Oil and Gas Industry Fiber Laser Solutions

- Home

- Industries

- Oil and Gas

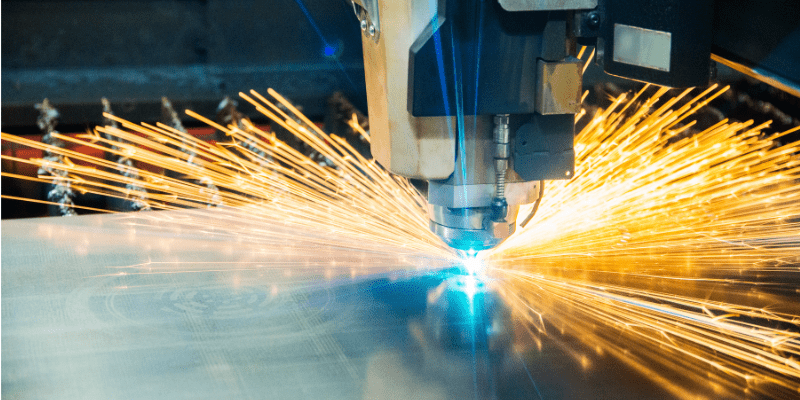

High-powered baison fiber laser machines have recently been integrated into the oil and gas market. The geothermal industry needs efficient welding, cutting, and cladding processes that fiber lasers fulfill.

As we know, pipes are crucial in extracting fuel from under the ground and oceans, which are subject to high pressure and stress. Only fiber lasers are capable of machining the parts in a precise manner while keeping the integrity of the material intact. Baison lasers provide the industry’s best automation solutions for orbital and longitudinal pipe machining.

Advantages of Fiber Laser Technology

The oil and gas industry is one of the oldest industries on the planet, and fiber laser can enhance its capabilities using the latest technology.

Exceptional Precision

Fiber laser technology produces the least tolerances at the highest precision. It’s especially needed for the oil and gas sector, where safety is crucial.

Adaptability

Fiber lasers can quickly adapt to light as well as heavy industries. No matter how complex the process is, the output is always faster and better.

Automation

Fiber lasers provide the avenue for automation as no other traditional process does. It successfully integrates CNC machining with minimum investments.

Fiber Laser Applications in the Oil and Gas Industry

The oil and gas sector covers a vast area of manufacturing. There is plenty of room for fiber lasers to integrate and make the process profitable. Here are a few examples.

Laser Cutting Applications

Oil and gas machinery deals with extraordinary pressure while extracting the fuels from under the ground. The pipelines, turbines, cranes, and other components are large compared to other industries. Laser cutting makes the process better with higher efficiency.

Laser Welding Applications

Laser welding is the most critical aspect of the oil and gas industry. Large fuel pipes require longitudinal and orbital welding that is hard to nail with traditional methods. Fiber laser automates the process and produces strong weld that can withstand tremendous pressure.

Laser Cleaning Applications

Oil and gas plants are prone to dust, dirt, sludge, oil, and rust, which is hard to clean and affects the efficiency of machines. Laser cleaning is best for removing such gunk out of the way keep things running smoothly.

Laser Marking Applications

Marking is crucial to identify the products. Since the machinery in this sector can get dirty quickly, permanent laser marking is the best solution for engraving.

Do You Want to Be More Productive?

Are you in need of fiber laser solutions to increase production? Our fiber laser experts will assist you in finding the suitable fiber laser system for your needs.