Let’s have a deep dive into the YAG vs. Fiber laser comparison. By the end of this article, you will better understand which laser type is best suited for your specific application. Let’s dive in!

What Is Fiber Laser and How Does It Work?

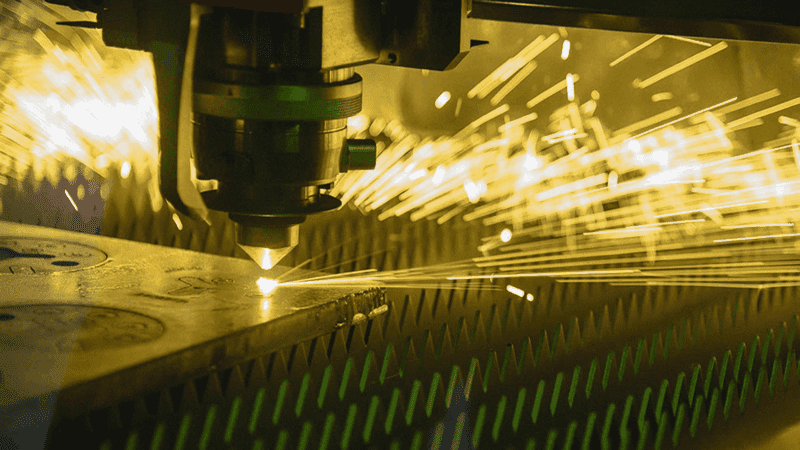

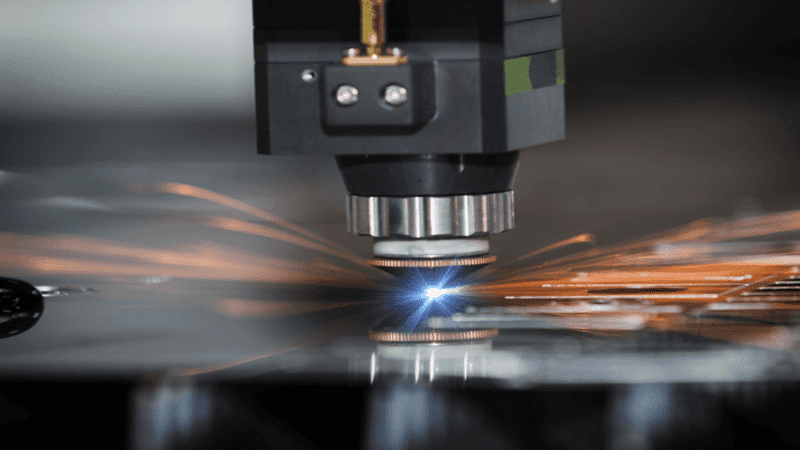

Fiber lasers are widely used by global businesses for cutting and welding. This technology involves using a highly intense laser beam with remarkable qualities. Some of these include high efficiency, extreme precision, and low maintenance requirements especially compared to older methods.

The fiber optic cable is infused with rare earth elements. This leads to a high-energy state that generates a consistent, single-wavelength light beam. On top of it, if you are a business looking to boost production, fiber lasers can definitely help with its efficiency and precision, producing excellent results for your customers.

Fiber Laser: What’s Good and What’s Not

Let’s begin with the advantages:

Advantages:

- Superior efficiency: With a high conversion efficiency, fiber lasers transform a significant portion of the input power into laser output power, resulting in reduced energy usage and operational expenses.

- Economical operation: Due to their heightened efficiency, low maintenance needs, and extended lifespan, fiber lasers boast cost-effective operation.

- Outstanding beam quality: Generating a concentrated, high-quality beam that retains its intensity over considerable distances. Fiber lasers do this task, which requires exceptional precision and accuracy.

- Remarkable precision and accuracy: Capable of creating tiny spot sizes and crisp edges, fiber lasers facilitate highly precise cutting and engraving on a range of materials.

- Durability and minimal maintenance: Fiber lasers possess fewer moving components compared to conventional laser systems, enhancing their dependability and simplifying maintenance. They can function continuously for extended periods without needing regular adjustments or component replacements.

- Accelerated production speeds: Fiber lasers operate at impressive velocities, promoting faster production rates and shorter cycle times.

Disadvantages:

- Restricted power output: Fiber laser exhibits lower power output compared to conventional laser systems, which could constrain their applicability in specific scenarios.

- Challenges in cutting specific materials: Fiber lasers might encounter difficulties when cutting certain materials, like reflective metals, due to their inherent wavelength and absorption characteristics.

- Higher initial investment than YAG laser: Fiber lasers may initially be more expensive than YAG lasers, although their superior efficiency and reduced operating costs often compensate for this difference in the long run.

Applications of Fiber Laser

Here are some applications of fiber lasers:

- Precision metal cutting: Fiber lasers excel in cutting intricate shapes and patterns in metals, including stainless steel, aluminum, and brass, for industries such as automotive, aerospace, and electronics.

- Welding and joining: Due to their high precision and control, fiber lasers are ideal for welding and joining applications, particularly for small and delicate components in industries such as medical devices, electronics, and automotive manufacturing.

- Additive manufacturing: In the realm of 3D printing, fiber lasers play a crucial role in selective laser sintering and melting processes, enabling the production of complex parts and components for industries like aerospace, automotive, and medical devices.

- Micromachining: Fiber lasers offer the ability to create minute features on various materials, making them an excellent choice for micromachining applications in fields like microelectronics, biotechnology, and semiconductor manufacturing.

- Surface treatments: Fiber lasers can be utilized for surface treatments, including polishing, texturing, and cleaning, to enhance the appearance, functionality, or longevity of materials in industries such as consumer goods, aerospace, and automotive.

- Engraving and marking: Fiber lasers are frequently employed for etching and marking various materials, including metals, plastics, ceramics, and glass, with high precision and accuracy, often used in product identification, traceability, and branding.

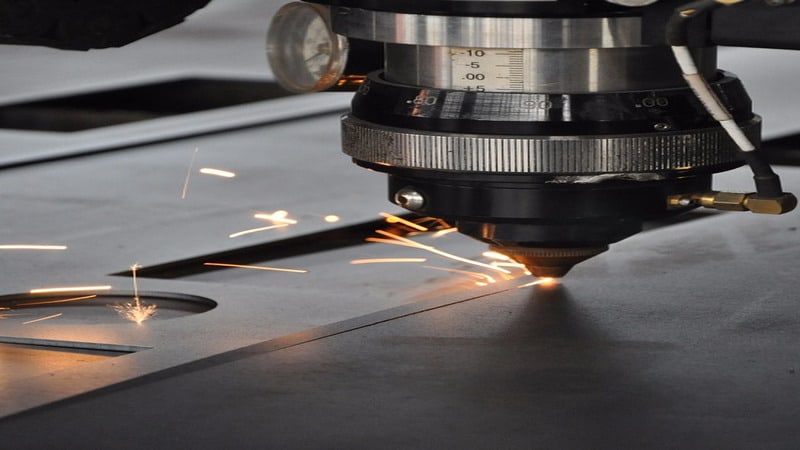

What Is YAG Laser and How Does It Work?

An nd: YAG laser, or yttrium aluminum garnet laser, is a type of solid-state laser that employs a synthetic crystal composed of yttrium, aluminum, and garnet as its lasing medium.

This crystal is doped with a rare earth element, typically neodymium, which serves as the active laser component. YAG lasers have been widely utilized in various industries and applications due to their high power output, flexibility, and versatility.

The operational mechanism of the YAG laser entails the supply of external energy into the neodymium-doped crystal, resulting in the excitation of the neodymium ions to higher energy levels.

Subsequently, the ions release photons coherently when returning to their ground state, creating a laser beam. YAG lasers can generate continuous or pulsed outputs depending on the application demands.

Advantages and Disadvantages of YAG Laser

Here is a detailed explanation of the advantages and disadvantages of YAG lasers:

Advantages:

- Strong power output: YAG lasers generate substantial power output, making them suitable for cutting and welding thick materials.

- Exceptional beam quality: beam quality is one area where ND: YAG lasers don’t lack behind. You can expect remarkable precision and accuracy.

- Applicable in medical and scientific fields: YAG lasers find use in medical and scientific applications, such as ophthalmology and dermatology treatments.

- Flexibility in operating modes: YAG lasers offer the option to function in either pulsed or continuous modes, catering to the specific needs of different applications.

- Compatibility with diverse materials: YAG lasers can process various materials, including metals, ceramics, and composites, rendering them highly versatile across multiple industries.

Disadvantages:

- Greater maintenance needs: Compared to fiber lasers, YAG lasers necessitate more maintenance, potentially raising the overall operational expenses.

- Restricted output wavelength choices: YAG lasers offer limited output wavelength alternatives compared to other laser systems, such as fiber lasers.

- Increased initial investment: YAG lasers may carry a higher initial cost than other laser types, potentially creating a barrier for some manufacturers. However, it is still cheaper than fiber lasers.

- Reduced efficiency: YAG lasers exhibit lower efficiency than fiber lasers, signifying that they convert a smaller portion of input power into laser output power.

Applications of YAG Laser

- Processing of metals: In the laser cutting and welding industry, YAG lasers have a good use for handling various materials, including steel, aluminum, and titanium. Their application spans sectors such as automotive, aerospace, and manufacturing.

- Research supporting cutting and welding: YAG lasers are utilized in scientific research, focusing on areas like material analysis and characterization, directly impacting the development of advanced cutting and welding technologies.

- LiDAR for industrial mapping: YAG lasers are employed in Light Detection and Ranging (LiDAR) systems, facilitating accurate distance measurement and high-resolution mapping that can be used for planning and optimizing cutting and welding operations in various industrial settings.

- Defense-related cutting and welding applications: YAG lasers assist with specialized cutting and welding tasks in the defense and security sector. Moreover, it also comes in handy for laser range finding, target designation, and countermeasure systems.

- Micro-scale fabrication: YAG lasers play a crucial role in micromachining applications, such as crafting small features on materials, which are vital in the microelectronics, semiconductor, and biotechnology industries.

- Precision engraving and marking: manufacturers use YAG lasers for precise engraving and marking on different materials. This help caters to the needs of industries like electronics, automotive, and aerospace for traceability, identification, and branding.

Comparison between YAG and Fiber Lasers

YAG and fiber lasers are two commonly used types of lasers in various industries. This table compares their characteristics and performance levels based on several criteria, including their active medium, output wavelength, power output, efficiency, maintenance requirements, initial cost, range of materials that can be cut, and applications.

| Criteria | YAG Lasers | Fiber Lasers |

| Active medium | YAG crystal | Optical fiber |

| Output wavelength | 1.06 microns | 1.06 or 1.55 microns |

| Power output | High power output | Moderate power output, but increasing |

| Efficiency | Lower efficiency compared to fiber lasers | Higher efficiency compared to YAG lasers |

| Maintenance requirements | Higher maintenance requirements | Lower maintenance requirements |

| Initial cost | Higher initial cost compared to fiber lasers | Lower initial cost compared to YAG lasers |

| Material Cutting Range | Wide range of materials, including metals, ceramics, and composites | Limited ability to cut certain materials, such as reflective metals |

| Applications | Cutting, welding, and medical/scientific applications | Cutting, welding, marking, and additive manufacturing |

What Should You Consider While Choosing Between YAG and Fiber Lasers

When deciding between YAG and fiber lasers, it is essential to consider the following factors:

- Application requirements: Analyze the specific needs of your application, such as cutting, engraving, or welding, and assess which laser type offers better performance, precision, and accuracy for the intended use.

- Power output and efficiency: Compare YAG and fiber lasers’ power output capabilities and conversion efficiency. Fiber lasers typically offer higher efficiency and lower operating costs, while YAG lasers may provide higher power output for certain applications.

- Maintenance and reliability: Consider each laser type’s maintenance requirements and overall reliability. Fiber lasers usually have fewer moving parts and require less maintenance, making them more reliable and cost-effective in the long run.

- Initial cost and long-term investment: Compare the initial cost of YAG and fiber lasers, keeping in mind that while YAG lasers may have a lower initial cost, fiber lasers often have lower operating costs and longer lifespans, making them a more cost-effective option over time.

- Material compatibility: Evaluate the materials you will be processing and determine which laser type is better suited for handling those materials. Do take into account the laser’s wavelength and absorption properties.

- Versatility and adaptability: Assess the flexibility of each laser type in terms of operating modes, such as continuous or pulsed operation, and their ability to adapt to different industrial applications and requirements.

Conclusion

In conclusion, choosing between YAG and fiber lasers requires a thorough assessment of your specific application requirements, material compatibility, power output, efficiency, maintenance, reliability, and overall cost.

Both laser types offer unique advantages and can excel in various industrial applications, from cutting and engraving to welding and micromachining. We encourage you to explore additional resources available on our website to gain further insights into laser technologies and their potential applications.

Unleash the Ultimate Laser Solution for Your Business with Baison

At Baison Laser, we are committed to providing cutting-edge laser solutions tailored to your specific needs. Our team of experts works closely with you to understand your requirements and deliver innovative, high-quality laser systems that boost productivity and efficiency. With Baison Laser as your partner, you can confidently harness the power of laser technology to propel your business to new heights. Request a quote today!