiber laser cutting machine offers cheaper and more precise solutions for heavier and larger metal cutting with a 15kW cutting head.

Messer

The Messer Cutting Systems is part of the Messer Group of companies that make the Messer World Brand.

For over 120 years, the Messer brand has developed from a small engineering company to a world leader in producing industrial gases and manufacturing advanced laser welding machine solutions and cutting technology.

The origins of the Messer World date back to 1898. Over the years, the subsidiaries and affiliates of the German pioneer company have committed to delivering top-notch cutting solutions to metal production industries in over 50 countries.

Messer Cutting Systems combine a 3-tier resource of intelligent software, reliable technology, and quality service. This way, the company sets world standards in manufacturing and supplying powerful laser cutting options with technical features such as low heat input and cooling systems.

The cutting options include:

- Straight-cutting fiber laser machines

- CO2 and fiber laser cutting machine (with bevel technologies)

- Fiber laser and plasma combination machines

The company’s powerful straight fiber laser and the laser-plasma combination have proven to be the preferred choices among metal processing business owners. These machines have up to 20kW maximum cutting power.

Salvagnini

The Italian, Guido Salvagnini, founded the company named after him in 1963. At the time, Salvagnini specialized in the manufacture of lubrication units.

Today, Salvagnini is a global brand offering cutting-edge laser solutions in sheet metal fabrication. Their range of products includes:

- Punching machines

- Panel benders

- Machine laser systems

- Press brakes

- Flexible manufacturing systems (FMS)

- Software

Salvagnini’s “Beyond Manufacture” concept points to the company’s ability to tap the challenge of changing times and combine digitization with technological evolution for today’s businesses and those of the future.

This innovative approach explains Salvagnini’s advanced fiber laser solutions in the sheet metal machines industry. Their L3 and L5 10kW laser sources are created to cut on any type and density of metal materials using oxygen and nitrogen molecules.

What’s more, the efficiency of these laser cutting machines can be enhanced using compressed air, reducing cutting costs.

Mitsubishi

Mitsubishi is an umbrella name for many independent companies in different industries, including fiber laser metal cutting. Since its founding in 1870 in Japan, the Mitsubishi name has marketed itself for many years, especially in the automotive industry.

Like all fiber laser cutting machine manufacturing experts, Mitsubishi creates coordinated laser systems by linking a machine with a resonator and a numerical control system.

By relying on a high-speed CNC controller incorporated into laser-cutting machine systems, Mitsubishi can vouch for its laser-cutting processes’ accuracy, reliability, and cost-efficiency.

Their move to combine laser technology with software for greater efficiency places Mitsubishi among the manufacturers that hold the future of machine laser systems.

The laser sources in these machines guarantee high productivity and profitability for the businesses that use them. This is true of the GX-F SERIES, a Mitsubishi AI masterpiece with up to 10kW laser power.

Tanaka

Tanaka is a company in Japan created in 1917 to offer solutions in metal cutting and gas flow control devices.

Among laser cutting machine manufacturers, Tanaka’s unique spot is in designing and creating machines that cut thick plates.

Tanaka’s fiber laser cutting machine products offer high-quality solutions in:

- Laser metal sheet cutting

- Plasma cutting

- Gas cutting

Besides metal cutting, Tanaka’s other products include blast pipe equipment, gas pressure regulators, and machine-cutting data transfer software.

To continue its legacy in cutting large metal plates, Tanaka has released its latest fiber laser cutting machine, FMR II, into the metal laser cutting machine market.

The machine’s fiber laser oscillator has 20kW power that handles thicker cutting materials, promising greater productivity and profitability for your business.

GWeike

GWeike Laser is the youngest in our list of top 10 global laser generator manufacturers. It started in 2004 in China.

With only 19 years in the fiber laser cutting machine manufacturing industry, the company has made a name for itself by providing high-quality solutions in metal cutting processes. GWeike products are sold to businesses in over 100 countries in all 5 continents.

The company has a wide choice of carbon dioxide laser and fiber laser cutters. The machines fit into 3 categories based on the following:

- Laser power: Including medium, high, and precision power machines.

- Machine efficiency: Machines in the category are rated as auto-feed, economical, or 3D robots.

- Metal shape: Tube or plate.

This vast range of laser cutters allows business owners to choose from small to large metal laser cutting machines with laser source power between 3kW and 12kW.

Concluding Thoughts

If you own a metal cutting business that uses laser machines, purchasing from the best laser cutting machine manufacturers will guarantee your business’s success.

We hope our list of the top 10 global laser generator manufacturers has made your search and choice easy.

Baison can provide you with perfect solutions for laser cutters with suitable laser generators. Want to get more information? Contact us today!