Application Industry

Exhaust duct

Elevator Industry

Auto Parts

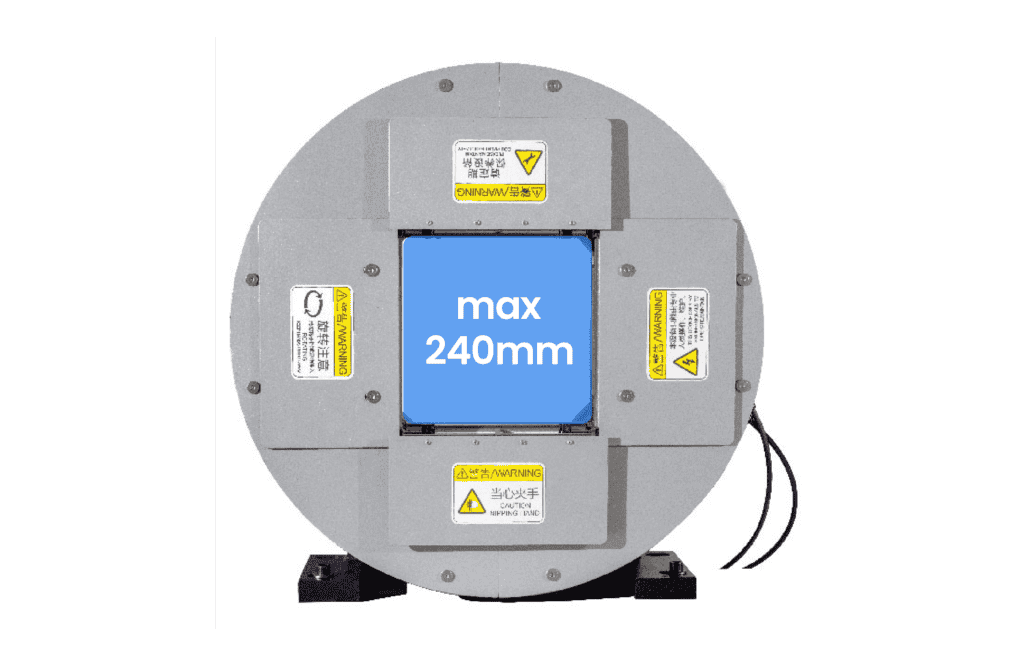

Break Through Cutting Limitations

Square through-hole chuck structure design, wider range of pipe processing, capable of cutting round, square, channel steel, I-beams, H-beams, and some special-shaped pipes, ensuring stable processing.

Full-stroke Professional Chuck

Designed with a fully sealed chuck, it offers highly efficient dust protection; with low inertia and rapid rotation speeds, it ensures high processing efficiency.

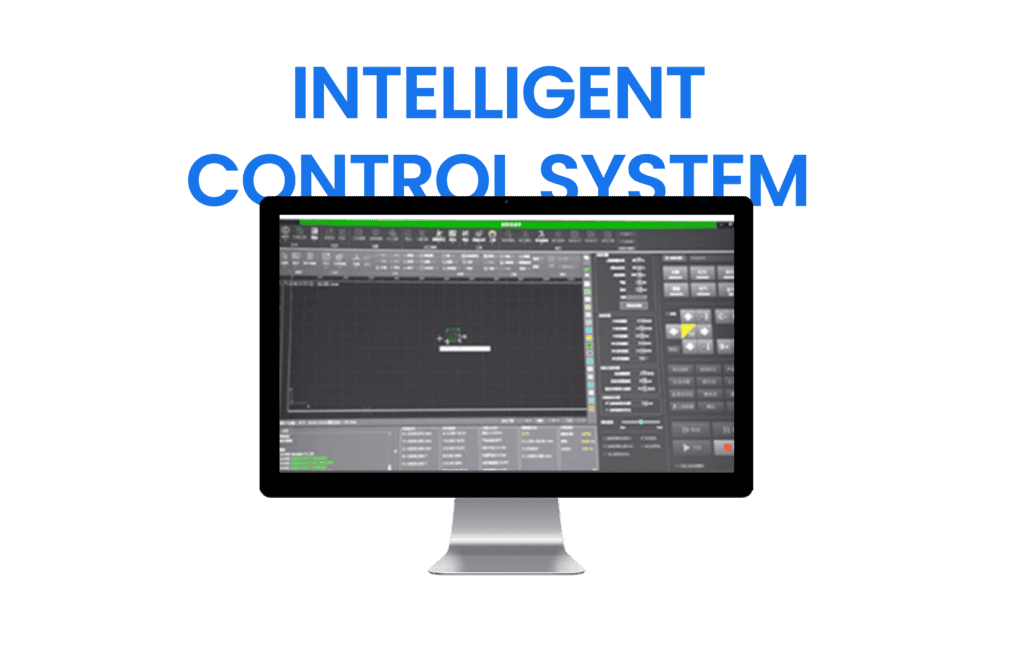

Intelligent Control System

Equipped with an extensive cutting process database as standard, it can meet the cutting motion requirements for various scenarios; the interface is simple and clear, with convenient and flexible operation.

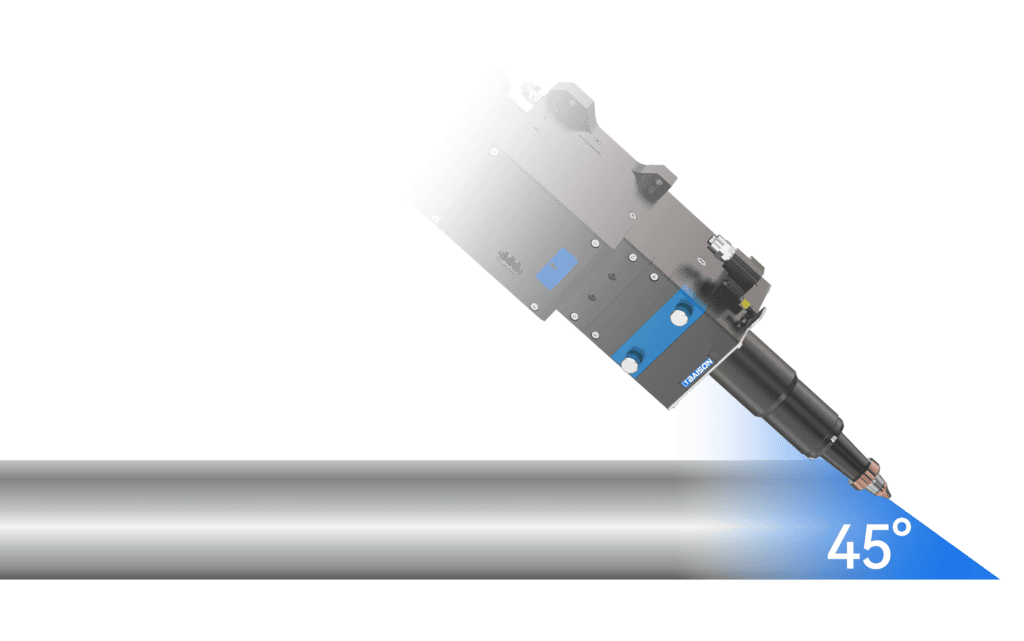

Excellent Bevel Cuts (*Optional)

Optional bevel cutting capability can be equipped with bevel cuts from -45° to +45°. Depending on the part geometry, simple V- and X-seams can be cut, as well as more complex V- or K-seams, etc.

Variable-Diameter Wheel Support

Reduces the extent of tube sagging, preventing tube whipping and enhancing precision. Ensures stable tube flipping to avoid scratches.

Equipment parameters

| G24 | |

|---|---|

| Laser Power | 1500W~6000W |

| Tubes can be processed | Round tube: φ10~240mm Square tube: 10*10~220*220mm (tube R angle greater than 30mm can be clamped 240mmx240mm) Channel steel: 20# (standard clamp, need to add nesting software) Angle iron: 20# (standard clamp, need to add nesting software) I-beam: 20# (standard clamp, need to add nesting software) H-steel maximum: 20# (standard clamp, need to add nesting software) |

| Tail length | ≥110mm |

| Tube processing length | 6500mm |

| Max Speed | 100m/min |

| Max load capacity of single tube | 300kg |

| Dimension(L*W*H) | 9300*1900*2400mm |