Automotive Industry Fiber Laser Solutions

- Home

- Industries

- Automotive

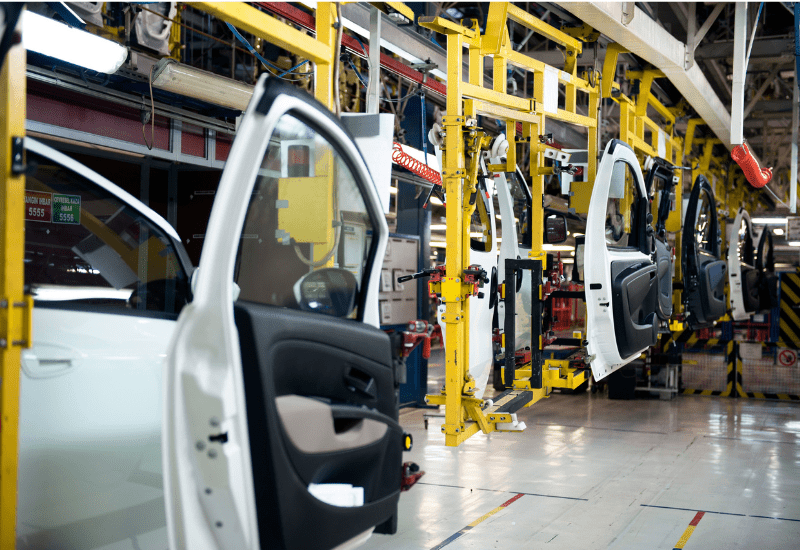

Automotive industry is adopting Baison’s dynamic and scalable fiber lasers to revolutionize the manufacturing process and maximize the efficacy of cutting, welding, cleaning, and engraving solutions.

As demand for intelligent, lightweight, and performance-driven car designs grows, so must the manufacturing capabilities. Baison fiber lasers meet this challenge by making excellent clean cuts that are ideal for interior detailing. Metal, rubber, plastic, and various textile products are precision cut using automated lasers.

Advantages of Fiber Laser Technology

Fiber Lasers are an upgrade over traditional manufacturing techniques in every sense. Today, they intrinsically synergize and improve nearly every facet of vehicle manufacturing.

Exceptional Precision

With fiber lasers, you can create increasingly complex and intricate parts with unparalleled precision.

High Reliability

A fiber laser’s lack of moving parts increases its reliability since the need for frequent maintenance, and part replacement is eliminated.

Outstandingly Efficient

Automakers worldwide have adopted fiber lasers due to their low power consumption and lower operating costs.

Fiber Laser Applications in Automotive Industry

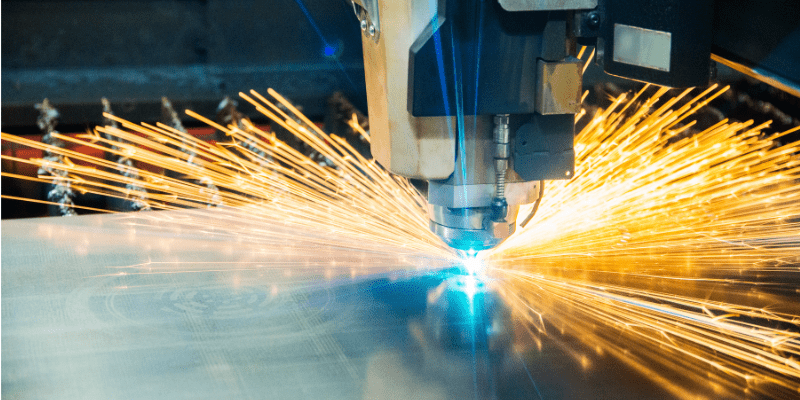

Today’s fiber lasers are more than just cutting tools. They are actively being deployed for several different applications on the production lines of modern automotive industries.

Laser Cutting Applications

Laser cutters are chiefly used for small and medium-sized automotive parts, including but not limited to exhaust components, bumpers, tube cutting, dashboard parts, battery elements, sheet metal work, and body panels.

Laser Welding Applications

Fiber lasers excel at automotive metal and non-metal welding operations. Laser welding is commonly used for ABS braking systems, gear components, door assemblies, fuel injectors, airbag elements, exhaust pipes, seat frames, headlights, aluminum welding, plastic joining, and more.

Laser Cleaning Applications

On the factory floor, it helps clean up welds, maintain cutting tools, and prepare metal surfaces before welding. Additionally, fiber lasers can quickly restore greasy, rusted, molded, and other dirty car parts.

Laser Marking Applications

Lasers have revolutionized metal branding and marking solutions. Dashboard control information, VINs, engine markings, key fobs, number plates, hydraulic fittings, part serial numbers, and media control buttons are generally marked and engraved using lasers.

Interested in Speaking with an Expert?

Take advantage of our fiber laser experts’ expertise to boost your production. Get in touch with us to find the fiber laser solution that is right for you.