This blog post will delve into the essence of bevel cutting, differentiating it from other cuts such as miter and square edge cuts. We’ll also explore the tools used in this process, like circular and table saws. Our goal is to equip you with valuable knowledge about bevel cutting and its practical applications, from creating picture frames to crafting complex geometrical shapes. Let’s get started.

What is Bevel Cutting?

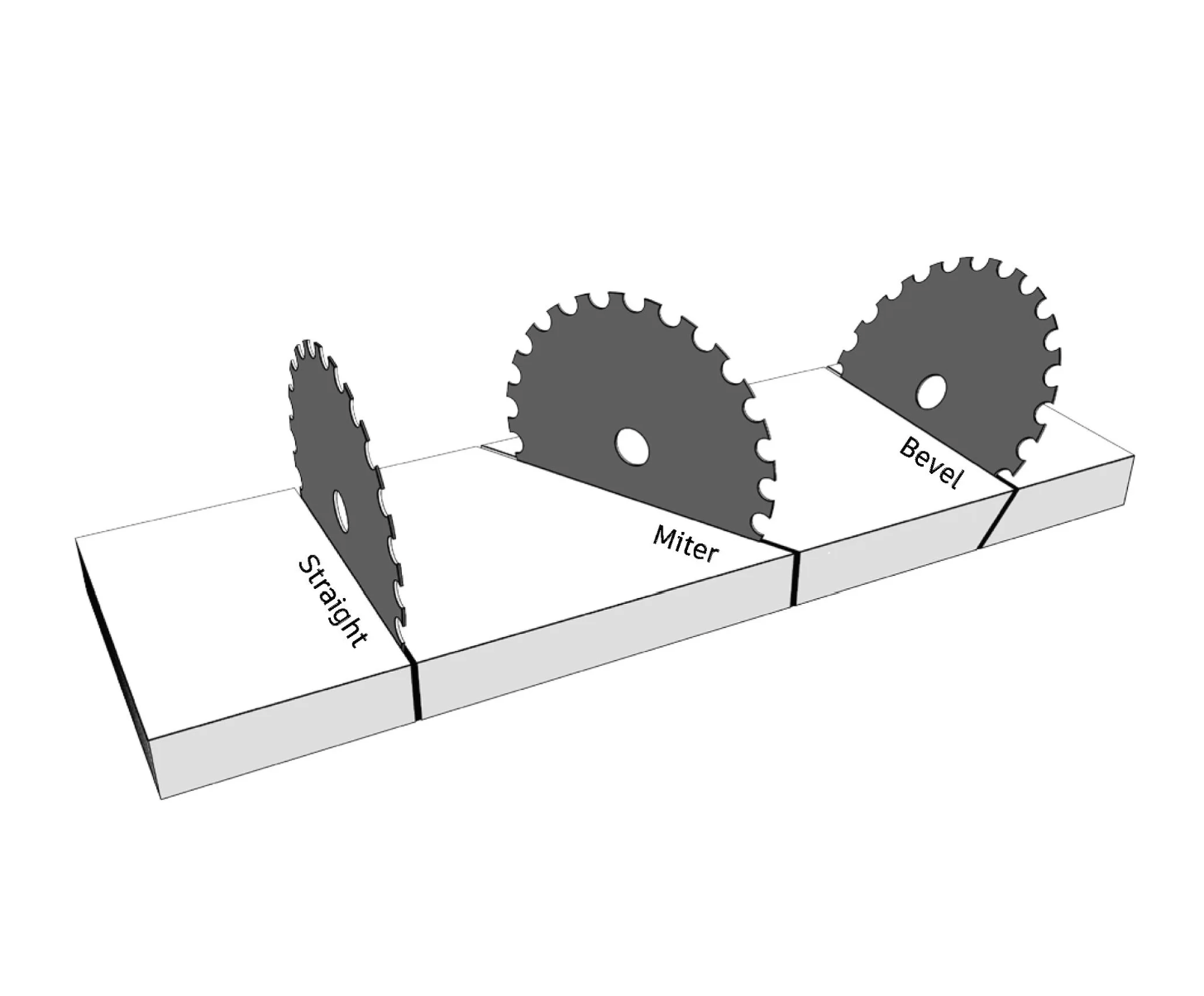

A bevel cut refers to an angled cut made on the edge of a material. The cut diverges from the typical square edge cut seen in most manufacturing processes. As a result, the tilted blade creates the desired angle, usually less than 90 degrees, resulting in a cut that is not perpendicular to the material’s top.

Therefore, a wide range of industries employ this cutting technique, from furniture making to construction. The bevel cut’s unique angled edges allow for seamless connections and more complex designs, such as the corner of a picture frame or crown molding. Moreover, with precision and the right tools, bevel cutting can take your projects to the next level.

Different Types of Bevels

Bevel cuts are versatile and adaptable to a variety of projects. Let’s delve into the distinct types of bevel cuts and how each serves a unique purpose in manufacturing.

1. Single Bevel Cut

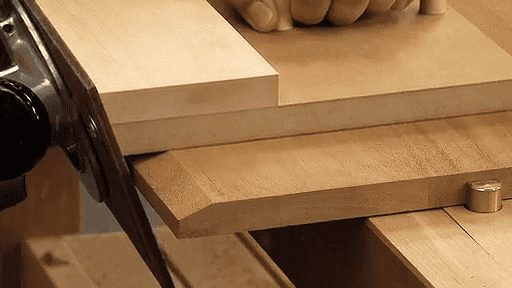

A single bevel cut refers to the process of cutting a single angled edge on a piece of wood or other material. Typically, circular saws or table saws are used for this purpose. The blade angle is altered relative to the vertical plane, providing the desired angle of the bevel cut.

2. Double Bevel Cut

A double bevel cut involves cutting beveled edges on both sides of the material. This is commonly used in intricate designs, such as picture frames and crown molding. Almost every circular saw and miter saw can achieve this cut by adjusting the blade angle on two planes.

3. Compound Bevel Cut

A compound bevel cut is a more complex variation, which involves making both the bevel cut and miter cut at the same time. This cut is often seen in more sophisticated projects, where an angled cut is needed in both the vertical and horizontal plane. Hence, compound miter saws make these cuts achievable with their tilting baseplate and adjustable blade.

For specific steps on miter and bevel cuts, check out this article.

4. Bevel and Miter Cuts

Bevel and miter cuts combine the principles of both bevel and miter cutting. A little adjustment to the miter angle and blade angle helps achieve the desired cuts. This combination is particularly useful in crafting geometrical shapes and intricate designs like picture frames and furniture pieces.

Tools for Bevel Cutting

Embracing the correct tools can greatly simplify the bevel-cutting process. Here’s what you should consider:

- Circular Saws: Almost every circular saw can perform bevel cuts, making it a go-to tool for many.

- Miter Saws: Ideal for precision work, miter saws are perfect for both miter and bevel cuts.

- Table Saws: A versatile powerhouse, a table saw can handle a range of cuts, from a simple square cut to a more complex compound cut.

Techniques for Bevel Cutting

While tools are essential, understanding the proper techniques is equally important in making successful bevel cuts:

I. Manual Bevel Cutting

Bevel cutting can be done using a hand-held bevel cutter. The most basic method involves manually cutting the bevel with a cutting tool. It is important to note that a bevel cutter is a sharp tool, so it should be handled with care.

II. Automatic Bevel Cutting

An automatic bevel cutter is a machine that is capable of cutting a bevel on a metal surface automatically. These machines are often used in industrial settings where efficiency is important. Bevel cutters can be attached to a lathe, for example, to cut bevels on a rotating piece of metal.

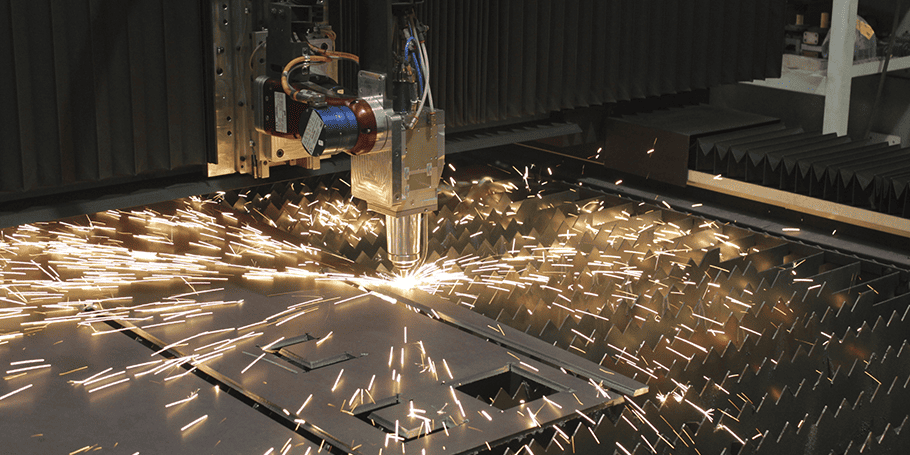

III. Plasma Cutting

Plasma cutting is a process that involves the use of a plasma arc to cut metal. This method is often used to cut thick or hard-to-cut materials. The plasma arc can be directed onto the material being cut, effectively melting and vaporizing the metal.

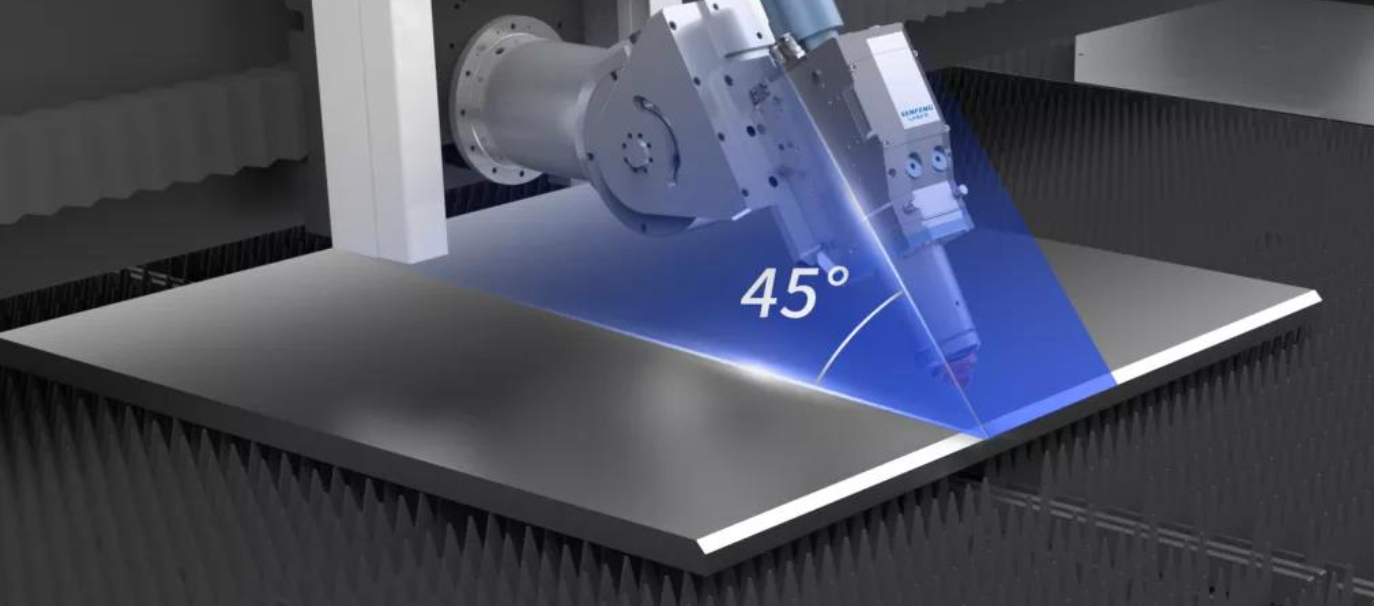

IV. Laser Cutting

Laser cutting is a process that involves the use of a high-powered laser to cut material. This method is often used to cut materials that are difficult to cut with traditional methods. The laser can be directed onto the material, effectively burning through the material to create a clean cut. This is a bevel-cutting demonstration about Baison Laser, let’s start watching!

V. Water Jet Cutting

Water jet cutting is a process that involves the use of a high-pressure water jet to cut metal. This method is often used to cut metals that are too thick or hard to cut with traditional methods. The water jet can cut through thick material with ease and can create precise cuts.

You may want to know the difference between jet cutting and laser cutting.

VI. Eddy Current Cutting

Eddy current cutting is a process that involves the use of a magnetic field to cut metal. This method is often used to cut nonferrous metals, such as copper, aluminum, and brass. The magnetic field is used as an electromagnet to generate an eddy current in the metal being cut, which effectively heats up the metal and allows it to be cut.

VII. Ultrasonic Cutting

Ultrasonic cutting is a process that involves the use of high-frequency vibrations to cut metal. This method is often used to cut thin materials, such as glass or ceramic. Ultrasonic cutting can create clean and precise cuts, which is often important in industries that require high levels of precision.

Applications of Bevel Cutting

Bevel cutting is not limited to a singular use but expands across several industries. Let’s look into some common applications where this cutting technique shines.

1. Woodworking and Carpentry

In the woodworking and carpentry industry, bevel cuts play a crucial role. From crafting picture frames to constructing furniture, a bevel cut’s angled edges offer seamless connections and aesthetically pleasing designs. Tools like hand tools, power tools, and especially the miter saw are used frequently for creating these cuts.

2. Metal Fabrication and Welding

Bevel cutting also finds its place in metal fabrication and welding. It allows for better fit-up between parts that need to be welded together, reducing the amount of filler material needed and providing stronger, more efficient welds. Certain cutting tools, including circular saws, are common in this field.

3. Construction and Remodeling

In construction and remodeling, bevel cuts are utilized in a variety of ways, from creating complex geometrical shapes to fitting crown molding and more. This method allows for angled cuts on both the vertical and horizontal plane, increasing the versatility of design possibilities. Whether it’s a table, saw, or compound miter saw, the right tools can help easily achieve the desired angle.

Benefits of Bevel Cutting

Bevel cutting brings a multitude of advantages to the manufacturing process. Here are a few notable benefits:

- Improved Joint Strength and Stability: Bevel cuts allow for a larger joint surface area, contributing to enhanced joint strength and stability. Whether it’s wood pieces in carpentry or metal parts in fabrication, bevel cuts ensure a secure fit, thus increasing the overall durability of the structure.

- Enhanced Aesthetics and Design Possibilities: Bevel cuts provide a more sophisticated and clean finish, enhancing the aesthetic appeal of the final product. From creating attractive picture frames to complex geometrical shapes, bevel cuts open a world of design possibilities.

- Efficient Material Utilization: Bevel cutting offers precision, producing less wasted material. It ensures that every piece of wood or metal is cut at the desired angle, maximizing the efficiency of the material utilization. With a proper blade and adjusted blade angle, a circular or miter saw can achieve precise bevel and miter cuts, making the most of your materials.

Challenges and Considerations in Bevel Cutting

Venturing into the bevel-cutting realm presents its own challenges and considerations. Before you dive in, here are a few aspects to keep in mind:

- Accuracy: Achieving the desired angle requires precision. A slight deviation can alter the final result.

- Material Compatibility: Not every material is suited for bevel cuts. Understanding compatibility is key.

- Tool Proficiency: The effectiveness of bevel cutting greatly depends on familiarity with the tools like circular saws, miter saws, and table saws.

Tips for Successful Bevel Cutting

A successful bevel cut can significantly enhance your project. Here are a few tips to ensure success:

- Understand Your Tools: Familiarize yourself with the tools you are using, understanding how the blade tilts and how to adjust for the desired angle.

- Practice: Bevel cutting, like any other skill, improves with practice. Start with simple cuts before moving on to more complex designs.

- Safety First: Always follow safety procedures, wear protective gear, and make sure your tools are in good working condition.

Q&A: Addressing Common Questions about Bevel Cutting

Here are some commonly asked questions about bevel cutting:

- What is the difference between a bevel cut and a miter cut?

A bevel cut angles through the thickness of the material, whereas a miter cut is angled across the width.

- Can all saws make bevel cuts?

Not all saws are designed for bevel cuts. However, circular, table, and miter saws usually have this capability.

- How do I adjust the angle for a bevel cut?

Most saws come equipped with adjustable blade angles. The blade tilts to the desired angle by adjusting a thumb screw or another control mechanism.

Conclusion

Mastering bevel cutting can significantly enhance your manufacturing projects, offering design versatility and superior structural stability. As we conclude this comprehensive guide, remember that accuracy, tool proficiency, and safety are pivotal to your bevel-cutting journey. Armed with the right tools and techniques, your craftsmanship can lead to remarkable creations. Explore our extensive collection of blogs on our website for further insights and resources on power tools and techniques.

Unleash Your Business’s Potential with Baison Laser

Ready to revolutionize your manufacturing process? At Baison Laser, we pride ourselves on offering top-notch solutions tailored to your business needs. We invite you to Request an Instant Quote and discover how our laser cutting and welding machines can help elevate your productivity and craftsmanship. We’re committed to ensuring your business thrives with the power of precision.