Rapid Manufacturing Industry Fiber Laser Solutions

- Home

- Industries

- Rapid manufacturing

Rapid manufacturing is a stepping stone for modern innovation, and Baison lasers are helping it reach its true potential. Rapid machining involves prototyping new products by use of 3d printing and modern CNC machines.

Prototypes have unconventional designs which aren’t convenient to machine using traditional tools. This is where Baison’s fiber laser technology helped smooth the process. With high-precision laser machines, the prototypes are rapidly machined, which reduces the cost significantly. Our machines offer many benefits for those industries that invest in prototyping while keeping regular production running.

Advantages of Fiber Laser Technology

Fiber laser technology is pivotal in establishing additive manufacturing for Rapid prototyping. It provides immense benefits and helps industries grow at a faster pace.

Complex Designs

Prototyping is inherently unconventional and has complex designs that are difficult for traditional technology to the machine.

High Speed

Fast prototyping is necessary for quick research and timely production. Fiber lasers deliver faster and more efficient machining at an unprecedented rate.

Cost Effective

Rapid manufacturing is only effective if it’s financially feasible. Thanks to fiber lasers, this industry can yield greater profits.

Fiber Laser Applications in Rapid Manufacturing

Fiber lasers have innate qualities of accuracy and adaptability, which favors rapid manufacturing. The mainstream laser application all play a vital part in this industry.

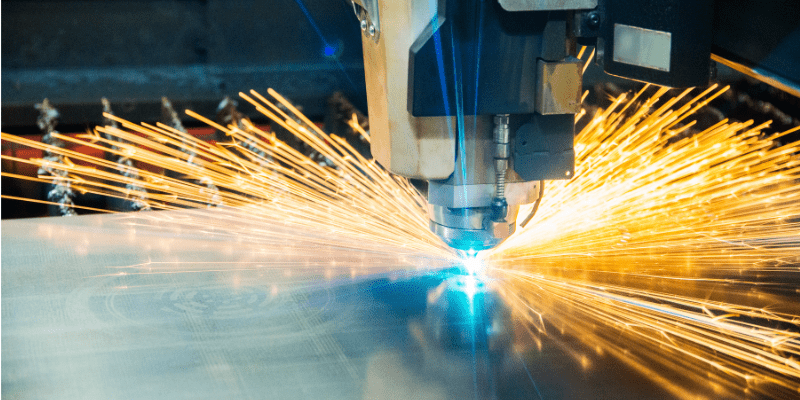

Laser Cutting Applications

Prototypes constantly challenge conventional designs. It could be complex gear that needs precision cutting or a new polymer that requires machining. Laser cutting is the way to go. It also provides finishing to products made from additive manufacturing.

Laser Welding Applications

Rapid prototyping mainly involves 3d printing the products. Sometimes these products are divided into components that are to be welded. Traditional welding isn’t compatible with polymers, unlike fiber lasers. Laser welding is helping rapid prototyping grow.

Laser Cleaning Applications

Cleaning the production floors, tools, storage facility, and machines is necessary to build good quality products. Laser marking makes the machinery clean and smooth for better quality production.

Laser Marking Applications

Rapid prototyping requires labeling much like any other product. In this case, it’s even more crucial to engrave certain logos, lettering, instructions, etc., for accurate identification. Laser marking does just that.

Speak With an Expert Now

Do you need fiber laser solutions to increase production? We will help you find the suitable fiber laser solution for your needs.