High-Performance Fiber Laser Welding Machines

From metal fabrication to furniture production, Baison fiber lasers provide a precise, reliable, high-speed welding solution for any number of manufacturing industries.

Fiber Laser Welding Machine Types W (air cooling)

Baison’s fiber laser welders have the highest-quality lasers, optics, and motor systems. Bringing significant reductions to production line costs while enhancing accuracy and productivity, our laser welders are a cost-effective way for manufacturers to remain competitive.

Handheld Laser Welding Machine

Baison’s handheld fiber laser welders are a perfect solution for the accurate and high-speed welding of everything from stainless steel and iron to galvanized and aluminum sheeting. Requiring minimal tooling, our handheld systems are a universal welding solution that is particularly well-suited to prototyping and product development.

- Easy to operate

- Consistent welding results

- Low noise and power consumption

- Comprehensive safety features

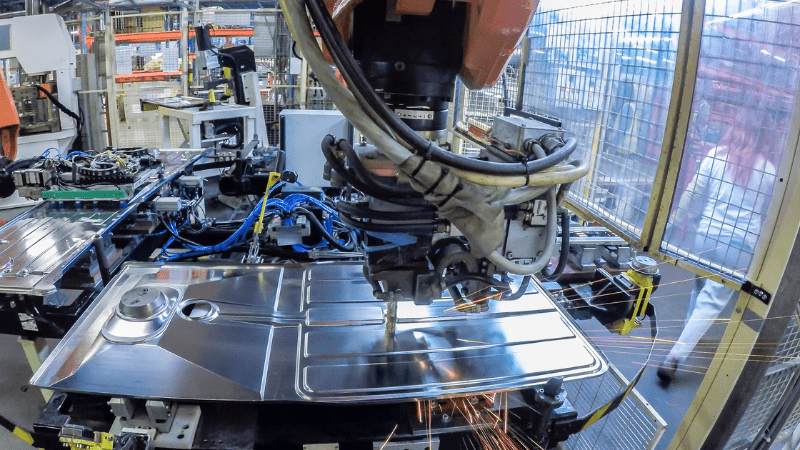

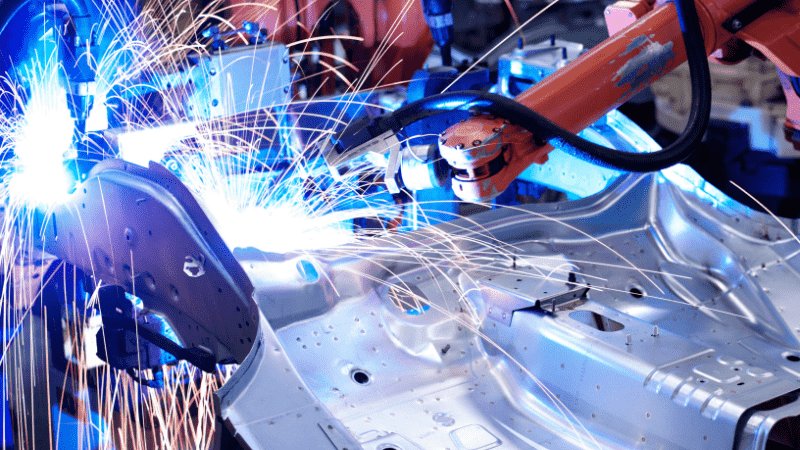

Laser Welding Robot

Our fully-articulated robots ensure repeatable precision welding on any scale required. Offering manufacturers the flexibility to perform even the most delicate welds reliably and consistently, our robots can perform pinpoint welds in the most hard-to-access areas. Baison’s automated system optimizes production line productivity while offering unmatched precision, versatility, and performance durability.

- Low heat affected zone reduces distortion.

- Streamlined arm designed for maximum access

- Substantial deposition rate

- Maximizes manufacturing capabilities

Not Sure Which Laser Welder is Right for You?

To discover which of our laser welders best suits your business, please don’t hesitate to contact us.

Features & Benefits of Our Welding Systems

Laser welding is a versatile and powerful tool that can be used for a variety of applications. Our laser welding systems are designed to provide precise, consistent welds with minimal heat distortion.

Accuracy & Reliability

Central to all our laser welders is their structure and power systems' stability, enhanced strength, increased accuracy, and operational lifespan.

Comprehensive Adaptability

Producing a wide range of laser welders that can be fully customized, we create welding solutions to meet any specific needs.

State-of-the-Art Technology

From our systems’ laser generators and cutting heads to their optics and motor systems, all Baison’s welding systems use the most advanced components.

Guaranteed Quality

With all our machines manufactured in-house, we’re able to maintain consistently high quality and rapid delivery.

End-to-End Service

We handle all aspects of your system, including design, manufacture, delivery, installation, and commissioning.

Full Customer Support

Our professional network of dealers provides our clients with rapid and extensive after-sales customer service.

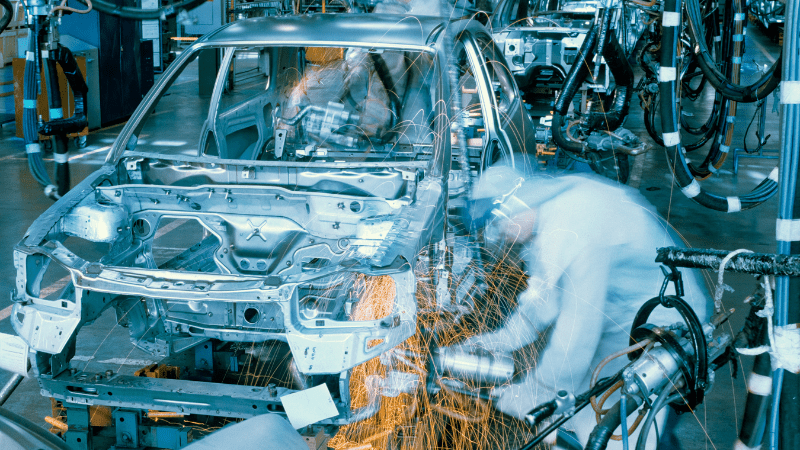

Fiber Laser Welding Solution for Industries

Our fiber laser welding machines are some of the best in the industry. We have a wide range of machines that can handle any material, from aluminum to stainless steel.

How Does Laser Welding Machine Work?

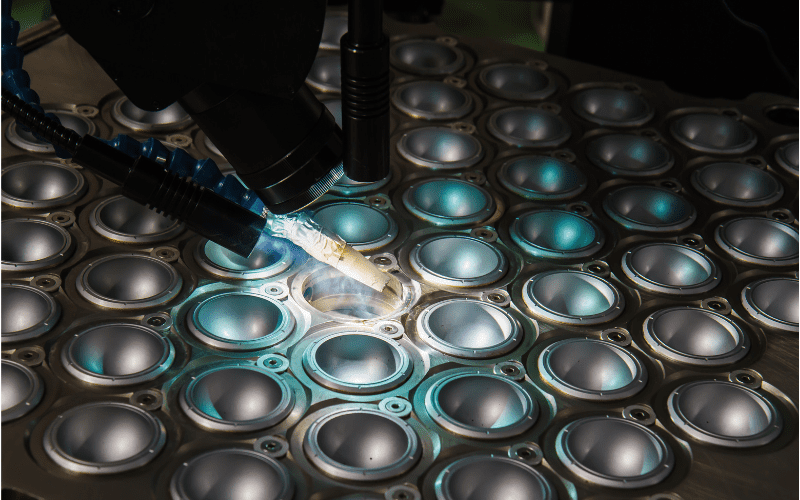

In contrast to traditional arc welding, which uses electricity to fuse metals, laser welding machines use high-powered laser light beams. Fiber lasers generate and deliver their light via optical fiber. They allow for far more precise and cleaner welds.

Not requiring contact with the target metals to weld them, laser welding machines have the added advantage of being able to weld from a distance, granting them access to a far greater range of possible welds.

With their control interface allowing the machine’s beam resolution and speed of operation to be easily adjusted, laser welders are now the preferred choice for any number of industries.

- Enhanced precision

- Cleaner, more aesthetic welds

- Unmatched flexibility

Import Welders From China, Easily and Reliably

With an extensive history dealing with companies across the globe, Baison makes purchasing a laser welding machine from China a simple and stress-free process.

Solution Tailored to Your Needs

Our expert R&D team can design laser welding systems that cater to the exact needs of any client.

Door to Door Logistics Solutions

We handle every step of the transportation and installation process, removing any possible headaches for the client.

Professional Ongoing Training

With all of our systems, you can take on new staff safely, knowing they will receive the proper training.

24/7 Online Support

There's always someone available to help you with any issues with our support team, available 24 hours a day.

Why Choose Baison?

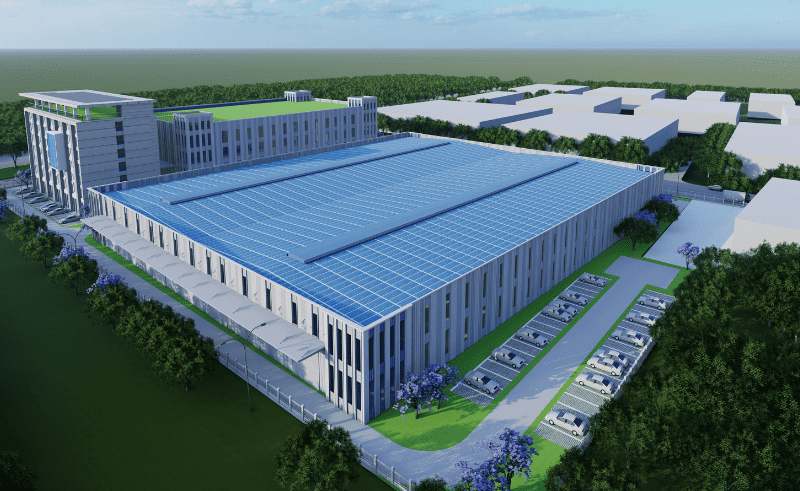

With over 20 years of experience manufacturing and exporting laser welding machines, Baison has sold systems in over 100 countries and has an extensive understanding of the specific requirements of each market.

Producing all our systems in-house, we provide a one-stop service for our customers that covers everything from design and development to installation and commissioning. With our expert R&D department conducting a thorough analysis of your needs before design, we create laser welding systems that enhance the quality and efficiency of your manufacturing process, no matter what business you’re in.

- Guaranteed quality and rapid delivery

- All your laser welding requirements under on roof

- Our extensive dealer network offers comprehensive after-sales service.

What Our Customer Has to Say

Our team of experts at Baison Laser takes pride in building long-lasting partnerships with clients. We have an overall 5-star rating for our services and top-notch fiber laser welding machines that create precision pieces every time! Here’s what customers say about us:

Our Happy Clients:

Frequently Asked Questions

Below are some common questions regarding fiber laser welding systems. If you have more questions or need to get a quote for our machine, please feel free to contact us.

Is fiber laser welding better than MIG welding?

Fiber laser welding is much better than MIG welding because it results in a smaller heat-affected zone (HAZ) and less distortion.

The beam is focused on a tiny spot with a fiber laser, so the heat is concentrated on a small area. This allows you to weld very thin sheets of metal without causing any damage to the surrounding area. In addition, the fiber laser produces less distortion than a MIG welder, so the welded joint is much more accurate. Read more about Laser Welding vs. MIG Welding

Is there a discount if we buy multiple fiber laser welders?

We offer discounts for bulk orders. Just tell us what quantity you are looking to order and your requirements, then our team will check the cost against all possible options so that it can be delivered at an affordable price! Contact now if this sounds like something of interest – just give me one moment while I get started on preparing everything necessary…

How long does it take to receive the machine after placing an order?

Production time is about 10-15 work days, and shipping will be 15 – 30, depending on where you live. That means 25 – 45 calendar weekdays from the day your order was placed! Ask for a quote now!

What is the warranty for your fiber laser welding machine?

We want to provide you with the best customer service possible. That is why all of our equipment comes equipped with a 3-year warranty, and if anything should break down during that period, we will help remotely solve any problem.

Contact one of Our Experts Today!

We invite manufacturers and prospective dealers to get in touch today. No matter what your manufacturing needs are, our fiber laser specialists can guide you toward the perfect solution – we’re ready when YOU ARE!