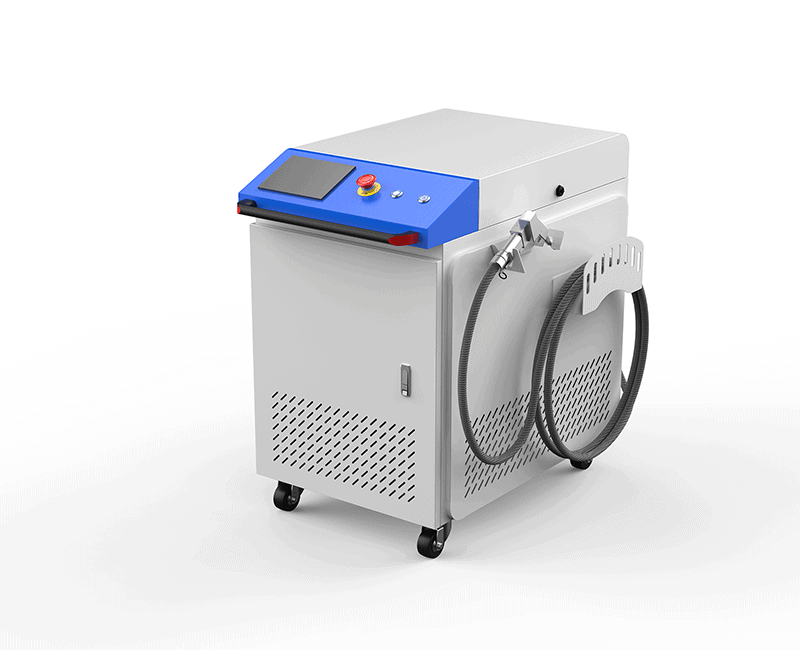

Innovative Pulse Laser Cleaning Machines

Baison’s pulse laser cleaning is a process used to remove rust, paint, oxide, and other contaminants from metal surfaces without harming the environment. Lasers can strip oil and grease, paint or coatings, and modify surface texture- like adding roughness for increased adhesion.

Pulse Laser Cleaning Solutions

Our handheld laser cleaning machines use pulsed or continuous wave lasers to clean metal surfaces. The pollution layer absorbs the energy of the focused laser, which then evaporates rust, paint, oil, and other contaminants on the surface.

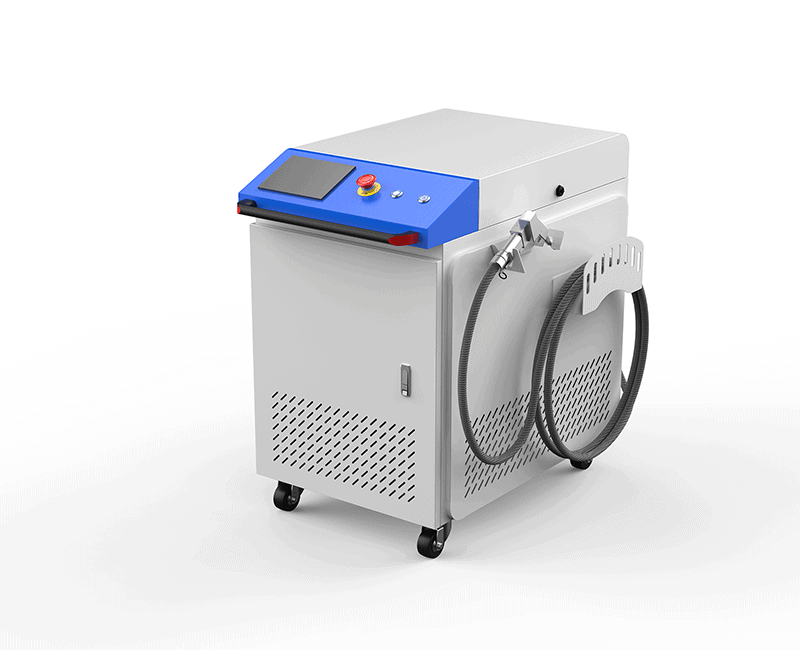

WL (continuous)

With 1500W/2000W/3000W of power, our laser cleaning system can remove rust and paint in seconds. The machine is equipped with high-quality components that make it more durable, efficient, and cost-effective than traditional methods. It’s also easy to use and requires minimal maintenance, making it the perfect solution for industrial applications.

- The non-contact process never degrades in quality.

- No damage to the substrate

- An easily automated process that can lower operating costs by eliminating labor while giving greater consistency in results

WM2 (Pulse)200W/300W/500W

Our 500W laser cleaning system is ideal for larger-scale industrial applications. This machine is highly powerful and efficient, making it a great choice for removing rust or paint from large metal surfaces in an incredibly short amount of time. It’s also very reliable and requires minimal maintenance, making it cost-effective and hassle-free.

- Precise cleaning. The laser machine cleaning process can precisely and efficiently clean hard-to-reach areas of complex objects.

- Non-contact cleaning method. Non-abrasive, no mechanical force, and zero damage to object surfaces.

- Safe and pollution-free.

Not Sure Which Laser Cleaning Machine is Right for You?

Contact our specialists now, and we will help you select suitable systems.

Benefits of Our Pulse Laser Cleaning Machine

Baison Laser’s fiber laser cleaning machines are the perfect choice for industrial applications. Compared to abrasive blasting, cold jetting, and chemical and thermal cleaning, the fiber laser application presents many benefits.

Elimination of Chemical Solvents

The laser cleaning metal process doesn't use chemicals, so it's more environmentally friendly and doesn't produce chemical pollution.

Non-Damaging Process

Adopting a fiber laser cleaning method is non-abrasive and doesn't require mechanical force; plus, it won't damage the surface of the objects you're cleaning.

Cost Reduction

The fiber laser cleaner is much faster than other traditional cleaning methods, cutting labor costs. Also, this rust removal tool can be used as soon as it's powered on.

Easy-to-Use Machines

Baison's fiber laser cleaning machines are designed with the user in mind. They are user-friendly and require minimal maintenance, making them ideal for industrial applications.

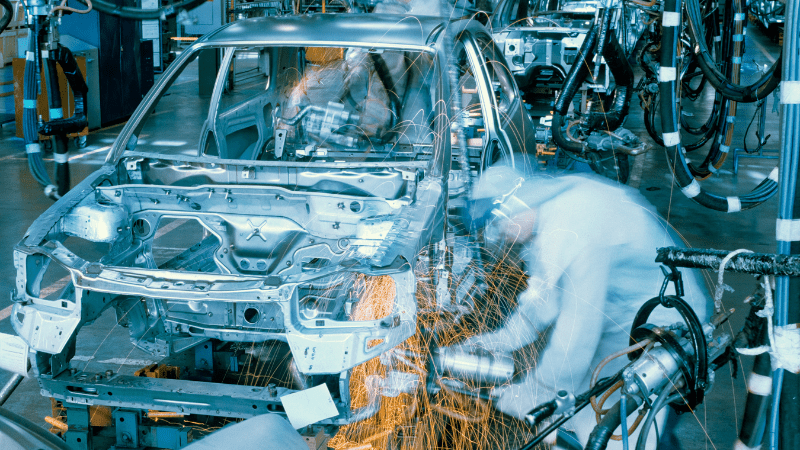

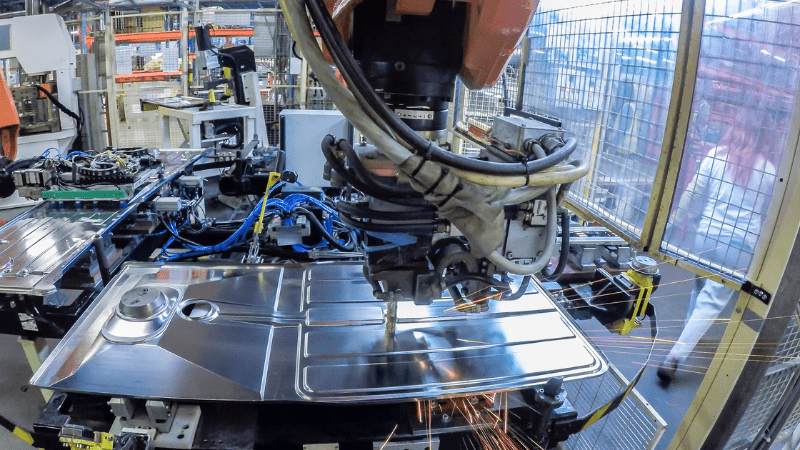

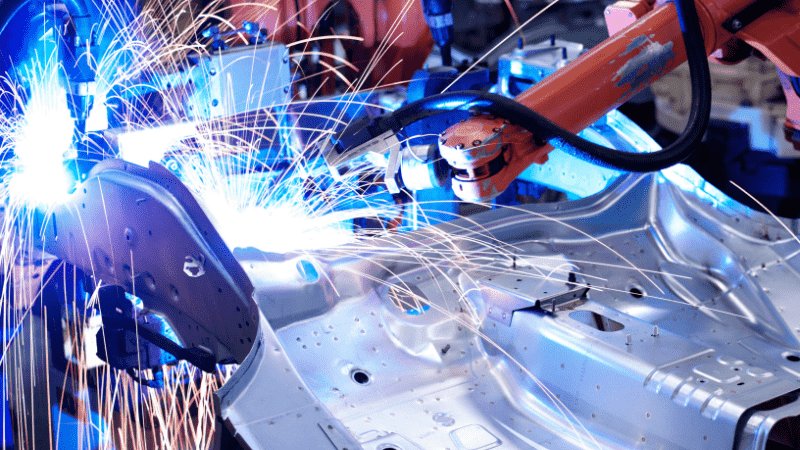

Pulse Laser Cleaning Solution for Industries

Industries across the board can benefit from using Baison’s fiber laser cleaning machines. Our products can be used in many fields, including automotive, oil and gas, shipbuilding, rapid manufacturing, and more.

How Does Pulse Laser Cleaning Machine Work?

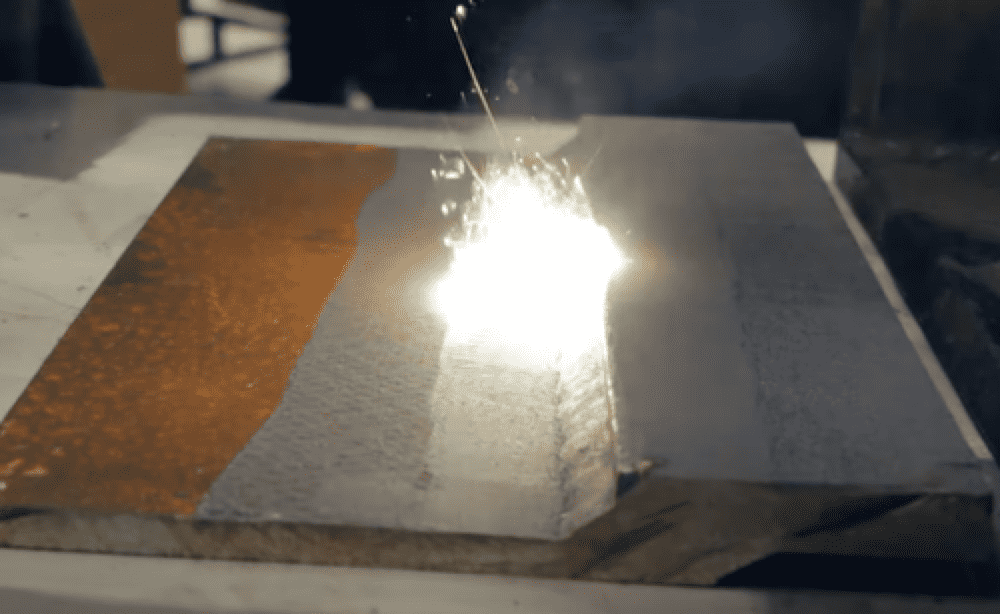

Laser cleaning technology sends nanosecond-length pulses of laser light toward a surface to remove contaminants. The laser light interacts with the pollutants, causing them to either turn into gas or detach from the surface.

Baison’s fiber laser cleaning machine is equipped with a high-power fiber laser that produces light pulses at a specific wavelength. The beam is then delivered to the target object through an optic focusing system. By controlling the pulse energy, duration, and other parameters, the user can precisely clean different contaminants on various surfaces:

- Utilize easy-to-use and flexible tools to clean effectively

- Reduce costs & environmental impact while saving time

- Reduce the risk of operator hearing damage

- Achieve optimal quality with selective cleaning applications

Import Machine from China Can Be Easy & Safe

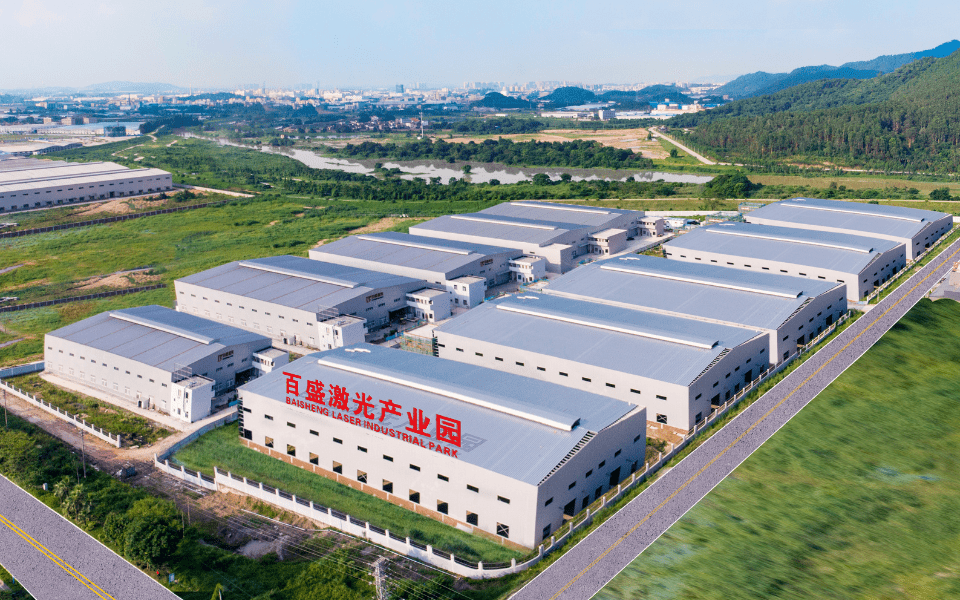

We understand that your machine’s performance is critical to your business’s success, so when you partner with Baison Laser, you can be sure that you’re getting the best laser cleaning machines on the market.

Solution Tailored to Your Needs

Baison can implement solutions across various industries with a complete line of products. From industrial lasers to precision parts cleaning and rust removal, we have the solution tailored to your needs.

Door to Door Logistics Solutions

Baison machines are manufactured in-house, so we can guarantee consistent quality and fast delivery. We also utilize a professional and responsible dealer system, providing more thoughtful and timely after-sales service for our customers.

Professional Ongoing Training

Training is essential to ensure the safe and effective use of our machines. Our experts can provide on-site installation, operation training, maintenance service, and after-sales technical support for all the machines we sell.

24/7 Engineer Online Support

We are committed to providing the best customer service experience and support. We have a team of experienced engineers who can provide quick and professional online help whenever needed.

Why Choose Baison?

At Baison, we have extensive experience exporting our machines and products to over 100 different countries. Our machines utilize laser generators and cutting heads from world-renowned brands to ensure optimal performance.

We offer design and development, production, transportation, installation, and commissioning services to help customers with all their needs in one stop. Our goal is to provide our customers with the best service, quality, and value.

- A complete line of in-house manufactured machines

- Over 20 years of export experience

- World-renowned laser generators and accessories

What Our Customer Has to Say

We are proud of our reputation and have worked with our customers for the past 20 years to improve their productivity and grow with them.

Our Happy Clients:

Frequently Asked Questions

Baison machines are designed to provide optimal performance, but our technical and customer service teams are always available if you have any questions or need help.

Can i get an application evaluation before place the order?

We understand that every application has its own needs, so we offer free application evaluations to help you select the right machine. Once you have submitted your request, our sales engineer will contact you and arrange the next steps.

How long does it take to receive the machine after placing an order

Our typical production time is 10-15 business days, though custom solutions may take a bit longer. Your shipping time will depend on your location and usually takes 15-30 days. So, you can expect the process to take 25-45 days from start to finish.

Is there a discount if we buy multiple fiber laser cleaning machine?

For bulk orders, we do provide a discount. Just let us know the quantity and your requirements, and we will check the costs for you. Feel free to contact us for a quote.

What is the warranty for your fiber laser cleaning machine?

We want you to feel confident about your purchase, which is why all our machines come with a three-year warranty. We will provide 24/7 online technical support to help you solve any problems.

Ready to Speak to one of Our Experts?

Baison Laser is ready to help you find the perfect fiber laser cleaning machine for your needs. Contact us today, and our team of experts will guide you through choosing the right machine for your application.