Appliance Manufacturing Industry Fiber Laser Solutions

- Home

- Industries

- Appliance Manufacturing

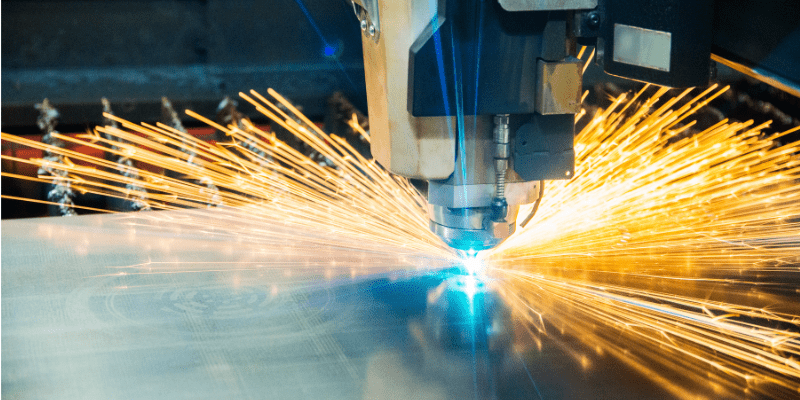

Baison Laser solutions have been quickly spreading across the appliance manufacturing industry. As demand for more premium and compact appliances increases, so do the manufacturing challenges. Our exceptionally high-quality fiber lasers empower companies to design and develop new and innovative culture-defining products of the future.

Modern households are full of complex and intricately designed appliances. Baison’s fiber lasers enable such designs’ development, prototyping, and mass production with their unmatched precision and efficiency.

Advantages of Fiber Laser Technology

Fiber lasers bring a new level of intuitive flexibility and core competency. They ensure the development of faster, stronger, more refined, and compact appliance designs.

Improved Efficiency

Baison lasers consume significantly less power than traditional manufacturing solutions, resulting in lower overall operational costs and higher productivity.

Fast and Convenient

Fiber lasers’ quick and easy setup allows you to speed up the cutting and welding processes leading to an appreciable decrease in turnaround times.

Material Compatibility

Baison’s laser solutions have practically zero material restrictions. Fabrics and plastics that struggled with traditional manufacturing become more manageable.

Fiber Laser Applications in Appliance Manufacturing

Fiber lasers offer a whole lot more than material-cutting services. Modern appliance manufacturing utilizes lasers for welding, cleaning, lettering, branding, and more.

Laser Cutting Applications

Laser cutters are chiefly used for small and medium-sized automotive parts, including but not limited to exhaust components, bumpers, tube cutting, dashboard parts, battery elements, sheet metal work, and body panels.

Laser Welding Applications

Laser welding outshines traditional welding when it comes to smaller and more complex designs, like the ones seen in newer kitchen appliances. Everything from sheet metal casings for microwaves to polymer components of blenders uses laser welding.

Laser Cleaning Applications

Baison Laser solutions can clean welds, maintain tool integrity, and prepare surfaces for post-processing like welding, anodizing, or painting. Lasers can also help restore and clean up long-term damage to older kitchen appliances and utensils.

Laser Marking Applications

Every appliance requires good and accurate marking for safe and convenient operation. Our precision fiber lasers are designed for branding, engraving, and lettering all material surfaces, including textile, glass, metal, plastic, and wood.

Interested in talking to an expert?

Boost your production with the expertise of our fiber laser experts. Let us help you find a suitable fiber laser solution.