Aviation and Aerospace Industry Fiber Laser Solutions

- Home

- Industries

- Aviation and Aerospace

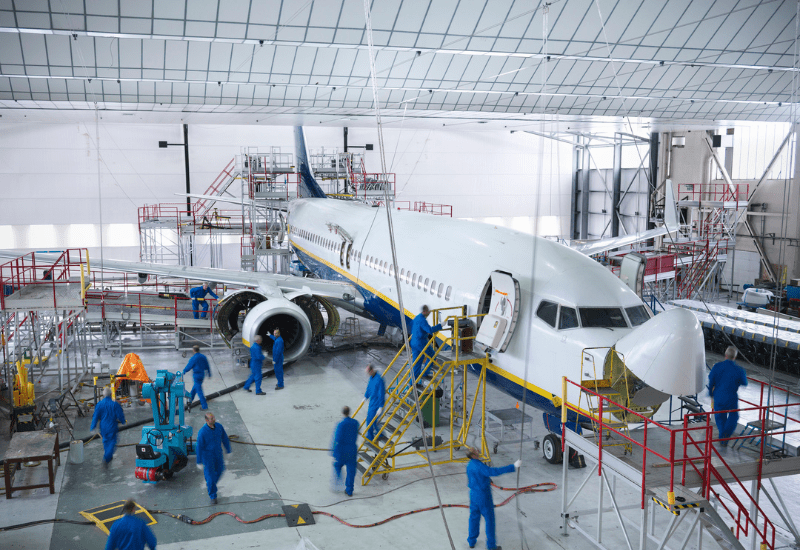

Baison laser machines are making waves in aerospace manufacturing. It’s a unique industry where immense research is underway as man yearns to reach the stars. The aviation industry continuously experiments with the latest manufacturing techniques to make better and safer air crafts. Also, many new materials, such as polymers, composites, and alloys, are constantly introduced to improve efficiency.

These materials are less dense and can be damaged by traditional manufacturing processes. This makes Baison’s fiber laser machines ideal as they are extremely compatible and offer precision and automation like none other.

Advantages of Fiber Laser Technology

Baison laser’s high-tech laser machines are suitable for various industrial applications. We offer contemporary technology synonymous with the modern industrial revolution.

Better Quality

Our fiber laser technology produces premium quality products. This results in less energy consumption, ultimately resulting in profits.

Material Compatibility

Fiber lasers can work with more than thirty different materials, which is far more than any traditional machine.

Automation

Fiber lasers provide special compatibility to automation in any industry. Its numeric control system can easily smooth the workflow.

Fiber Laser Applications in Aviation and Aerospace Industry

Aviation and Aerospace crafts deal with complex design and manufacturing that can withstand intense air pressures. Fiber lasers are suited for both research and manufacturing of space crafts.

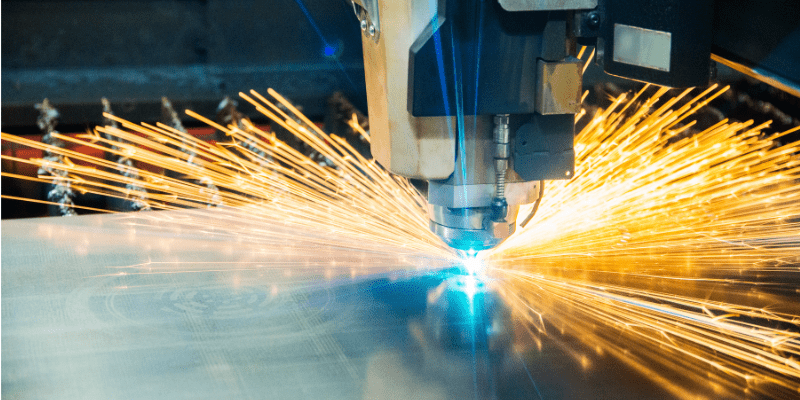

Laser Cutting Applications

In the aerospace industry, cutting material parts is of great significance as minor faults can introduce stresses in the component. Laser cutting is precise enough to keep the stresses to a minimum while not compromising quality.

Laser Welding Applications

High-powered laser machines are popular in aircraft fuselage welding. It’s compatible with various materials, which makes it easier to work with composites and other alloys. Laser welding seams are also strong enough to withstand high pressure.

Laser Cleaning Applications

Laser cleaning makes the machining process way smoother and better. Many aircraft manufacturers use it to clean old paint jobs, rust, and corrosion from the parts. It’s efficient and economical.

Laser Marking Applications

Space crafts have hundreds of thousands of intricate parts that need to be labeled for better production. Laser marking makes the process easier. The engravings are permanent, which makes them more reliable.

Are You Looking for More Productivity?

Get in touch with Baison today. You will be able to choose the most suitable fiber laser system for your needs with the help of our fiber laser experts.