Laser Pipe Cutting in the Oil and Gas Industry – Uses & Benefits Explained

In the gas and oil industries, pipes are used to transport oil and chemicals safely from one location to another. For the precise cutting of these pipes, laser cutting is used. If you work in oil and gas, or are a procurement manager or a field project engineer, this article is for you, as it explains why laser cutting is important in the oil and gas industry.

Why Pipe Cutting Matters in Oil & Gas Projects?

The oil and gas industry is among those that have benefited the most from the modern method of cutting pipes, i.e., using a laser beam to cut pipes accurately. In these industries, pipes are widely used to carry oils, gas, chemicals, and other fluids from one location to another.

These pipes are often exposed to extreme pressures and temperatures. This is the reason why every joint and segment of the pipe must be perfect and precise. In oil and gas projects, a poorly cut pipe can lead to welding issues, contribute to fluid leakage, pose a safety threat, and result in increased costs.

Laser cutting for oil and gas pipes is crucial, as it ensures enhanced safety, contributes to cost efficiency, and promotes long-term reliability.

What Is Laser Pipe Cutting and How Does It Work?

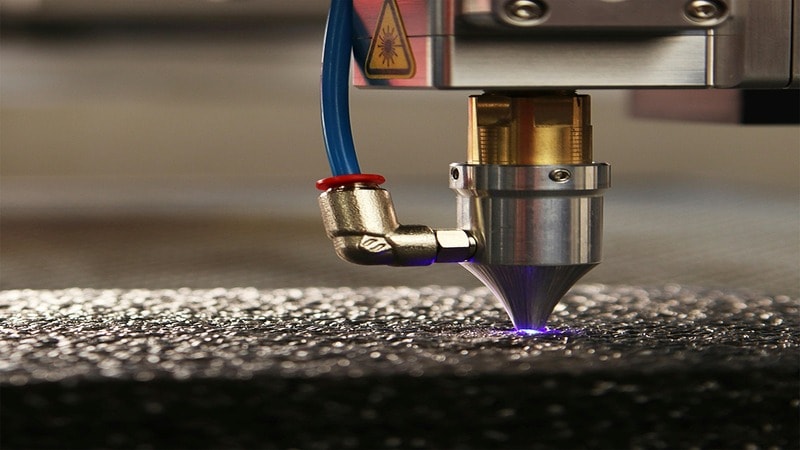

Laser pipe cutting, as the name indicates, involves using a focused laser beam to cut metal pipe precisely. Laser beams melt, burn, and vaporise the material, resulting in precise and accurate cutting.

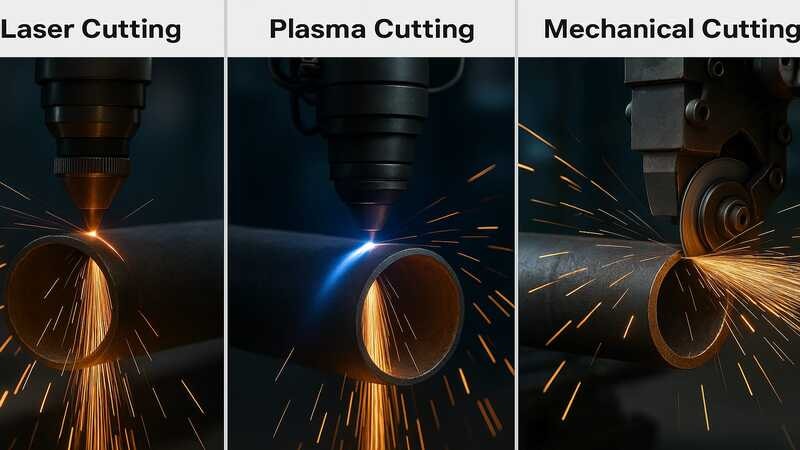

Mechanical and plasma cutting differ from laser cutting, as they use physical force or plasma to cut the pipe, whereas laser cutting uses heat. Using heat, laser cutting results in smooth edges and eliminates the need for additional grinding and finishing.

Laser cutting is a popular pipe-cutting technique in the gas industry, as it is suitable for a wide range of materials, including carbon steel, stainless steel, duplex stainless steel, and other alloys.

Best Use Cases of Laser Pipe Cutting in the Oil & Gas Industry

Multiple key operations in the oil and gas industry utilize laser pipe cutting to improve operational efficiency. The following are some of the most critical cases of laser cutting in the oil and gas industry:

Onshore and Offshore Pipeline Construction

In the oil and gas industry, onshore pipeline construction refers to the construction of pipelines on land. In contrast, offshore pipeline construction involves laying pipes beneath the sea for the transportation of oil, gas, or other chemicals.

In both offshore and onshore pipeline construction, laser-cutting technology is widely used. Laser pipe cutting enables multi-angle precision cuts for complex pipe layouts. Similarly, it allows remote cutting using mobile CNC laser systems.

A CNC laser cutting machine can be referred to as the best pipe-cutting machine for oil and gas. CNC stands for Computer Numerical Control, which means that the laser machine is programmed to cut pipes automatically and precisely.

Additionally, laser cutting reduces the need for hot work in hazardous zones, i.e., Zone 1 and Zone 2. Zone 1 and Zone 2 are areas where flammable gases or vapors are present. Using laser cutting avoids fire and explosion risks in hazardous areas.

Fabrication of Pipe Spools and Skids

Fabrication is the process of assembling different parts, like pipes, fittings, valves, and frames, such as pipe spools and skids. Pipe spools are assembled sections of piping, whereas a skid is a portable steel frame that holds equipment and piping modules.

In the oil and gas industry, laser cutting ensures a clean fit-up for challenging components, such as elbows, tees, and reducers, thereby enhancing the precision of laser welding. Also, it helps save time by eliminating the need for smoothing the edges.

Lastly, in high-volume FPSOs (Floating Production Storage and Offloading units), laser cutting — especially CNC laser systems — reduces workload, errors, and delays.

Maintenance and Repair of Existing Infrastructure

Laser cutting not only aids in the construction of new pipes but also helps maintain and repair existing ones.

While maintaining, laser cutting precisely cuts the damaged pipe segment without damaging the nearby pipe or segments. It also helps reduce workload by providing well-finished edges. Similarly, it supports fast turnarounds during emergencies.

Subsea Equipment Fabrication

Subsea equipment is installed under the sea to transport and extract the oil and gas. This equipment includes risers, manifolds, and connectors. Laser cutting provides high-tolerance cuts, which help ensure proper fit-up, leak-free welding, and long-term reliability.

Subsea equipment is often made from materials that are hard to cut with conventional methods; thus, laser-grade cuts come to the rescue in this case.

Based on all the advantages, laser-cutting machines are preferred for critical subsea applications when selecting the best pipe cutting machine for the oil and gas industry.

Benefits of Laser Pipe Cutting in Oil & Gas Operations

The benefits of laser cutting in this industry are as follows:

Superior Precision

As discussed earlier, laser cutting offers high precision. It reduces the risk of mismatch during welding, which is a common issue in manual or traditional cutting methods.

Additionally, laser cutting meets the established standards of the API and ASME, making it a reliable choice for high-specification oil and gas projects. High-precision pipe cutting for the energy sector can be achieved using the laser cutting method.

Speed and Efficiency

Another benefit of laser cutting is that it ensures speed and efficiency. Laser machines have fast cycle times and are perfect for repetitive tasks. This helps speed up production, especially in modular fabrication projects.

It is crucial to note that among all pipe-cutting techniques in the gas industry, using lasers is among the fastest and most efficient methods.

Safety and Clean Cutting

When comparing laser vs plasma cutting for pipelines, it is worth noting that laser does not produce harmful sparks like plasma. Thus, in Zone 1 and Zone 2, laser cutting is the safest option.

Compatibility With Automation

Another benefit of laser pipe cutting in the gas sector is that it is compatible with automation. CNC laser pipe-cutting oilfield operations are programmed for high accuracy. This reduces labour and the chance of human error, while increasing output.

Lower Material Waste

The other primary benefit of using laser cutting is that it generates less material waste. Laser cutting leaves behind smooth, burr-free edges, which means less scrap. Laser cutting not only reduces waste material but also saves money when working with expensive materials.

Owing to all the above benefits, laser-cutting machines are considered the best pipe-cutting machines for oil and gas.

Laser vs Plasma vs Mechanical Cutting in Oil & Gas

The side-by-side comparison of laser vs plasma vs mechanical cutting for the oil and gas industry is given below:

| Factor | Laser Cutting | Plasma Cutting | Mechanical Cutting |

|---|---|---|---|

| Precision | High precision; requires no finishing | Moderate; suitable for general cuts - may require finishing | Low precision; requires finishing |

| Heat-Affected Zone | Very small; minimal thermal distortion | Large; it can affect material properties | None, but it causes mechanical stress |

| Safety | Safe; no sparks/fumes; ideal for Zone 1 & 2 | Generates sparks and toxic fumes | Risk of injury from blades |

| Portability | Moderate; portable CNC laser units available | High, handheld units are common | High-quality, basic tools are easy to carry |

| Speed | Fast, clean results, no rework needed | Fast, but often requires finishing | Slowest of all three |

| Cost per Cut | Higher upfront but cost-effective in the long term (less rework/scrap) | Medium: lower setup cost but more rework | Lowest upfront, but higher long-term due to inefficiency |

Best Practices for Laser Pipe Cutting in Oil & Gas Projects

To reap all the benefits of laser cutting, you need to follow some key practices given below:

- Conduct proper material identification

- Use the correct laser power settings

- Use laser marking to add serial numbers or QR codes on each part for traceability.

- Maintain cutting optics and cooling systems

- Implement automation for batch jobs

- Pre-test for weldability and heat effects

Final Verdict

The precision offered by laser cutting makes it highly popular in the oil and gas industry. The safety, reduced material waste, compatibility with automation, and other benefits compel procurement engineers to choose lasers for cutting pipes.

Whether for fabrication, new pipe construction, or repairing existing pipes, laser cutting technology outperforms traditional methods.

So what are you waiting for? Upgrade your cutting system with fiber laser cutting machines, and to reap the benefits of laser cutting, make sure to get in touch with a leading laser system manufacturer.

Upgrade Your Oil & Gas Cutting Capabilities with Baison

With over 20 years of experience in assisting manufacturing industries in increasing their productivity through advanced fiber laser systems, we at Baison stand ready to help you transform your oil and gas industry.

Contact us today to get answers to all your questions or to request a quote for your required laser solution.

FAQs

Q: What is the difference between gas cutting and laser cutting?

Gas cutting, as the name indicates, uses gas to cut metal pipes. Laser cutting, however, uses a focused laser beam for precise and clean cutting of pipes.

Q: Which pipes are used in the oil and gas industry?

The standard pipes used in the oil and gas industry for transporting oil and gases include, but are not limited to, carbon steel, stainless steel, duplex, Inconel, and other alloy pipes.